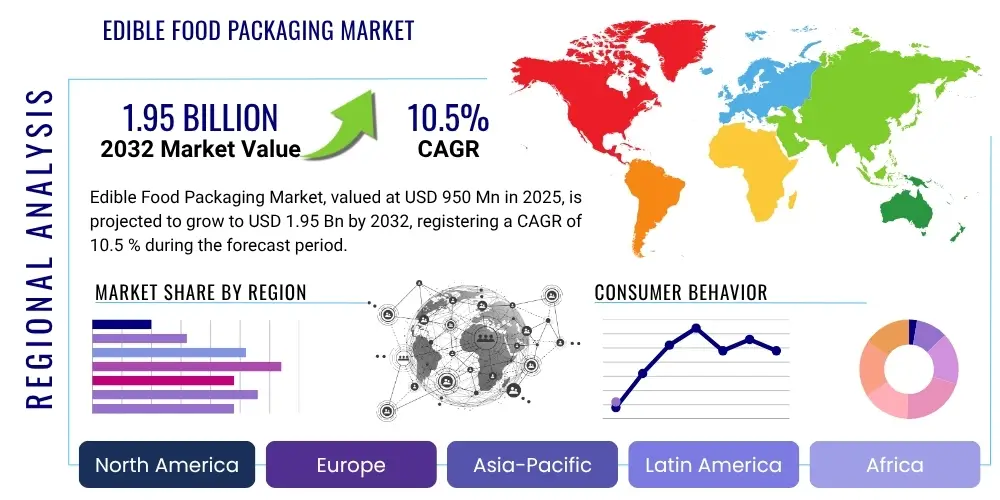

Edible Food Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427921 | Date : Oct, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Edible Food Packaging Market Size

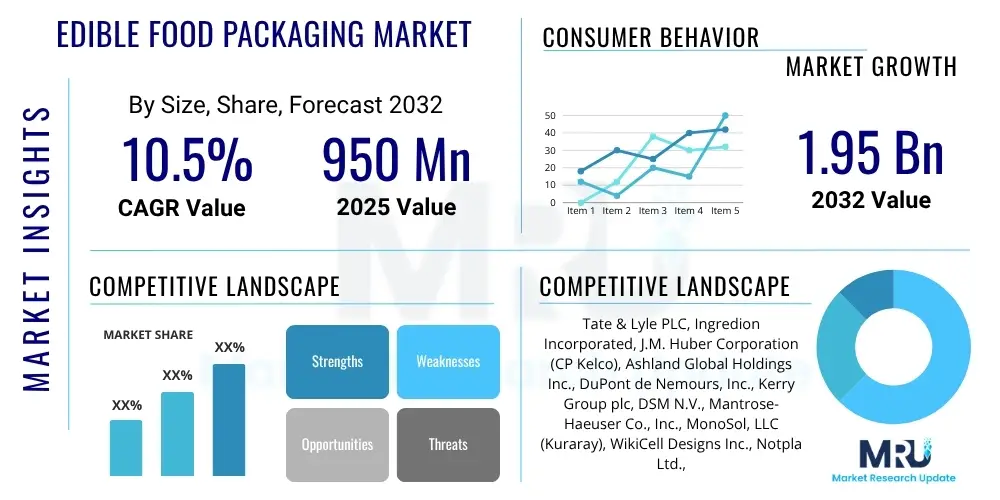

The Edible Food Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2025 and 2032. The market is estimated at USD 950 million in 2025 and is projected to reach USD 1.95 billion by the end of the forecast period in 2032.

Edible Food Packaging Market introduction

The Edible Food Packaging Market encompasses innovative solutions designed to reduce environmental impact by offering food packaging that can be consumed alongside the product, or that naturally degrades after use. These packaging materials, often derived from natural biopolymers such as proteins, polysaccharides, and lipids, serve to protect food from spoilage, extend shelf life, and enhance food safety. Major applications span a wide array of food categories including fresh fruits and vegetables, confectionery, bakery products, and dairy items, as well as single-serve beverages and condiments. The primary benefits include a significant reduction in plastic waste, improved sustainability credentials for food manufacturers, and in some cases, enhanced nutritional value or flavor retention for the packaged food.

The market is experiencing robust growth driven by escalating consumer awareness regarding environmental degradation caused by conventional plastic packaging and the increasing demand for sustainable alternatives. Regulatory pressures and bans on single-use plastics in various regions are further catalyzing the adoption of edible packaging solutions. Continuous advancements in material science and food technology are making edible films and coatings more functional, durable, and commercially viable, addressing historical challenges related to moisture barrier properties, mechanical strength, and shelf life limitations. These factors collectively propel the edible food packaging sector towards mainstream adoption and expansion.

Edible Food Packaging Market Executive Summary

The Edible Food Packaging Market is poised for substantial growth, driven by an urgent global demand for sustainable solutions and a shift in consumer preferences towards eco-friendly products. Business trends indicate a surge in research and development activities focused on novel biopolymer formulations, aimed at improving barrier properties, mechanical strength, and scalability of edible films and coatings. Partnerships between food manufacturers, material science companies, and academic institutions are becoming increasingly common, fostering innovation and accelerating market entry for new products. Furthermore, the market is witnessing strategic investments from venture capitalists and established corporations keen on capitalizing on the burgeoning bio-based economy and the reduction of plastic waste.

Regional trends reveal North America and Europe as early adopters due to stringent environmental regulations and high consumer awareness, leading to significant market penetration. The Asia Pacific region is expected to demonstrate the highest growth rate, fueled by rapid urbanization, increasing disposable incomes, and growing concerns over environmental pollution, particularly in emerging economies. Segment trends highlight polysaccharides and proteins as dominant material types, with fresh fruits and vegetables, as well as confectionery, being key application areas. There is also a notable rise in demand for edible packaging in portion-controlled and on-the-go food products, reflecting changing lifestyles and consumption patterns.

AI Impact Analysis on Edible Food Packaging Market

The integration of Artificial Intelligence (AI) into the edible food packaging sector holds transformative potential, addressing critical challenges and unlocking new avenues for innovation. Users frequently inquire about how AI can enhance the performance and applicability of edible packaging, especially concerning its ability to manage complex material properties, optimize production processes, and ensure product safety. Key themes revolve around AI's role in predictive analytics for ingredient sourcing and quality control, enabling precise formulation adjustments to achieve desired barrier properties and mechanical stability. There is also significant interest in AI-driven solutions for real-time monitoring of packaged food conditions, extending shelf life, and minimizing waste throughout the supply chain. Expectations center on AI making edible packaging more efficient, cost-effective, and adaptable to diverse food products.

- AI-powered material design: Optimizing biopolymer formulations for enhanced barrier properties, mechanical strength, and solubility through predictive modeling.

- Predictive quality control: AI algorithms analyze raw material characteristics and processing parameters to ensure consistent quality and performance of edible films.

- Shelf-life extension: AI-driven sensors and data analytics monitor food freshness within edible packaging, predicting spoilage and optimizing storage conditions.

- Supply chain optimization: AI streamlines logistics, reduces waste, and minimizes energy consumption in the production and distribution of edible packaged goods.

- Personalized packaging: AI can facilitate the customization of edible films with specific nutritional additives or flavors, tailored to consumer preferences.

- Process automation: AI-controlled systems enhance efficiency and precision in deposition, drying, and sealing of edible coatings and films.

- Waste reduction analytics: AI identifies patterns of waste generation in the packaging process, enabling targeted improvements and sustainability gains.

DRO & Impact Forces Of Edible Food Packaging Market

The Edible Food Packaging Market is influenced by a dynamic interplay of driving forces, inherent restraints, and significant opportunities, alongside broader impact forces shaping its trajectory. Drivers predominantly include the urgent global imperative to reduce plastic pollution, fueled by increasing consumer environmental consciousness and proactive governmental regulations banning single-use plastics. Technological advancements in biomaterials science are also playing a crucial role, enabling the development of more functional and robust edible films and coatings with improved barrier properties and extended shelf life capabilities. The rising demand for convenience foods and sustainable food systems further propels market growth, positioning edible packaging as a viable alternative to conventional materials.

However, the market faces several notable restraints. High production costs associated with novel materials and specialized manufacturing processes present a significant barrier to widespread adoption, especially when compared to the cost-effectiveness of traditional plastics. Technical challenges related to maintaining the structural integrity, moisture resistance, and microbial safety of edible packaging for diverse food products remain complex. Additionally, scalability issues, consumer skepticism regarding the safety and appeal of edible packaging, and a fragmented regulatory landscape across different regions further impede market expansion. Addressing these technical and economic hurdles is crucial for the market to achieve its full potential.

Despite these challenges, substantial opportunities exist within the Edible Food Packaging Market. Innovation in multi-functional edible films, such as those embedded with antimicrobial agents, antioxidants, or nutritional supplements, offers avenues for differentiation and value addition. Expanding applications into new food categories, including dairy, meat, and processed foods, can unlock significant market segments. Collaborations across the value chain, from raw material suppliers to food manufacturers and retailers, are vital for developing integrated solutions and streamlining market entry. Furthermore, the integration of smart packaging technologies with edible materials, such as edible sensors for freshness monitoring, represents a futuristic growth frontier. The impact forces, including the bargaining power of buyers and suppliers, the threat of new entrants and substitutes, and competitive intensity, continuously shape market dynamics, pushing for greater innovation and efficiency.

Segmentation Analysis

The Edible Food Packaging Market is meticulously segmented based on various factors, providing a granular understanding of its diverse components and growth avenues. These segmentations are critical for identifying specific market niches, understanding consumer preferences, and tailoring product development strategies. The primary segmentation criteria include the type of material used, the specific application areas where these packaging solutions are employed, and the end-use industries that benefit from these innovative products. Each segment presents unique challenges and opportunities, reflecting the varied requirements of different food products and consumer demographics. This detailed breakdown enables stakeholders to accurately assess market potential and formulate targeted investment strategies.

- By Material Type:

- Polysaccharides

- Starch

- Cellulose

- Chitosan

- Alginate

- Pectin

- Carrageenan

- Gums (e.g., Arabic, Xanthan)

- Proteins

- Collagen

- Gelatin

- Whey Protein

- Casein

- Soy Protein

- Zein

- Lipids

- Waxes (e.g., Candelilla, Beeswax)

- Fatty Acids

- Acylglycerols

- Composites/Blends

- Polysaccharides

- By Application:

- Fresh Fruits & Vegetables

- Bakery & Confectionery Products

- Dairy Products

- Meat, Poultry & Seafood

- Beverages

- Nutritional Supplements

- Frozen Food

- Ready-to-Eat Meals

- By End-Use Industry:

- Food & Beverage Industry

- Pharmaceuticals Industry

- Cosmetics Industry

- Retail & Food Service

Value Chain Analysis For Edible Food Packaging Market

The value chain for the Edible Food Packaging Market is a multi-layered process, commencing with the sourcing of raw materials and extending through various stages of processing, manufacturing, distribution, and ultimately, consumption. The upstream segment of the value chain involves the procurement of natural biopolymers and other additives. This includes agricultural suppliers providing starch, cellulose, and protein sources (like whey, soy, or gelatin), as well as chemical companies supplying food-grade lipids and processing aids. Research and development institutions also play a crucial upstream role in discovering new materials and optimizing existing formulations, often collaborating with raw material providers to ensure quality and sustainability standards.

Moving downstream, the value chain encompasses specialized manufacturers who process these raw materials into edible films, coatings, or capsules using advanced technologies such as extrusion, electrospinning, and film casting. These intermediate products are then supplied to food and beverage manufacturers, who integrate the edible packaging into their production lines for various applications, ranging from fruit coatings to single-serve sachets. The distribution channel for edible food packaging can be both direct and indirect. Direct channels involve manufacturers selling directly to large food corporations or specialized food service providers. Indirect channels typically involve distributors and wholesalers who supply edible packaging components or finished products to a broader range of food businesses, including small and medium-sized enterprises (SMEs) and retail chains. This multifaceted approach ensures market reach and accessibility, although logistics and supply chain complexities remain a key consideration due to the unique nature of edible materials.

Post-consumption, the value chain for edible packaging ideally culminates in full consumption or natural biodegradation, eliminating the need for traditional waste management. This lifecycle offers a significant environmental advantage, fundamentally differentiating it from conventional packaging materials. The efficiency of this value chain, from sustainable sourcing to seamless integration into food products and ultimately, environmentally benign disposal, is critical for the overall success and widespread adoption of edible food packaging solutions. Continuous innovation across each stage, from optimizing raw material properties to enhancing manufacturing efficiencies and streamlining distribution, is essential for advancing market growth and achieving broader commercial viability.

Edible Food Packaging Market Potential Customers

The primary potential customers for the Edible Food Packaging Market are diverse and span across various sectors within the food and beverage industry, as well as adjacent markets such as pharmaceuticals and cosmetics. At the forefront are food manufacturing companies seeking innovative ways to enhance product shelf life, improve food safety, and most significantly, meet escalating consumer demand for sustainable and environmentally friendly packaging solutions. This includes large-scale producers of fresh produce, baked goods, confectionery, dairy products, meat, poultry, and seafood, all of whom can benefit from edible films and coatings to protect their products naturally and reduce plastic waste. Quick-service restaurants (QSRs) and catering services represent another significant customer segment, particularly for single-serve condiment packets, beverage capsules, and portion-controlled edible wraps, aligning with convenience and sustainability goals.

Beyond traditional food manufacturing, the pharmaceutical industry shows growing interest in edible packaging for drug delivery systems, particularly for encapsulating vitamins, supplements, and certain medications, offering precise dosing and improved patient compliance. The cosmetics industry also presents potential applications for edible films in single-use beauty products or samples, aligning with their focus on natural ingredients and eco-conscious branding. Furthermore, supermarkets and retail chains are increasingly seeking out products with sustainable packaging to cater to their environmentally aware customer base, driving demand for brands that adopt edible packaging solutions. These end-users are driven by a combination of regulatory compliance, corporate social responsibility initiatives, cost-efficiency gains from reduced waste, and the desire to gain a competitive edge by appealing to green consumer preferences, making them crucial stakeholders in the expansion of the edible food packaging market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 950 Million |

| Market Forecast in 2032 | USD 1.95 Billion |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tate & Lyle PLC, Ingredion Incorporated, J.M. Huber Corporation (CP Kelco), Ashland Global Holdings Inc., DuPont de Nemours, Inc., Kerry Group plc, DSM N.V., Mantrose-Haeuser Co., Inc., MonoSol, LLC (Kuraray), WikiCell Designs Inc., Notpla Ltd., Apeel Sciences, Inc., Do Eat, Tipa Corp., Biopac India Corporation Ltd., Watson Inc., Safetrack LLC, Protabit Biotech Inc., Nagase & Co. Ltd., Mitsubishi Chemical Holdings Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Edible Food Packaging Market Key Technology Landscape

The Edible Food Packaging Market is underpinned by a diverse and rapidly evolving technology landscape, crucial for converting natural biopolymers into functional and safe packaging materials. At the core of these technologies are various processing methods designed to create thin films, coatings, or capsules with desirable mechanical and barrier properties. Film-forming techniques such as casting, extrusion, and electrospinning are widely employed. Casting involves dissolving film-forming agents in a solvent, spreading the solution, and then drying it to form a thin film. Extrusion, on the other hand, is a continuous process where molten biopolymer blends are forced through a die to create films or tubes, offering scalability for industrial production. Electrospinning is a more advanced method capable of producing ultra-fine fibers and nanofibers, which can result in highly porous and effective barrier layers for specific applications.

Beyond basic film formation, technologies for applying coatings are equally vital. Spray coating, dipping, and roll-to-roll coating systems are utilized to apply edible solutions directly onto food surfaces, particularly for fresh produce or baked goods, forming an invisible protective layer. These methods require precise control over solution viscosity, application temperature, and drying conditions to ensure uniform coverage and optimal adherence without affecting the food's sensory attributes. Furthermore, advancements in 3D printing and additive manufacturing are beginning to explore personalized edible packaging designs and structures, enabling complex geometries and multi-layered protection tailored to specific food items.

The technological landscape also extends to the integration of active compounds and intelligent features within edible packaging. This involves microencapsulation techniques to embed antimicrobial agents, antioxidants, or probiotics into the edible matrix, enhancing food preservation and safety. Biosensors and indicators, although still largely in the research phase, are being explored for their potential to be integrated into edible films to monitor freshness or detect contaminants, offering a new dimension of smart packaging. Material science innovations, including the development of composite films using combinations of proteins, polysaccharides, and lipids, are continuously pushing the boundaries of barrier properties and mechanical stability, making edible packaging more versatile and resilient against environmental stressors, thus overcoming many of the historical limitations of these sustainable solutions.

Regional Highlights

- North America: A leading market driven by high consumer awareness regarding environmental issues, stringent regulations on plastic waste, and significant investment in R&D for sustainable packaging solutions. The presence of key market players and a robust food processing industry further stimulates growth.

- Europe: Demonstrates strong adoption rates, particularly in Western European countries, due to proactive government policies like the EU's Single-Use Plastics Directive and a deeply entrenched culture of sustainability. Innovations in biopolymer technology and collaboration between academia and industry are prominent.

- Asia Pacific (APAC): Expected to exhibit the highest growth rate, fueled by rapid economic development, increasing disposable incomes, and a growing middle class. Rising environmental concerns in populous countries like China and India, coupled with expanding food and beverage industries, create vast opportunities for edible packaging adoption.

- Latin America: An emerging market with increasing awareness of eco-friendly packaging. Government initiatives and consumer demand for sustainable products are slowly gaining traction, particularly in countries like Brazil and Mexico, creating a nascent but promising market.

- Middle East and Africa (MEA): Currently a smaller market, but with growing recognition of the need for sustainable solutions due to increasing environmental awareness and tourism. Opportunities exist for niche applications and regions with supportive policies, though infrastructural and cost barriers remain.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Edible Food Packaging Market.- Tate & Lyle PLC

- Ingredion Incorporated

- J.M. Huber Corporation (CP Kelco)

- Ashland Global Holdings Inc.

- DuPont de Nemours, Inc.

- Kerry Group plc

- DSM N.V.

- Mantrose-Haeuser Co., Inc.

- MonoSol, LLC (Kuraray)

- WikiCell Designs Inc.

- Notpla Ltd.

- Apeel Sciences, Inc.

- Do Eat

- Tipa Corp.

- Biopac India Corporation Ltd.

- Watson Inc.

- Safetrack LLC

- Protabit Biotech Inc.

- Nagase & Co. Ltd.

- Mitsubishi Chemical Holdings Corporation

Frequently Asked Questions

What are the primary benefits of edible food packaging?

Edible food packaging offers several key benefits, including a significant reduction in plastic waste, improved environmental sustainability, and in some cases, extended shelf life for food products. It can also enhance the food's nutritional value or flavor, providing a unique consumer experience while addressing eco-conscious demands.

Is edible food packaging safe for consumption?

Yes, edible food packaging is designed to be safe for human consumption. It is typically made from food-grade ingredients such as proteins, polysaccharides, and lipids that are generally recognized as safe (GRAS). Manufacturers adhere to strict food safety regulations and standards during production to ensure purity and safety.

How does edible packaging affect the shelf life of food products?

Edible packaging can enhance or extend the shelf life of food products by providing a protective barrier against oxygen, moisture, and microbial contamination. Some edible films are also incorporated with antimicrobial agents or antioxidants, further safeguarding the food and reducing spoilage, thereby minimizing food waste.

What are the main challenges facing the edible food packaging market?

Key challenges include the relatively high production cost compared to conventional plastics, technical hurdles in achieving sufficient mechanical strength and moisture barrier properties for all food types, scalability issues for mass production, and consumer perception or acceptance of novel packaging formats. Regulatory clarity for novel materials is also an evolving concern.

What types of foods can be packaged with edible materials?

Edible packaging is versatile and can be used for a wide range of foods. Common applications include fresh fruits and vegetables (as coatings), confectionery, bakery items, dairy products, single-serve sauces and condiments, and even certain beverages or nutritional supplements. The suitability depends on the specific barrier requirements and physical properties of the food item.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager