Duct Industrial Heater Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427901 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Duct Industrial Heater Market Size

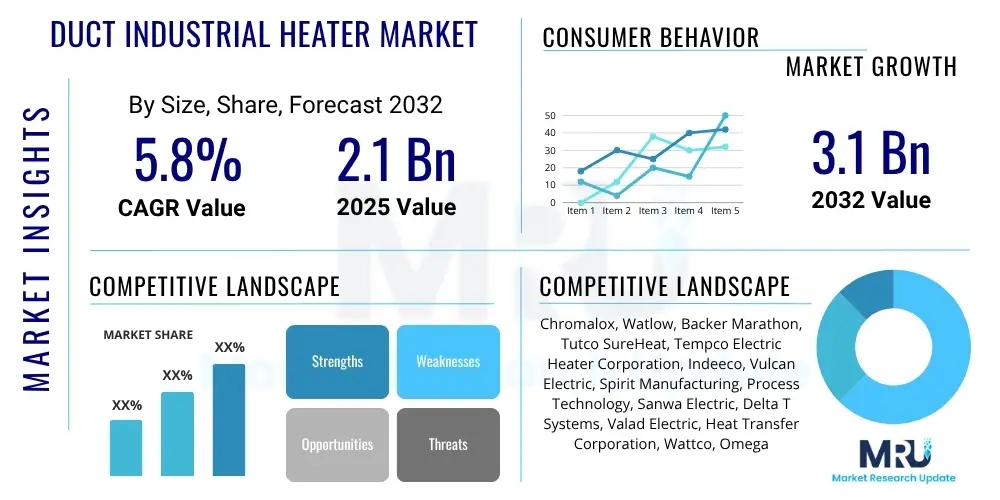

The Duct Industrial Heater Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 2.1 Billion in 2025 and is projected to reach USD 3.1 Billion by the end of the forecast period in 2032.

Duct Industrial Heater Market introduction

The Duct Industrial Heater Market encompasses a wide range of heating solutions essential for various industrial and commercial processes, designed to heat air or other gases as they pass through a duct system. These heaters are critical components in maintaining specific temperatures, drying materials, preventing condensation, and facilitating chemical reactions across diverse sectors. Products within this market include electric duct heaters, gas-fired duct heaters, steam duct heaters, and hot water coil duct heaters, each offering unique advantages in terms of energy source, efficiency, and application suitability. Electric duct heaters are valued for their precise temperature control, ease of installation, and environmental friendliness, while gas-fired units provide high heating capacities suitable for large-scale operations. Steam and hot water variants leverage existing utility infrastructure, offering cost-effective and robust heating in specific industrial settings. Major applications span industrial HVAC systems, manufacturing processes requiring controlled heating or drying, food processing and packaging, pharmaceuticals, automotive paint booths, and power generation facilities where preheating or post-heating of gases is necessary. The core benefits of utilizing advanced duct industrial heaters include enhanced energy efficiency through optimized heat transfer and precise temperature regulation, improved operational safety via integrated controls and robust construction, extended equipment lifespan by preventing corrosive condensation, and compliance with stringent environmental regulations due to cleaner heating methods and reduced emissions. The market is significantly driven by persistent industrial expansion globally, particularly in emerging economies, coupled with an increasing emphasis on energy efficiency and sustainability in manufacturing and processing. Stricter environmental regulations compel industries to adopt cleaner heating solutions, while ongoing infrastructure development projects necessitate advanced HVAC systems. The growing demand for automation and process optimization also fuels the adoption of sophisticated duct industrial heaters capable of seamless integration into modern industrial control systems, ensuring consistent product quality and operational reliability across numerous industries.

Duct Industrial Heater Market Executive Summary

The Duct Industrial Heater Market is experiencing dynamic shifts driven by evolving business trends, distinct regional growth patterns, and technological advancements across its various segments. A significant business trend observed is the accelerating adoption of Industry 4.0 principles, leading to the integration of smart heating solutions equipped with IoT capabilities for remote monitoring, predictive maintenance, and optimized energy consumption. There is a strong movement towards customization and modular designs, allowing manufacturers to offer tailored solutions that meet specific industrial process requirements, enhancing operational flexibility and efficiency. Sustainability initiatives are also profoundly influencing the market, with a rising demand for energy-efficient and environmentally friendly heating systems that reduce carbon footprints and operating costs. Digitalization in manufacturing and supply chain management is improving production efficiency and market responsiveness. From a regional perspective, Asia-Pacific is projected to exhibit the highest growth, fueled by rapid industrialization, burgeoning manufacturing sectors, and extensive infrastructure development in countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, are characterized by a robust demand for replacement units and upgrades to more energy-efficient and technologically advanced systems, driven by stringent energy efficiency standards and environmental mandates. Latin America and the Middle East & Africa are emerging as promising markets due to increasing industrial investments, diversification of economies, and growth in the oil & gas, mining, and construction sectors. Within segment trends, electric duct heaters are gaining traction due to their precise control and cleaner operation, especially in sensitive environments, while gas-fired heaters continue to dominate applications requiring high heat output. Demand for process heating applications remains strong, driven by complex manufacturing processes in chemicals, pharmaceuticals, and food & beverage. The end-use industry segment sees significant growth in manufacturing, HVAC, and food processing, where controlled atmospheric conditions and precise heating are paramount for product quality and safety. The overall market trajectory is poised for sustained growth, underpinned by ongoing industrial modernization efforts, environmental concerns, and a continuous push for operational excellence across global industries.

AI Impact Analysis on Duct Industrial Heater Market

The integration of Artificial Intelligence (AI) is poised to revolutionize the Duct Industrial Heater Market by addressing critical user questions related to operational efficiency, predictive maintenance, and smart control. Users are increasingly concerned about optimizing energy consumption, minimizing downtime, and enhancing the safety and reliability of their heating systems. AI-driven solutions offer direct answers to these needs by enabling sophisticated data analysis from sensors to identify inefficiencies, anticipate potential failures before they occur, and automate complex temperature control processes. The key themes emerging from user expectations include the desire for proactive problem-solving, real-time performance insights, and the ability to adapt to changing operational demands without manual intervention. While concerns about initial investment costs and the complexity of AI implementation exist, the long-term benefits in terms of cost savings, increased productivity, and enhanced system longevity are driving significant interest in AI-enabled heating solutions. Users also seek clarity on how AI can integrate seamlessly with existing industrial infrastructure and contribute to sustainable manufacturing practices, making intelligent automation a paramount feature.

- AI-powered predictive maintenance: Utilizes machine learning algorithms to analyze operational data from heaters, identifying patterns indicative of impending component failure, thereby enabling proactive maintenance and significantly reducing unscheduled downtime and repair costs.

- Optimized energy consumption: AI systems can dynamically adjust heating output based on real-time environmental conditions, load demands, and energy prices, leading to substantial energy savings and reduced operational expenditures.

- Enhanced process control: AI algorithms can learn and adapt to complex industrial processes, providing more precise and stable temperature control than traditional PID controllers, which is crucial for sensitive manufacturing and chemical reactions.

- Remote monitoring and diagnostics: AI-enabled systems allow for comprehensive remote oversight of heater performance, enabling technicians to diagnose issues and make adjustments from any location, improving response times and efficiency.

- Smart integration with industrial IoT (IIoT): AI facilitates seamless communication and data exchange between duct heaters and other factory equipment, creating an interconnected ecosystem that optimizes overall plant operations and resource allocation.

- Automated fault detection and self-correction: AI can autonomously detect operational anomalies, trigger alarms, and in some cases, initiate corrective actions or switch to backup systems to maintain continuous operation.

- Customized heating profiles: AI can develop and implement bespoke heating profiles for different products or processes, ensuring consistent quality and reducing waste by adapting heating parameters precisely to specific requirements.

DRO & Impact Forces Of Duct Industrial Heater Market

The Duct Industrial Heater Market is influenced by a complex interplay of Drivers, Restraints, Opportunities, and broader Impact Forces that shape its growth trajectory and competitive landscape. Key drivers propelling market expansion include the consistent global industrialization and expansion of manufacturing sectors, particularly in emerging economies, which inherently increases the demand for process and space heating solutions. Stringent energy efficiency regulations and environmental mandates worldwide are forcing industries to upgrade to more advanced, efficient, and cleaner heating technologies, thereby stimulating the adoption of modern duct industrial heaters. Furthermore, significant investments in infrastructure development, including commercial and industrial buildings, contribute directly to the demand for HVAC-integrated duct heating systems. The rising need for precise temperature control in sensitive manufacturing processes, such as pharmaceuticals, food & beverage, and electronics, further underscores the importance of reliable and accurate heating equipment. The replacement and modernization of aging industrial infrastructure in developed regions also presents a consistent demand for new, technologically superior heater installations. However, the market faces several restraints that could impede its growth, including the relatively high initial capital expenditure required for sophisticated industrial heating systems, which can be a barrier for small and medium-sized enterprises. Volatility in raw material prices, particularly for metals and specialized heating elements, can impact manufacturing costs and, consequently, end-product pricing. Competition from alternative heating methods, such as radiant heaters or boilers for certain applications, also poses a challenge. The technical complexity involved in the installation, integration, and maintenance of advanced duct heaters requires specialized expertise, which can sometimes limit adoption. Despite these restraints, substantial opportunities abound. The increasing trend towards smart manufacturing and Industry 4.0 creates significant avenues for integrating IoT-enabled and AI-powered heaters, offering predictive maintenance and optimized energy use. The growing demand for customized and modular heating solutions allows manufacturers to cater to diverse and specific industrial needs, enhancing market penetration. Emerging economies, with their rapid industrial growth and developing infrastructure, represent untapped potential for market expansion. Moreover, the focus on green and sustainable heating solutions, including those powered by renewable energy or designed for minimal environmental impact, presents a lucrative niche. The aftermarket services sector, including maintenance, repairs, and spare parts, also provides a continuous revenue stream. The market is also subject to broader impact forces such as evolving regulatory frameworks governing industrial emissions and energy consumption, which can either foster or restrict growth. Global economic conditions and cycles directly influence industrial investment and expansion plans. Rapid technological advancements in materials science, control systems, and heating element design constantly introduce new product innovations. Environmental mandates related to carbon footprint reduction and clean energy adoption profoundly shape product development and market demand. Finally, potential supply chain disruptions, exacerbated by geopolitical events or natural disasters, can affect production and delivery timelines, influencing market stability.

Segmentation Analysis

The Duct Industrial Heater Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. These segmentations are critical for analyzing market trends, identifying growth opportunities, and understanding the specific needs of various end-users. The market can be broadly categorized by the type of heating element or energy source, the primary application for which the heater is utilized, the specific end-use industry it serves, and the operating temperature range it supports. This granular breakdown enables manufacturers to tailor their product offerings, distributors to optimize their supply chains, and end-users to select the most appropriate heating solutions for their unique operational requirements, driving efficiency and effectiveness across the industrial landscape.

- By Type

- Electric Duct Heaters: Utilized for precise temperature control, clean operation, and ease of installation in various industrial HVAC and process heating applications.

- Gas-fired Duct Heaters: Offer high heating capacity and are commonly used in large industrial spaces or processes where natural gas is readily available and cost-effective.

- Steam Duct Heaters: Leverage existing steam infrastructure in industrial facilities, providing robust and efficient heating for air or gas streams.

- Hot Water Coil Duct Heaters: Integrate with hot water systems, ideal for applications requiring moderate temperatures and energy efficiency through water-based heat transfer.

- By Application

- Space Heating: Primarily for maintaining comfortable or controlled temperatures within large industrial buildings, warehouses, or commercial complexes.

- Process Heating: Critical for industrial processes such as drying, curing, preheating, and maintaining specific temperatures for chemical reactions or material processing.

- Drying & Curing: Essential in industries like textiles, coatings, automotive, and manufacturing for rapid and efficient drying or curing of products.

- HVAC Systems: Integral components in industrial and large commercial heating, ventilation, and air conditioning systems for climate control.

- Comfort Heating: For maintaining optimal ambient temperatures for personnel in industrial settings or specific operational zones.

- By End-Use Industry

- Manufacturing: Diverse applications including metal fabrication, plastics, machinery production, and general assembly lines requiring heat treatment or space heating.

- Food & Beverage: Used in drying, baking, pasteurization, sterilization, and maintaining sanitary conditions in processing plants.

- Pharmaceuticals: Essential for controlled drying of active pharmaceutical ingredients, maintaining sterile environments, and specific process heating steps.

- Automotive: Employed in paint booths, curing ovens, material preheating, and general facility heating in manufacturing and assembly plants.

- Oil & Gas: Applications include pipeline heating, preventing condensation in equipment, process fluid heating, and maintaining optimal temperatures in hazardous environments.

- Power Generation: Used for preheating combustion air, fuel oil, or gas, and preventing condensation in electrical components or turbines.

- Chemical & Petrochemical: Critical for reaction heating, distillation processes, drying of chemical products, and maintaining process temperatures.

- Textiles: For drying fabrics, yarns, and fibers, as well as for heat-setting and curing processes.

- Healthcare: Used in climate control for hospitals and medical facilities, sterilization equipment, and specialized laboratory heating.

- Commercial & Institutional: Includes large commercial buildings, schools, universities, and government facilities requiring robust heating solutions.

- By Operating Temperature

- Low Temperature (up to 100°C): Typically for comfort heating, HVAC systems, and some drying processes.

- Medium Temperature (100°C-300°C): Common for general process heating, certain curing applications, and industrial drying.

- High Temperature (above 300°C): Required for specialized industrial processes such as high-temperature curing, heat treatment, and specific chemical reactions.

Value Chain Analysis For Duct Industrial Heater Market

The value chain for the Duct Industrial Heater Market encompasses a series of interconnected activities, beginning from the procurement of raw materials and extending to the final delivery and aftermarket support for end-users, involving both upstream and downstream processes. Upstream analysis focuses on the sourcing and supply of critical raw materials and components necessary for heater manufacturing. This typically includes specialized metals like stainless steel and inconel for heating elements and casings, ceramic materials for insulation, electrical components such as thermostats, sensors, and control panels, as well as gas combustion components for gas-fired units. Suppliers in this segment play a crucial role in ensuring the quality, availability, and cost-effectiveness of these foundational materials, which directly impact the performance and durability of the final product. Downstream analysis involves the manufacturing, assembly, distribution, and installation of the duct industrial heaters, culminating in their use by various end-user industries. Manufacturers transform raw materials and components into finished products, often incorporating advanced engineering and quality control measures. The distribution channel is multifaceted, comprising direct sales, where manufacturers sell directly to large industrial clients or specific project tenders, and indirect channels, which involve a network of distributors, wholesalers, and value-added resellers. These intermediaries are vital for reaching a broader customer base, particularly small to medium-sized enterprises, and for providing localized sales and support. Direct channels offer manufacturers greater control over pricing and customer relationships, while indirect channels provide wider market reach and often offer additional services like installation and maintenance. The choice of distribution channel often depends on the type of heater, the target industry, and the geographical reach desired. Post-sales services, including installation support, maintenance contracts, spare parts supply, and technical troubleshooting, form a crucial part of the downstream value chain, ensuring long-term customer satisfaction and generating recurring revenue streams for market players.

Duct Industrial Heater Market Potential Customers

The potential customers for Duct Industrial Heaters are diverse and span across numerous industrial, commercial, and institutional sectors, representing the end-users and buyers of these essential heating solutions. These customers are primarily entities that require precise and efficient heating of air or gases for their operational processes, climate control, or specialized applications. Key buyers include industrial facilities managers and plant engineers responsible for maintaining operational efficiency, safety, and productivity within manufacturing plants, chemical processing units, food and beverage production lines, and pharmaceutical factories. HVAC contractors and engineering firms form another significant customer segment, as they frequently specify and install duct heaters as integral components of larger industrial and commercial heating, ventilation, and and air conditioning systems. Procurement departments in large corporations and government agencies also represent major potential customers, often seeking bulk purchases or specialized solutions for new construction projects, facility upgrades, or system modernizations. Furthermore, operators in the oil and gas industry, power generation plants, automotive manufacturing, and textile industries are consistent buyers due to the critical role duct heaters play in their process heating, drying, and preheating applications. Any industry with stringent environmental control needs, such as data centers requiring controlled humidity and temperature, or those with cleanroom requirements, will also be prime candidates. Essentially, any enterprise that relies on controlled atmospheric conditions, process heating, or energy-efficient air heating for product quality, operational safety, or personnel comfort, falls within the potential customer base for duct industrial heaters, constantly seeking robust, reliable, and technologically advanced heating solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.1 Billion |

| Market Forecast in 2032 | USD 3.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Chromalox, Watlow, Backer Marathon, Tutco SureHeat, Tempco Electric Heater Corporation, Indeeco, Vulcan Electric, Spirit Manufacturing, Process Technology, Sanwa Electric, Delta T Systems, Valad Electric, Heat Transfer Corporation, Wattco, Omega Engineering, Powerblanket, Proheat, Gaumer Process, Thermcraft, Heatrex Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Duct Industrial Heater Market Key Technology Landscape

The Duct Industrial Heater Market is characterized by a rapidly evolving technology landscape, driven by the persistent demand for greater efficiency, precision, and smart integration in industrial heating processes. A pivotal technological advancement is the widespread adoption of Internet of Things (IoT) integration, which enables duct heaters to communicate seamlessly with other industrial equipment and central control systems. This connectivity facilitates real-time performance monitoring, remote diagnostics, and data logging, empowering operators with unparalleled insights into heater operation and system health. Smart sensors, incorporating advanced thermistors, thermocouples, and flow meters, are becoming standard, providing highly accurate and instantaneous data on temperature, air velocity, and energy consumption. These sensors are crucial for optimizing heater performance and ensuring safety. Advanced control systems, often leveraging Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS), are increasingly sophisticated, offering granular control over heating elements, multi-zone heating capabilities, and complex sequencing for diverse process requirements. The development of more efficient heating elements, such as finned tubular heaters and open coil elements with improved materials and designs, enhances heat transfer efficiency and extends operational lifespan. Energy recovery technologies, including heat exchangers integrated into duct systems, are gaining traction by capturing waste heat and reusing it, significantly reducing overall energy consumption and operational costs. Material science advancements are leading to the use of more robust and corrosion-resistant alloys for heater casings and elements, particularly for applications in harsh or hazardous environments, ensuring greater durability and reduced maintenance. Furthermore, modular designs are becoming prevalent, allowing for easier customization, installation, and scalability of heating systems to meet evolving industrial needs. The emergence of digital twin technology is also enabling virtual simulation and optimization of heater performance before physical deployment, further enhancing efficiency and predictability. These technological innovations collectively contribute to the development of more intelligent, sustainable, and high-performance duct industrial heaters, essential for modern industrial operations.

Regional Highlights

- North America: This region represents a mature yet robust market for duct industrial heaters, primarily driven by the ongoing need for replacement and modernization of aging industrial infrastructure. Strict energy efficiency standards and environmental regulations in the U.S. and Canada compel industries to invest in more advanced, energy-saving heating solutions. The presence of well-established manufacturing, automotive, and food and beverage industries, alongside a strong focus on automation and smart manufacturing (Industry 4.0), contributes to a consistent demand for high-performance and IoT-enabled heating systems. The region also exhibits a significant demand for customized solutions catering to specialized industrial processes.

- Europe: The European market is characterized by stringent environmental protection policies and a strong emphasis on sustainability and energy conservation. This drives the adoption of highly efficient and low-emission duct industrial heaters. Countries like Germany, the UK, and France are leaders in industrial innovation, fostering demand for technologically advanced heating solutions that integrate with smart factory concepts. The region’s robust automotive, chemical, pharmaceutical, and food processing industries are significant end-users, seeking precise temperature control and reliable heating for their complex manufacturing processes. Investments in green technologies and the refurbishment of older industrial facilities further stimulate market growth.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market, propelled by rapid industrialization, massive infrastructure development, and an expanding manufacturing base, particularly in China, India, Japan, and Southeast Asian countries. The region's burgeoning economies are witnessing significant investments in new industrial plants across sectors like electronics, textiles, automotive, and power generation, directly translating into high demand for various types of duct industrial heaters. Lower manufacturing costs and increasing disposable incomes also contribute to the growth of end-use industries. While energy efficiency is a growing concern, the sheer scale of industrial expansion is the primary growth driver.

- Latin America: This region is an emerging market for duct industrial heaters, experiencing steady growth driven by increasing industrial investments, particularly in Brazil, Mexico, and Argentina. The expansion of mining, oil and gas, food processing, and automotive industries is fueling the demand for industrial heating solutions. While the market is still developing compared to more mature regions, a growing focus on improving manufacturing efficiency and modernizing existing facilities presents significant opportunities for market players. Economic stabilization and foreign direct investments are expected to further bolster market development in the coming years.

- Middle East and Africa (MEA): The MEA market is primarily driven by significant investments in the oil and gas sector, petrochemical industries, and large-scale infrastructure and construction projects, particularly in Gulf Cooperation Council (GCC) countries. The need for specialized heating solutions in hazardous environments and for process-critical applications is a key demand factor. Economic diversification efforts in countries like Saudi Arabia and UAE are also leading to growth in manufacturing and other industrial sectors, gradually increasing the demand for duct industrial heaters beyond traditional applications. Climate control in commercial and residential developments also contributes to the market.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Duct Industrial Heater Market.- Chromalox

- Watlow

- Backer Marathon

- Tutco SureHeat

- Tempco Electric Heater Corporation

- Indeeco

- Vulcan Electric

- Spirit Manufacturing

- Process Technology

- Sanwa Electric

- Delta T Systems

- Valad Electric

- Heat Transfer Corporation

- Wattco

- Omega Engineering

- Powerblanket

- Proheat

- Gaumer Process

- Thermcraft

- Heatrex Inc.

Frequently Asked Questions

Analyze common user questions about the Duct Industrial Heater market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a Duct Industrial Heater and its primary function?

A Duct Industrial Heater is a specialized heating device designed to warm air or other gases as they flow through a duct system in industrial and commercial settings. Its primary function is to maintain specific temperatures for processes, space heating, drying, curing, or to prevent condensation, crucial for operational efficiency and product quality across various industries.

What are the main types of Duct Industrial Heaters available?

The main types include Electric Duct Heaters, known for precise control and clean operation; Gas-fired Duct Heaters, offering high capacity for large spaces; Steam Duct Heaters, utilizing existing steam infrastructure; and Hot Water Coil Duct Heaters, integrating with hot water systems for moderate temperature needs.

How does AI impact the efficiency and maintenance of these heaters?

AI significantly enhances efficiency through optimized energy consumption, dynamically adjusting heating based on real-time data. For maintenance, AI enables predictive analysis, identifying potential failures before they occur, thus reducing downtime, extending equipment life, and lowering operational costs through proactive servicing.

Which industries are the largest end-users of Duct Industrial Heaters?

The largest end-users include manufacturing, food & beverage, pharmaceuticals, automotive, oil & gas, and power generation industries. These sectors heavily rely on precise temperature control for their production processes, climate management, and equipment protection, driving consistent demand for advanced heating solutions.

What are the key drivers and restraints shaping the market growth?

Key drivers include global industrial expansion, stringent energy efficiency regulations, and infrastructure development. Restraints encompass high initial investment costs, volatile raw material prices, and competition from alternative heating technologies, which collectively influence market adoption and development.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager