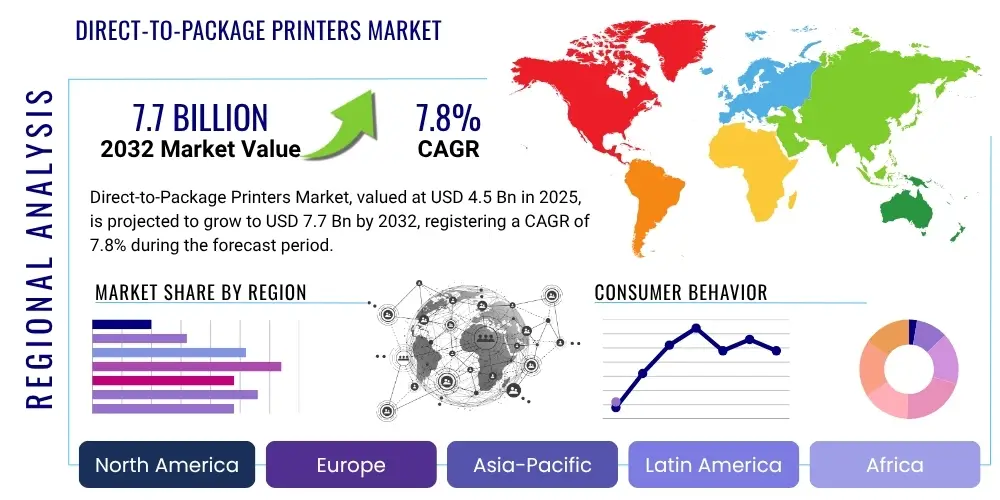

Direct-to-Package Printers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430450 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Direct-to-Package Printers Market Size

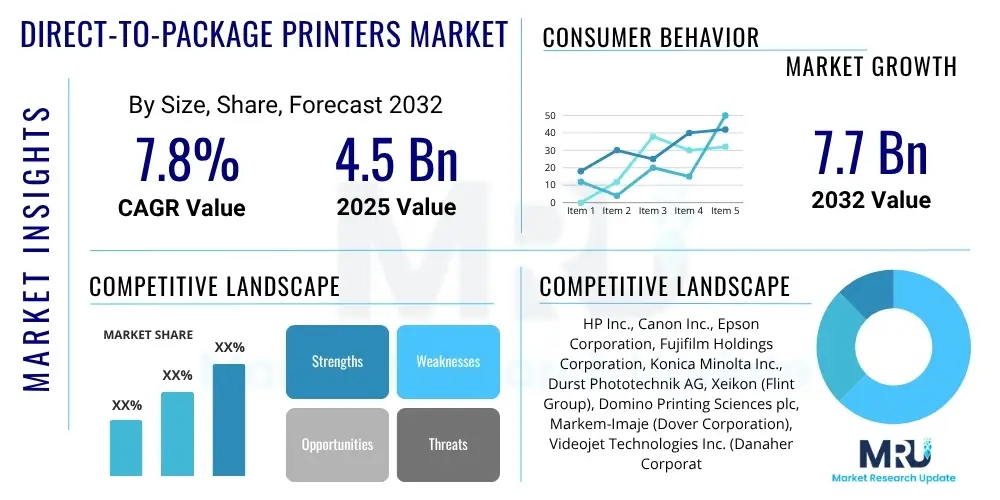

The Direct-to-Package Printers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 4.5 Billion in 2025 and is projected to reach USD 7.7 Billion by the end of the forecast period in 2032.

Direct-to-Package Printers Market introduction

The Direct-to-Package Printers Market encompasses advanced digital printing technologies that enable direct application of graphics, text, and variable data onto various packaging materials without the need for labels or films. These innovative systems are revolutionizing packaging processes across numerous industries by offering unparalleled flexibility, speed, and customization capabilities. They facilitate on-demand printing, short-run production, and highly personalized packaging solutions, which are increasingly crucial in today's dynamic consumer landscape. The primary objective of these printers is to enhance brand appeal, provide critical product information, and streamline manufacturing workflows.

Products within this market range from industrial-scale inkjet systems to sophisticated thermal transfer and laser printing solutions, designed to handle a diverse array of substrates including cardboard, plastics, glass, metal, and flexible pouches. These printers are integrated into existing production lines, allowing for real-time printing directly onto pre-formed packages, flat sheets, or even during the packaging assembly process. The versatility extends to various ink types, such as UV-curable, aqueous, and solvent-based, each tailored for specific material adhesion, durability, and regulatory compliance, ensuring optimal performance and aesthetic quality.

Major applications span a wide spectrum of industries, including food and beverage, pharmaceuticals, cosmetics, consumer electronics, and logistics. The benefits are substantial, encompassing reduced material waste, faster time-to-market for new products, enhanced brand engagement through unique designs, and improved supply chain efficiency. Key driving factors include the exponential growth of e-commerce necessitating personalized and robust packaging, escalating demand for sustainable packaging solutions, stringent regulatory requirements for product traceability, and the continuous advancement in digital printing technology enabling higher resolutions and faster print speeds.

Direct-to-Package Printers Market Executive Summary

The Direct-to-Package Printers Market is experiencing robust expansion driven by significant shifts in consumer behavior, manufacturing practices, and technological advancements. A key business trend is the widespread adoption of digital transformation initiatives across industries, pushing manufacturers towards more agile and efficient packaging operations. This involves leveraging automation and integrated systems to respond rapidly to market demands, minimize inventory holding costs, and offer highly differentiated products. The transition from traditional labeling to direct printing also reflects a broader industry move towards sustainability, as it often reduces material consumption and simplifies recycling processes, appealing to environmentally conscious brands and consumers.

Regional trends indicate that Asia Pacific continues to dominate the market, propelled by its massive manufacturing base, burgeoning e-commerce sector, and increasing disposable incomes that fuel demand for packaged goods. Countries such as China, India, and Japan are at the forefront of adopting advanced printing solutions to enhance productivity and cater to diverse local markets. North America and Europe, while more mature, are characterized by high innovation adoption rates, focusing on advanced features like AI integration, predictive maintenance, and high-resolution printing for premium and regulated products, particularly in the pharmaceutical and gourmet food sectors. Latin America and the Middle East and Africa are emerging as significant growth regions, driven by industrialization and the expansion of the retail landscape.

Segment trends reveal that inkjet technology holds a significant share due to its versatility, speed, and capability to handle variable data and complex graphics effectively. UV-curable inks are gaining traction for their durability and fast curing times, suitable for various non-porous substrates. In terms of applications, the food and beverage industry remains the largest consumer, driven by the sheer volume of packaged goods and the constant need for branding updates and regulatory information. The pharmaceutical sector is another critical segment, demanding high precision, compliance with strict regulations, and robust traceability features that direct-to-package printers can reliably deliver, making them indispensable for product integrity and consumer safety.

AI Impact Analysis on Direct-to-Package Printers Market

User inquiries concerning AI's influence on Direct-to-Package Printers frequently revolve around its potential to enhance operational efficiency, personalize packaging at scale, ensure print quality, and facilitate predictive maintenance. Users are keenly interested in how AI can streamline workflows, reduce errors, and contribute to more intelligent manufacturing processes. The themes generally center on automation, optimization of printing parameters for various substrates, real-time quality control, and the generation of dynamic, personalized designs. Expectations include AI leading to significant cost reductions, improved product aesthetics, and more responsive production cycles, ultimately transforming how packaging is designed, produced, and managed throughout the supply chain.

- AI-driven Quality Control: Real-time inspection of printed packages for defects, color accuracy, and data integrity, ensuring consistent output and reducing material waste by identifying issues early in the production run.

- Predictive Maintenance: Algorithms analyze printer performance data to anticipate potential failures, schedule proactive maintenance, and minimize downtime, thereby extending equipment lifespan and optimizing operational efficiency.

- Personalized Design and Customization: AI tools facilitate the rapid generation of unique packaging designs, allowing for hyper-personalization based on consumer data, regional preferences, or individual order requirements, enhancing brand engagement.

- Optimized Workflow Automation: AI integrates with existing production systems to automate job scheduling, ink management, substrate calibration, and data processing, leading to increased throughput and reduced manual intervention.

- Supply Chain Integration: AI enhances traceability and inventory management by integrating printing data with broader supply chain systems, enabling smarter forecasting, reducing stockouts, and improving overall logistics.

DRO & Impact Forces Of Direct-to-Package Printers Market

The Direct-to-Package Printers Market is significantly influenced by a confluence of driving forces, inherent restraints, and emerging opportunities, all shaped by various impact forces. A primary driver is the accelerating growth of the e-commerce sector, which necessitates agile, customizable, and protective packaging solutions capable of rapid deployment. The increasing consumer demand for personalized products and unique brand experiences further fuels the adoption of direct-to-package printing, enabling companies to differentiate their offerings effectively. Furthermore, a growing emphasis on sustainable packaging practices globally prompts industries to seek solutions that reduce material consumption and environmental impact, where direct printing often presents a more eco-friendly alternative to traditional labeling. The continuous innovation in digital printing technology, offering higher resolutions, faster speeds, and broader substrate compatibility, acts as a crucial enabler for market expansion. Lastly, stringent regulatory requirements, particularly in the pharmaceutical and food and beverage industries, for product traceability and information accuracy, make direct-to-package solutions indispensable for compliance and consumer safety.

Segmentation Analysis

The Direct-to-Package Printers Market is broadly segmented across several critical dimensions, including the underlying technology employed, the type of ink utilized, the specific application areas, and the various end-use industries served. This multifaceted segmentation provides a comprehensive understanding of the market landscape, highlighting the diverse needs and preferences of different sectors. Each segment represents distinct technological capabilities, operational considerations, and market demands, ranging from high-speed industrial applications to specialized printing for highly regulated environments. The careful analysis of these segments reveals key growth areas and informs strategic decisions for manufacturers, suppliers, and end-users within the packaging ecosystem.

- By Technology

- Inkjet Printing: Dominant segment, offering versatility, high resolution, and variable data printing capabilities for diverse substrates.

- Thermal Transfer Printing: Ideal for durable, high-contrast prints on specific materials, often used for barcodes and batch codes.

- Laser Printing: Provides permanent, high-definition marking for traceability and anti-counterfeiting, particularly on rigid packaging.

- Others: Includes lesser-utilized specialized technologies tailored for niche applications.

- By Ink Type

- UV-curable Inks: Fast-drying, durable, and highly resistant to fading and chemicals, suitable for non-porous surfaces like plastics and metals.

- Aqueous Inks: Environmentally friendly, often used for porous materials such as paper and cardboard, particularly in food packaging.

- Solvent-based Inks: Offer strong adhesion to challenging substrates and rapid drying, though with environmental considerations.

- Others: Includes specialty inks like edible inks, security inks, and high-adhesion formulations.

- By Application

- Food and Beverage: High volume demand for branding, nutritional information, and expiration dates on primary and secondary packaging.

- Pharmaceuticals: Strict requirements for traceability, serialization, and regulatory compliance on drug packaging.

- Cosmetics and Personal Care: Focus on aesthetic appeal, brand differentiation, and ingredient lists on product containers.

- Industrial: Marking of durable goods, components, and bulk packaging for identification and logistics.

- Others: Encompasses applications in electronics, automotive, textiles, and various consumer goods.

- By End-Use Industry

- Retail: Covers packaging for products sold directly to consumers, emphasizing brand visibility and consumer information.

- Manufacturing: Integration into production lines for in-line marking and coding of manufactured goods.

- Logistics: Used for shipping labels, barcodes, and tracking information on transport packaging.

- E-commerce: Custom packaging for online orders, often requiring variable data and personalized branding.

- Agriculture: Marking on fresh produce packaging and agricultural product containers.

Value Chain Analysis For Direct-to-Package Printers Market

The value chain for the Direct-to-Package Printers Market is intricate, involving a series of interconnected stages from raw material procurement to end-user consumption. Upstream analysis highlights the critical role of suppliers of specialized components and consumables. This includes manufacturers of printheads, a core technology that dictates print quality and speed, as well as developers of advanced inks and coatings tailored for various packaging substrates. Other essential upstream contributors include suppliers of electronic components, software developers for printer control systems, and raw material providers for printer chassis and mechanical parts. The quality and innovation at this stage directly influence the capabilities and performance of the final printing solutions.

Midstream activities involve the manufacturing, assembly, and integration of the direct-to-package printing systems. This segment comprises the primary original equipment manufacturers (OEMs) who design, produce, and brand the printers. These OEMs often engage in extensive research and development to introduce new technologies, improve existing systems, and ensure compatibility with evolving packaging trends and industry standards. They also focus on developing comprehensive software suites for design, workflow management, and data handling, making their solutions user-friendly and highly efficient for integration into diverse production environments. This stage is crucial for ensuring product quality, technological superiority, and market competitiveness.

Downstream analysis focuses on the distribution channels and the end-users. Printers are typically distributed through direct sales forces, specialized distributors, value-added resellers (VARs), and system integrators who provide installation, training, and ongoing technical support. These channels are vital for reaching a broad customer base and ensuring effective deployment of complex printing solutions. Direct distribution allows OEMs to maintain close relationships with large enterprise clients, while indirect channels leverage regional expertise and broader market penetration for small and medium-sized enterprises. The ultimate end-users are packaging manufacturers, brand owners, co-packers, and various industries like food and beverage, pharmaceuticals, and cosmetics, who incorporate these printers into their packaging lines to achieve efficient, customizable, and high-quality product branding and information delivery.

Direct-to-Package Printers Market Potential Customers

The Direct-to-Package Printers Market caters to a diverse array of potential customers, primarily comprising businesses across various sectors that utilize packaging for their products. These end-users are characterized by their need for efficient, high-quality, and often customizable printing solutions that can be seamlessly integrated into their production workflows. A significant segment of potential customers includes large-scale consumer goods manufacturers, particularly in the food and beverage industry, which requires high-speed printing for branding, nutritional information, and expiration dates on a vast volume of products ranging from beverages to snacks. Their demand is driven by rapid product cycles, seasonal promotions, and the necessity to comply with strict labeling regulations.

Another crucial customer base resides within the pharmaceutical and medical device industries. These sectors require printing solutions that offer unparalleled precision, security, and traceability features. Direct-to-package printers enable serialization, batch coding, and regulatory compliance markings directly onto primary and secondary packaging, which is vital for anti-counterfeiting measures and patient safety. Companies in these highly regulated environments prioritize reliability, data integrity, and the ability to produce tamper-evident or specialized security features. The cosmetic and personal care industry also represents a strong potential customer segment, driven by the need for premium aesthetics, diverse packaging shapes, and frequently updated branding to capture consumer attention and convey luxury.

Furthermore, the booming e-commerce sector and logistics companies are emerging as significant potential customers. With the proliferation of online shopping, there is an increasing demand for personalized packaging that enhances the unboxing experience and provides efficient tracking information. Direct-to-package printers facilitate on-demand printing of variable data, such as unique order numbers, personalized messages, and specific shipping details, directly onto cartons or mailer bags. Contract packagers, who provide packaging services for multiple brands, also form a critical customer group as they seek versatile and flexible printing systems that can adapt to a wide range of client requirements and product specifications, optimizing their operational efficiency and service offerings.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.5 Billion |

| Market Forecast in 2032 | USD 7.7 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | HP Inc., Canon Inc., Epson Corporation, Fujifilm Holdings Corporation, Konica Minolta Inc., Durst Phototechnik AG, Xeikon (Flint Group), Domino Printing Sciences plc, Markem-Imaje (Dover Corporation), Videojet Technologies Inc. (Danaher Corporation), Bobst SA, SCREEN Holdings Co. Ltd., Ricoh Company Ltd., Mimaki Engineering Co. Ltd., Agfa-Gevaert Group, Landa Digital Printing, EFI (Electronics For Imaging), Brother Industries, Xaar plc, Kodak Alaris. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Direct-to-Package Printers Market Key Technology Landscape

The technological landscape of the Direct-to-Package Printers Market is characterized by rapid innovation, primarily driven by advancements in digital printing, ink chemistry, and automation. At the core are sophisticated printhead technologies, predominantly inkjet-based, which have evolved to offer higher resolutions, faster firing frequencies, and increased nozzle counts, enabling crisp graphics and precise variable data printing at industrial speeds. These printheads are designed for robustness and longevity, capable of handling a wide array of specialized inks. Developments in drop-on-demand (DOD) technology, including piezo and thermal inkjet, allow for precise droplet placement and control, which is essential for consistent print quality across different substrates and complex geometries.

Parallel advancements in ink formulations are critical to the market's growth. UV-curable inks, for instance, have seen significant improvements in adhesion, flexibility, and resistance to abrasion, chemicals, and environmental factors, making them suitable for durable package printing on non-porous materials like plastics and metals. Aqueous inks are continually being refined for better performance on porous substrates, with a focus on food safety compliance and environmental sustainability. Solvent-based inks continue to serve niche applications requiring strong adhesion to challenging surfaces. Furthermore, the integration of specialized functional inks, such as security inks for anti-counterfeiting or tactile inks for sensory experiences, is expanding the capabilities and value proposition of direct-to-package printing.

Beyond the fundamental printing components, the market's technology landscape is increasingly defined by the integration of Industry 4.0 principles, including automation, robotics, and artificial intelligence. Digital workflow management software provides seamless integration from design to print, optimizing job scheduling, color management, and data handling. Robotics are employed for automated loading, unloading, and handling of packages, improving efficiency and reducing manual labor. AI and machine learning algorithms are being utilized for real-time quality inspection, predictive maintenance of printing equipment, and dynamic personalization of packaging designs based on consumer data, collectively transforming direct-to-package printing into a highly intelligent, efficient, and versatile manufacturing process.

Regional Highlights

- North America: A highly innovative market, characterized by early adoption of advanced digital printing technologies and a strong focus on premium packaging, personalization, and sustainable solutions. The presence of major e-commerce players and stringent regulatory demands in pharmaceuticals drive continuous investment in direct-to-package printing, particularly for short runs and variable data.

- Europe: Driven by strict environmental regulations and a strong emphasis on automation and efficiency in manufacturing. Western European countries are leaders in implementing smart factory concepts, integrating direct-to-package printers into highly automated production lines. Demand for eco-friendly packaging and advanced traceability solutions, especially in food and beverage and pharmaceuticals, propels market growth.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by its vast manufacturing base, booming e-commerce sector, and increasing disposable incomes. Countries like China, India, and Japan are significant contributors, with a strong focus on cost-effective, high-speed printing for a massive consumer market. Rapid industrialization and urbanization further fuel demand across diverse industries.

- Latin America: An emerging market experiencing significant growth due to increasing industrialization, expanding retail sectors, and rising consumer demand for packaged goods. Investment in modern packaging technologies, including direct-to-package printers, is gaining momentum as local manufacturers seek to improve product branding and compete with international players.

- Middle East and Africa (MEA): This region presents substantial growth opportunities, driven by economic diversification, increasing foreign investment, and expanding consumer markets. Growing food and beverage processing, pharmaceutical manufacturing, and retail infrastructure are catalyzing the adoption of direct-to-package printing solutions to enhance product presentation and comply with evolving standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Direct-to-Package Printers Market.- HP Inc.

- Canon Inc.

- Epson Corporation

- Fujifilm Holdings Corporation

- Konica Minolta Inc.

- Durst Phototechnik AG

- Xeikon (Flint Group)

- Domino Printing Sciences plc

- Markem-Imaje (Dover Corporation)

- Videojet Technologies Inc. (Danaher Corporation)

- Bobst SA

- SCREEN Holdings Co. Ltd.

- Ricoh Company Ltd.

- Mimaki Engineering Co. Ltd.

- Agfa-Gevaert Group

- Landa Digital Printing

- EFI (Electronics For Imaging)

- Brother Industries

- Xaar plc

- Kodak Alaris

Frequently Asked Questions

What is a Direct-to-Package Printer?

A Direct-to-Package Printer is a digital printing system that applies graphics, text, and variable data directly onto packaging materials, eliminating the need for labels or films. These printers offer high flexibility, speed, and customization for various substrates.

What are the primary benefits of using Direct-to-Package Printers?

Key benefits include enhanced customization and personalization, reduced material waste from labels, faster time-to-market for products, improved brand differentiation, and increased operational efficiency through streamlined production processes.

Which industries are the largest adopters of Direct-to-Package Printers?

The food and beverage, pharmaceutical, cosmetics and personal care, and e-commerce industries are among the largest adopters. These sectors benefit from the technology's ability to provide branding, critical information, and traceability.

How does AI impact the Direct-to-Package Printers Market?

AI significantly impacts the market by enabling advanced quality control, predictive maintenance, automated workflow optimization, and hyper-personalized design generation, leading to greater efficiency, reduced waste, and enhanced product appeal.

What are the key technological advancements driving this market?

Key technological advancements include high-resolution inkjet printheads, advanced UV-curable and aqueous ink formulations, sophisticated digital workflow software, and the integration of automation, robotics, and AI for smart manufacturing processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager