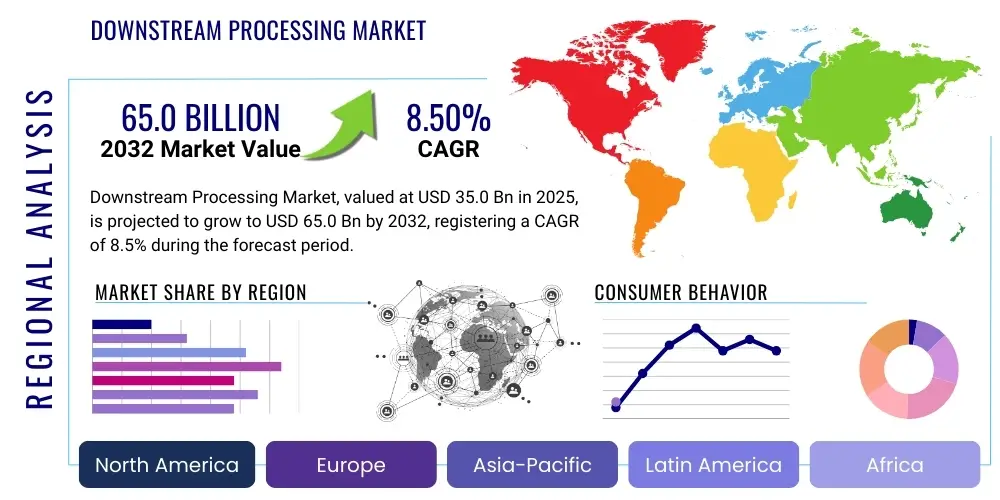

Downstream Processing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427662 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Downstream Processing Market Size

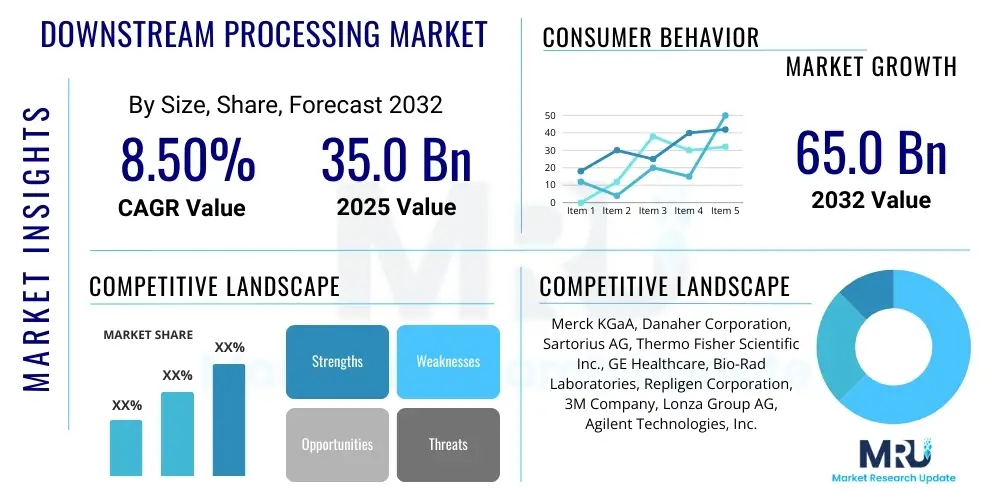

The Downstream Processing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 35.0 billion in 2025 and is projected to reach USD 65.0 billion by the end of the forecast period in 2032.

Downstream Processing Market introduction

Downstream processing (DSP) represents a critical phase in biopharmaceutical manufacturing, focusing on the recovery and purification of biotechnologically produced products, such as proteins, antibodies, and nucleic acids, from cell cultures or fermentation broths. This intricate process is essential to ensure the safety, efficacy, and quality of biotherapeutics by removing impurities, host cell proteins, DNA, and other contaminants to meet stringent regulatory standards for clinical use. The techniques employed in DSP are diverse and highly specialized, encompassing various separation, purification, and concentration methods that are tailored to the specific properties of the target molecule.

Major applications of downstream processing span the entire biopharmaceutical industry, including the production of monoclonal antibodies (mAbs), recombinant proteins, vaccines, gene therapies, and cell therapies. The demand for these advanced therapeutic modalities, driven by an aging global population and the increasing prevalence of chronic and complex diseases, directly fuels the growth of the DSP market. Effective downstream processing not only enhances product purity and yield but also significantly contributes to cost reduction in manufacturing by optimizing resource utilization and minimizing waste.

The markets expansion is fundamentally driven by several key factors. Foremost among these is the escalating global demand for biologics, which continues to be the fastest-growing segment of the pharmaceutical industry. Advances in bioprocessing technologies, including the advent of single-use systems, continuous manufacturing, and integrated purification platforms, are revolutionizing DSP operations, offering greater flexibility, scalability, and efficiency. Furthermore, substantial investments in biopharmaceutical research and development, coupled with a robust pipeline of novel biologic drugs, consistently create new challenges and opportunities for innovative downstream processing solutions.

Downstream Processing Market Executive Summary

The Downstream Processing Market is currently experiencing robust growth, propelled by the expanding biopharmaceutical sector and continuous technological advancements. Business trends indicate a significant shift towards outsourcing downstream processing activities to Contract Manufacturing Organizations (CMOs) and Contract Development and Manufacturing Organizations (CDMOs) due to their specialized expertise, infrastructure, and ability to handle complex purification challenges. This trend allows biopharmaceutical companies to focus on core research and development, while leveraging external capacities for efficient and cost-effective manufacturing. Additionally, the adoption of single-use technologies is accelerating, offering benefits such as reduced cleaning validation, faster turnaround times, and lower capital investment, thereby enhancing operational flexibility across the industry.

Regional trends highlight North America and Europe as leading markets, primarily due to well-established biopharmaceutical industries, extensive research and development activities, and significant investment in advanced manufacturing infrastructure. However, the Asia-Pacific region is emerging as a dynamic growth hub, driven by increasing healthcare expenditure, a rising number of biomanufacturing facilities, and government initiatives promoting local drug production and innovation. Countries like China, India, and South Korea are rapidly expanding their biopharmaceutical capabilities, attracting substantial foreign investment and fostering domestic industry growth, which in turn boosts the demand for sophisticated downstream processing solutions.

Segmentation trends reveal that chromatography remains the cornerstone of downstream purification, with affinity and ion-exchange chromatography systems accounting for a substantial market share due to their high specificity and resolution. Filtration technologies, including ultrafiltration, microfiltration, and depth filtration, are also critical for clarification, concentration, and sterile filtration, demonstrating consistent growth. The application segment sees monoclonal antibodies dominating, reflecting their therapeutic importance and pipeline robustness, while the growing interest in gene and cell therapies is opening new avenues for specialized DSP techniques. End-users such as biopharmaceutical companies continue to be the largest consumers, though academic and research institutes, alongside CMOs, are significant contributors to market demand and innovation.

AI Impact Analysis on Downstream Processing Market

The integration of Artificial Intelligence (AI) within the Downstream Processing Market is rapidly becoming a pivotal area of innovation, addressing long-standing challenges related to process efficiency, scalability, and product quality. Users frequently inquire about how AI can optimize purification steps, predict potential bottlenecks, and reduce the overall time and cost associated with biopharmaceutical manufacturing. There is a strong interest in AIs capacity to analyze vast datasets generated during experiments and production runs, thereby identifying optimal operating parameters and accelerating process development. Expectations are high regarding AIs ability to enhance process understanding, automate routine tasks, and enable real-time monitoring and control, leading to more robust and consistent manufacturing outcomes.

Concerns often revolve around the initial investment costs for AI implementation, the need for specialized data science expertise within bioprocessing teams, and the validation of AI-driven decisions within a highly regulated environment. Users are keen to understand how AI can manage the complexity of multi-step purification processes, especially for novel modalities like gene and cell therapies, where traditional optimization methods can be time-consuming and labor-intensive. The potential for AI to minimize human error, improve yield, and ensure compliance with Good Manufacturing Practices (GMP) is a recurring theme in discussions, highlighting a forward-looking perspective on leveraging advanced analytics for operational excellence.

Ultimately, the overarching expectation is that AI will transform downstream processing from an empirical, trial-and-error approach into a data-driven, predictive science. This shift is anticipated to streamline development cycles, reduce batch failures, and enable continuous process improvement, contributing significantly to bringing life-saving biotherapeutics to market more efficiently and affordably. The market is increasingly looking towards AI not just as a tool for incremental improvement but as a disruptive technology capable of fundamentally reshaping the economics and performance of biopharmaceutical purification.

- Optimizes process parameters for enhanced yield and purity.

- Predicts equipment failures and facilitates predictive maintenance.

- Automates data analysis and reporting, reducing manual effort.

- Enables real-time process monitoring and control for consistency.

- Accelerates process development through machine learning models.

- Identifies critical process parameters and attributes more efficiently.

- Facilitates the design of experiments (DoE) with fewer runs.

- Improves resource allocation and reduces overall operational costs.

DRO & Impact Forces Of Downstream Processing Market

The Downstream Processing Market is profoundly shaped by a dynamic interplay of drivers, restraints, and opportunities, alongside significant impact forces. Key drivers include the ever-increasing demand for biopharmaceuticals, particularly monoclonal antibodies, recombinant proteins, and novel advanced therapies, necessitating more efficient and scalable purification solutions. Global investments in biopharmaceutical research and development are consistently pushing the boundaries of discovery, which in turn generates a demand for sophisticated downstream processing technologies capable of handling complex molecules. Furthermore, the imperative for improved process economics, driven by a need to reduce manufacturing costs and accelerate time-to-market for new drugs, fosters innovation in DSP techniques.

Conversely, the market faces several notable restraints. The high capital investment required for state-of-the-art downstream processing equipment and facilities poses a significant barrier, especially for smaller biopharmaceutical companies and startups. The scarcity of highly skilled personnel with expertise in bioprocess engineering and advanced analytical techniques represents another critical challenge, impacting both process development and manufacturing operations. Moreover, the stringent regulatory landscape, which demands rigorous validation and compliance at every stage of biopharmaceutical production, can extend development timelines and increase operational complexities.

Despite these challenges, substantial opportunities exist for market expansion and technological advancement. Emerging economies in Asia-Pacific, Latin America, and Eastern Europe are rapidly expanding their biomanufacturing capabilities, presenting new markets for DSP solutions. The growing adoption of continuous processing strategies promises to revolutionize downstream operations by offering higher throughput, reduced footprint, and improved process control. Additionally, the rapid development of gene and cell therapies, along with personalized medicine, creates unique purification challenges that drive the need for highly specialized and adaptable downstream technologies, opening new avenues for innovation and market growth. The convergence of these factors, coupled with the persistent push for more sustainable and cost-effective manufacturing, defines the strategic landscape of the downstream processing sector.

Segmentation Analysis

The Downstream Processing Market is comprehensively segmented based on various critical parameters, including product, technique, application, and end-user. This multi-faceted segmentation provides a detailed understanding of market dynamics, enabling stakeholders to identify key growth areas and tailor strategies to specific niches. The product segment encompasses a wide array of equipment and consumables essential for purification and separation. Techniques categorize the methodologies employed, highlighting the diversity of approaches required for complex biomolecules. Applications delineate the therapeutic areas and product types benefiting from DSP, while end-users represent the diverse organizations utilizing these processes in their operations, from large biopharmaceutical companies to academic research institutions. This structured approach to market analysis ensures a granular view of market trends and competitive landscapes.

- Product:

- Chromatography Systems (e.g., Affinity Chromatography, Ion-Exchange Chromatography, Size Exclusion Chromatography)

- Filtration Systems (e.g., Ultrafiltration, Microfiltration, Depth Filtration, Sterile Filtration)

- Centrifugation Systems

- Cell Disruption Equipment

- Bioreactors and Fermenters (for initial product recovery)

- Consumables (e.g., Chromatography Resins, Filtration Membranes, Buffers, Media)

- Technique:

- Purification (e.g., Chromatography, Extraction)

- Separation (e.g., Centrifugation, Filtration)

- Concentration (e.g., Ultrafiltration, Evaporation)

- Cell Disruption

- Inactivation

- Formulation

- Application:

- Monoclonal Antibody Production

- Vaccine Production

- Recombinant Protein Production

- Gene Therapy and Cell Therapy Production

- Insulin Production

- Blood Plasma Fractionation

- Other Biologics

- End-user:

- Biopharmaceutical Companies

- Contract Manufacturing Organizations (CMOs) and Contract Development and Manufacturing Organizations (CDMOs)

- Academic and Research Institutes

- Biotechnology Companies

- Diagnostic Laboratories

Downstream Processing Market Value Chain Analysis

The value chain for the Downstream Processing Market is intricate, spanning from the supply of raw materials and equipment to the final distribution of purified biopharmaceutical products. The upstream analysis typically begins with suppliers providing critical raw materials such as chromatography resins, filtration membranes, specialized buffers, and media. These suppliers are crucial for ensuring the quality and consistency of inputs required for effective purification. Equipment manufacturers, another key upstream component, design and produce the sophisticated systems used in DSP, including chromatography skids, filtration units, centrifuges, and single-use processing bags, continuously innovating to meet evolving industry demands for efficiency and scalability.

The core of the downstream analysis involves the biopharmaceutical manufacturers themselves, along with Contract Development and Manufacturing Organizations (CDMOs). These entities perform the actual downstream processing steps, which include cell separation, clarification, primary purification, intermediate purification, polishing, and final formulation. This stage demands significant technical expertise, advanced analytical capabilities, and strict adherence to regulatory guidelines to achieve the desired product purity, yield, and safety profile. Continuous optimization of these processes is paramount to reduce costs and accelerate time-to-market for critical biotherapeutics.

Distribution channels in the Downstream Processing Market are primarily divided into direct and indirect routes. Direct sales are common for high-value, specialized equipment and complex service contracts, where manufacturers engage directly with biopharmaceutical companies and CDMOs through their dedicated sales forces and technical support teams. This approach allows for customized solutions and strong customer relationships. Indirect distribution, on the other hand, involves distributors and third-party logistics providers who handle the sales and delivery of consumables, reagents, and less specialized equipment, particularly in regions where direct presence is less feasible. The efficiency of these distribution networks is vital for ensuring timely supply chain operations and supporting the global demand for bioprocessing solutions.

Downstream Processing Market Potential Customers

The Downstream Processing Market serves a diverse range of end-users and buyers, all of whom are engaged in the development and manufacturing of biological products. Primarily, large biopharmaceutical companies constitute the largest customer segment. These companies possess extensive research and development capabilities and established manufacturing infrastructure for producing a wide array of biologics, including blockbuster monoclonal antibodies, vaccines, and recombinant proteins. Their continuous need for advanced and efficient DSP solutions is driven by a robust pipeline of novel therapeutic candidates and the ongoing pressure to optimize existing manufacturing processes for cost-effectiveness and increased output.

Contract Development and Manufacturing Organizations (CDMOs) represent another significant customer base. As biopharmaceutical companies increasingly outsource various stages of drug development and manufacturing, CDMOs have become critical partners. They offer specialized expertise, state-of-the-art facilities, and scalable capacities for downstream processing, catering to both emerging biotech firms and established pharmaceutical giants. CDMOs are significant purchasers of DSP equipment and consumables, constantly investing in the latest technologies to provide comprehensive and competitive services to their clients, thereby driving market growth through their expanding service portfolios.

Furthermore, smaller biotechnology companies and academic and research institutes are vital potential customers. Biotechnology startups, often focused on novel therapeutic modalities such as gene and cell therapies, require efficient and flexible DSP solutions for process development and small-scale clinical manufacturing. Academic and government research laboratories, while typically operating at a smaller scale, also contribute to the demand by using DSP equipment for basic research, protein characterization, and early-stage drug discovery. These institutions drive innovation and often serve as early adopters of new technologies, influencing future market trends and demands for purification and separation tools.

Downstream Processing Market Key Technology Landscape

The Downstream Processing Market is characterized by a dynamic and continuously evolving technological landscape, driven by the need for higher purity, increased yield, and greater efficiency in biopharmaceutical manufacturing. Chromatography remains the foundational technology, with advancements focusing on higher capacity resins, faster flow rates, and improved selectivity. Techniques such as affinity chromatography, ion-exchange chromatography, and multimodal chromatography are constantly being refined to handle the increasing complexity and diversity of therapeutic biomolecules. Furthermore, single-use chromatography systems are gaining traction, offering benefits in terms of reduced cleaning validation, faster changeovers, and lower cross-contamination risks, thereby aligning with lean manufacturing principles and enhancing operational flexibility.

Filtration technologies are equally critical and are seeing significant innovations. Ultrafiltration and microfiltration are essential for concentration, buffer exchange, and clarification steps, while depth filtration plays a crucial role in removing cell debris and aggregates early in the process. Recent developments include highly robust and scalable membranes, integrated filtration systems, and advancements in virus filtration to ensure viral safety in biopharmaceutical products. The integration of various filtration steps into continuous or semi-continuous workflows is a major trend, aiming to minimize hold times and improve overall process economics by streamlining the purification train.

Beyond traditional methods, the industry is increasingly adopting and refining advanced technologies such as continuous processing and process intensification. Continuous downstream processing aims to replace batch-based operations with continuous flow, offering smaller equipment footprint, reduced buffer consumption, and improved overall productivity. This includes techniques like multi-column chromatography and tangential flow filtration (TFF) operated in a continuous mode. Moreover, enhanced automation, advanced analytics, and the application of Process Analytical Technology (PAT) are becoming standard practice, enabling real-time monitoring, control, and optimization of DSP steps. These technological advancements collectively drive the market towards more robust, cost-effective, and compliant biomanufacturing processes.

Regional Highlights

- North America: Dominates the market due to a well-established biopharmaceutical industry, significant R&D investments, a robust presence of key market players, and high adoption rates of advanced bioprocessing technologies. The United States is a primary contributor, with numerous biotech startups and large pharmaceutical companies.

- Europe: A strong second market, characterized by stringent regulatory frameworks, substantial government funding for life sciences research, and a mature biomanufacturing landscape. Germany, the UK, Switzerland, and France are key countries fostering innovation and production.

- Asia-Pacific: Emerging as the fastest-growing region, driven by increasing healthcare expenditure, expanding biomanufacturing capabilities, government initiatives promoting local drug production, and a growing patient population. China, India, Japan, and South Korea are leading this growth with increasing investments in biotech infrastructure.

- Latin America: Experiencing gradual growth, supported by rising investments in healthcare infrastructure and an increasing focus on local drug production and vaccine manufacturing. Brazil and Mexico are notable markets in this region.

- Middle East & Africa: Represents a nascent but growing market, propelled by improving healthcare access, increasing government focus on diversifying economies, and emerging biopharmaceutical R&D activities. Investments in biotechnology infrastructure are beginning to create opportunities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Downstream Processing Market.- Merck KGaA

- Danaher Corporation (Cytiva)

- Sartorius AG

- Thermo Fisher Scientific Inc.

- GE Healthcare

- Bio-Rad Laboratories

- Repligen Corporation

- 3M Company

- Lonza Group AG

- Agilent Technologies, Inc.

Frequently Asked Questions

What is downstream processing in biopharmaceuticals?

Downstream processing is the critical stage in biopharmaceutical manufacturing dedicated to the recovery and purification of biologically derived products from cell cultures or fermentation broths. It involves a series of separation, purification, and concentration steps designed to isolate the target molecule, remove impurities, and ensure the product meets strict quality, safety, and purity standards for therapeutic use.

Why is downstream processing important?

Downstream processing is paramount for several reasons: it ensures the purity and safety of biopharmaceuticals by removing contaminants like host cell proteins and DNA; it maximizes product yield, thereby improving manufacturing economics; and it enables the concentration of therapeutic molecules to achieve desired formulation specifications. Without effective DSP, biopharmaceutical products would not meet regulatory requirements for clinical application.

What are the key technologies used in downstream processing?

Key technologies in downstream processing include chromatography (e.g., affinity, ion-exchange, size exclusion) for highly selective purification, various filtration methods (e.g., ultrafiltration, microfiltration, depth filtration) for clarification, concentration, and sterile filtration, and centrifugation for cell separation. Emerging technologies such as continuous processing, single-use systems, and advanced automation are also transforming the landscape.

What are the major challenges in downstream processing?

Major challenges in downstream processing involve high capital investment for equipment, the need for highly skilled personnel, and the complexity of developing efficient purification schemes for diverse and often sensitive biomolecules. Additionally, meeting stringent regulatory requirements, managing process scalability from lab to commercial production, and addressing sustainability concerns pose significant hurdles.

How is AI impacting the downstream processing market?

AI is significantly impacting the downstream processing market by enabling advanced process optimization, predictive maintenance of equipment, and automated data analysis. It helps in identifying optimal operating parameters, accelerating process development, improving yield and purity, and ensuring real-time process control, ultimately leading to more efficient, cost-effective, and robust biomanufacturing operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager