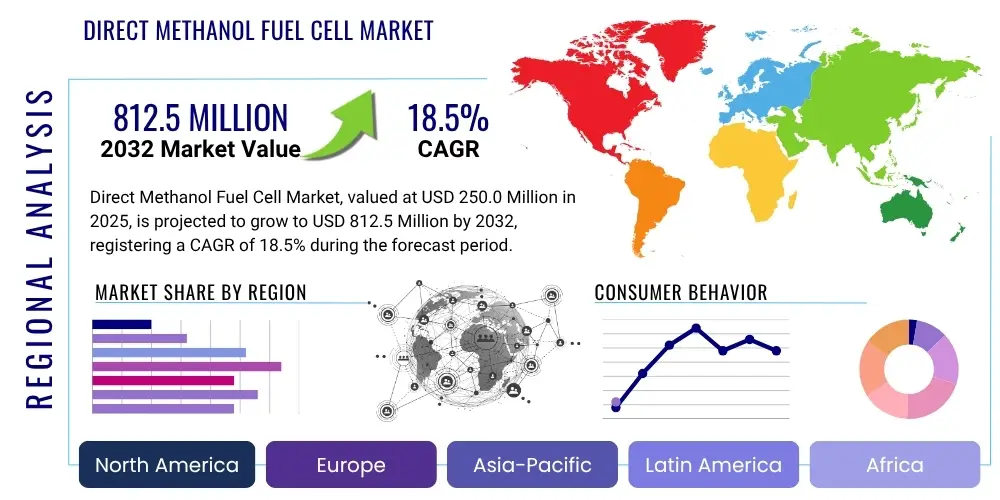

Direct Methanol Fuel Cell Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428716 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Direct Methanol Fuel Cell Market Size

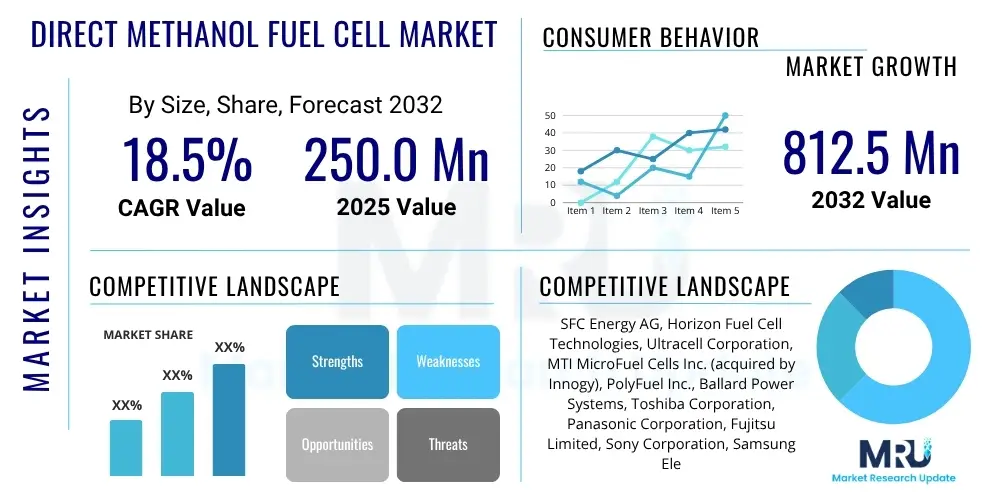

The Direct Methanol Fuel Cell Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2025 and 2032. The market is estimated at $250.0 Million in 2025 and is projected to reach $812.5 Million by the end of the forecast period in 2032.

Direct Methanol Fuel Cell Market introduction

The Direct Methanol Fuel Cell (DMFC) market is at the forefront of innovative portable power solutions, offering a compelling alternative to traditional battery technologies. DMFCs are electrochemical devices that directly convert the chemical energy of methanol and oxygen into electrical energy, water, and carbon dioxide, without combustion. This direct conversion process eliminates the need for reforming methanol into hydrogen, simplifying the system design and reducing operational complexity. The core of a DMFC typically consists of a proton exchange membrane (PEM) sandwiched between two electrodes – an anode where methanol is oxidized, and a cathode where oxygen is reduced. This technology stands out for its high energy density, which translates to longer run-times for devices compared to conventional batteries, and its ability to be refueled quickly by simply replacing a methanol cartridge or refilling a tank.

Major applications for Direct Methanol Fuel Cells span a diverse range of sectors requiring reliable, long-duration, and quiet power. These include portable electronic devices like laptops and military communication equipment, where extended operational time is critical. Beyond consumer and defense applications, DMFCs are increasingly employed in remote power generation for telecommunications towers, meteorological stations, and off-grid sensors, where access to grid power is limited or unreliable. The technology also finds utility as auxiliary power units (APUs) in recreational vehicles, marine vessels, and certain automotive applications, providing power for onboard electronics and climate control without idling the main engine.

The benefits of DMFC technology are substantial, driving its market growth. These benefits encompass superior energy density, leading to lighter and more compact power sources that can operate for significantly longer periods on a single charge or refill compared to batteries. DMFCs are also environmentally friendly, producing fewer emissions than fossil fuel generators, and operate silently, making them ideal for sensitive environments or covert military operations. Key driving factors for the market include the escalating global demand for portable and mobile power solutions, particularly in remote and off-grid locations, coupled with growing environmental consciousness and stringent regulations promoting cleaner energy alternatives. The convenience of methanol as a liquid fuel, easy to store and transport, further bolsters its appeal in diverse applications.

Direct Methanol Fuel Cell Market Executive Summary

The Direct Methanol Fuel Cell market is witnessing dynamic business trends driven by a confluence of technological advancements, increasing demand for portable and remote power, and a growing emphasis on sustainable energy solutions. Key business trends include the miniaturization of DMFC systems, making them suitable for a wider array of portable electronic devices, and improvements in efficiency and durability. Strategic partnerships between fuel cell manufacturers and electronics companies or defense contractors are becoming more prevalent, aimed at integrating DMFC technology into mainstream products. Furthermore, there is a clear trend towards developing more cost-effective production methods and robust supply chains for methanol fuel, addressing previous market entry barriers. Investment in research and development remains strong, focusing on advanced catalyst materials and improved membrane designs to enhance overall performance and reduce per-unit costs, thereby broadening market appeal beyond niche applications.

Regionally, the market exhibits varying adoption rates and growth trajectories. North America and Europe currently represent significant market shares, driven by robust defense sector spending, strong innovation ecosystems, and an early embrace of clean energy technologies. These regions benefit from established research facilities and government initiatives supporting fuel cell development. Asia Pacific is emerging as a rapidly growing market, primarily due to increasing industrialization, rising demand for consumer electronics, and expanding telecommunications infrastructure, particularly in countries like China, Japan, and South Korea. Latin America and the Middle East and Africa regions are expected to show steady growth as infrastructure development progresses and the need for reliable off-grid power solutions in remote areas becomes more pronounced, driven by applications in mining, oil and gas, and rural electrification projects.

Segmentation trends within the DMFC market highlight distinct areas of growth. By power output, systems below 50W are anticipated to maintain dominance due to their widespread use in portable electronics and small-scale remote sensors. However, the 50W-200W segment is projected to experience substantial growth, fueled by demand from military and telecommunications applications requiring more robust power. In terms of application, the defense and military sector continues to be a crucial driver, valuing DMFCs for their quiet operation, long endurance, and logistical simplicity in the field. The remote power segment, including telecommunications and surveillance, is also a significant growth area. Consumer electronics, while slower to adopt due to cost and existing battery solutions, hold immense long-term potential as DMFC costs decrease and performance improves. The industrial segment, covering backup power and specialized equipment, is steadily expanding its adoption of DMFC technology for critical infrastructure.

AI Impact Analysis on Direct Methanol Fuel Cell Market

User inquiries concerning the integration of Artificial Intelligence into the Direct Methanol Fuel Cell market reveal a strong interest in how AI can optimize performance, enhance reliability, and accelerate the development cycle. Common questions revolve around AI's role in predictive maintenance, improving fuel cell efficiency, designing advanced materials, and optimizing system integration. Users express expectations that AI will lead to more intelligent power management systems, extend the operational lifespan of DMFC units, and significantly reduce manufacturing costs through streamlined processes. There is also curiosity about AI's potential to model complex electrochemical reactions, thus shortening the time required for catalyst discovery and membrane innovation, directly addressing some of the historical barriers to wider DMFC adoption. The overarching theme is the anticipation that AI will unlock new levels of performance and cost-effectiveness, making DMFCs more competitive across various applications.

- AI driven predictive maintenance for fuel cell health and fault detection.

- Optimization of methanol-air stoichiometry for enhanced energy conversion efficiency.

- Accelerated discovery of novel catalyst materials and membrane electrolytes.

- AI powered design and simulation for miniaturized and more robust DMFC stacks.

- Intelligent power management systems for dynamic load balancing and extended runtime.

- Data analytics for supply chain optimization and methanol logistics.

- Automated quality control and manufacturing process optimization.

- Smart grid integration and energy storage management for hybrid systems.

DRO & Impact Forces Of Direct Methanol Fuel Cell Market

The Direct Methanol Fuel Cell market is influenced by a complex interplay of Drivers, Restraints, and Opportunities, shaping its growth trajectory and competitive landscape. A primary driver is the increasing global demand for extended run-time portable power, especially in applications where traditional batteries fall short due to weight, volume, or recharge time limitations. The military and defense sectors, for instance, highly value DMFCs for their operational longevity in remote field conditions, reducing the logistical burden of battery resupply. Furthermore, the growing environmental awareness and governmental push for cleaner energy solutions contribute significantly to market expansion, as DMFCs offer a lower emission alternative to internal combustion engine generators. The compact form factor and quiet operation of these cells also make them attractive for noise-sensitive or space-constrained environments.

Despite these strong drivers, the DMFC market faces several significant restraints. One major hurdle is the relatively high upfront cost of DMFC systems compared to conventional power sources, which can deter broad adoption, particularly in cost-sensitive consumer electronics markets. The infrastructure for methanol refueling, while simpler than hydrogen, is not yet as widely established as gasoline or diesel, posing logistical challenges for widespread commercial deployment. Methanol toxicity also necessitates careful handling and storage, which can be a concern for some end-users. Additionally, DMFCs often exhibit lower power density compared to some advanced battery technologies or other fuel cell types, limiting their application in high-power demand scenarios. The challenge of methanol crossover through the proton exchange membrane, leading to efficiency losses and degradation, also remains a technical constraint that researchers are actively working to mitigate.

However, the market is rife with opportunities that could overcome these restraints and propel DMFCs into broader acceptance. Continuous advancements in materials science, particularly in developing more efficient catalysts and improved membranes, promise to reduce costs and enhance performance significantly. The expansion of applications into emerging areas such as unmanned aerial vehicles (UAVs), robotics, and IoT devices presents new lucrative markets for compact, long-duration power. Strategic partnerships and collaborations among manufacturers, research institutions, and end-users are fostering innovation and accelerating market entry for new products. Moreover, government incentives and policies supporting fuel cell technology and renewable energy sources are creating a favorable regulatory environment for DMFC adoption, facilitating investment in infrastructure and manufacturing capabilities. The growing demand for resilient and independent power solutions in disaster relief and emergency response scenarios also opens a substantial niche for DMFCs.

Segmentation Analysis

The Direct Methanol Fuel Cell market is comprehensively segmented to provide a detailed understanding of its varied applications, power requirements, and end-user profiles. This granular analysis allows stakeholders to identify specific growth areas and tailor their product development and marketing strategies. The primary segmentation categories include power output, application, and end-user industry, each revealing unique market dynamics and demand patterns. Understanding these segments is crucial for strategic planning, competitive positioning, and assessing market potential across different verticals. The differentiation within these segments reflects the diverse needs that DMFC technology addresses, from very low-power portable devices to more robust systems for industrial and defense uses.

- By Power Output

- Below 50W

- 50W - 200W

- Above 200W

- By Application

- Portable Electronic Devices

- Defense and Military

- Remote Power

- Automotive Auxiliary Power

- Telecommunications

- Other Industrial Applications

- By End User

- Consumer Electronics

- Commercial

- Industrial

- Government and Defense

Value Chain Analysis For Direct Methanol Fuel Cell Market

The value chain for the Direct Methanol Fuel Cell market encompasses a series of interconnected stages, beginning with the sourcing of raw materials and extending through manufacturing, assembly, distribution, and end-user consumption. Upstream analysis focuses on the procurement of critical components and materials essential for DMFC production. This includes the supply of high-purity methanol, which serves as the primary fuel source, along with the acquisition of specialized catalyst materials such such as platinum-ruthenium alloys for the anode and platinum for the cathode. Additionally, the value chain considers the manufacturing of proton exchange membranes, gas diffusion layers, and various balance-of-plant components like pumps, sensors, and control electronics. The efficiency and cost-effectiveness of these upstream processes significantly impact the final product's performance and market competitiveness.

Midstream activities involve the intricate process of manufacturing the fuel cell stack, which is the heart of any DMFC system. This stage includes the fabrication of membrane electrode assemblies (MEAs), careful assembly of individual cells into a stack, and the integration of these stacks with other system components such as fuel tanks, pumps, cooling systems, and power management units. Quality control and rigorous testing are paramount at this stage to ensure the reliability, durability, and safety of the final DMFC product. System integrators play a crucial role here, taking individual components and assembling them into a functional, compact, and efficient power solution tailored for specific applications. Optimization of manufacturing techniques and automation are key drivers for reducing production costs and increasing scalability.

Downstream analysis covers the distribution channels and direct sales strategies employed to bring DMFC products to market and support their deployment. Distribution channels can be both direct and indirect. Direct channels involve manufacturers selling directly to original equipment manufacturers (OEMs) who integrate DMFCs into their end products, or directly to large industrial and government clients. Indirect channels utilize a network of distributors, resellers, and value-added integrators who help reach a broader customer base, particularly in niche markets or geographies where direct sales are less feasible. Aftermarket services, including maintenance, repairs, and the supply of methanol cartridges or refueling services, are also vital components of the downstream value chain, ensuring customer satisfaction and continued product utility. The logistical infrastructure for methanol supply is a critical element, influencing both the feasibility and sustainability of DMFC deployment.

Direct Methanol Fuel Cell Market Potential Customers

The Direct Methanol Fuel Cell market targets a diverse range of potential customers, segmented by their specific needs for portable, reliable, and long-duration power solutions. A significant portion of end-users are within the defense and military sectors, where the demand for lightweight, quiet, and easily refuelable power sources for field operations, communication equipment, and unmanned systems is exceptionally high. Soldiers and tactical units require power for portable electronics, surveillance drones, and essential communication gear that can operate for extended periods without frequent resupply or loud generators. The logistical advantages of methanol in remote environments make DMFCs a preferred choice over traditional batteries or fossil-fuel alternatives, driving considerable procurement from government and defense agencies globally.

Beyond the defense sector, commercial and industrial enterprises represent a growing customer base. This includes telecommunication companies needing reliable backup or primary power for remote cell towers and sensor networks, particularly in areas lacking stable grid connectivity. Businesses involved in remote monitoring, environmental sensing, and security systems also constitute key buyers, as DMFCs offer continuous, unattended operation for extended durations. The commercial segment also encompasses industries requiring auxiliary power for recreational vehicles (RVs), marine applications, and specialized industrial equipment that benefits from quiet, long-lasting, and independent power sources, reducing reliance on conventional engines or generators that incur higher operational costs and environmental impact.

The consumer electronics market, while currently a smaller segment due to cost and size considerations compared to advanced batteries, represents substantial long-term potential. As DMFC technology matures and miniaturization efforts succeed, consumers seeking extended battery life for laptops, smartphones, and other personal electronic devices, particularly for travel or off-grid usage, will become increasingly viable customers. Furthermore, the market for emergency power solutions and disaster relief offers another avenue for DMFCs, where rapid deployment of reliable, long-lasting power is critical. The distinct advantages of DMFCs in terms of energy density and quiet operation cater to these diverse customer needs, positioning them as an attractive solution across multiple applications requiring robust off-grid power.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $250.0 Million |

| Market Forecast in 2032 | $812.5 Million |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SFC Energy AG, Horizon Fuel Cell Technologies, Ultracell Corporation, MTI MicroFuel Cells Inc. (acquired by Innogy), PolyFuel Inc., Ballard Power Systems, Toshiba Corporation, Panasonic Corporation, Fujitsu Limited, Sony Corporation, Samsung Electronics Co. Ltd., Oorja Protonics Inc., Neah Power Systems Inc., Protonex Technology Corporation (now Vicor Corporation), Acta S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Direct Methanol Fuel Cell Market Key Technology Landscape

The technological landscape of the Direct Methanol Fuel Cell market is characterized by continuous innovation aimed at improving efficiency, durability, and cost-effectiveness. Central to DMFC operation are the anode and cathode catalysts, primarily platinum-ruthenium alloys for methanol oxidation at the anode and platinum for oxygen reduction at the cathode. Research efforts are heavily focused on developing novel catalyst materials that can reduce or eliminate the reliance on expensive platinum group metals, explore non-precious metal alternatives, and enhance catalytic activity and methanol tolerance to mitigate issues like methanol crossover. Advancements in catalyst support materials and electrode structures are also critical for maximizing reaction rates and improving fuel utilization, directly impacting overall system performance.

Another pivotal area of technological development is the proton exchange membrane (PEM), which facilitates proton transport while minimizing methanol crossover from the anode to the cathode. Current research explores new membrane materials, including various perfluorosulfonic acid (PFSA) derivatives and hydrocarbon-based membranes, designed to offer superior proton conductivity, chemical stability, and methanol impermeability. Improved membrane electrode assembly (MEA) fabrication techniques are also key, as the MEA is the core component where electrochemical reactions occur. Innovations here aim to create thinner, more robust MEAs with optimized interfaces between catalyst layers, membranes, and gas diffusion layers to reduce internal resistance and enhance power density.

Beyond the core electrochemical components, significant technological advancements are occurring in the balance of plant (BOP) components and system integration. This includes the development of more efficient and compact micro-pumps for methanol and air delivery, advanced heat management systems to dissipate waste heat, and sophisticated power management electronics for optimal energy conversion and regulation. Miniaturization techniques are crucial for embedding DMFCs into portable devices, requiring innovative designs for methanol cartridges, fuel cell stacks, and peripheral components to achieve high power density in a small form factor. Furthermore, the integration of advanced sensors and control algorithms is enhancing the reliability and autonomy of DMFC systems, paving the way for more intelligent and self-sustaining power solutions across diverse applications.

Regional Highlights

- North America: This region is a leading market, driven by substantial defense spending and early adoption of advanced power solutions for military applications. Strong R&D infrastructure and government support for clean energy initiatives also contribute to market growth. The United States and Canada are key players, with ongoing projects in portable power and remote sensing.

- Europe: Europe represents a significant market, propelled by stringent environmental regulations and a focus on reducing carbon emissions. Germany, the UK, and Scandinavia are at the forefront, with growing adoption in telecommunications backup power, leisure applications (RVs, marine), and small-scale industrial power.

- Asia Pacific (APAC): The APAC region is poised for rapid growth, primarily due to increasing industrialization, expanding consumer electronics market, and burgeoning telecommunications infrastructure. Countries like China, Japan, and South Korea are investing heavily in fuel cell technology, with applications ranging from portable devices to remote power for surveillance and IoT.

- Latin America: This region is an emerging market, driven by the need for reliable off-grid power solutions in remote areas, particularly for mining operations, rural telecommunications, and agricultural monitoring. Brazil and Mexico are showing increasing interest in DMFCs for specialized industrial uses.

- Middle East and Africa (MEA): The MEA region offers considerable growth potential, especially in oil and gas sector remote monitoring, off-grid power for rural communities, and military applications. The demand for robust, independent power sources in challenging environments is a key market driver here.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Direct Methanol Fuel Cell Market.- SFC Energy AG

- Horizon Fuel Cell Technologies

- Ultracell Corporation

- MTI MicroFuel Cells Inc. (acquired by Innogy)

- PolyFuel Inc.

- Ballard Power Systems

- Toshiba Corporation

- Panasonic Corporation

- Fujitsu Limited

- Sony Corporation

- Samsung Electronics Co. Ltd.

- Oorja Protonics Inc.

- Neah Power Systems Inc.

- Protonex Technology Corporation (now Vicor Corporation)

- Acta S.p.A.

- Vairex Air Systems

- Hydrocell GmbH

- Brunton Outdoor Group

- Power Trekk (MyFC)

Frequently Asked Questions

What are the primary advantages of Direct Methanol Fuel Cells?

Direct Methanol Fuel Cells offer high energy density, leading to longer operating times compared to traditional batteries. They are also quietly operated, environmentally friendlier with low emissions, and can be refueled quickly by simply replacing methanol cartridges or refilling tanks, making them ideal for portable and remote power applications.

What are the main applications for DMFC technology?

DMFCs are primarily used in portable electronic devices, defense and military equipment (e.g., communication, surveillance), remote power generation for telecommunications towers and sensors, and as auxiliary power units (APUs) in recreational vehicles and marine vessels due to their extended run-time capabilities.

What challenges does the Direct Methanol Fuel Cell market face?

Key challenges include the relatively high upfront cost compared to conventional power sources, the developing infrastructure for methanol refueling, methanol crossover issues which affect efficiency, and system complexity. Ongoing research aims to address these by improving catalyst materials, membranes, and overall system design.

How does AI impact the development and adoption of DMFCs?

AI significantly impacts DMFCs by optimizing fuel cell design and materials, enabling predictive maintenance for improved reliability, enhancing power management systems for peak efficiency, and accelerating the discovery of new catalysts and membranes. This leads to more efficient, durable, and cost-effective DMFC solutions.

Which regions are leading in DMFC market adoption?

North America and Europe are currently leading in DMFC market adoption, driven by defense applications, stringent environmental regulations, and strong R&D initiatives. The Asia Pacific region is rapidly emerging as a significant market due to its expanding industrial base, consumer electronics demand, and telecommunications infrastructure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Direct Methanol Fuel Cell (DMFC) Market Size Report By Type ( 1 KW, 1 KW-5 KW), By Application (Defense&Security, Mobility&Industrial Application, Leisure, Materials Handling Equipment, Telecommunications, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Automotive Direct Methanol Fuel Cell Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Methanol Aqueous Solution, Steam Methanol), By Application (Passenger Cars, LCVs, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager