Eddy-Current Testing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429906 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Eddy-Current Testing Market Size

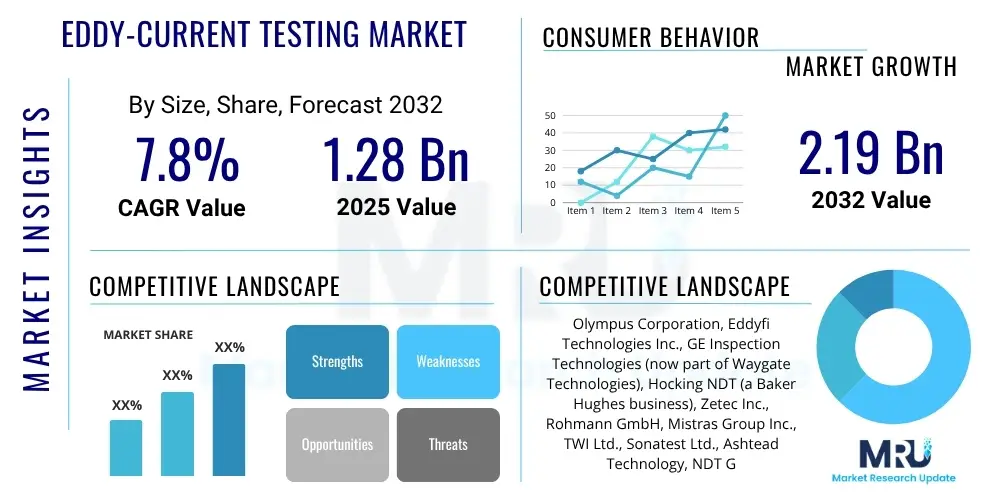

The Eddy-Current Testing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 1.28 Billion in 2025 and is projected to reach USD 2.19 Billion by the end of the forecast period in 2032.

Eddy-Current Testing Market introduction

The Eddy-Current Testing (ECT) market encompasses the global industry for non-destructive testing (NDT) solutions that utilize electromagnetic induction to detect surface and sub-surface flaws in conductive materials. ECT is a versatile technique employed across numerous sectors for inspecting metallic components, ensuring structural integrity, and preventing failures. This method involves inducing electric currents, known as eddy currents, into a material using an electromagnetic probe. Changes in these currents, caused by defects like cracks, corrosion, or variations in material properties, are then detected and analyzed to identify potential issues without causing damage to the component.

The primary applications of Eddy-Current Testing span a wide range of industries, including aerospace, automotive, oil and gas, power generation, and manufacturing, where precision and reliability in material inspection are paramount. ECT devices are crucial for identifying minute discontinuities, measuring coating thickness, distinguishing between different alloys, and assessing heat damage. The non-contact nature of ECT and its ability to detect flaws through non-conductive coatings make it a preferred method for critical inspections.

Key benefits of employing Eddy-Current Testing include its high sensitivity to small cracks and pitting, rapid inspection speeds, and the absence of couplants, which simplifies the testing process. The market's growth is predominantly driven by increasing safety regulations, the need for stringent quality control in high-reliability industries, and the continuous advancements in ECT technology, such as the integration of advanced signal processing and multi-frequency capabilities, enhancing its diagnostic accuracy and efficiency.

Eddy-Current Testing Market Executive Summary

The Eddy-Current Testing (ECT) market is poised for significant expansion, propelled by escalating demand for quality assurance across vital industrial sectors. Business trends indicate a strong move towards automation and integration of ECT systems into production lines, enabling faster and more consistent inspections. There is a noticeable shift towards advanced portable ECT devices and software-driven analytics, which enhance user experience, data interpretation, and overall operational efficiency for field and laboratory applications. Strategic partnerships and mergers among key players are also contributing to technological advancements and broader market reach.

Regional trends reveal North America and Europe as established markets due to stringent regulatory frameworks and robust industrial bases in aerospace and power generation. However, the Asia Pacific region is emerging as a high-growth market, driven by rapid industrialization, burgeoning manufacturing sectors, and increasing investment in infrastructure projects. Latin America, the Middle East, and Africa are also showing promising growth, fueled by investments in oil and gas, infrastructure development, and manufacturing capacity expansion.

Segment-wise, advanced techniques such as Eddy-Current Array (ECA) and Pulsed Eddy-Current (PEC) are gaining traction due to their enhanced capabilities in defect detection and broader coverage. The aerospace and defense sector remains a dominant end-user, but the automotive, oil and gas, and power generation industries are exhibiting accelerated adoption rates for ECT solutions. The demand for sophisticated probes, instruments, and specialized software continues to grow, signifying a market that values precision, speed, and comprehensive data analysis in its non-destructive testing requirements.

AI Impact Analysis on Eddy-Current Testing Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) can enhance the accuracy, efficiency, and interpretability of Eddy-Current Testing (ECT). Common questions revolve around AI's role in automating defect recognition, reducing false positives, and managing vast amounts of inspection data. There is also significant interest in AI's potential to enable predictive maintenance by analyzing trends in inspection data over time, and its capacity to lower the skill threshold required for operating complex ECT equipment. Concerns often include data security, the initial investment in AI-integrated systems, and the validation processes for AI algorithms in safety-critical applications.

AI's integration into ECT systems represents a transformative shift, moving beyond traditional signal processing to intelligent data interpretation. Machine learning algorithms can be trained on extensive datasets of eddy current signals, correlating specific signal patterns with known defect types, sizes, and locations. This capability significantly enhances the speed and accuracy of defect detection, allowing for automated real-time analysis during high-volume inspections. AI also contributes to anomaly detection by identifying deviations from baseline signals that might indicate novel or evolving material degradation, offering a proactive approach to maintenance.

Furthermore, AI-powered systems can optimize probe settings, minimize human error in data acquisition, and provide intelligent guidance to operators, thereby streamlining the entire inspection workflow. The ability of AI to learn from continuous data inputs also promises to improve the reliability and robustness of ECT over time, adapting to new material characteristics and environmental conditions. This evolution is expected to expand ECT's applicability, especially in industries demanding high throughput and precision, while simultaneously addressing the challenge of a limited pool of highly skilled NDT technicians.

- Automated Defect Recognition: AI algorithms identify and classify defects with minimal human intervention, increasing inspection speed and consistency.

- Reduced False Positives/Negatives: Machine learning models improve accuracy in distinguishing genuine flaws from noise or irrelevant signals.

- Predictive Maintenance Integration: AI analyzes historical ECT data to forecast potential component failures, enabling proactive maintenance scheduling.

- Enhanced Data Interpretation: AI assists in processing complex multi-frequency and array data, making results more understandable and actionable.

- Operator Skill Augmentation: AI provides real-time guidance and interpretation, lowering the expertise barrier for effective ECT operation.

- Optimized Inspection Parameters: AI can recommend optimal probe frequencies, scan speeds, and gain settings for specific inspection scenarios.

- Data Management and Reporting: AI streamlines the organization, analysis, and generation of comprehensive inspection reports from large datasets.

DRO & Impact Forces Of Eddy-Current Testing Market

The Eddy-Current Testing (ECT) market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, shaping its growth trajectory and adoption across industries. Key drivers include the stringent regulatory landscape mandating non-destructive inspections for safety-critical components, particularly in aerospace, nuclear power, and oil and gas. The increasing focus on predictive maintenance strategies across manufacturing sectors further fuels demand for reliable NDT techniques like ECT, which can detect incipient flaws before they lead to catastrophic failures. Moreover, the inherent benefits of ECT, such as its high sensitivity to surface and near-surface defects, speed of inspection, and ability to test through coatings, position it as a preferred method for quality assurance and control.

However, the market faces several restraints that could impede its expansion. The high initial capital investment required for advanced ECT equipment, including multi-channel systems and specialized probes, can be a barrier for smaller enterprises or those with limited budgets. Another significant restraint is the necessity for highly skilled and certified personnel to operate and interpret complex ECT results, which contributes to operational costs and limits widespread adoption where such expertise is scarce. Furthermore, ECT is primarily limited to electrically conductive materials, restricting its use in non-conductive composites or ceramics, which are increasingly prevalent in modern industrial applications. Environmental factors such as electromagnetic interference can also affect testing accuracy.

Despite these challenges, numerous opportunities are emerging to drive future growth. The integration of artificial intelligence and machine learning into ECT systems promises to enhance automation, improve defect detection accuracy, and simplify data interpretation, thereby addressing the need for skilled operators. Miniaturization and the development of portable, handheld ECT devices are expanding the technology's reach into field applications and remote inspection scenarios. The growing demand from emerging economies, spurred by rapid industrialization and infrastructure development, presents substantial untapped market potential. Innovations in sensor technology, multi-frequency capabilities, and Eddy-Current Array (ECA) systems are also opening new avenues for more comprehensive and efficient inspections, making ECT increasingly versatile and indispensable.

Segmentation Analysis

The Eddy-Current Testing (ECT) market is comprehensively segmented based on various factors including the technique employed, its specific applications, the end-use industries it serves, the components that constitute an ECT system, and the services offered. This segmentation provides a granular view of the market, highlighting the diverse needs and applications of ECT technology across different sectors. Each segment reflects unique technological advancements, user demands, and market penetration, contributing distinctly to the overall market landscape.

- By Technique: Single-Frequency Eddy-Current Testing, Multi-Frequency Eddy-Current Testing, Pulsed Eddy-Current Testing (PEC), Eddy-Current Array (ECA), Remote Field Eddy Current (RFEC).

- By Application: Crack Detection, Thickness Measurement, Material Sorting and Characterization, Corrosion Detection, Weld Inspection, Surface Inspection, Internal Defect Detection.

- By End-Use Industry: Aerospace and Defense, Automotive, Oil and Gas, Power Generation, Manufacturing, Infrastructure, Marine, Medical.

- By Component: Probes and Coils, Eddy-Current Testing Instruments, Software, Accessories.

- By Service: Inspection Services, Calibration Services, Training and Certification, Equipment Rental.

Value Chain Analysis For Eddy-Current Testing Market

The value chain for the Eddy-Current Testing market begins with upstream activities focused on the research, development, and manufacturing of core components and raw materials. This includes the production of specialized conductive materials for probes and coils, sophisticated electronic components for instrumentation, and the development of advanced algorithms for software. Key players in this stage are often technology developers and specialized manufacturers who innovate new sensor designs, signal processing capabilities, and data acquisition hardware, laying the foundation for cutting-edge ECT solutions.

Moving downstream, the value chain involves the assembly and integration of these components into complete ECT systems, followed by their distribution to end-users. Manufacturers of full ECT systems, such as leading NDT equipment providers, integrate probes, instruments, and software to create comprehensive solutions. Distribution channels are critical and typically include direct sales teams for large industrial clients, a network of specialized distributors and resellers who provide local support and expertise, and increasingly, online platforms for accessories and basic equipment. Direct sales are prevalent for complex, high-value systems requiring extensive technical consultation, while indirect channels cater to broader market access and regional penetration.

The final stages of the value chain involve the deployment, operation, and ongoing support of ECT solutions. This includes inspection services provided by third-party NDT service companies, who utilize ECT equipment to conduct examinations for various industries. Post-sales support such as calibration, maintenance, software updates, and training and certification services are crucial for ensuring the accurate and reliable performance of ECT systems throughout their lifecycle. These downstream activities contribute significantly to customer satisfaction and repeat business, solidifying the market's long-term sustainability and growth.

Potential Customers For Eddy-Current Testing Market

The Eddy-Current Testing (ECT) market primarily serves a diverse range of end-users and buyers across industries where material integrity, safety, and operational efficiency are paramount. These customers are typically organizations engaged in manufacturing, maintenance, and quality assurance processes involving conductive materials. The inherent ability of ECT to detect surface and near-surface defects, measure thickness, and sort materials non-destructively makes it indispensable for these sectors. Potential customers are driven by regulatory compliance, a need to prevent costly failures, optimize asset lifecycles, and maintain high product quality standards.

Key end-user segments include the aerospace and defense industry, where ECT is critical for inspecting aircraft components, turbine blades, and structural elements for fatigue cracks and corrosion in highly regulated environments. The automotive sector relies on ECT for quality control of engine parts, chassis components, and welds, ensuring vehicle safety and performance. In the oil and gas industry, ECT is vital for inspecting pipelines, heat exchangers, and storage tanks for corrosion and cracking, mitigating risks in hazardous environments and extending asset life. Power generation, particularly nuclear and conventional power plants, utilizes ECT for examining steam generator tubes, heat exchangers, and other critical components to prevent outages and ensure safe operation.

Furthermore, the manufacturing sector, encompassing metallurgy, heavy machinery, and electronics, uses ECT for material sorting, defect detection in raw materials and finished products, and quality control during production processes. Infrastructure development projects often require ECT for assessing structural integrity of bridges and other metallic structures. Marine and medical industries also represent growing customer bases, with applications ranging from ship hull inspections to the quality control of medical devices. These diverse applications underscore the broad utility and essential nature of ECT for any organization that requires robust non-destructive material evaluation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.28 Billion |

| Market Forecast in 2032 | USD 2.19 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Olympus Corporation, Eddyfi Technologies Inc., GE Inspection Technologies (now part of Waygate Technologies), Hocking NDT (a Baker Hughes business), Zetec Inc., Rohmann GmbH, Mistras Group Inc., TWI Ltd., Sonatest Ltd., Ashtead Technology, NDT Global (part of Eddyfi Technologies), FujiFilm NDT Systems, Teledyne FLIR (now Teledyne Technologies), Cygnus Instruments Ltd., Magnaflux (a Division of ITW), KARL DEUTSCH Prüf- und Messgerätebau GmbH + Co KG, Centurion NDT, ETher NDE, Advanced NDT LLC, MME Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Key Technology Landscape For Eddy-Current Testing Market

The Eddy-Current Testing (ECT) market is characterized by a dynamic and evolving technological landscape, continuously driven by the demand for higher accuracy, efficiency, and broader applicability. Core to this landscape are advancements in probe and sensor technology, including the development of sophisticated Eddy-Current Array (ECA) probes. These probes feature multiple coils arranged in various configurations, allowing for wider coverage, faster scanning speeds, and enhanced defect characterization compared to traditional single-coil probes. The ability of ECA to provide real-time C-scan mapping and 3D visualization of defects significantly improves inspection reliability and data interpretation, making it a cornerstone technology.

Another critical area of technological innovation lies in instrumentation and software. Modern ECT instruments are increasingly compact, powerful, and integrated with advanced digital signal processing (DSP) capabilities. Multi-frequency and pulsed eddy current (PEC) systems are gaining prominence, offering the ability to penetrate deeper into materials and inspect through thick non-conductive coatings, which was previously a challenge. Software plays an equally vital role, with intuitive user interfaces, advanced data analysis tools, and integration with data management platforms becoming standard. These software solutions enable complex calculations, facilitate automated defect detection algorithms, and support comprehensive reporting functionalities, crucial for regulatory compliance and audit trails.

Emerging technologies like Artificial Intelligence (AI) and Machine Learning (ML) are also profoundly influencing the ECT market. AI algorithms are being developed to automate the interpretation of complex eddy current signals, reduce false calls, and predict material degradation trends, thereby enhancing inspection accuracy and reducing the need for extensive human expertise. Furthermore, the development of robotic and drone-mounted ECT systems is enabling inspections in hazardous or hard-to-reach areas, improving safety and operational efficiency. Wireless connectivity, cloud-based data storage, and remote monitoring capabilities are further streamlining data flow and collaborative analysis, propelling the ECT market into a new era of smart, connected inspection solutions.

Regional Highlights

The global Eddy-Current Testing (ECT) market exhibits significant regional variations in adoption, growth drivers, and competitive landscapes. Established industrial economies in North America and Europe have traditionally dominated the market, fueled by stringent regulatory frameworks, high levels of industrial automation, and substantial investment in advanced manufacturing and infrastructure. However, the Asia Pacific region is rapidly emerging as a critical growth engine, driven by its burgeoning industrial base and increasing foreign direct investment in manufacturing and energy sectors. Latin America, the Middle East, and Africa are also showing promising growth, albeit from a smaller base, as industrialization efforts intensify and awareness of NDT benefits increases.

- North America: Highly mature market with significant adoption in aerospace, automotive, and power generation; driven by strict safety regulations and technological innovation.

- Europe: Strong presence in manufacturing, automotive, and energy sectors; emphasis on quality control and compliance with EU directives; Germany and UK are key contributors.

- Asia Pacific (APAC): Fastest-growing region due to rapid industrialization, infrastructure development, and increasing investment in manufacturing and oil & gas in countries like China, India, Japan, and South Korea.

- Latin America: Growing market fueled by investments in oil and gas, mining, and infrastructure, particularly in Brazil and Mexico.

- Middle East and Africa (MEA): Emerging market with rising demand from oil and gas, power generation, and construction sectors, especially in Saudi Arabia and UAE.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Eddy-Current Testing Market.- Olympus Corporation

- Eddyfi Technologies Inc.

- GE Inspection Technologies (now part of Waygate Technologies)

- Hocking NDT (a Baker Hughes business)

- Zetec Inc.

- Rohmann GmbH

- Mistras Group Inc.

- TWI Ltd.

- Sonatest Ltd.

- Ashtead Technology

- NDT Global (part of Eddyfi Technologies)

- FujiFilm NDT Systems

- Teledyne FLIR (now Teledyne Technologies)

- Cygnus Instruments Ltd.

- Magnaflux (a Division of ITW)

- KARL DEUTSCH Prüf- und Messgerätebau GmbH + Co KG

- Centurion NDT

- ETher NDE

- Advanced NDT LLC

- MME Group

Frequently Asked Questions

What is Eddy-Current Testing (ECT) and how does it work?

Eddy-Current Testing (ECT) is a non-destructive testing method that uses electromagnetic induction to detect surface and near-surface flaws in conductive materials. An alternating current is passed through a coil to create a magnetic field, which induces circular eddy currents in the test material. Any defect or change in material properties disrupts these currents, causing a detectable change in the coil's impedance, which is then analyzed to identify flaws.

What are the primary advantages of using Eddy-Current Testing?

The primary advantages of ECT include its high sensitivity to small surface and near-surface cracks, corrosion, and material variations. It is a non-contact method, meaning no couplant is required, and it can inspect through non-conductive coatings. ECT offers rapid inspection speeds, making it efficient for high-volume quality control, and provides immediate results without needing post-processing steps.

Which industries are the main adopters of Eddy-Current Testing technology?

Major industries adopting ECT include aerospace and defense for inspecting aircraft components, automotive for vehicle part quality control, oil and gas for pipeline and heat exchanger integrity, and power generation for critical plant component examination. Manufacturing sectors also extensively use ECT for material sorting and defect detection during production.

How is Artificial Intelligence (AI) influencing the Eddy-Current Testing market?

AI is significantly influencing the ECT market by enhancing automation, accuracy, and data interpretation. AI algorithms can automate defect recognition, reduce false positives, and analyze large datasets to predict material degradation, thereby improving inspection efficiency, lowering operational costs, and reducing the reliance on highly skilled human operators.

What are the main limitations of Eddy-Current Testing?

The main limitations of ECT include its restriction to electrically conductive materials, meaning it cannot inspect non-conductive composites. It is also less effective at detecting deep sub-surface defects compared to other NDT methods like ultrasonic testing. High initial equipment costs and the requirement for specialized operator training are additional considerations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager