Dunnage Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428339 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Dunnage Packaging Market Size

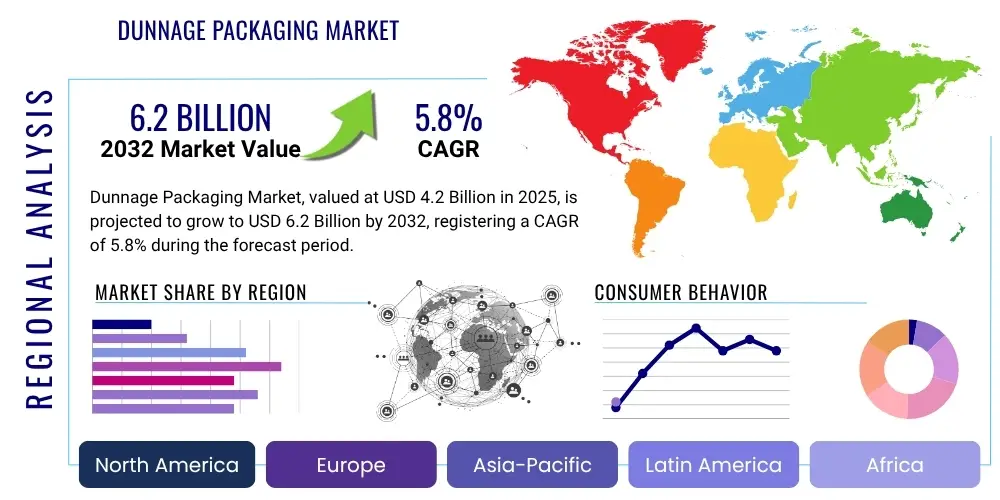

The Dunnage Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at $4.2 Billion in 2025 and is projected to reach $6.2 Billion by the end of the forecast period in 2032.

Dunnage Packaging Market introduction

Dunnage packaging plays a critical role in the global supply chain, serving as a protective material designed to cushion, brace, and secure products during transit and storage. Its primary function is to prevent damage from shocks, vibrations, and movements, thereby minimizing losses and ensuring goods arrive at their destination intact. The dunnage packaging market is characterized by a diverse range of materials and customized solutions, addressing the specific needs of various industries from automotive components to delicate electronic devices and consumer goods.

This essential packaging solution encompasses a broad spectrum of products, including custom-molded foam inserts, corrugated cardboard dividers, plastic trays, wooden crates, and fabric bags, each selected based on the fragility, weight, and dimensions of the items being protected. The versatility of dunnage allows it to be tailored for single-use applications or designed for reusability in closed-loop supply systems, emphasizing both efficiency and sustainability. Major applications span high-value sectors such as automotive manufacturing, where complex parts require precise protection, and the rapidly expanding e-commerce industry, which demands robust solutions for diverse product shipments.

The core benefits of effective dunnage packaging extend beyond simple damage prevention; it significantly contributes to reduced shipping costs by allowing for denser packing and mitigating returns due to breakage. Moreover, it enhances operational efficiency in warehouses and assembly lines by providing organized, easily identifiable, and often reusable packaging components. The market's growth is primarily driven by the relentless expansion of global trade, the increasing sophistication of manufacturing processes requiring precision component handling, and the exponential rise of e-commerce, which places immense pressure on secure and efficient logistics. Furthermore, stringent industry regulations regarding product quality and safe delivery standards compel businesses to invest in high-quality dunnage solutions.

Dunnage Packaging Market Executive Summary

The Dunnage Packaging Market is experiencing robust growth fueled by several interconnected factors, predominantly the surging demand from the e-commerce sector and the expanding global manufacturing landscape, especially in automotive and electronics industries. Business trends indicate a strong move towards customization, as companies seek tailored solutions that offer superior protection for increasingly complex and diverse product portfolios. This shift necessitates advancements in design and material science, pushing manufacturers to innovate with lightweight, durable, and often reusable dunnage options. Sustainability remains a pivotal concern, driving significant investment in eco-friendly materials and closed-loop systems, impacting purchasing decisions and R&D efforts across the industry.

Regionally, the Asia Pacific market stands as the dominant force, propelled by its status as a global manufacturing hub and the rapid urbanization and economic growth driving consumer demand and e-commerce penetration. North America and Europe, while more mature markets, are characterized by high adoption of advanced dunnage solutions, a strong emphasis on automation in packaging processes, and increasing regulatory pressure for sustainable practices. These regions are pioneers in developing smart dunnage integrating IoT for tracking and condition monitoring. Latin America and the Middle East and Africa are emerging markets, witnessing considerable infrastructure development and industrialization, leading to escalating demand for effective packaging solutions as their logistics networks mature.

Segmentation trends highlight the widespread preference for corrugated cardboard and plastic dunnage due to their cost-effectiveness and versatility, although foam solutions maintain a strong foothold for delicate and high-value items requiring superior shock absorption. The automotive end-use segment continues to be a major consumer, utilizing highly customized dunnage for component protection during assembly and transit. There is also a significant trend towards multi-material dunnage systems that combine the benefits of different materials for optimal protection and efficiency. The demand for reusable dunnage is also on a consistent upward trajectory, aligning with corporate sustainability objectives and offering long-term cost savings in repetitive shipping scenarios.

AI Impact Analysis on Dunnage Packaging Market

The integration of Artificial intelligence (AI) within the dunnage packaging market is poised to address key user questions related to optimizing packaging efficiency, reducing waste, and enhancing protection for diverse product ranges. Common queries revolve around how AI can minimize material usage, predict potential damage points, automate design processes, and streamline inventory management. Users are particularly interested in AI's ability to create custom dunnage solutions rapidly and cost-effectively, adapting to evolving product specifications and supply chain dynamics. The overarching themes include leveraging AI for predictive analytics, smart logistics, and improved sustainable practices, aiming to achieve a delicate balance between robust protection and environmental responsibility.

- Automated Design Optimization: AI algorithms can analyze product dimensions, fragility, and shipping routes to generate optimal dunnage designs, minimizing material usage while maximizing protection, often faster and more efficiently than traditional manual methods.

- Predictive Analytics for Damage Prevention: AI systems can process historical shipping data, sensor inputs from transit (temperature, humidity, shock), and environmental factors to predict potential damage risks and recommend proactive dunnage adjustments or alternative packaging strategies.

- Supply Chain and Inventory Management: AI optimizes dunnage inventory levels by forecasting demand based on production schedules and shipping volumes, reducing carrying costs and ensuring timely availability of necessary packaging components.

- Quality Control and Inspection: AI-powered vision systems can perform rapid, consistent quality checks on manufactured dunnage, identifying defects, ensuring dimensional accuracy, and maintaining high standards for protective performance before deployment.

- Material Selection and Sustainability: AI can assist in recommending the most appropriate and sustainable dunnage materials by evaluating properties, cost, recyclability, and environmental impact data, aiding companies in meeting their green initiatives.

DRO & Impact Forces Of Dunnage Packaging Market

The Dunnage Packaging Market is significantly shaped by a dynamic interplay of drivers, restraints, and opportunities, all influenced by broader impact forces. Key drivers include the robust growth of the e-commerce sector, which demands secure and efficient packaging for individual parcel shipments globally, coupled with the consistent expansion of the automotive and electronics manufacturing industries, which rely heavily on customized dunnage for protecting sensitive components. Furthermore, stringent regulations pertaining to product safety and damage-free delivery across various sectors, along with an increasing focus on sustainable packaging solutions, push manufacturers towards innovative dunnage designs and materials. The escalating complexity of global supply chains also necessitates advanced protective packaging to withstand diverse transit conditions.

However, the market faces notable restraints that could temper its growth trajectory. The volatile prices of raw materials, such as plastic resins, paper pulp, and timber, directly impact manufacturing costs and, subsequently, the end-user prices of dunnage. Environmental concerns related to single-use plastics and non-recyclable materials present a significant challenge, driving demand for more sustainable alternatives but often at a higher initial cost. The lack of standardized dunnage solutions across different industries and product types can lead to inefficiencies and increased customization costs, particularly for smaller businesses. Additionally, the challenge of disposing or recycling specialized dunnage materials post-use can be complex and expensive, creating logistical hurdles.

Opportunities within the dunnage packaging market are substantial and primarily center around innovation and sustainability. The development of advanced, lightweight, and durable materials, including bio-based plastics and recycled content, offers a pathway to more environmentally friendly solutions. The integration of smart packaging technologies, such as RFID and IoT sensors, into dunnage can enhance traceability, provide real-time condition monitoring, and improve overall supply chain visibility. Moreover, the growing trend towards reusable and returnable dunnage systems presents a significant opportunity for cost savings and waste reduction in closed-loop logistics. Customization services, leveraging technologies like 3D printing for rapid prototyping and tailored designs, also represent a lucrative segment for specialized manufacturers, meeting the precise protection needs of high-value and unique products.

Segmentation Analysis

The Dunnage Packaging Market is extensively segmented across various parameters, allowing for a detailed understanding of its complex dynamics and diverse applications. These segmentations provide crucial insights into material preferences, product types, the specific end-use industries driving demand, and the fundamental functions that dunnage serves. Analyzing these segments helps identify key growth areas, technological advancements, and shifts in consumer and industrial requirements, enabling market players to develop targeted strategies and innovative solutions. The market caters to a broad array of protection needs, from heavy industrial components to fragile consumer electronics, reflecting its critical role in safeguarding product integrity throughout the supply chain.

- By Material:

- Foam: Polyethylene, Polypropylene, Polyurethane, Expanded Polystyrene (EPS)

- Corrugated: Single Wall, Double Wall, Triple Wall

- Wood: Plywood, Solid Wood, Oriented Strand Board (OSB)

- Plastic: High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Polyvinyl Chloride (PVC)

- Fabric: Non-woven fabrics, Woven fabrics, Felt

- By Product Type:

- Custom Dunnage: Tailored for specific products and applications

- Standard Dunnage: General purpose, off-the-shelf solutions

- By End-use Industry:

- Automotive: Parts and components, finished vehicles

- Electronics: Consumer electronics, industrial electronics, semiconductors

- Aerospace: Aircraft parts, sensitive instruments

- Logistics and E-commerce: General merchandise, fragile goods

- Consumer Goods: Food and beverages, personal care, home goods

- Healthcare and Pharmaceuticals: Medical devices, pharmaceutical products

- Manufacturing: Industrial machinery, general manufacturing components

- By Function:

- Cushioning: Shock absorption, vibration dampening

- Bracing: Securing items in place, preventing movement

- Blocking: Filling voids, preventing shifting

- Void Fill: Light protection, space optimization

Value Chain Analysis For Dunnage Packaging Market

The value chain for the dunnage packaging market begins with the upstream suppliers of raw materials, forming the foundational layer of the entire industry. These primary suppliers provide the essential inputs such as plastic resins (polyethylene, polypropylene), paper pulp for corrugated board manufacturing, various types of timber for wooden dunnage, and chemicals required for foam production (polyurethane, polyethylene foam). The quality and availability of these raw materials directly influence the cost, durability, and environmental footprint of the final dunnage products. Strategic relationships with these suppliers are crucial for ensuring a stable supply chain, managing input costs, and meeting specific material specifications for different dunnage applications, including those focused on sustainability.

Following raw material procurement, the value chain progresses to dunnage manufacturing and conversion, where these materials are transformed into finished dunnage products. This stage involves complex processes such as molding, cutting, thermoforming, and assembly to create custom-fit inserts, dividers, trays, or other protective structures. Manufacturers often specialize in specific materials or end-use applications, developing proprietary designs and utilizing advanced machinery. Downstream in the value chain, the completed dunnage products are distributed through various channels to reach the end-users. These include packaging distributors, third-party logistics (3PL) providers, and direct sales to large original equipment manufacturers (OEMs) or industrial clients who integrate dunnage into their own packaging and shipping operations. The efficiency of this distribution network is paramount for timely delivery and cost-effectiveness.

The distribution channel within the dunnage packaging market operates through both direct and indirect models, tailored to the scale and specific requirements of the customers. Direct sales are common for large volume orders, customized solutions, or for major industrial clients like automotive manufacturers and aerospace companies who require close collaboration with dunnage suppliers for bespoke designs and ongoing support. This direct relationship allows for greater control over specifications, quality, and often involves long-term contracts. Indirect channels, on the other hand, typically involve distributors, wholesalers, and e-commerce platforms that serve a broader base of smaller to medium-sized businesses, offering standard or semi-custom dunnage solutions. These intermediaries provide wider market reach, inventory management, and regional accessibility, ensuring that a diverse range of customers can access appropriate dunnage products efficiently, thereby completing the cycle from raw material to product protection.

Dunnage Packaging Market Potential Customers

The potential customers for the Dunnage Packaging Market are highly diverse, spanning numerous industries that rely on the safe and secure transit of their products, ranging from delicate electronic components to heavy industrial machinery. At the forefront are original equipment manufacturers (OEMs) and major industrial enterprises, particularly those in the automotive, aerospace, and general manufacturing sectors. These companies require highly customized and durable dunnage to protect complex, high-value parts during internal transfers between assembly stages, as well as for external shipment to suppliers and distributors. Their demand often involves reusable dunnage systems that integrate seamlessly into their lean manufacturing and logistics processes, emphasizing material compatibility, ergonomic handling, and long-term cost efficiency.

Another significant segment of potential customers includes businesses within the electronics industry, encompassing manufacturers of consumer electronics, industrial control systems, and semiconductor components. The extreme fragility and high monetary value of these products necessitate sophisticated dunnage solutions, typically involving anti-static foams, precision-molded plastic trays, or specialized corrugated inserts designed to prevent electrostatic discharge (ESD) and physical damage. E-commerce retailers and third-party logistics (3PL) providers also represent a rapidly expanding customer base. With the exponential growth of online shopping, there is an immense need for flexible, efficient, and protective dunnage to handle a wide variety of parcel sizes and product types, often requiring solutions that are lightweight, cost-effective, and easy to pack and unpack by consumers.

Furthermore, the healthcare and pharmaceutical industries are crucial end-users, where the safe and sterile transport of medical devices, pharmaceutical products, and laboratory equipment is paramount, often under stringent regulatory requirements. This sector demands dunnage that is often cleanroom-compatible, sterilizable, and precisely engineered to protect sensitive instruments and vials. Beyond these, the food and beverage industry utilizes dunnage for securing bottled goods, delicate produce, and packaged foods, while the consumer goods sector broadly requires protective inserts for everything from personal care items to home appliances. The diversity of these end-user needs underscores the market's extensive reach and the imperative for dunnage providers to offer a comprehensive portfolio of materials, designs, and services to address unique industry-specific challenges and ensure product integrity across the entire value chain.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $4.2 Billion |

| Market Forecast in 2032 | $6.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sealed Air Corporation, Sonoco Products Company, Smurfit Kappa Group, DS Smith Plc, WestRock Company, Huhtamaki Oyj, Nefab Group, Pregis LLC, Reusable Transport Packaging, Menasha Corporation, UFP Technologies Inc, Macatawa Plastics, MJS Packaging, Dunnage Engineering, Rengo Co Ltd, Greif Inc, Berry Global Inc, Pactiv Evergreen Inc, Amcor PLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dunnage Packaging Market Key Technology Landscape

The dunnage packaging market is continuously evolving through the adoption of advanced technologies aimed at enhancing efficiency, customization, and sustainability. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems are fundamental, allowing manufacturers to precisely design and produce intricate dunnage inserts and structures tailored to exact product specifications. These technologies enable rapid prototyping and iterative design improvements, significantly reducing development cycles and ensuring optimal fit and protection for complex components. The integration of advanced simulation software further enhances this capability, enabling virtual testing of dunnage performance under various shipping conditions, minimizing the need for costly physical prototypes and accelerating time-to-market for new packaging solutions.

Material science innovations play a pivotal role in shaping the dunnage technology landscape, with ongoing research focused on developing lighter, stronger, and more sustainable packaging materials. This includes the creation of high-performance plastics with enhanced impact resistance, bio-based polymers derived from renewable resources, and advanced corrugated board designs that offer superior strength-to-weight ratios. The development of multi-material dunnage systems, combining the best properties of foam, plastic, and corrugated materials, allows for hybrid solutions that offer superior protection while addressing specific challenges like vibration dampening, chemical resistance, or anti-static requirements. Furthermore, smart material technologies, such as those capable of sensing environmental changes or providing visual alerts for damage, are beginning to emerge, adding another layer of sophistication to protective packaging.

Automation and smart packaging technologies are increasingly integrated into the dunnage market to streamline processes and provide enhanced functionality. Automated manufacturing processes, including robotic handling and assembly of dunnage components, improve production speed and consistency while reducing labor costs. The adoption of RFID (Radio Frequency Identification) and IoT (Internet of Things) sensors within dunnage solutions enables real-time tracking of packages, environmental monitoring (temperature, humidity, shock), and inventory management throughout the supply chain. This technological integration provides invaluable data for optimizing logistics, preventing damage, and improving overall operational transparency. Furthermore, advanced recycling technologies and closed-loop systems are being developed to facilitate the efficient recovery and reuse of dunnage materials, aligning with circular economy principles and addressing environmental concerns, thereby contributing to a more sustainable and technologically advanced dunnage packaging ecosystem.

Regional Highlights

- North America: This region showcases a mature market characterized by high automation in manufacturing and logistics, significant e-commerce growth, and a strong emphasis on innovative, high-performance dunnage solutions. The automotive, aerospace, and electronics industries are major drivers, demanding customized and often reusable dunnage to optimize supply chain efficiency and reduce environmental impact.

- Europe: The European market is highly influenced by stringent environmental regulations and a strong corporate focus on sustainability, leading to a high demand for eco-friendly and reusable dunnage materials. Key industries such as automotive, pharmaceuticals, and luxury goods drive the need for precision-engineered protective packaging, with a growing adoption of smart dunnage technologies for improved traceability and condition monitoring.

- Asia Pacific (APAC): As the world's manufacturing hub, APAC represents the largest and fastest-growing market for dunnage packaging. Rapid industrialization, expanding domestic consumption, and the explosive growth of e-commerce in countries like China and India fuel immense demand. While cost-effectiveness remains a key consideration, there is a rising trend towards higher quality and more sustainable dunnage solutions, especially in developed economies within the region.

- Latin America: This region is witnessing significant infrastructure development and industrial expansion, particularly in Brazil and Mexico, driving increased demand for dunnage packaging across automotive, consumer goods, and agricultural sectors. Growth is propelled by improving logistics networks and foreign investments in manufacturing, creating a steady need for protective packaging solutions that prioritize both cost efficiency and product safety for internal and export markets.

- Middle East and Africa (MEA): The MEA region is experiencing steady growth driven by diversification efforts away from oil, leading to increased manufacturing activities and infrastructure projects. Investments in logistics and supply chain capabilities are spurring demand for dunnage, particularly in the construction, automotive assembly, and emerging e-commerce sectors. The market is developing with a focus on durable and robust packaging to withstand challenging environmental conditions and extended transit times.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dunnage Packaging Market.- Sealed Air Corporation

- Sonoco Products Company

- Smurfit Kappa Group

- DS Smith Plc

- WestRock Company

- Huhtamaki Oyj

- Nefab Group

- Pregis LLC

- Reusable Transport Packaging

- Menasha Corporation

- UFP Technologies Inc

- Macatawa Plastics

- MJS Packaging

- Dunnage Engineering

- Rengo Co Ltd

- Greif Inc

- Berry Global Inc

- Pactiv Evergreen Inc

- Amcor PLC

Frequently Asked Questions

What is dunnage packaging and its primary purpose?

Dunnage packaging refers to materials used to fill empty spaces, cushion, or brace products within a shipping container or package. Its primary purpose is to prevent movement, absorb shocks, and protect items from damage during transportation and storage, ensuring they arrive at their destination in pristine condition.

Why is dunnage packaging considered essential in global logistics and supply chains?

Dunnage packaging is essential because it minimizes product damage, reduces shipping costs by preventing returns and enabling denser packing, and improves operational efficiency in handling. It is critical for safeguarding goods in complex global supply chains exposed to various environmental and transit stressors.

What are the most common materials used for dunnage packaging?

Common materials include foam (polyethylene, polyurethane) for delicate items, corrugated cardboard for versatility and cost-effectiveness, plastics (HDPE, LDPE) for durability and reusability, wood (plywood, solid wood) for heavy-duty applications, and fabric for non-abrasive protection of finished surfaces.

How does dunnage packaging contribute to environmental sustainability efforts?

Dunnage contributes to sustainability through the increasing use of recycled and bio-based materials, as well as the adoption of reusable and returnable dunnage systems. These efforts reduce waste, conserve resources, and lower the overall carbon footprint of packaging operations, aligning w

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager