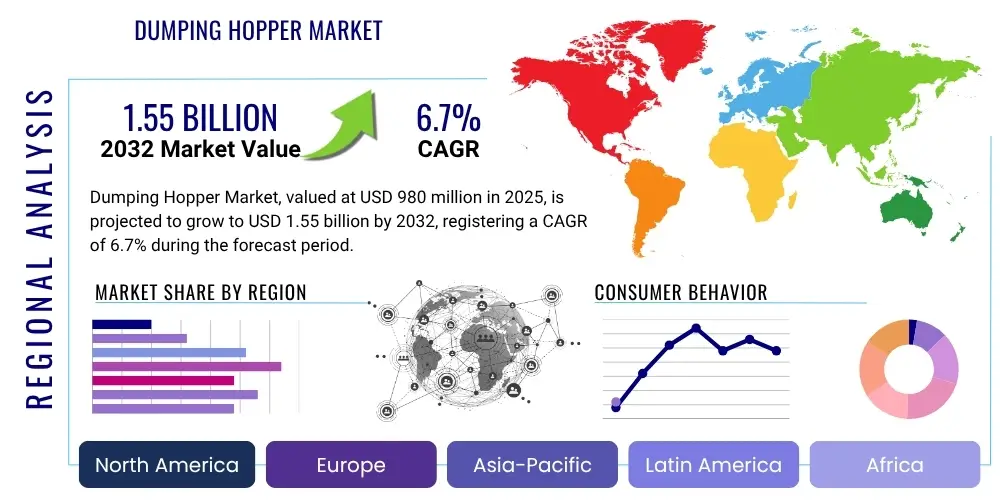

Dumping Hopper Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428773 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Dumping Hopper Market Size

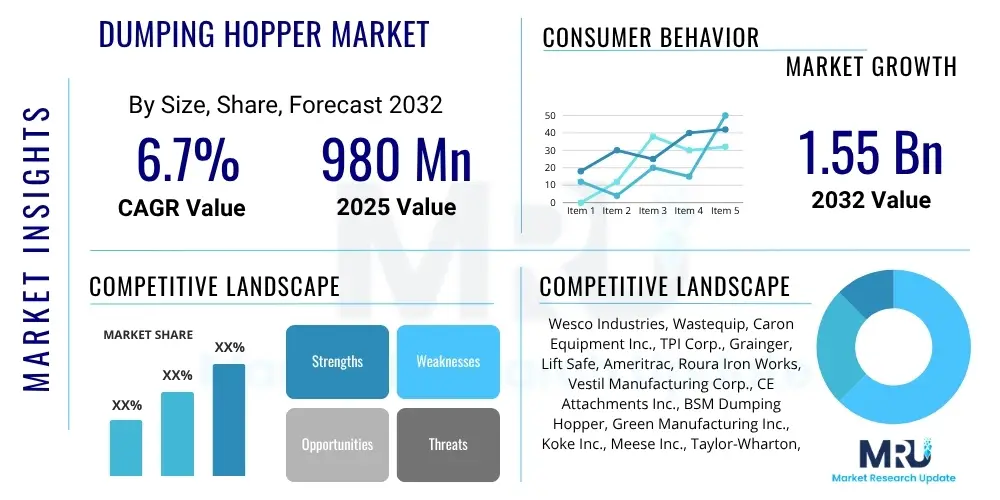

The Dumping Hopper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032. The market is estimated at USD 980 million in 2025 and is projected to reach USD 1.55 billion by the end of the forecast period in 2032.

Dumping Hopper Market introduction

The Dumping Hopper Market encompasses the manufacturing, distribution, and sales of specialized containers designed for efficient collection, transportation, and controlled discharge of bulk materials, waste, and debris. These robust containers, often equipped with mechanisms for automated or semi-automated emptying, are critical tools across a multitude of industrial, commercial, and agricultural settings. Their primary function is to enhance operational efficiency, improve workplace safety by minimizing manual handling, and streamline material flow processes, from scrap collection in manufacturing plants to debris removal on construction sites.

Dumping hoppers come in various designs, including self-dumping hoppers, which automatically tip when released and return to an upright locked position, and heavy-duty hoppers, built for more demanding loads and environments. They are typically constructed from durable materials like steel, stainless steel, or high-density polyethylene, chosen based on the type of material being handled and the environmental conditions. Major applications span construction for managing rubble, manufacturing for scrap and waste collection, waste management and recycling facilities for sorting and moving recyclables, agriculture for grain and feed handling, and mining for ore and aggregate transport.

The benefits derived from the adoption of dumping hoppers are significant, including substantial improvements in labor efficiency by reducing manual effort and speeding up material transfers. They contribute to enhanced safety by mitigating risks associated with heavy lifting and hazardous material handling. Furthermore, these devices aid in better waste segregation and management, leading to reduced disposal costs and supporting sustainability initiatives. Key driving factors propelling market growth include increasing industrialization, stringent waste management regulations, a rising focus on workplace safety, and the ongoing demand for efficient material handling solutions across diverse end-use sectors globally.

Dumping Hopper Market Executive Summary

The Dumping Hopper Market is experiencing robust growth, driven by an escalating emphasis on operational efficiency, worker safety, and improved waste management practices across global industries. Business trends indicate a strong move towards customization and automation, with manufacturers developing hoppers tailored to specific industry needs, incorporating advanced features like forklift compatibility, precise dumping mechanisms, and durable, corrosion-resistant materials. The market also observes an increasing demand for environmentally friendly solutions, prompting innovations in design for better waste segregation and the use of recyclable materials in hopper construction. Investments in advanced manufacturing techniques are also shaping product development, aiming for longer lifespan and reduced maintenance requirements for industrial users.

Regionally, Asia Pacific is projected to lead market expansion, fueled by rapid industrialization, burgeoning construction activities, and significant growth in manufacturing sectors across countries like China, India, and Southeast Asian nations. North America and Europe continue to be strong markets, characterized by stringent safety regulations and a high adoption rate of automated material handling equipment, driving demand for technologically advanced and compliant dumping hoppers. Latin America and the Middle East and Africa regions are also showing promising growth, attributed to developing infrastructure projects, expanding mining operations, and increased investment in industrial facilities.

From a segmentation perspective, self-dumping hoppers remain a dominant category due to their efficiency and ease of use, particularly with forklift integration. The demand for heavy-duty hoppers is also consistently high, driven by industries handling dense or abrasive materials. End-use industries such as construction, manufacturing, and waste management represent the largest segments, continuously investing in robust and high-capacity hoppers to streamline their operations. Furthermore, there is a growing trend towards specialized hoppers designed for niche applications, offering tailored solutions for unique material handling challenges, thereby diversifying the market landscape.

AI Impact Analysis on Dumping Hopper Market

User inquiries about AI's impact on the dumping hopper market primarily revolve around how artificial intelligence can enhance efficiency, reduce operational costs, and improve safety in material handling processes. Common questions explore predictive maintenance for hoppers, optimization of material flow using real-time data, and the integration of smart features for automated operation and inventory management. Users are particularly interested in how AI can move dumping hoppers beyond simple mechanical tools to intelligent components within a larger, interconnected industrial ecosystem, thereby addressing concerns about equipment downtime, labor intensity, and material waste, while expecting solutions that are both practical and cost-effective for their operations.

- Enhanced predictive maintenance by analyzing usage patterns and wear, reducing unscheduled downtime.

- Optimized material flow and inventory management through real-time data analytics from smart hoppers.

- Automated sorting and segregation of waste or materials when integrated with vision systems and robotic arms.

- Improved safety protocols through AI-driven monitoring of hopper operations, detecting potential hazards.

- Increased operational efficiency by intelligent routing and scheduling of hopper movements within facilities.

- Customized hopper designs and material selection recommendations based on AI analysis of operational requirements.

DRO & Impact Forces Of Dumping Hopper Market

The Dumping Hopper Market is significantly influenced by a confluence of drivers, restraints, and opportunities. Key drivers include the escalating demand for efficient and safe material handling solutions across various industries, stimulated by global industrial expansion and infrastructure development projects. Strict occupational safety regulations compel businesses to adopt mechanized solutions like dumping hoppers to minimize manual labor risks and enhance compliance. The rising volume of industrial and commercial waste, coupled with evolving waste management and recycling policies, further fuels the adoption of hoppers for streamlined collection and segregation. Furthermore, the push towards automation in manufacturing and logistics sectors is creating a favorable environment for advanced and integrated hopper systems.

However, the market also faces notable restraints. The initial capital investment required for high-quality, durable dumping hoppers can be substantial, particularly for small and medium-sized enterprises (SMEs), potentially hindering adoption. Ongoing maintenance costs, including parts replacement and servicing, also add to the operational expenses. Economic downturns or uncertainties can lead to reduced industrial spending and delayed equipment upgrades, negatively impacting market growth. Additionally, the challenge of customizing hoppers for highly specific applications, which often requires significant engineering and manufacturing adjustments, can be a limiting factor for broad-scale market penetration, increasing lead times and costs.

Opportunities for growth are abundant, primarily through the development of sustainable material hoppers utilizing recycled content or environmentally friendly production processes, aligning with global green initiatives. The integration of smart technologies, such as IoT sensors for fill levels and GPS for tracking, presents significant avenues for innovation and value addition, leading to more efficient and data-driven operations. Emerging markets in Asia Pacific, Latin America, and the Middle East and Africa offer substantial untapped potential due to their rapid industrialization and growing need for modern material handling infrastructure. Moreover, the creation of specialized hoppers designed for niche applications, addressing unique material properties or environmental conditions, can open new market segments and drive product differentiation.

Segmentation Analysis

The Dumping Hopper Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation helps in analyzing market trends, identifying key growth areas, and understanding specific customer needs across various applications and product types. The primary categories for segmentation include the type of hopper, the material used in its construction, its capacity, and the end-use industry it serves, each offering distinct insights into market behavior and competitive landscapes. This layered approach ensures that market participants can strategically position their products and services to address targeted demands within the broader industrial ecosystem.

- By Type:

- Self-Dumping Hoppers

- Forklift Hoppers

- Heavy-Duty Hoppers

- Tilting Hoppers

- Portable Hoppers

- Specialty Hoppers

- By Material:

- Steel Hoppers

- Stainless Steel Hoppers

- Plastic Hoppers

- Hybrid Material Hoppers

- By Capacity:

- Light Capacity Hoppers (under 1 cubic yard)

- Medium Capacity Hoppers (1-3 cubic yards)

- Heavy Capacity Hoppers (over 3 cubic yards)

- By End-Use Industry:

- Manufacturing & Industrial

- Construction

- Waste Management & Recycling

- Agriculture

- Mining

- Logistics & Warehousing

Value Chain Analysis For Dumping Hopper Market

The value chain for the Dumping Hopper Market begins with upstream activities, primarily involving the sourcing and processing of raw materials. This includes suppliers of steel, stainless steel, and various plastic resins, which are fundamental components for hopper construction, along with manufacturers of specialized parts such as hydraulic systems, casters, wheels, and locking mechanisms. These raw material and component suppliers play a crucial role in determining the quality, durability, and cost-effectiveness of the final dumping hopper product. Relationships with reliable and cost-efficient upstream partners are essential for manufacturers to maintain competitive pricing and consistent product standards, directly impacting production capabilities and market agility.

Further down the value chain, manufacturers transform these raw materials and components into finished dumping hoppers through processes like cutting, welding, assembly, and finishing. Following manufacturing, the distribution channel plays a pivotal role in delivering products to end-users. This typically involves a mix of direct sales channels, where manufacturers sell directly to large industrial clients or through their dedicated sales force, and indirect channels, which include industrial distributors, equipment rental companies, and online marketplaces. Indirect channels often provide broader market reach, particularly to smaller businesses and diverse geographical locations, by leveraging existing networks and logistical capabilities.

Downstream activities focus on reaching the potential customers and providing after-sales support. Direct distribution channels allow manufacturers to build strong customer relationships, offer customized solutions, and provide direct technical support and maintenance services. Indirect channels, while offering extensive reach, require manufacturers to work closely with distributors to ensure product knowledge, availability, and adequate customer service. The overall effectiveness of the value chain relies on seamless coordination between all stages, from material procurement to product delivery and post-purchase support, ensuring customer satisfaction and fostering repeat business within the dynamic Dumping Hopper Market.

Dumping Hopper Market Potential Customers

Potential customers for dumping hoppers represent a broad spectrum of industries, all sharing a common need for efficient, safe, and organized material handling and waste management. These end-users are typically entities involved in activities that generate significant bulk materials, scrap, or debris, or require the organized transport of various goods within their operations. The diverse applications of dumping hoppers make them indispensable tools for businesses looking to optimize their workflow, comply with safety regulations, and manage their operational costs effectively, demonstrating a universal appeal across different economic sectors.

Key end-user segments include construction companies, which utilize hoppers for debris removal, concrete transport, and managing aggregates on job sites, and manufacturing plants, which rely on them for collecting metal scraps, waste materials, and transporting components between workstations. Waste management and recycling centers are substantial buyers, using hoppers for sorting, collecting, and moving various types of recyclables and refuse. Agricultural enterprises employ hoppers for handling grain, feed, and other farm products, while mining operations use heavy-duty versions for ore, rock, and overburden transport, demanding robustness and durability.

Additionally, logistics and warehousing facilities form a growing customer base, as they use dumping hoppers for temporary storage, consolidation of goods, and managing packaging waste, contributing to cleaner and more efficient warehouse environments. The versatility and increasing specialization of dumping hoppers mean that any organization engaged in material processing, waste generation, or bulk transport within industrial, commercial, or even municipal contexts could be considered a potential customer, driving consistent demand across mature and emerging economies alike.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 980 million |

| Market Forecast in 2032 | USD 1.55 billion |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Wesco Industries, Wastequip, Caron Equipment Inc., TPI Corp., Grainger, Lift Safe, Ameritrac, Roura Iron Works, Vestil Manufacturing Corp., CE Attachments Inc., BSM Dumping Hopper, Green Manufacturing Inc., Koke Inc., Meese Inc., Taylor-Wharton, DuraCast, Eagle Manufacturing Company, AK Material Handling Systems, Valley Craft Industries, Steel King Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dumping Hopper Market Key Technology Landscape

The Dumping Hopper Market is increasingly benefiting from advancements in material science and engineering, leading to the development of hoppers that are more durable, lighter, and resistant to corrosion and abrasion. Innovations in steel alloys, stainless steel grades, and high-density plastics allow manufacturers to produce hoppers capable of withstanding harsh industrial environments, extreme temperatures, and heavy-duty use while reducing overall weight for improved maneuverability and fuel efficiency in transport. Specialized coatings and liners are also becoming prevalent, enhancing chemical resistance for specific waste types and prolonging the lifespan of the equipment, thereby offering a better return on investment for end-users.

Automation and smart technology integration are transforming traditional dumping hoppers into more sophisticated material handling assets. The incorporation of sensors, such as load cells for measuring fill levels and proximity sensors for precise positioning, allows for greater operational control and efficiency. These smart features enable real-time monitoring of hopper usage, facilitate predictive maintenance by identifying potential wear and tear before failure, and can even integrate with facility management systems to optimize material flow and schedule emptying operations. The adoption of IoT (Internet of Things) capabilities enables remote monitoring and data collection, paving the way for data-driven decision-making in logistics and waste management.

Furthermore, ergonomic design principles and enhanced safety features are becoming standard, driven by regulatory compliance and a growing emphasis on worker well-being. This includes innovations in latching mechanisms that ensure secure transport and controlled dumping, improved forklift pockets for stable handling, and visible safety markings. Design modifications also focus on making hoppers easier to clean and maintain, reducing downtime and operational costs. These technological advancements collectively contribute to a market offering more efficient, safer, and economically viable solutions for diverse material handling challenges, pushing the boundaries of what dumping hoppers can achieve within industrial settings.

Regional Highlights

- North America: A mature market characterized by advanced industrial infrastructure and stringent safety regulations. High adoption of automated and heavy-duty hoppers in construction, manufacturing, and waste management sectors. Strong emphasis on ergonomic and environmentally compliant solutions.

- Europe: Driven by strict environmental policies and a focus on circular economy principles. High demand for sustainable and high-quality hoppers, with significant investments in smart material handling technologies and efficient recycling processes. Germany and the UK are key markets.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, burgeoning construction activities, and significant growth in manufacturing across China, India, and Southeast Asian countries. Increasing adoption of modern material handling equipment to boost productivity and manage expanding waste volumes.

- Latin America: Showing promising growth due to expanding mining operations, agricultural development, and ongoing infrastructure projects. Demand is rising for robust and cost-effective dumping hoppers to support heavy industrial applications and raw material transport.

- Middle East and Africa (MEA): An emerging market with substantial investments in mega construction projects, industrial diversification, and infrastructure development. Increasing demand for durable hoppers for construction debris, industrial waste, and logistics support, particularly in GCC countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dumping Hopper Market.- Wesco Industries

- Wastequip

- Caron Equipment Inc.

- TPI Corp.

- Grainger

- Lift Safe

- Ameritrac

- Roura Iron Works

- Vestil Manufacturing Corp.

- CE Attachments Inc.

- BSM Dumping Hopper

- Green Manufacturing Inc.

- Koke Inc.

- Meese Inc.

- Taylor-Wharton

- DuraCast

- Eagle Manufacturing Company

- AK Material Handling Systems

- Valley Craft Industries

- Steel King Industries

Frequently Asked Questions

What is the projected growth rate of the Dumping Hopper Market?

The Dumping Hopper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032, indicating steady expansion.

Which industries are the primary users of dumping hoppers?

Primary industries include Manufacturing, Construction, Waste Management & Recycling, Agriculture, Mining, and Logistics & Warehousing, all requiring efficient material and waste handling.

How does AI impact the Dumping Hopper Market?

AI integration enables predictive maintenance, optimized material flow, automated sorting, and enhanced safety, transforming hoppers into smart, efficient industrial tools.

What are the main types of dumping hoppers available?

Common types include self-dumping hoppers, forklift hoppers, heavy-duty hoppers, tilting hoppers, portable hoppers, and specialty hoppers, each designed for specific applications.

What are the key driving factors for market growth?

Key drivers include global industrial growth, enhanced safety standards, increasing demands for efficient waste management, and the ongoing trend towards automation in material handling operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager