Dispensing Guns Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430308 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Dispensing Guns Market Size

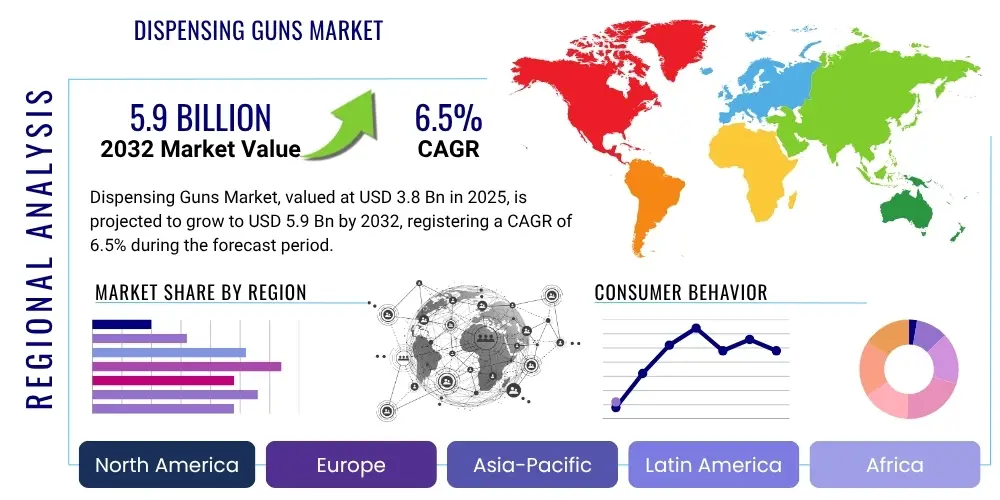

The Dispensing Guns Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 3.8 Billion in 2025 and is projected to reach USD 5.9 Billion by the end of the forecast period in 2032.

Dispensing Guns Market introduction

The Dispensing Guns Market encompasses a wide range of devices designed for the precise application of various materials, including adhesives, sealants, caulks, epoxies, and greases. These tools are critical across numerous industries for assembly, bonding, sealing, and repair tasks, offering improved efficiency and reduced material waste compared to manual application methods. The market includes manual, pneumatic, and electric/battery-powered variants, each suited for different material viscosities, application volumes, and user ergonomic requirements.

Product descriptions vary significantly, from basic manual caulking guns for household use to sophisticated pneumatic and electric models utilized in industrial assembly lines. Major applications span construction, automotive, aerospace, electronics, and general industrial manufacturing, where precise and consistent material deposition is paramount. The benefits of using dispensing guns include enhanced application accuracy, consistent bead size, increased productivity, reduced operator fatigue, and superior material utilization, which collectively contribute to higher quality outputs and lower operational costs. Key driving factors for market growth include the increasing demand for automation in manufacturing processes, the proliferation of specialized adhesive and sealant technologies, growth in the construction sector, and advancements in battery technology making cordless options more viable and powerful.

Dispensing Guns Market Executive Summary

The Dispensing Guns Market is experiencing robust growth driven by industrial expansion, technological advancements, and increasing demand for precision application across various sectors. Business trends indicate a shift towards more automated, ergonomic, and cordless dispensing solutions, catering to the rising need for efficiency and mobility in application tasks. Manufacturers are focusing on developing smart dispensing guns integrated with IoT capabilities for enhanced control and data analytics, addressing the growing complexity of modern bonding and sealing requirements.

Regionally, the Asia Pacific market is poised for significant expansion, fueled by rapid industrialization, burgeoning construction activities, and a flourishing automotive manufacturing sector in countries like China and India. North America and Europe, while mature, continue to innovate, particularly in high-precision and automated dispensing systems for advanced manufacturing and aerospace. Segment trends highlight a strong demand for pneumatic and electric dispensing guns due to their consistent performance and suitability for high-volume applications, alongside a consistent need for manual options in smaller scale or specialized tasks. The adhesives and sealants segment remains a dominant application area, with increasing adoption of dispensing guns for these materials across all end-use industries.

AI Impact Analysis on Dispensing Guns Market

User queries regarding AI's impact on dispensing guns frequently revolve around how AI can enhance precision, optimize material usage, predict maintenance needs, and integrate with automated systems. There is significant interest in AI's potential to move beyond simple automation to intelligent application, ensuring consistent quality and adapting to varying surface conditions or material properties. Concerns often include the cost-effectiveness of AI integration, the complexity of implementation, and the need for specialized skills to operate and maintain such advanced systems. Users also seek to understand if AI can reduce human error, improve ergonomic design, and contribute to more sustainable manufacturing practices by minimizing waste.

- Enhanced precision and consistency through real-time feedback and adaptive control algorithms.

- Optimized material flow and dosage, leading to significant reduction in waste and improved cost efficiency.

- Predictive maintenance for dispensing equipment, minimizing downtime and extending tool lifespan.

- Seamless integration with robotic arms and automated manufacturing lines for fully autonomous dispensing processes.

- Quality control augmentation, using AI vision systems to detect application defects instantly.

- Personalized dispensing profiles and parameter adjustments based on material type, environmental conditions, and desired outcome.

- Improved operator training and guidance through AI-powered simulation and performance analysis.

DRO & Impact Forces Of Dispensing Guns Market

The Dispensing Guns Market is propelled by several key drivers, including the expanding global construction industry, the robust growth in automotive manufacturing requiring precise bonding and sealing, and the increasing demand for specialized adhesives and sealants across diverse industrial applications. The need for enhanced productivity, consistent quality, and reduced material waste in manufacturing and assembly processes significantly boosts the adoption of advanced dispensing solutions. Furthermore, ergonomic benefits and the development of cordless, battery-powered options improve user comfort and operational flexibility, serving as strong market drivers.

However, the market also faces restraints such as the relatively high initial investment cost for advanced pneumatic and electric dispensing systems, which can be a barrier for small and medium-sized enterprises. The availability of low-cost alternatives, especially manual guns, in developing regions also poses a competitive challenge. Additionally, the need for skilled labor to operate and maintain sophisticated dispensing equipment and potential economic downturns impacting industrial output can hinder market growth. Opportunities in the market are abundant, particularly in emerging economies where industrialization is accelerating, and in the development of smart, IoT-enabled dispensing guns offering greater control and data insights. The increasing focus on automation and precision in high-value industries like aerospace and medical devices also presents significant growth avenues.

- Drivers: Growing construction sector, expanding automotive manufacturing, increasing use of advanced adhesives and sealants, demand for precision and efficiency, focus on ergonomics and worker safety.

- Restraints: High initial cost of advanced systems, competition from low-cost alternatives, maintenance requirements, economic fluctuations impacting industrial output.

- Opportunities: Emerging markets industrialization, integration of smart technologies and IoT, development of cordless and battery-powered solutions, demand from specialized industries (aerospace, medical).

- Impact Forces: Economic growth, technological advancements, regulatory standards for safety and environmental protection, consumer demand for durable and high-quality products.

Segmentation Analysis

The Dispensing Guns Market is extensively segmented to reflect the diverse applications and technological variations within the industry. This segmentation helps in understanding the specific needs of different end-user industries and tailoring product development accordingly. Key segments include categorization by the type of gun, the material being dispensed, the primary application, and the overarching end-use industry. This granular analysis provides insights into market dynamics, growth potential, and competitive landscape within each niche, allowing manufacturers and suppliers to strategically target their offerings.

Further analysis within these segments often highlights a trend towards specialized solutions, such as high-pressure guns for viscous materials or precision micro-dispensers for electronics. The demand for eco-friendly and sustainable dispensing solutions, alongside innovations in battery technology for enhanced portability and power, are also influencing segment growth. Understanding these segments is crucial for market participants to identify lucrative opportunities and adapt to the evolving requirements of industrial and professional users, fostering innovation and competitive differentiation.

- By Type:

- Manual Dispensing Guns

- Pneumatic Dispensing Guns

- Electric/Battery-Powered Dispensing Guns

- Cordless Dispensing Guns

- Robotic Dispensing Systems

- By Material Dispensed:

- Adhesives (Epoxies, Urethanes, Cyanoacrylates)

- Sealants (Silicones, Acrylics, Polyurethanes)

- Caulks

- Greases

- Foams

- Fillers

- Pastes

- Compounds

- By Application:

- Construction and Building (Window and Door Installation, Sealing, Roofing)

- Automotive Assembly and Repair (Body Sealing, Gasketing, Bonding)

- Electronics Manufacturing (Component Bonding, Encapsulation)

- Aerospace and Defense (Structural Bonding, Sealing)

- General Industrial Manufacturing

- DIY and Household Use

- Medical and Dental

- By End-Use Industry:

- Manufacturing (Automotive, Electronics, General Assembly)

- Construction and Infrastructure

- Maintenance, Repair, and Overhaul (MRO)

- Packaging

- Woodworking

- Plumbing

Value Chain Analysis For Dispensing Guns Market

The value chain for the Dispensing Guns Market begins with the upstream analysis, primarily focusing on the sourcing of raw materials and components. This includes suppliers of various plastics (e.g., ABS, PVC), metals (e.g., steel, aluminum) for the gun body and internal mechanisms, and electronic components such as motors, batteries, and control boards for powered dispensing guns. Manufacturers often engage with specialized component suppliers to ensure quality, durability, and cost-effectiveness. Research and development activities also form a crucial part of the upstream segment, driving innovation in design, ergonomics, and functionality.

Moving downstream, the value chain encompasses manufacturing, assembly, and testing processes where raw materials are transformed into finished dispensing guns. Once manufactured, these products are distributed through a complex network comprising wholesalers, distributors, specialized industrial suppliers, and online retail platforms. Direct sales channels are also utilized for large industrial clients or for highly customized solutions. The distribution channel plays a critical role in reaching diverse customer segments, from large industrial buyers to individual DIY enthusiasts. Both direct and indirect distribution methods are employed to maximize market penetration and ensure product availability across different geographical regions and customer types, often supported by after-sales service and technical support.

Dispensing Guns Market Potential Customers

The Dispensing Guns Market serves a broad spectrum of potential customers across various industries, each with specific requirements for precision, volume, and material compatibility. End-users range from large-scale industrial manufacturing facilities that require automated or high-volume dispensing solutions to individual tradespeople and DIY enthusiasts seeking reliable tools for smaller projects. Understanding these diverse customer segments is crucial for manufacturers to develop targeted products and marketing strategies, ensuring their offerings align with specific application needs and budget constraints.

Key buyers of dispensing guns include construction companies that rely on these tools for sealing, caulking, and bonding applications in residential and commercial projects. Automotive assembly plants utilize them extensively for applying adhesives, sealants, and sound dampeners during vehicle production. Furthermore, electronics manufacturers use precision dispensing guns for applying conductive pastes, encapsulants, and conformal coatings. Other significant customer groups include aerospace industries for structural bonding, general industrial facilities for maintenance and repair operations, and even medical and dental professionals for specialized material application. The versatility of dispensing guns makes them indispensable across a wide economic landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.8 Billion |

| Market Forecast in 2032 | USD 5.9 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sulzer AG, Nordson Corporation, COX (Soudal Group), Albion Engineering Company, Newborn Brothers Co., Inc., Milwaukee Tool, DeWalt, Makita Corporation, Ryobi Limited, Techcon Systems (OK International), Tajima Tool Corporation, Kraft Tool Co., Jiangsu Hongxin Group, Shanghai Weiwo Industrial Co., Ltd., Hangzhou Baike Adhesive Products Co., Ltd., Focke & Co., EFD Inc. (Nordson), Sealant Equipment & Engineering, Dispense Works Inc., Loctite (Henkel AG & Co. KGaA) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dispensing Guns Market Key Technology Landscape

The Dispensing Guns Market is characterized by a dynamic technological landscape that continuously strives for enhanced precision, efficiency, and user comfort. Advancements in battery technology have revolutionized the market, leading to the proliferation of powerful and long-lasting cordless electric dispensing guns that offer unparalleled portability and freedom of movement, reducing reliance on pneumatic lines or power outlets. Ergonomic design innovations are also paramount, with manufacturers focusing on lighter materials, balanced weight distribution, and comfortable grips to minimize operator fatigue during extended use, thereby improving productivity and reducing the risk of repetitive strain injuries.

Furthermore, the integration of smart features and IoT capabilities is increasingly becoming a critical differentiator. This includes digital displays for precise material flow control, programmable dispensing volumes, and connectivity options for data logging and remote monitoring. Such technologies enable greater accuracy, process repeatability, and allow for sophisticated analysis of application parameters, which is particularly valuable in highly regulated industries or for complex manufacturing processes. Material recognition systems and adaptive dispensing capabilities, which automatically adjust pressure and speed based on material viscosity or ambient temperature, are also emerging, pushing the boundaries of automated and intelligent material application.

Regional Highlights

- North America: A mature market characterized by high adoption of advanced pneumatic and electric dispensing guns in automotive, aerospace, and construction sectors. Emphasis on automation, high-precision applications, and ergonomic designs. Strong R&D activities and presence of key global players.

- Europe: Similar to North America, Europe shows strong demand for high-quality, efficient, and technologically advanced dispensing solutions. Strict regulatory standards drive innovation in safety and environmental compliance. Germany, France, and the UK are key contributors to market growth, particularly in manufacturing and infrastructure projects.

- Asia Pacific (APAC): The fastest-growing region, driven by rapid industrialization, massive construction projects, and expanding automotive and electronics manufacturing bases in China, India, Japan, and South Korea. Increased disposable income also fuels the DIY segment. Offers significant opportunities for both established and emerging players.

- Latin America: An emerging market with growing industrialization and urbanization. Brazil and Mexico are leading the adoption of dispensing guns in their respective construction and automotive industries. The market is sensitive to economic fluctuations but presents long-term growth potential.

- Middle East and Africa (MEA): Marked by significant infrastructure development projects and a burgeoning construction sector, particularly in the GCC countries. Increasing foreign investment and diversification efforts are boosting demand for industrial dispensing solutions. Africa's developing economies also offer future growth prospects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dispensing Guns Market.- Sulzer AG

- Nordson Corporation

- COX (Soudal Group)

- Albion Engineering Company

- Newborn Brothers Co., Inc.

- Milwaukee Tool

- DeWalt

- Makita Corporation

- Ryobi Limited

- Techcon Systems (OK International)

- Tajima Tool Corporation

- Kraft Tool Co.

- Jiangsu Hongxin Group

- Shanghai Weiwo Industrial Co., Ltd.

- Hangzhou Baike Adhesive Products Co., Ltd.

- Focke & Co.

- EFD Inc. (Nordson)

- Sealant Equipment & Engineering

- Dispense Works Inc.

- Loctite (Henkel AG & Co. KGaA)

Frequently Asked Questions

What are the primary benefits of using an electric dispensing gun over a manual one?

Electric dispensing guns offer consistent bead application, reduced hand fatigue, faster work completion, and often feature adjustable speed and flow control for enhanced precision. They are ideal for high-volume tasks or dispensing viscous materials.

How do I choose the correct dispensing gun for my specific application?

Selecting the right dispensing gun depends on the material viscosity, cartridge/sachet size, application volume, desired precision, and power source preference (manual, pneumatic, or electric). Consider the specific end-use industry requirements and ergonomic needs.

What types of materials can dispensing guns effectively apply?

Dispensing guns are highly versatile and can apply a wide range of materials including adhesives (epoxies, silicones), sealants (caulks, urethanes), greases, foams, fillers, and various pastes or compounds used in construction, automotive, and electronics industries.

What are the latest technological innovations in the dispensing guns market?

Recent innovations include cordless battery-powered models with extended runtimes, smart dispensing guns with IoT connectivity for data tracking and precise control, ergonomic designs to minimize user fatigue, and systems capable of adaptive dispensing based on material properties or environmental conditions.

How does automation impact the future of the dispensing guns market?

Automation is driving the integration of dispensing guns into robotic systems and automated assembly lines, leading to higher precision, increased throughput, and reduced labor costs. This trend enhances efficiency, consistency, and is particularly crucial in advanced manufacturing sectors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager