Electric Hoist Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431000 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Electric Hoist Market Size

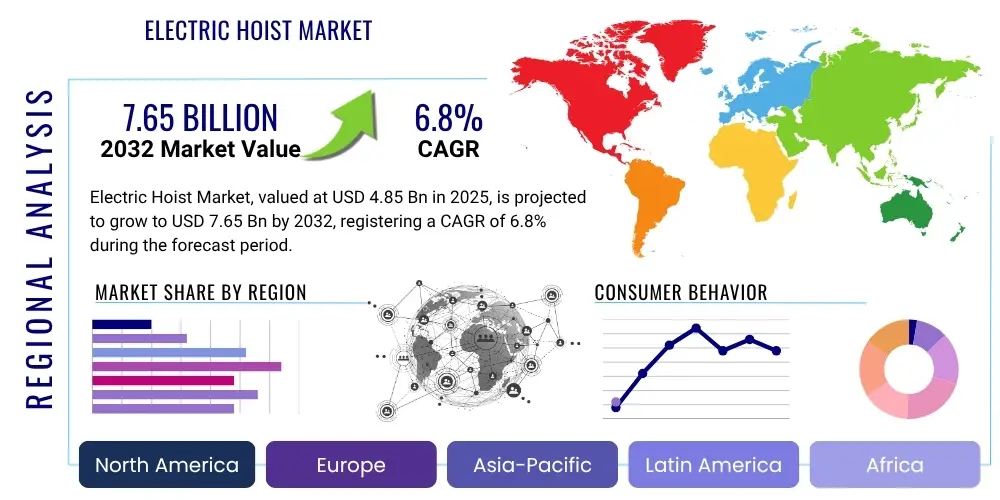

The Electric Hoist Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 4.85 Billion in 2025 and is projected to reach USD 7.65 Billion by the end of the forecast period in 2032.

Electric Hoist Market introduction

The Electric Hoist Market encompasses the global demand for lifting equipment powered by electricity, designed for vertical lifting and lowering of loads. These devices are integral to various industries, providing efficient and safe material handling solutions. Electric hoists are categorized by their lifting mechanism, such as wire rope or chain, and by their operational characteristics, including fixed, monorail, or top-running configurations. The primary function is to enhance productivity and safety in environments requiring heavy lifting, minimizing manual labor and reducing the risk of workplace injuries.

Major applications for electric hoists span across construction, manufacturing, shipping and logistics, automotive, and mining sectors. In construction, they are vital for lifting structural components and materials; in manufacturing, they facilitate assembly lines and machine loading. The benefits of deploying electric hoists include increased operational efficiency due to faster lifting speeds, enhanced safety through precise control and robust design, and cost savings from reduced labor requirements and improved material flow. The market is significantly driven by global industrial expansion, infrastructure development projects, and a growing emphasis on workplace safety regulations, which mandate the use of reliable and automated lifting solutions.

Electric Hoist Market Executive Summary

The Electric Hoist Market is experiencing robust growth driven by accelerating industrialization and modernization across key sectors globally. Business trends indicate a strong focus on automation, integration of smart technologies, and demand for customized lifting solutions that cater to specific industrial requirements. Companies are investing in research and development to introduce hoists with improved lifting capacities, energy efficiency, and enhanced safety features, positioning themselves competitively in a dynamic market landscape. The shift towards sustainable manufacturing practices also influences product design, favoring eco-friendly materials and energy-efficient motor systems. Furthermore, strategic collaborations and mergers and acquisitions are observed as key players consolidate market share and expand their technological portfolios.

Regionally, Asia Pacific continues to dominate the market due to rapid industrial growth in countries like China and India, coupled with significant infrastructure investments. North America and Europe also present substantial market opportunities, driven by technological advancements and the adoption of advanced material handling systems in mature industries. Emerging economies in Latin America, the Middle East, and Africa are showing promising growth, fueled by urbanization, development projects, and increasing foreign direct investment in manufacturing and logistics. Segment trends highlight the increasing preference for electric wire rope hoists for heavy-duty applications and electric chain hoists for lighter, more versatile tasks. The demand for hoists with variable speed drives and remote control capabilities is also rising, reflecting the broader trend towards operational flexibility and precision in industrial settings. Service and maintenance contracts are also becoming a crucial revenue stream, emphasizing the long-term operational needs of hoist users.

AI Impact Analysis on Electric Hoist Market

Common user questions regarding AI's impact on the Electric Hoist Market primarily revolve around how artificial intelligence can enhance operational efficiency, predictive maintenance, safety, and automation levels in lifting applications. Users are keen to understand if AI can make hoists 'smarter' by anticipating failures, optimizing lifting paths, or integrating seamlessly into broader smart factory ecosystems. Concerns often include the cost of AI integration, data security, the need for specialized training, and the reliability of AI-driven decisions in critical lifting operations. Expectations are high for AI to transform hoists from mere mechanical devices into intelligent, self-monitoring, and adaptable tools that can significantly reduce downtime and improve overall material handling safety and productivity.

- Enhanced Predictive Maintenance: AI algorithms analyze operational data to forecast potential failures, enabling proactive maintenance and reducing unscheduled downtime.

- Optimized Lifting Operations: AI can calculate the most efficient lifting paths and speeds, minimizing energy consumption and improving cycle times.

- Advanced Safety Features: AI-powered vision systems and sensors can detect obstacles, monitor load stability, and prevent collisions, significantly improving workplace safety.

- Integration with Smart Factory Systems: AI facilitates seamless communication and coordination between electric hoists and other automated systems within a smart manufacturing environment.

- Automated Troubleshooting and Diagnostics: AI can quickly identify and diagnose operational issues, guiding operators or maintenance staff through troubleshooting steps.

- Customized Performance: AI allows hoists to adapt their performance characteristics based on specific load types, environmental conditions, and operational requirements.

DRO & Impact Forces Of Electric Hoist Market

The Electric Hoist Market is significantly influenced by a confluence of driving factors, restraining elements, and emerging opportunities, which collectively shape its growth trajectory and competitive landscape. Key drivers include the global surge in industrial manufacturing, rapid expansion of construction activities, and increasing investment in logistics and warehousing infrastructure, all of which necessitate efficient material handling solutions. Stricter occupational safety regulations worldwide also compel industries to adopt automated and safer lifting equipment like electric hoists, replacing manual and less secure methods. The continuous technological advancements leading to more efficient, durable, and intelligent hoist designs further fuel market growth, offering improved productivity and lower operational costs to end-users.

Conversely, the market faces several restraints. Economic slowdowns and fluctuating raw material prices, particularly for steel and copper, can impact manufacturing costs and consumer purchasing power, thereby hindering market expansion. The high initial investment associated with advanced electric hoists, especially for small and medium-sized enterprises (SMEs), can also act as a barrier to adoption. Intense competition from conventional lifting equipment and the availability of alternative material handling solutions in certain niche applications also present challenges. Additionally, the need for specialized skills for installation, operation, and maintenance of sophisticated electric hoists can limit their widespread adoption in regions with a less developed industrial workforce.

Despite these restraints, significant opportunities exist for market players. The rising demand for customized and modular hoist systems that can be tailored to specific industry needs presents a growth avenue. The integration of Industry 4.0 technologies, such as IoT and AI, into hoist systems offers the potential for smart hoists with predictive maintenance, remote monitoring, and enhanced automation capabilities, creating premium product segments. Expansion into untapped markets in developing economies with nascent industrial sectors provides substantial growth potential. Furthermore, a growing focus on energy-efficient and environmentally friendly hoist solutions aligns with global sustainability trends, offering opportunities for innovation and market differentiation. The increasing adoption of automation in warehouses and distribution centers also provides a fertile ground for electric hoist deployment, particularly those integrated with automated guided vehicles (AGVs) and robotic systems.

Segmentation Analysis

The Electric Hoist Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation helps in analyzing market trends, identifying key growth areas, and understanding consumer preferences across various applications and operational environments. The primary segments typically include classification by product type, lifting capacity, control type, end-user industry, and geographical region, each offering unique insights into market behavior and demand patterns. These categorizations enable manufacturers, suppliers, and investors to develop targeted strategies and allocate resources effectively, ensuring optimal market penetration and competitive advantage.

- Product Type

- Electric Wire Rope Hoist

- Electric Chain Hoist

- Electric Belt Hoist

- Lifting Capacity

- Less than 5 Tons

- 5-10 Tons

- 10-25 Tons

- Over 25 Tons

- Control Type

- Pendant Control

- Remote Control

- Cabin Control

- End-User Industry

- Manufacturing

- Construction

- Shipping and Logistics

- Automotive

- Mining

- Energy

- Aerospace and Defense

- Waste Management

Value Chain Analysis For Electric Hoist Market

The value chain for the Electric Hoist Market begins with upstream activities involving the sourcing of raw materials and components. This stage includes the procurement of high-grade steel for frames and structural components, copper for motors and electrical wiring, gears, ropes, chains, and various electronic control units from specialized suppliers. Key upstream players include metal manufacturers, bearing suppliers, motor manufacturers, and electronic component providers. Quality control and cost-effectiveness at this stage are crucial as they directly impact the final product's performance and market price. Strong supplier relationships and strategic sourcing are vital for maintaining a competitive edge.

Midstream activities primarily focus on the manufacturing and assembly of electric hoists. This involves design and engineering, fabrication of components, motor integration, electrical wiring, assembly, testing, and quality assurance processes. Manufacturers often specialize in different types of hoists, leveraging advanced production technologies and skilled labor. Downstream activities encompass the distribution, sales, installation, and after-sales services for electric hoists. Distribution channels are varied and include direct sales by manufacturers to large industrial clients, sales through a network of authorized distributors, dealers, and value-added resellers. These intermediaries play a critical role in reaching diverse customer segments, providing local support, and offering integrated solutions.

The distribution network for electric hoists can be segmented into direct and indirect channels. Direct channels involve manufacturers selling directly to large industrial enterprises, offering customized solutions, and maintaining direct customer relationships for installation and long-term service agreements. This approach allows for greater control over customer experience and direct feedback for product improvement. Indirect channels utilize distributors, wholesalers, and specialized equipment retailers who provide broader market reach, inventory management, and regional technical support. These channels are crucial for serving smaller businesses and diverse geographical areas. After-sales services, including maintenance, repairs, and spare parts supply, represent a significant part of the value chain, ensuring product longevity and customer satisfaction, and often generating recurring revenue for manufacturers and their partners.

Electric Hoist Market Potential Customers

The potential customers for electric hoists are incredibly diverse, spanning across numerous industrial and commercial sectors that require efficient and safe lifting and material handling capabilities. End-users typically include manufacturing facilities, such as automotive assembly plants, machinery production units, and electronics factories, where hoists are indispensable for moving components along production lines, loading heavy parts, and facilitating maintenance operations. In the construction industry, general contractors, civil engineering firms, and building developers frequently utilize electric hoists for lifting structural elements, prefabricated sections, and various building materials on job sites. The robust and reliable nature of electric hoists makes them suitable for demanding construction environments, contributing significantly to project timelines and safety.

Beyond traditional manufacturing and construction, the shipping and logistics sector represents a substantial customer base, with warehouses, distribution centers, and port authorities employing electric hoists for loading, unloading, and organizing heavy cargo. The automotive industry relies heavily on hoists for engine assembly, vehicle body positioning, and garage servicing. Mining operations use specialized hoists for lifting equipment, materials, and sometimes personnel within shafts and processing plants. Furthermore, the energy sector, including power generation plants and renewable energy facilities, utilizes hoists for turbine maintenance and equipment installation. Waste management facilities also employ hoists for moving and sorting heavy refuse. Any business or institution involved in processes that require the vertical movement of heavy or bulky items stands as a potential buyer, underscoring the broad applicability and essential nature of electric hoists in modern industrial operations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.85 Billion |

| Market Forecast in 2032 | USD 7.65 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Konecranes, Demag, Columbus McKinnon, Gorbel, Street Crane Company, ABUS Kransysteme, Spanco, Ingersoll Rand, R&M Materials Handling, EMH Inc., Verlinde, Hitachi Industrial Equipment Systems, Zhejiang Wuyi Machinery, SWF Krantechnik, KITO Corporation, J.D. Neuhaus, Stahl CraneSystems, Vestil Manufacturing, Harrington Hoists, Weihua Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electric Hoist Market Key Technology Landscape

The Electric Hoist Market is continuously evolving with significant technological advancements aimed at improving performance, safety, and operational efficiency. One of the primary technological trends is the integration of advanced motor control systems, such as Variable Frequency Drives (VFDs), which allow for precise speed control, smoother lifting and lowering operations, and enhanced energy efficiency. VFDs reduce mechanical wear and tear, minimize load swing, and provide precise positioning, which is critical in delicate handling operations. This technology also contributes to extending the lifespan of the hoist and reducing overall maintenance costs, making it a highly valued feature in modern electric hoists.

Another crucial aspect of the technology landscape involves the incorporation of smart sensors and IoT (Internet of Things) capabilities. These sensors monitor various operational parameters such as load weight, motor temperature, brake performance, and duty cycle, providing real-time data for predictive maintenance and operational analytics. IoT connectivity enables remote monitoring and diagnostics, allowing maintenance teams to anticipate potential failures before they occur, thereby minimizing downtime and optimizing maintenance schedules. This shift towards intelligent, connected hoists is transforming material handling into a more data-driven and proactive process, aligning with broader Industry 4.0 initiatives. Furthermore, advancements in ergonomic control systems, including wireless remote controls with intuitive interfaces and advanced safety interlocks, are enhancing operator comfort and safety. Collision avoidance systems, often employing laser or ultrasonic sensors, are also becoming standard features, further reducing the risk of accidents and improving overall workplace safety.

Regional Highlights

- Asia Pacific: This region is a dominant force in the Electric Hoist Market, primarily driven by rapid industrialization, massive infrastructure projects, and a booming manufacturing sector in countries like China, India, Japan, and South Korea. Increased foreign direct investment, expanding automotive production, and significant urbanization contribute to sustained demand.

- North America: Characterized by technological innovation and a strong emphasis on automation and safety in industrial settings, North America is a significant market. The region benefits from investments in advanced manufacturing, aerospace, and logistics, coupled with stringent safety regulations encouraging the adoption of modern electric hoists.

- Europe: A mature market with a focus on advanced engineering and high safety standards, Europe shows steady demand for electric hoists. Countries like Germany, the UK, and France lead in adopting sophisticated lifting solutions, particularly in automotive, general manufacturing, and construction sectors, with an increasing shift towards energy-efficient and smart hoist systems.

- Latin America: This region presents emerging opportunities, fueled by growth in infrastructure development, mining activities, and expanding manufacturing bases, particularly in Brazil, Mexico, and Argentina. Investment in modernizing industrial facilities drives the adoption of electric hoists for improved efficiency and safety.

- Middle East and Africa (MEA): The MEA region is experiencing substantial growth due to significant investments in construction, oil and gas, and logistics infrastructure, especially in the GCC countries and South Africa. Large-scale development projects and efforts to diversify economies away from oil are creating new avenues for the Electric Hoist Market.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electric Hoist Market.- Konecranes

- Demag

- Columbus McKinnon

- Gorbel

- Street Crane Company

- ABUS Kransysteme

- Spanco

- Ingersoll Rand

- R&M Materials Handling

- EMH Inc.

- Verlinde

- Hitachi Industrial Equipment Systems

- Zhejiang Wuyi Machinery

- SWF Krantechnik

- KITO Corporation

- J.D. Neuhaus

- Stahl CraneSystems

- Vestil Manufacturing

- Harrington Hoists

- Weihua Group

Frequently Asked Questions

What is an electric hoist and how does it differ from other lifting equipment?

An electric hoist is a motorized lifting device that uses electric power to lift and lower loads, typically heavier items, with precision and controlled speed. It differs from manual hoists by eliminating human effort, offering higher lifting capacities, faster operations, and often integrating advanced safety features. Compared to hydraulic or pneumatic systems, electric hoists are generally more energy-efficient and offer quieter operation, making them suitable for a broader range of indoor and outdoor industrial environments.

What are the primary benefits of using electric hoists in industrial applications?

Electric hoists offer significant benefits including enhanced operational efficiency through faster lifting speeds and precise load positioning, leading to increased productivity. They also vastly improve workplace safety by minimizing manual handling, reducing the risk of injuries, and incorporating safety features like overload protection. Furthermore, electric hoists provide cost savings by reducing labor requirements and potential damage to materials, ensuring a more streamlined and secure material handling process in various industrial settings.

Which industries are the major end-users of electric hoists?

The major end-users of electric hoists span across a wide array of industries. Manufacturing is a significant sector, utilizing hoists for assembly lines and machine loading. The construction industry employs them for lifting structural components and materials on job sites. Shipping and logistics, automotive, and mining sectors also heavily rely on electric hoists for efficient and safe material handling, cargo movement, vehicle maintenance, and equipment relocation, respectively.

How is AI impacting the future development of electric hoists?

AI is profoundly impacting electric hoist development by enabling smart functionalities such as predictive maintenance, optimizing lifting operations for efficiency, and enhancing safety features. AI-driven systems can analyze real-time operational data to anticipate failures, suggest optimal lifting paths, and integrate seamlessly into broader smart factory ecosystems. This leads to more reliable, energy-efficient, and safer hoists with reduced downtime and improved overall productivity.

What are the key factors driving the growth of the Electric Hoist Market?

Key factors driving the market growth include global industrial expansion, particularly in manufacturing and construction, along with significant investments in infrastructure development. Increased emphasis on workplace safety regulations, which mandate reliable lifting solutions, also fuels demand. Additionally, continuous technological advancements in hoist design, leading to improved efficiency, durability, and integration with automation systems, are major growth contributors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager