Electric Industrial Heater Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427164 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Electric Industrial Heater Market Size

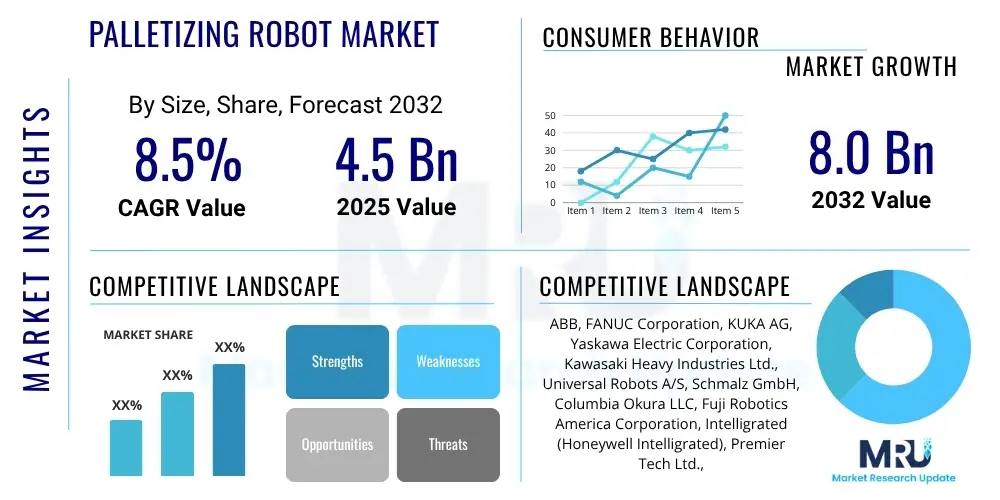

The Electric Industrial Heater Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 10.5 billion in 2025 and is projected to reach USD 16.7 billion by the end of the forecast period in 2032.

Electric Industrial Heater Market introduction

The Electric Industrial Heater Market encompasses a diverse range of heating solutions essential for numerous industrial processes, offering a cleaner, more efficient, and precisely controllable alternative to traditional fossil-fuel-based heating systems. These heaters convert electrical energy directly into thermal energy, providing heat for critical applications such as process fluid heating, space heating in hazardous environments, drying, curing, melting, and sterilization. Key product types include immersion heaters, circulation heaters, radiant heaters, tubular heaters, and strip heaters, each designed to meet specific operational demands and environmental conditions. The intrinsic benefits of electric heaters, such as high energy efficiency, minimal emissions, reduced maintenance, and superior temperature control, position them as indispensable components across a multitude of manufacturing and processing sectors.

Major applications for electric industrial heaters span a vast industrial landscape, reflecting their versatility and reliability. In the oil and gas sector, they are crucial for heating viscous crude, maintaining pipeline temperatures, and gas superheating. Chemical processing relies on them for reactor heating, heat transfer fluids, and vaporizers. The food and beverage industry utilizes electric heaters for sanitation, cooking, and pasteurization, while pharmaceuticals employ them for sterile processing and drug formulation. Furthermore, industries like plastics, automotive, textiles, and metallurgy leverage these heaters for molding, paint drying, fabric treatment, and metal annealing. The market’s continuous expansion is directly linked to the global drive for industrial optimization, energy conservation, and stricter environmental compliance, making electric heating a preferred choice for modern industrial operations seeking both performance and sustainability.

The primary benefits of electric industrial heaters extend beyond mere heat generation, contributing significantly to operational excellence and environmental stewardship. Their precise temperature control capabilities enable manufacturers to achieve stringent process requirements, minimize product waste, and enhance overall quality. The absence of direct combustion eliminates exhaust gases, making them ideal for cleanrooms and sensitive production environments, while also reducing a company's carbon footprint. Safety is another paramount advantage, as electric heaters eliminate the risks associated with open flames, fuel storage, and combustion byproducts, particularly in volatile industrial settings. These driving factors, coupled with advancements in material science and control technologies, are propelling the electric industrial heater market forward, fostering innovation and broader adoption across all industrial sectors globally.

Electric Industrial Heater Market Executive Summary

The Electric Industrial Heater Market is experiencing robust growth, driven by a confluence of factors including increasing industrial automation, stringent environmental regulations, and the rising demand for energy-efficient heating solutions. Business trends indicate a shift towards customized heating systems that integrate advanced controls, IoT capabilities, and predictive maintenance features, allowing industries to optimize processes, reduce operational costs, and enhance safety. Companies are focusing on developing modular and scalable electric heaters that can be easily integrated into existing infrastructure, catering to both large-scale industrial complexes and specialized niche applications. Furthermore, there is a growing emphasis on smart heating solutions that can communicate with plant-wide control systems, enabling real-time monitoring and dynamic adjustment of heating parameters to maximize efficiency and productivity.

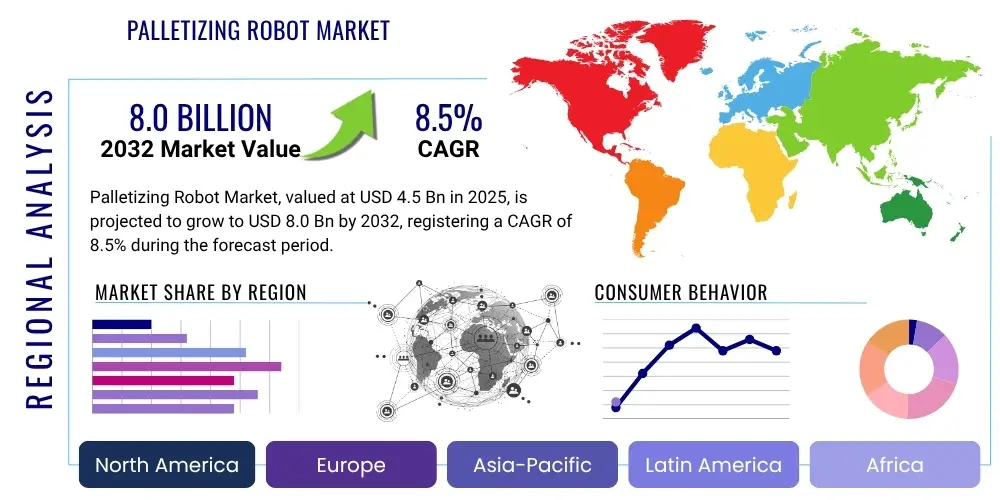

Regional trends reveal Asia-Pacific as the fastest-growing market, propelled by rapid industrialization, infrastructure development, and increasing foreign investments in manufacturing across countries like China, India, and Southeast Asian nations. North America and Europe, while more mature, are demonstrating consistent growth, fueled by the modernization of existing industrial facilities, the adoption of advanced manufacturing techniques, and strong regulatory frameworks promoting energy efficiency and decarbonization. These regions are also at the forefront of technological innovation, leading the development of high-power density heaters, explosion-proof designs, and advanced digital control systems. Latin America, the Middle East, and Africa are showing promising growth potential, driven by expanding industrial bases, particularly in oil and gas, mining, and food processing, which are increasingly seeking reliable and cost-effective heating solutions.

Segmentation trends highlight process heating as the dominant application segment, indispensable for a myriad of industries requiring precise temperature control for fluid heating, gas superheating, and material processing. By product type, immersion and circulation heaters continue to hold significant market shares due to their efficiency in direct fluid heating, while radiant and tubular heaters are gaining traction for applications requiring indirect or localized heating. End-use industries such as oil and gas, chemicals, food and beverage, and pharmaceuticals remain significant consumers, yet emerging sectors like electric vehicle battery manufacturing, advanced ceramics, and renewable energy components are rapidly increasing their demand for specialized electric heating solutions. The market is also seeing a trend towards higher power output heaters to meet the demands of large-scale industrial operations, alongside micro-heaters for highly specialized and compact applications, indicating a broad spectrum of innovation across the entire product portfolio.

AI Impact Analysis on Electric Industrial Heater Market

User inquiries concerning AI's influence on the Electric Industrial Heater Market frequently center around how artificial intelligence can optimize energy consumption, enhance predictive maintenance, improve process control accuracy, and integrate seamlessly with existing industrial ecosystems. There is a strong expectation that AI will transform industrial heating from a static, reactive process into a dynamic, proactive, and highly efficient operation. Users are particularly interested in AI's ability to analyze vast amounts of operational data from sensors and historical performance, identify subtle anomalies, predict potential equipment failures before they occur, and autonomously adjust heating parameters to maintain optimal efficiency and product quality. Concerns often revolve around the complexity of AI integration, data security, and the initial investment required, but the overarching sentiment remains positive regarding AI's potential to deliver substantial operational savings and environmental benefits.

- AI-powered predictive maintenance reduces downtime by forecasting heater component failures, enabling proactive repairs and minimizing unplanned interruptions.

- Optimized energy consumption through real-time data analysis, allowing AI algorithms to adjust heating cycles and power output to match demand precisely, leading to significant energy cost savings.

- Enhanced process control and temperature accuracy, as AI systems learn from process variations and adapt heater performance to maintain tight tolerances, improving product consistency and quality.

- Integration with smart manufacturing ecosystems (Industry 4.0) for seamless data exchange and coordinated operation with other production equipment, increasing overall plant efficiency.

- Automated fault detection and diagnostics, enabling quicker identification and resolution of operational issues, reducing the need for manual troubleshooting.

- Development of self-learning heating systems that continuously improve their performance and efficiency over time based on operational feedback and environmental conditions.

- Customization and dynamic configuration of heating profiles for diverse products or processes, allowing for greater flexibility and faster changeovers in manufacturing lines.

DRO & Impact Forces Of Electric Industrial Heater Market

The Electric Industrial Heater Market is primarily propelled by several significant drivers that underscore its growing adoption across global industries. A key driver is the escalating demand for energy-efficient industrial processes, where electric heaters offer superior thermal efficiency and precise control compared to fossil fuel alternatives, leading to reduced operational costs and energy consumption. The stringent environmental regulations globally, particularly concerning carbon emissions and air quality, compel industries to transition towards cleaner heating solutions, positioning electric heaters as a vital component in decarbonization strategies. Furthermore, the rapid industrialization and expansion of manufacturing sectors, particularly in emerging economies, are creating substantial demand for robust and reliable heating equipment. The inherent safety advantages of electric heating, eliminating open flames and fuel storage, also make them a preferred choice in hazardous and regulated environments, further fueling market growth.

Despite these strong drivers, the market faces several restraints that could impede its growth trajectory. The relatively high initial capital expenditure associated with installing electric industrial heating systems, including the cost of specialized heating elements, advanced control systems, and potentially upgraded electrical infrastructure, can be a deterrent for smaller enterprises or those operating on tight budgets. Competition from established fossil fuel heating systems, which often have lower upfront costs and are deeply entrenched in many industries, also poses a significant challenge. Additionally, the reliance on a stable and cost-effective electricity supply is a critical factor; fluctuations in electricity prices or unreliable grid infrastructure in certain regions can affect operational costs and diminish the attractiveness of electric heating solutions. The technical complexity of integrating sophisticated electric heating systems into legacy industrial setups can also be a barrier for some manufacturers.

Opportunities within the Electric Industrial Heater Market are abundant and poised to drive significant innovation and expansion. The growing trend towards industrial automation and Industry 4.0 provides a fertile ground for the development and adoption of smart electric heaters integrated with IoT, AI, and advanced analytics for predictive maintenance and optimized process control. The increasing focus on sustainability and the circular economy is creating new avenues for electric heaters in renewable energy applications, such as hydrogen production, battery manufacturing, and waste-to-energy processes. Moreover, market players have the opportunity to develop highly customized and application-specific heating solutions, catering to the unique requirements of niche industries, thereby expanding their market reach. Investing in research and development for new materials, higher power densities, and improved insulation technologies will also unlock significant growth potential, offering more compact, durable, and even more efficient heating solutions. The impact forces collectively push towards a more sustainable, efficient, and technologically advanced industrial heating landscape, compelling continuous evolution and adaptation within the market.

Segmentation Analysis

The Electric Industrial Heater Market is meticulously segmented to provide a granular understanding of its diverse components, end-user applications, and geographical spread. This comprehensive segmentation allows market participants to identify specific growth areas, develop targeted strategies, and innovate solutions that cater to distinct industrial needs. The market can be broadly categorized by product type, application, end-use industry, and power output, each offering unique insights into demand patterns and technological preferences. Understanding these segments is crucial for stakeholders to effectively navigate the market, identify competitive advantages, and capitalize on emerging opportunities across various industrial ecosystems globally.

- By Product Type

- Immersion Heaters

- Circulation Heaters

- Radiant Heaters

- Tubular Heaters

- Strip Heaters

- Band Heaters

- Cartridge Heaters

- Flexible Heaters

- By Application

- Process Heating (e.g., Fluid Heating, Gas Superheating, Vaporization)

- Space Heating

- Curing & Drying

- Melting & Holding

- Heat Treating & Annealing

- Sterilization

- Baking & Roasting

- Freeze Protection

- By End-Use Industry

- Oil & Gas

- Chemicals & Petrochemicals

- Food & Beverage

- Pharmaceuticals

- Plastics & Rubber

- Automotive

- Metals & Mining

- Power Generation

- Textiles

- Electronics

- Semiconductors

- Construction

- Aerospace

- Pulp & Paper

- By Power Output

- Low Power (< 50 kW)

- Medium Power (50 kW - 500 kW)

- High Power (> 500 kW)

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Electric Industrial Heater Market

The value chain for the Electric Industrial Heater Market is a complex network of interconnected activities, beginning from the sourcing of raw materials to the final installation and after-sales support for end-users. Upstream activities involve the procurement and processing of essential raw materials such as high-grade metals (e.g., nickel-chromium alloys, stainless steel for heating elements and casings), electrical insulation materials (e.g., magnesium oxide, mica), refractory ceramics, and advanced polymer compounds. Suppliers in this segment are crucial for ensuring the quality, durability, and performance of heating elements and related components. Component manufacturers then transform these raw materials into specialized parts like resistors, thermostats, temperature sensors, wiring, and sophisticated control panels. The efficiency and reliability of these upstream suppliers directly influence the overall quality and cost-effectiveness of the finished electric industrial heaters.

Midstream in the value chain, manufacturers of electric industrial heaters undertake the design, engineering, assembly, and testing of diverse heating solutions. This stage involves significant research and development to innovate new heater designs, improve energy efficiency, enhance safety features, and incorporate smart technologies such as IoT connectivity and AI-driven controls. Fabrication processes include welding, bending, insulation, and the integration of heating elements with control systems. Quality assurance and rigorous testing are paramount at this stage to ensure products meet stringent industry standards, safety certifications, and performance specifications. Manufacturers often specialize in specific types of heaters or cater to particular industrial applications, building expertise and brand reputation in their chosen niches. The ability to customize products to client specifications is a key differentiator in this competitive market.

Downstream activities focus on reaching the end-users and providing essential services. The distribution channel plays a critical role, encompassing both direct sales from manufacturers to large industrial clients and indirect sales through a network of distributors, wholesalers, and system integrators. Direct sales often involve complex engineering consultations and custom solutions for specific projects, requiring a deep understanding of the client's operational needs. Indirect channels leverage the extensive reach and local presence of distributors who provide inventory, logistics, and often initial technical support. After-sales services, including installation, commissioning, maintenance, repair, and technical support, are vital for customer satisfaction and long-term relationships. These services ensure the optimal performance and longevity of the electric industrial heaters, contributing significantly to the total cost of ownership and overall value proposition for end-users. Effective management of this entire value chain is essential for market success, requiring strong coordination and collaboration among all stakeholders.

Electric Industrial Heater Market Potential Customers

The Electric Industrial Heater Market caters to an incredibly diverse base of potential customers across virtually all industrial sectors, driven by their universal need for precise and reliable heat in various processes. The primary end-users are large manufacturing and processing industries that require heat for fluid heating, gas superheating, drying, curing, sterilization, and material melting. This includes heavy industries such as oil and gas, where heaters are critical for crude oil processing, gas re-heating, and pipeline temperature maintenance, ensuring viscosity control and preventing blockages. Similarly, the chemical and petrochemical industries rely heavily on electric heaters for reactor heating, heat transfer fluid systems, and distillation processes, where precise temperature control is paramount for product quality and safety. The continuous operational demands and critical nature of these applications make these sectors significant and consistent buyers of advanced electric heating solutions.

Beyond the heavy process industries, a broad spectrum of other sectors represents substantial potential customer segments. The food and beverage industry utilizes electric heaters for pasteurization, cooking, sterilization of equipment, and maintaining product temperatures during processing and packaging, driven by strict hygiene and quality standards. Pharmaceutical and biotechnology companies are crucial customers, demanding highly controlled and sterile heating for drug manufacturing, fermentation, and laboratory applications, where product integrity and contamination prevention are non-negotiable. Furthermore, the plastics and rubber industry employs electric heaters for molding, extrusion, and curing processes, while the automotive sector uses them in paint shops for drying, engine block heating, and other manufacturing stages. These industries are constantly seeking ways to improve efficiency, reduce operational costs, and meet increasingly stringent regulatory requirements, making electric heaters an attractive investment.

Emerging industries and specialized applications are also rapidly expanding the customer base for electric industrial heaters. The burgeoning electric vehicle (EV) battery manufacturing sector requires precise heating for electrode drying, electrolyte filling, and cell formation. Advanced materials industries, including those involved in ceramics, composites, and semiconductors, demand highly accurate and contaminant-free heating for sintering, bonding, and deposition processes. The increasing focus on renewable energy and sustainable technologies also positions potential customers in fields such as green hydrogen production, waste-to-energy conversion, and energy storage systems. Moreover, smaller businesses and specialized workshops requiring localized heating, quick heat-up times, or specific atmospheric conditions also form a significant, albeit fragmented, customer segment. These varied demands underscore the versatility and critical importance of electric industrial heaters across the modern industrial landscape, with companies continuously seeking customized, energy-efficient, and technologically advanced heating solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 10.5 billion |

| Market Forecast in 2032 | USD 16.7 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Watlow Electric Manufacturing Company, Chromalox, Inc., NIBE Industrier AB, Industrial Heater Corporation, Indeeco, Vulcan Electric Company, Tempco Electric Heater Corporation, Durex Industries, Tutco-Farnam Custom Products, Spirax-Sarco Engineering plc, Hotwatt, Inc., Zoppas Industries Heating Element Technologies, Delta Manufacturing Inc., Thermon, Inc., Danfoss A/S, San Electro Heat A/S, Heatrod Elements, O.E.M. Heaters, BriskHeat, LEISTER Technologies AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electric Industrial Heater Market Key Technology Landscape

The technological landscape of the Electric Industrial Heater Market is characterized by continuous innovation aimed at enhancing efficiency, precision, safety, and integration capabilities. A crucial aspect is the advancement in heating element materials, with a focus on extending lifespan and improving heat transfer rates. This includes the utilization of high-performance alloys such as Incoloy, Inconel, and various grades of stainless steel, which offer superior corrosion resistance and high-temperature tolerance. Furthermore, the development of ceramic and composite heating elements provides solutions for ultra-high temperature applications and aggressive chemical environments. Innovations in insulation materials, such as advanced refractory fibers and microporous insulation, are also vital, reducing heat loss and improving energy efficiency by ensuring that heat is directed precisely where needed within the industrial process.

Control systems represent another frontier of technological advancement, transforming electric industrial heaters into smart, interconnected devices. Modern heaters are increasingly equipped with sophisticated PID (Proportional-Integral-Derivative) controllers, Programmable Logic Controllers (PLCs), and Supervisory Control and Data Acquisition (SCADA) systems that enable highly accurate temperature regulation and process automation. The integration of IoT (Internet of Things) capabilities allows for real-time monitoring of heater performance, energy consumption, and operational parameters from remote locations. This connectivity facilitates data analytics for predictive maintenance, enabling operators to anticipate failures, optimize service schedules, and prevent costly downtime. Furthermore, advanced diagnostic tools are being incorporated to provide immediate feedback on system health, enhancing operational reliability and reducing troubleshooting time.

The market is also witnessing a surge in modular designs and customization technologies, allowing manufacturers to offer highly tailored heating solutions for diverse industrial requirements. This includes adaptable heater configurations, adjustable power outputs, and specialized sheath materials designed to withstand specific chemical exposures or mechanical stresses. Energy recovery systems, which capture and reuse waste heat, are gaining prominence as industries prioritize sustainability and energy conservation. Safety technologies, such as enhanced over-temperature protection, redundant control circuits, and explosion-proof designs (e.g., ATEX, UL, CSA certifications), are continuously being refined to meet stringent international standards for operation in hazardous locations. These technological advancements collectively contribute to making electric industrial heaters more efficient, reliable, safe, and adaptable to the evolving demands of modern manufacturing and processing environments.

Regional Highlights

- North America: This region demonstrates a mature but robust market for electric industrial heaters, driven by continuous upgrades of industrial infrastructure, strong emphasis on energy efficiency, and stringent safety regulations. The presence of diversified industries such as oil and gas, chemicals, automotive, and food and beverage, coupled with high technological adoption rates, fuels consistent demand. Investments in smart manufacturing and Industry 4.0 initiatives further propel the integration of advanced electric heating solutions with IoT capabilities and AI-driven controls. The United States and Canada are leading contributors, with a focus on innovation in high-power and explosion-proof heater designs.

- Europe: The European market for electric industrial heaters is characterized by a strong commitment to decarbonization and sustainability, along with well-established manufacturing sectors. Strict environmental policies, such as the EU Green Deal, encourage industries to replace fossil fuel-based heating systems with cleaner electric alternatives. Countries like Germany, the UK, France, and Italy are significant markets, benefiting from advanced technological capabilities and a focus on precision engineering. The region also sees a strong demand for customized heating solutions that comply with various European safety and performance standards (e.g., CE marking).

- Asia Pacific (APAC): APAC is the fastest-growing region in the Electric Industrial Heater Market, propelled by rapid industrialization, burgeoning manufacturing sectors, and expanding infrastructure across countries such as China, India, Japan, and South Korea. The increasing demand for energy-efficient and precise heating in industries like electronics, semiconductors, automotive, and chemicals drives significant market expansion. Government initiatives supporting manufacturing growth and foreign direct investments in industrial setups further contribute to the market’s vigorous development. The region presents substantial opportunities for both established global players and local manufacturers.

- Latin America: The Latin American market is experiencing steady growth, primarily influenced by expanding industrial bases in countries like Brazil, Mexico, and Argentina. Key demand drivers include the development of the oil and gas sector, mining, food processing, and chemical industries. While adoption rates might be slower compared to developed regions, there is a growing awareness of the benefits of electric heating, particularly concerning energy efficiency and process optimization. Investments in modernizing industrial plants and improving energy infrastructure are expected to boost market penetration in the coming years.

- Middle East & Africa (MEA): The MEA region offers significant potential, driven by its vast oil and gas reserves, expansion of petrochemical industries, and growing investments in industrial diversification. Countries like Saudi Arabia, UAE, and South Africa are key markets. Electric industrial heaters are essential for various processes in oil refineries, gas processing plants, and desalination facilities. The push for economic diversification away from traditional oil revenues is also leading to investments in new manufacturing sectors, creating fresh demand for reliable and efficient heating solutions, though political stability and infrastructure development remain critical factors influencing market growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electric Industrial Heater Market.- Watlow Electric Manufacturing Company

- Chromalox, Inc.

- NIBE Industrier AB

- Industrial Heater Corporation

- Indeeco

- Vulcan Electric Company

- Tempco Electric Heater Corporation

- Durex Industries

- Tutco-Farnam Custom Products

- Spirax-Sarco Engineering plc

- Hotwatt, Inc.

- Zoppas Industries Heating Element Technologies

- Delta Manufacturing Inc.

- Thermon, Inc.

- Danfoss A/S

- San Electro Heat A/S

- Heatrod Elements

- O.E.M. Heaters

- BriskHeat

- LEISTER Technologies AG

Frequently Asked Questions

What are the primary advantages of electric industrial heaters over traditional heating methods?

Electric industrial heaters offer several distinct advantages, including superior energy efficiency due to direct energy conversion and minimal heat loss, leading to reduced operational costs. They provide extremely precise temperature control, essential for critical industrial processes, which improves product quality and reduces waste. Furthermore, electric heaters generate zero direct emissions, making them environmentally friendly and suitable for cleanroom applications, while also enhancing safety by eliminating open flames, combustion byproducts, and fuel storage risks inherent in fossil fuel systems. Their compact design, ease of installation, and low maintenance requirements also contribute significantly to their appeal in modern industrial settings, particularly as industries prioritize sustainability and operational efficiency.

Which industries are the largest consumers of electric industrial heaters, and for what applications?

The largest consumers of electric industrial heaters span across several heavy and specialized industries. The oil and gas sector extensively uses them for crude oil heating, gas superheating, and maintaining pipeline temperatures to prevent viscosity issues and ensure smooth flow. The chemical and petrochemical industries rely on them for reactor heating, heat transfer fluid systems, and vaporization processes where precise temperature management is critical for chemical reactions and safety. The food and beverage industry employs electric heaters for pasteurization, cooking, sanitation, and maintaining product temperatures. Additionally, pharmaceuticals and biotechnology utilize them for sterile processing, fermentation, and laboratory heating, ensuring product purity and compliance with strict regulatory standards. These diverse applications highlight the versatility and essential role of electric heaters in modern industrial production.

How do electric industrial heaters contribute to sustainability and environmental compliance?

Electric industrial heaters play a crucial role in advancing sustainability and achieving environmental compliance for industries globally. By converting electricity directly into heat without combustion, they produce zero direct greenhouse gas emissions (such as CO2, NOx, and SOx) at the point of use, significantly reducing an industry's carbon footprint. When powered by renewable energy sources, their environmental benefits are amplified, supporting broader decarbonization efforts. Their high energy efficiency minimizes energy waste, while precise temperature control reduces product spoilage and resource consumption. This aligns with increasingly stringent environmental regulations and corporate sustainability goals, enabling companies to meet compliance standards and enhance their public image as environmentally responsible operators, contributing positively to air quality and overall ecological impact reduction.

What technological advancements are shaping the future of the electric industrial heater market?

The future of the electric industrial heater market is being shaped by several key technological advancements focused on enhancing intelligence, efficiency, and reliability. The integration of IoT connectivity, AI-driven analytics, and advanced control systems is enabling smart heaters capable of predictive maintenance, real-time performance optimization, and autonomous operation. This allows for dynamic adjustment of heating parameters, minimizing energy consumption and maximizing uptime. Innovations in material science are leading to more durable, energy-efficient, and high-temperature-resistant heating elements and insulation. Furthermore, modular designs and customization capabilities are becoming standard, offering greater flexibility for various industrial applications. These advancements collectively lead to more sophisticated, interconnected, and highly efficient heating solutions that are integral to Industry 4.0 environments, fostering greater operational efficiency and sustainability.

What are the main factors driving growth in the Asia Pacific electric industrial heater market?

The Asia Pacific (APAC) electric industrial heater market is experiencing significant growth driven by several powerful factors. Rapid industrialization and robust economic expansion across countries like China, India, and Southeast Asian nations are fueling the demand for new industrial equipment, including heating solutions. Extensive infrastructure development and increasing investments in manufacturing sectors, such as electronics, automotive, chemicals, and pharmaceuticals, are creating a substantial need for efficient and precise heating processes. Furthermore, a growing awareness of energy efficiency and environmental sustainability, coupled with evolving regulatory landscapes, is encouraging industries to adopt cleaner electric heating alternatives. The increasing adoption of advanced manufacturing technologies and automation also contributes to the rising demand for sophisticated and integrated electric industrial heater solutions in the region.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager