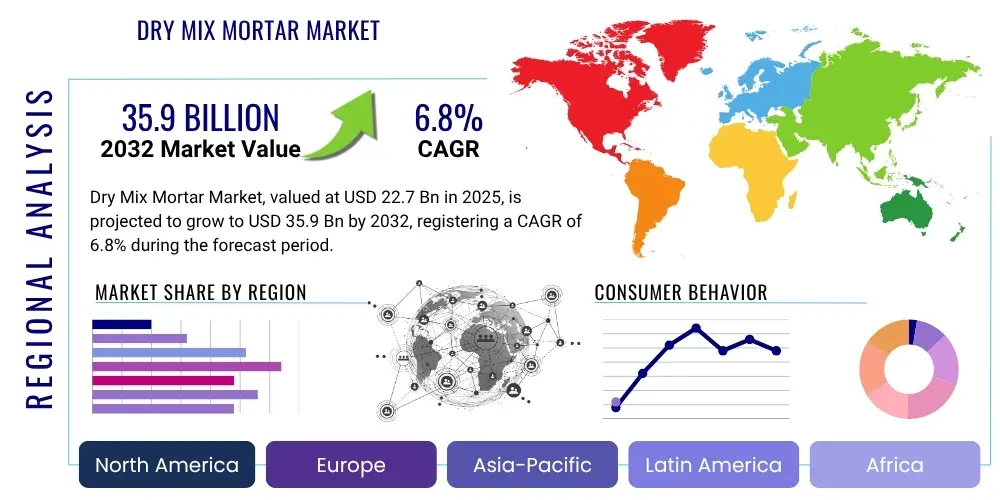

Dry Mix Mortar Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430887 | Date : Nov, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Dry Mix Mortar Market Size

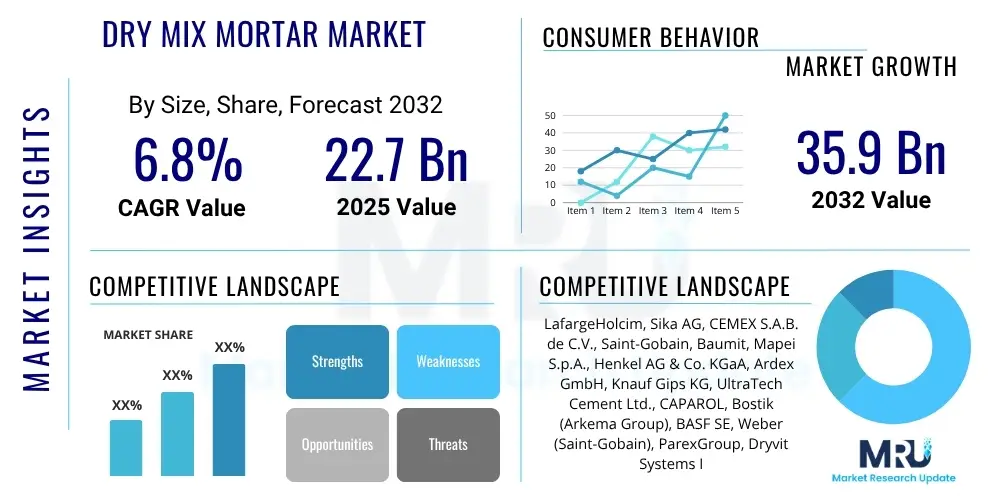

The Dry Mix Mortar Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $22.7 Billion in 2025 and is projected to reach $35.9 Billion by the end of the forecast period in 2032.

Dry Mix Mortar Market introduction

The Dry Mix Mortar Market encompasses a diverse range of factory-produced, ready-to-use cement or gypsum-based mixtures requiring only the addition of water at the construction site. These sophisticated blends integrate aggregates, binders, and chemical additives to deliver superior performance characteristics compared to traditional site-batched mortars. Key products include tile adhesives, plasters, renders, masonry mortars, and self-leveling compounds, catering to a broad spectrum of construction needs.

Major applications for dry mix mortars span residential, commercial, and infrastructure projects, offering solutions for new construction, renovation, and repair works. Their pre-mixed nature ensures consistent quality, enhanced workability, faster application times, and reduced material waste, significantly improving construction efficiency and project timelines. The market's expansion is fundamentally driven by rapid urbanization, increasing infrastructure development, and a growing emphasis on high-performance, sustainable, and convenient building materials.

Dry Mix Mortar Market Executive Summary

The Dry Mix Mortar market is experiencing robust growth fueled by several key business trends, including the increasing adoption of modern construction practices, a rising demand for specialized and high-performance building materials, and a global shift towards sustainable construction. Manufacturers are focusing on product innovation, offering customized solutions that address specific environmental challenges and application requirements, such as enhanced durability, water resistance, and thermal insulation. Strategic collaborations and mergers among key players are also shaping the competitive landscape, aiming to expand product portfolios and geographical reach while optimizing supply chains and manufacturing efficiencies. The market demonstrates a clear trajectory towards more technologically advanced and environmentally friendly formulations, addressing both performance demands and regulatory pressures.

Regionally, the Asia Pacific continues to dominate the market, primarily due to unprecedented rates of urbanization and massive infrastructure investments in countries like China and India. Europe and North America show steady growth, driven by renovation activities, stringent building codes, and a strong emphasis on energy efficiency in construction. The Middle East and Africa are emerging as significant growth hubs, propelled by large-scale commercial and residential developments. Segment-wise, specialty mortars, including those for tiling and EIFS (Exterior Insulation Finishing Systems), are exhibiting higher growth rates compared to traditional masonry mortars, reflecting a trend towards specialized applications and higher value-added products. This diversification is critical for meeting the evolving demands of a complex global construction industry, where efficiency, durability, and aesthetics are paramount.

AI Impact Analysis on Dry Mix Mortar Market

Common user questions regarding AI's impact on the Dry Mix Mortar market often revolve around its potential to optimize production processes, enhance quality control, and improve supply chain efficiency. Users are keenly interested in how AI can contribute to predictive maintenance for manufacturing equipment, refine formulation accuracy through data analytics, and ultimately lead to more sustainable and cost-effective product development. There is also curiosity about AI's role in autonomous construction techniques, where intelligent systems could potentially guide robotic application of dry mix mortars, minimizing human error and accelerating project timelines. The overarching expectation is that AI will usher in an era of greater precision, efficiency, and resource optimization across the entire value chain of dry mix mortar production and application.

- Enhanced quality control through AI-powered sensors and image recognition during production.

- Optimized inventory management and logistics via predictive analytics, reducing waste.

- Predictive maintenance for manufacturing machinery, minimizing downtime and increasing output.

- Development of new, high-performance mortar formulations using AI-driven material science.

- Automation of dry mix mortar application processes on construction sites with robotic systems.

- Improved energy efficiency in production facilities through AI-managed systems.

- Personalized product development based on regional climate data and performance requirements.

DRO & Impact Forces Of Dry Mix Mortar Market

The Dry Mix Mortar market is primarily driven by global urbanization and rapid infrastructure development, particularly in emerging economies. The increasing demand for aesthetically pleasing and high-performance building materials, coupled with a growing preference for convenient and consistent construction solutions, further propels market expansion. Technological advancements leading to improved product formulations offering enhanced durability, workability, and specialized properties are also significant growth catalysts. Additionally, the rising adoption of modern construction techniques and the emphasis on reducing construction time and labor costs contribute substantially to market demand, as dry mix mortars offer significant advantages in these areas, ensuring project efficiencies.

However, the market faces restraints such as the volatile pricing of raw materials, including cement, sand, and various chemical additives, which can impact profit margins. A shortage of skilled labor for application in some regions and a lack of awareness or initial resistance to adopt modern mortar systems among traditional builders in developing markets also pose challenges. Opportunities for growth lie in the increasing demand for green building materials and sustainable construction practices, leading to the development of eco-friendly dry mix mortars. The expansion into niche applications like specialized repair mortars, protective coatings, and decorative finishes also presents lucrative avenues. The burgeoning renovation and retrofitting activities in mature markets provide a consistent demand base, ensuring sustained growth in the foreseeable future.

Segmentation Analysis

The Dry Mix Mortar market is comprehensively segmented to provide granular insights into its diverse applications and product categories, allowing for a detailed understanding of market dynamics. These segments differentiate products based on their chemical composition, intended use, and the specific performance characteristics they offer. Understanding these distinctions is crucial for manufacturers to tailor their product offerings and for end-users to select the most appropriate mortar for their construction needs. The market’s segmentation reflects the broad range of construction activities and the increasing specialization within the building materials industry, from basic structural applications to advanced decorative and protective finishes.

Further analysis within these segments often includes factors such as regional adoption rates, technological advancements impacting product performance, and the competitive landscape within each specific segment. The market is constantly evolving with innovations in material science and processing technologies, leading to new product introductions that cater to emerging construction trends and stricter regulatory standards. This detailed segmentation facilitates strategic planning for market players, helping them identify high-growth areas, allocate resources effectively, and develop targeted marketing strategies to capture specific market shares within the global dry mix mortar industry.

- By Product Type:

- Tile Adhesive Mortar

- Masonry Mortar

- Render and Plaster Mortar

- Screeds and Floor Leveling Compounds

- Waterproofing Mortar

- Repair Mortar

- EIFS Mortar (Exterior Insulation Finishing Systems)

- Grout Mortar

- Others (e.g., Decorative Mortar, Sprayed Mortar)

- By Application:

- Residential Construction

- Commercial Construction (e.g., Offices, Retail, Hospitals)

- Infrastructure Development (e.g., Roads, Bridges, Tunnels)

- Industrial Construction

- Renovation and Repair

- By End-Use Sector:

- New Construction

- Renovation & Rehabilitation

- By Form:

- Ordinary Dry Mix Mortar

- Special Dry Mix Mortar

Value Chain Analysis For Dry Mix Mortar Market

The value chain for the Dry Mix Mortar market begins with the procurement of essential raw materials, including cement, aggregates (sand, gravel), and various chemical additives such as polymers, cellulose ethers, and defoamers. Upstream suppliers play a critical role in providing these components, where quality, consistency, and cost effectiveness are paramount for the final product's performance and profitability. Research and development activities also form a crucial part of this initial stage, focusing on developing new formulations and improving existing ones to meet evolving market demands and performance standards. Efficient sourcing and strong supplier relationships are key to maintaining a competitive edge in manufacturing.

Following raw material procurement, the manufacturing process involves precise batching, mixing, and packaging of the dry ingredients at specialized production plants. This stage ensures the consistent quality and homogeneity that define dry mix mortars. Downstream, the distribution channel is multifaceted, comprising both direct and indirect routes. Direct sales often involve large construction companies or project developers purchasing directly from manufacturers, especially for bulk orders or specialized applications. Indirect channels include a robust network of distributors, wholesalers, and retailers who supply smaller contractors, individual builders, and DIY consumers through hardware stores and building material outlets. Effective logistics and warehousing are vital to ensure timely delivery and product availability across diverse geographical markets, supporting widespread adoption and market penetration.

Dry Mix Mortar Market Potential Customers

The potential customers for dry mix mortar products are extensive and diverse, primarily encompassing various entities within the construction and building industry. These include large-scale residential and commercial developers who require high volumes of consistent quality materials for their multi-unit projects. General contractors and specialized subcontractors, such as those focusing on tiling, plastering, or masonry, form another significant customer base, valuing the efficiency and reliability that dry mix mortars offer in their daily operations. The convenience and performance benefits of these products directly translate into faster project completion and superior finish quality, making them attractive to professionals seeking to optimize their workflow and deliver high-standard results across different construction types and scales.

Beyond professional contractors, the market also serves individual home builders undertaking custom projects, as well as the rapidly growing segment of DIY (Do-It-Yourself) enthusiasts and homeowners involved in renovation and repair activities. These buyers are drawn to the user-friendliness, reduced mess, and guaranteed mix consistency of dry mix mortars, which simplify complex tasks and minimize potential errors. Furthermore, prefabrication companies and modular construction firms are increasingly adopting dry mix mortars for their controlled environment applications, leveraging their precise formulations for rapid assembly and superior structural integrity. This broad spectrum of end-users underscores the widespread applicability and market penetration of dry mix mortar products across the entire construction ecosystem, from industrial scale projects to individual home improvements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $22.7 Billion |

| Market Forecast in 2032 | $35.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | LafargeHolcim, Sika AG, CEMEX S.A.B. de C.V., Saint-Gobain, Baumit, Mapei S.p.A., Henkel AG & Co. KGaA, Ardex GmbH, Knauf Gips KG, UltraTech Cement Ltd., CAPAROL, Bostik (Arkema Group), BASF SE, Weber (Saint-Gobain), ParexGroup, Dryvit Systems Inc., LATICRETE International, Inc., PPG Industries, Inc., Pidilite Industries Ltd., Akzo Nobel N.V. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dry Mix Mortar Market Key Technology Landscape

The Dry Mix Mortar market is continuously evolving with significant technological advancements aimed at improving product performance, manufacturing efficiency, and sustainability. Key technologies in this landscape include advanced mixing and batching systems that ensure precise ingredient proportions and homogeneous blending, leading to consistent product quality. Automated production lines, equipped with sophisticated sensors and control systems, minimize human error and optimize throughput, significantly enhancing manufacturing capabilities. Furthermore, micronization techniques for raw materials are being employed to achieve finer particle sizes, which in turn improves the workability, adhesion, and overall strength of the final mortar product. This focus on precision engineering and automation is critical for meeting the high standards required in modern construction.

Innovation also extends to the development of new chemical additives, such as high-performance polymers, cellulose ethers, and superplasticizers, which impart specific properties like enhanced flexibility, water repellency, faster setting times, and improved durability. These additives allow for the creation of specialized dry mix mortars tailored for challenging environments or unique application requirements, such as extreme weather resistance or rapid repair scenarios. Furthermore, the integration of digital technologies, including IoT sensors for real-time monitoring of production parameters and AI-driven algorithms for optimizing formulations, is becoming increasingly prevalent. These technological shifts not only contribute to superior product characteristics but also drive cost efficiencies and support the industry's move towards more sustainable and environmentally friendly building solutions.

Regional Highlights

- Asia Pacific: Dominates the market due to massive infrastructure projects, rapid urbanization, and significant residential construction in countries like China, India, and Southeast Asian nations.

- Europe: Characterized by a mature construction sector, strong emphasis on renovation, energy-efficient building standards, and a high demand for specialized and sustainable dry mix mortar products, particularly in Germany, France, and the UK.

- North America: Driven by a steady recovery in the construction industry, increasing adoption of advanced building materials, and a focus on both new construction and repair & maintenance activities in the United States and Canada.

- Middle East & Africa (MEA): Experiencing substantial growth fueled by mega-projects in commercial and residential sectors, especially in the GCC countries, coupled with efforts to diversify economies and invest in infrastructure.

- Latin America: Showing promising growth due to expanding construction markets, government investments in infrastructure, and rising residential development in key economies like Brazil, Mexico, and Argentina.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dry Mix Mortar Market.- LafargeHolcim

- Sika AG

- CEMEX S.A.B. de C.V.

- Saint-Gobain

- Baumit

- Mapei S.p.A.

- Henkel AG & Co. KGaA

- Ardex GmbH

- Knauf Gips KG

- UltraTech Cement Ltd.

- CAPAROL

- Bostik (Arkema Group)

- BASF SE

- Weber (Saint-Gobain)

- ParexGroup

- Dryvit Systems Inc.

- LATICRETE International, Inc.

- PPG Industries, Inc.

- Pidilite Industries Ltd.

- Akzo Nobel N.V.

Frequently Asked Questions

What are the primary benefits of using dry mix mortar in construction?

Dry mix mortars offer consistent quality, improved workability, faster application, reduced material waste, and enhanced durability compared to traditional site-batched mortars, leading to higher construction efficiency.

How do dry mix mortars contribute to sustainable construction practices?

Many dry mix mortars are formulated with eco-friendly binders and recycled aggregates, reduce on-site waste, and improve building longevity, aligning with green building certifications and sustainability goals.

What are the main types of dry mix mortars available in the market?

Key types include tile adhesives, masonry mortars, renders and plasters, floor leveling compounds, waterproofing mortars, and specialty repair mortars, each designed for specific applications.

Which regions are driving the growth of the Dry Mix Mortar Market?

Asia Pacific, particularly countries like China and India, is a primary growth driver due to rapid urbanization and extensive infrastructure development, while Europe and North America show steady growth from renovation.

What technological advancements are impacting the dry mix mortar industry?

Technological advancements include automated mixing and batching systems, development of high-performance chemical additives, micronization techniques for raw materials, and the integration of IoT and AI for optimized production and formulation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager