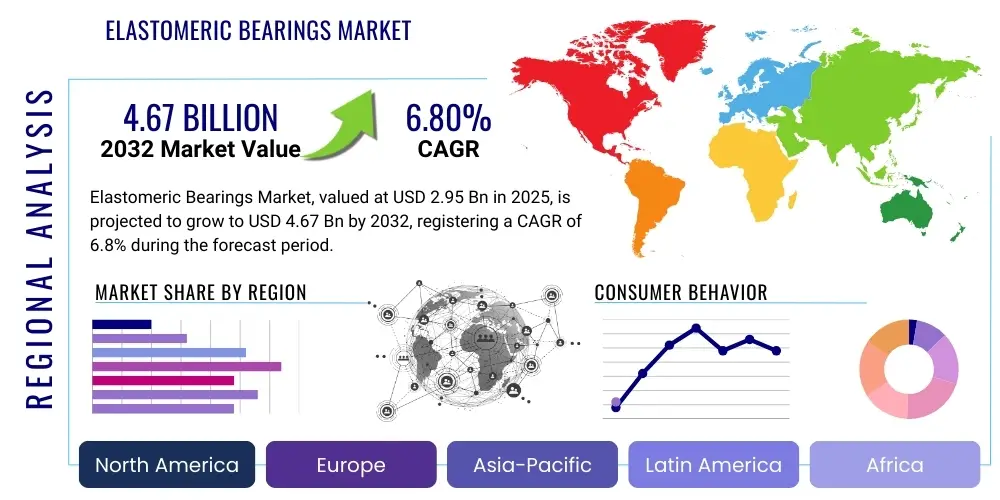

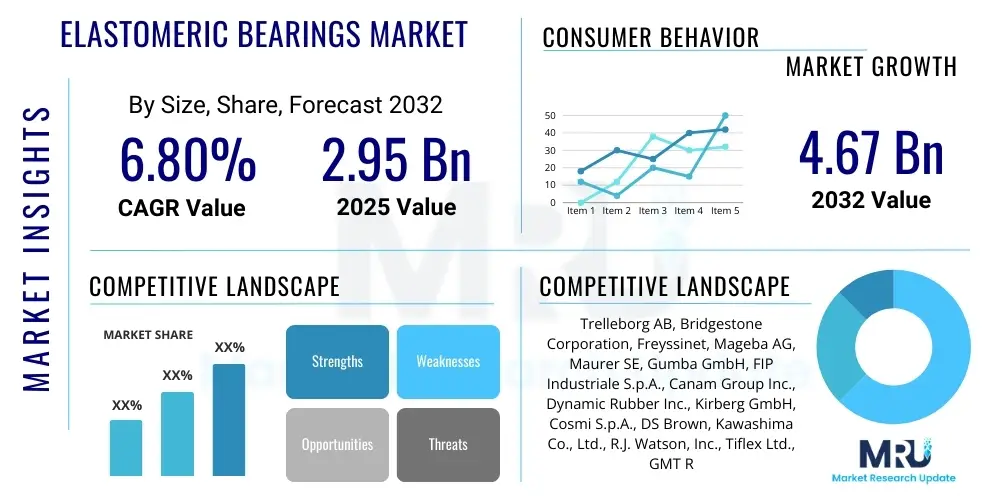

Elastomeric Bearings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427749 | Date : Oct, 2025 | Pages : 254 | Region : Global | Publisher : MRU

Elastomeric Bearings Market Size

The Elastomeric Bearings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 2.95 billion in 2025 and is projected to reach USD 4.67 billion by the end of the forecast period in 2032.

Elastomeric Bearings Market introduction

Elastomeric bearings are critical components in modern infrastructure and structural engineering, primarily designed to accommodate movements, rotations, and provide vibration isolation in various structures. These bearings are typically made from natural rubber or synthetic elastomers, often reinforced with steel laminates, to provide a balance of flexibility and load-carrying capacity. Their primary function is to transfer loads from the superstructure to the substructure while allowing for movements caused by thermal expansion and contraction, seismic events, wind loads, or structural deflections, thereby preventing stress concentrations and ensuring the long-term integrity and safety of the structure.

Major applications of elastomeric bearings span across a wide range of infrastructure projects, including bridges, buildings, industrial structures, and even specific machinery foundations. In bridge construction, they are essential for accommodating expansion and contraction movements of bridge decks and providing seismic isolation. For buildings, particularly in seismic zones, these bearings are crucial for isolating the structure from ground motions, significantly reducing the impact of earthquakes. Industrial applications include vibration isolation for heavy machinery, protecting sensitive equipment, and minimizing operational noise and wear.

The benefits derived from the use of elastomeric bearings are substantial, encompassing enhanced structural longevity, improved safety, and reduced maintenance costs. They offer excellent seismic protection by absorbing and dissipating energy during an earthquake, preventing the transmission of damaging forces to the main structure. Furthermore, their ability to accommodate thermal movements and deflections prevents structural fatigue and cracking, extending the service life of bridges and buildings. Key driving factors for market growth include the global surge in infrastructure development, increasing awareness and adoption of stringent seismic codes, technological advancements in material science leading to enhanced performance, and the growing demand for durable and low-maintenance structural solutions in both developing and developed economies.

Elastomeric Bearings Market Executive Summary

The Elastomeric Bearings Market is experiencing robust growth, driven by escalating global investments in infrastructure, particularly in transportation networks and urban development, coupled with an increased focus on structural resilience against seismic activities and other environmental stressors. Business trends indicate a rising demand for high-performance and customized elastomeric solutions, pushing manufacturers towards innovation in material compounds and design methodologies. There is a notable emphasis on sustainability, with a growing interest in eco-friendly elastomers and manufacturing processes that minimize environmental impact, along with a move towards smart bearings integrated with sensors for real-time monitoring of structural health. The market is characterized by intense competition, prompting key players to differentiate through superior product quality, certifications, and comprehensive customer support, including design consultation and after-sales services.

Regionally, the Asia Pacific market is poised for significant expansion, fueled by rapid urbanization, extensive infrastructure development projects, and a proactive approach towards adopting advanced structural engineering practices in countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, continue to demonstrate steady demand, largely due to ongoing maintenance, repair, and upgrade of aging infrastructure, alongside strict adherence to updated building codes and seismic design standards. Latin America, the Middle East, and Africa are emerging as promising markets, driven by increasing government spending on public works and the initiation of large-scale construction projects, often with international funding and technical expertise, leading to the adoption of modern bearing technologies.

In terms of segmentation, the market observes diverse trends across different product types and applications. Laminated elastomeric bearings, due to their versatile applications and superior load-bearing capacity, continue to dominate a significant share. However, high-damping rubber bearings are gaining traction, especially in seismic isolation applications, owing to their enhanced energy dissipation capabilities. The bridge construction segment remains the largest application area, but the use of elastomeric bearings in buildings for seismic protection and in industrial structures for vibration isolation is growing rapidly. Demand is also influenced by the specific needs of end-users, ranging from large government infrastructure projects to private commercial developments, each requiring tailored bearing solutions that balance performance, cost-effectiveness, and compliance with local regulations.

AI Impact Analysis on Elastomeric Bearings Market

User inquiries regarding AIs influence on the Elastomeric Bearings Market frequently revolve around optimizing design processes, enhancing predictive maintenance, and integrating smart monitoring capabilities for improved structural performance and longevity. Key themes include questions on how AI can streamline the complex design of seismic isolation systems, whether machine learning can predict bearing degradation, and the potential for AI-driven sensors to provide real-time health assessments of these critical structural components. There is also interest in AIs role in material science innovation for developing next-generation elastomers, and its application in risk assessment for infrastructure projects utilizing elastomeric bearings, aiming for more resilient and cost-effective solutions. Users seek to understand how AI can transform the traditional manufacturing, deployment, and operational aspects of elastomeric bearings, moving towards more intelligent and autonomous systems that improve safety and efficiency.

- AI can optimize elastomeric bearing design by analyzing complex load scenarios and material properties, leading to more efficient and resilient solutions.

- Predictive maintenance schedules for bearings can be developed using AI algorithms that analyze sensor data, reducing unexpected failures and maintenance costs.

- AI-driven smart sensors integrated into bearings can provide real-time structural health monitoring, detecting anomalies and potential issues proactively.

- Machine learning algorithms can accelerate the discovery and development of advanced elastomeric materials with improved durability, flexibility, and seismic performance.

- AI can enhance quality control in manufacturing by identifying defects in elastomeric components with greater precision and speed.

- Risk assessment and lifecycle management of infrastructure projects can be improved through AI analysis of bearing performance data under various environmental conditions.

DRO & Impact Forces Of Elastomeric Bearings Market

The Elastomeric Bearings Market is significantly shaped by a confluence of driving factors, pervasive restraints, and emerging opportunities, all interacting with various impact forces that define the industry landscape. Key drivers include the global push for enhanced infrastructure development, particularly in bridge and road networks, alongside increasing urbanization trends in developing economies that necessitate robust and resilient building solutions. The escalating frequency and intensity of seismic events worldwide have also amplified the demand for advanced seismic isolation technologies, where elastomeric bearings play a crucial role. Additionally, a growing emphasis on long-term structural integrity and reduced maintenance costs fuels the adoption of these durable components. These drivers collectively create a strong momentum for market expansion, pushing innovation and product adoption across various applications.

Despite the strong growth drivers, the market faces several restraints that could impede its progress. The relatively high initial cost of elastomeric bearings compared to conventional bearing types can be a significant barrier for budget-constrained projects, especially in price-sensitive markets. The complex design and installation requirements, often necessitating specialized engineering expertise, can also limit their widespread adoption. Furthermore, the variability in raw material prices, primarily rubber and steel, introduces cost volatility for manufacturers. Competition from alternative bearing technologies, such as mechanical bearings or sliding bearings, also poses a restraint, as project developers may opt for solutions perceived to offer similar benefits at a lower cost or with simpler installation. Regulatory hurdles and varying construction standards across different regions can add complexity to market entry and product deployment.

Opportunities within the Elastomeric Bearings Market are substantial, especially with the global shift towards smart infrastructure and sustainable construction practices. The integration of IoT sensors and smart monitoring capabilities into elastomeric bearings presents a significant avenue for growth, offering real-time performance data and predictive maintenance insights. The development of advanced, eco-friendly elastomeric materials with enhanced durability and performance characteristics provides another strong opportunity. Furthermore, the retrofitting of existing infrastructure to meet modern seismic and structural resilience standards, particularly in older, high-risk regions, represents a vast untapped market. Emerging economies with burgeoning infrastructure needs, coupled with increasing awareness of seismic protection, offer lucrative expansion prospects. The market also benefits from strategic collaborations between manufacturers, engineering firms, and research institutions to drive innovation and address specific project challenges. The impact forces, such as competitive rivalry, are high due to numerous established players and new entrants, while buyer power is moderate as large infrastructure projects can command better terms. Supplier power is also moderate, influenced by the availability and cost of raw materials. The threat of substitutes, though present, is somewhat mitigated by the unique performance benefits of elastomeric bearings, especially in seismic applications. The threat of new entrants is moderate, as high capital investment, technical expertise, and stringent quality certifications act as barriers.

Segmentation Analysis

The Elastomeric Bearings Market is segmented to provide a granular view of its dynamics, facilitating a deeper understanding of market trends, consumer preferences, and growth opportunities across various dimensions. This comprehensive segmentation allows market players to identify specific niches, tailor product offerings, and devise targeted strategies. The market is primarily broken down by type, which includes natural rubber, neoprene, high-damping rubber, and lead rubber bearings, each offering distinct characteristics suited for different structural requirements. Further segmentation by application, such as bridges, buildings, and industrial structures, highlights the diverse end-uses and the varied demands placed on bearing performance in different environments. Additionally, the market can be segmented by end-user, distinguishing between government agencies, private contractors, and industrial entities, reflecting varying procurement processes and project scales. Geographical segmentation further provides insights into regional growth drivers and market maturity, essential for strategic expansion.

- By Type:

- Natural Rubber Bearings

- Neoprene Bearings

- High Damping Rubber Bearings

- Lead Rubber Bearings

- Pot Bearings

- Spherical Bearings

- Other Elastomeric Bearings

- By Application:

- Bridges

- Buildings (Seismic Isolation)

- Industrial Structures

- Specialty Applications (e.g., machinery isolation)

- By End-User:

- Construction Companies

- Government Agencies (Public Works, Transportation)

- Architectural Firms

- Industrial Manufacturers

- Consulting Engineers

Elastomeric Bearings Market Value Chain Analysis

The value chain for the Elastomeric Bearings Market begins with the upstream activities focused on raw material procurement and processing. This stage involves suppliers of various critical components, including natural rubber latex, synthetic elastomers like neoprene, steel plates for reinforcement, and chemical additives used in vulcanization and bonding processes. The quality and availability of these raw materials directly impact the performance and cost-effectiveness of the final product. Key upstream players include chemical companies, rubber plantations, and steel manufacturers. Research and development efforts at this stage are crucial for innovating new material compounds that offer enhanced durability, seismic resistance, and environmental sustainability, ensuring the bearings meet stringent industry standards and project-specific requirements.

Moving downstream, the value chain encompasses the manufacturing, distribution, and end-use stages. Manufacturers transform raw materials into finished elastomeric bearings through complex processes involving compounding, molding, vulcanization, and lamination with steel plates. These manufacturers often specialize in various bearing types and may also provide design consultation services. Distribution channels play a vital role in connecting manufacturers with end-users. Direct sales typically occur for large, customized infrastructure projects where manufacturers work closely with engineering firms and contractors. Indirect channels involve distributors, suppliers, and construction material dealers who cater to a broader range of projects and provide localized support. The final stage involves the installation and ongoing maintenance of the bearings in bridges, buildings, and other structures by construction companies and specialized contractors, often with continued technical support from the manufacturers.

The distribution of elastomeric bearings can be categorized into direct and indirect channels. Direct distribution involves manufacturers selling directly to large-scale construction projects, government agencies, or major contractors. This approach allows for close collaboration on custom designs, technical specifications, and timely delivery for critical infrastructure. Indirect distribution, on the other hand, utilizes a network of authorized distributors, local suppliers, and resellers who stock various standard bearing types and can quickly supply smaller projects or provide immediate replacements. This channel offers wider market reach, local presence, and often includes value-added services such as inventory management and logistics. The choice of channel often depends on the project size, complexity, geographical location, and the manufacturers market penetration strategy, with a blend of both direct and indirect methods commonly employed to optimize market coverage and customer service.

Elastomeric Bearings Market Potential Customers

The primary potential customers for elastomeric bearings are entities involved in large-scale infrastructure development and construction, where structural integrity, seismic resilience, and long-term performance are paramount. This includes a broad spectrum of end-users ranging from governmental bodies to private sector enterprises. Government agencies, particularly those responsible for public works, transportation departments, and urban development authorities, represent a significant customer base. These entities commission projects such as national highways, railway bridges, port facilities, and public buildings, all of which require robust and reliable bearing solutions. Their procurement processes often involve stringent technical specifications, competitive bidding, and adherence to national and international engineering standards, emphasizing durability and safety in their choices.

Beyond the public sector, the construction industry, comprising large general contractors, specialized civil engineering firms, and architectural design consultants, forms another major customer segment. These companies are responsible for executing diverse projects, including commercial complexes, high-rise residential buildings, industrial facilities, and private infrastructure. They select elastomeric bearings based on project-specific design requirements, budget constraints, and compliance with local building codes. Structural engineers and architects play a crucial role in specifying the type and performance characteristics of bearings, making them influential in the purchasing decision. Additionally, industrial end-users, such as manufacturers of heavy machinery or developers of power plants, also procure elastomeric bearings for vibration isolation and structural support in their facilities, seeking solutions that enhance operational efficiency and protect sensitive equipment from dynamic loads and environmental stresses.

In essence, the end-users and buyers of elastomeric bearings are those entities whose projects demand advanced structural support systems capable of accommodating movements, dissipating energy, and ensuring the longevity and safety of the built environment. This encompasses a broad ecosystem of stakeholders including, but not limited to, civil engineering contractors who directly purchase and install the bearings, bridge builders who integrate them into complex bridge designs, and structural engineers who specify the technical parameters. Furthermore, government agencies responsible for public infrastructure and urban planning are key decision-makers, as they fund and oversee major projects. Private developers of commercial and residential properties, especially in seismically active regions, also represent a growing segment. Industrial facility developers and operators, seeking to mitigate vibration and ensure structural stability for heavy machinery, complete the spectrum of crucial potential customers for this specialized market.

Elastomeric Bearings Market Key Technology Landscape

The technology landscape for the Elastomeric Bearings Market is characterized by continuous innovation aimed at enhancing material performance, improving manufacturing efficiency, and integrating smart functionalities. A foundational aspect is advanced materials science, focusing on developing superior elastomer compounds. This includes research into natural rubber formulations with improved aging resistance and flexibility, and synthetic elastomers like neoprene and high-damping rubbers that offer enhanced energy dissipation capabilities and resilience under extreme conditions. The integration of specialty additives and fillers further refines properties such as ozone resistance, UV stability, and fire retardancy. The goal is to create materials that can withstand diverse environmental stresses, provide consistent performance over long lifespans, and meet increasingly stringent structural demands.

Manufacturing technologies are also critical, with a strong emphasis on precision engineering and quality control. Techniques such as compression molding and injection molding are employed to create precise bearing shapes, while advanced vulcanization processes ensure optimal bonding between elastomer layers and steel laminates, which are crucial for the bearings structural integrity and load-carrying capacity. Automated production lines and robotic systems are increasingly utilized to ensure consistency, reduce human error, and accelerate production cycles. Furthermore, sophisticated testing and validation protocols, including fatigue testing, load deflection tests, and seismic simulation, are integral to ensuring that manufactured bearings comply with international standards and project-specific performance criteria, guaranteeing their reliability and safety in critical applications.

Emerging technologies are set to revolutionize the market, particularly with the advent of smart infrastructure. The integration of Internet of Things (IoT) sensors into elastomeric bearings allows for real-time monitoring of structural health, movement, temperature, and strain. These embedded sensors provide valuable data for predictive maintenance, enabling engineers to assess bearing performance proactively and identify potential issues before they escalate. Advanced design software, leveraging Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), facilitates highly accurate simulations of bearing behavior under various load conditions, including seismic events, optimizing designs for both performance and material efficiency. Furthermore, additive manufacturing (3D printing) holds potential for prototyping complex bearing geometries and exploring customized designs, while advanced recycling techniques for elastomeric materials are being explored to align with sustainability goals, contributing to a circular economy in the construction sector.

Regional Highlights

- Asia Pacific: This region is projected to be the fastest-growing market for elastomeric bearings, driven by massive investments in infrastructure development, including extensive road networks, high-speed rail projects, and urban expansion in countries like China, India, and Southeast Asian nations. Rapid urbanization and a growing awareness of seismic protection in earthquake-prone areas further fuel the demand for advanced bearing solutions.

- North America: A mature market characterized by stringent building codes and a strong focus on maintaining and upgrading existing infrastructure. The demand here is largely influenced by the need for seismic retrofitting of older structures, ongoing bridge rehabilitation projects, and new construction adhering to advanced structural resilience standards. Technological innovation and a focus on high-performance bearings are key trends.

- Europe: The European market demonstrates steady growth, propelled by the need to modernize aging infrastructure, comply with evolving European design standards, and address environmental concerns through sustainable construction practices. Countries such as Germany, France, and the UK invest heavily in transport infrastructure and sustainable building projects, driving demand for quality elastomeric bearings.

- Middle East & Africa (MEA): This region presents significant growth opportunities due to large-scale infrastructure projects, including new cities, transportation hubs, and commercial developments, particularly in the GCC countries. Increased government spending on construction and an influx of international investment are key drivers, though the market is still in its developing stages for specialized bearing applications.

- Latin America: The market in Latin America is growing due to increasing government investments in public infrastructure, particularly in countries like Brazil, Mexico, and Chile. The regions susceptibility to seismic activity also drives the adoption of elastomeric bearings for earthquake protection in new constructions and existing structures. Economic stability and policy support for infrastructure are critical for sustained growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Elastomeric Bearings Market.- Trelleborg AB

- Bridgestone Corporation

- Freyssinet (Vinci Construction)

- Mageba AG

- Maurer SE

- Gumba GmbH

- FIP Industriale S.p.A.

- Canam Group Inc.

- Dynamic Rubber Inc.

- Kirberg GmbH

- Cosmi S.p.A.

- DS Brown

- Kawashima Co., Ltd.

- R.J. Watson, Inc.

- Tiflex Ltd.

- GMT Rubber-Metal-Technic AG

Frequently Asked Questions

What are elastomeric bearings and their primary function?

Elastomeric bearings are flexible structural components typically made from rubber (natural or synthetic) and often reinforced with steel. Their primary function is to transfer loads from a superstructure to a substructure while accommodating movements caused by thermal expansion, contraction, structural deflections, and seismic events, thereby protecting structural integrity and enhancing safety.

Where are elastomeric bearings commonly used?

Elastomeric bearings are predominantly used in civil engineering and infrastructure projects. Their most common applications include bridges to allow for deck movements, buildings for seismic isolation in earthquake-prone regions, and industrial structures for vibration isolation of heavy machinery and equipment.

What benefits do elastomeric bearings offer in construction?

Key benefits include superior seismic protection by absorbing and dissipating earthquake energy, accommodation of thermal movements to prevent stress, reduced maintenance requirements due to their durable design, and extended structural lifespan. They also provide effective vibration isolation, enhancing comfort and protecting sensitive equipment.

How do elastomeric bearings provide seismic protection?

During an earthquake, elastomeric bearings decouple the structure from ground motion. They deform laterally, absorbing and dissipating seismic energy, which reduces the forces transmitted to the structure, preventing damage and improving the buildings or bridges ability to withstand seismic events.

What are the different types of elastomeric bearings available in the market?

Common types include natural rubber bearings (NRB), neoprene bearings (CRB), high-damping rubber bearings (HDRB), and lead rubber bearings (LRB). Other specialized types like pot bearings and spherical bearings also utilize elastomeric elements or principles for specific movement and load requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager