Electric Vehicle Thermal Management System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427950 | Date : Oct, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Electric Vehicle Thermal Management System Market Size

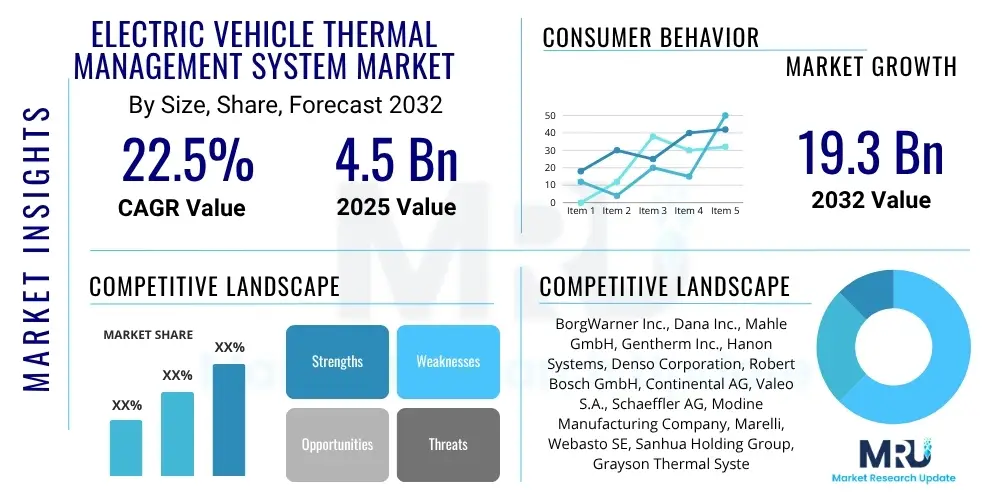

The Electric Vehicle Thermal Management System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 22.5% between 2025 and 2032. The market is estimated at USD 4.5 Billion in 2025 and is projected to reach USD 19.3 Billion by the end of the forecast period in 2032.

Electric Vehicle Thermal Management System Market introduction

The Electric Vehicle Thermal Management System Market encompasses the technologies and solutions designed to regulate and optimize the temperature of key components within electric vehicles, primarily batteries, electric motors, and power electronics. These systems are critical for ensuring the longevity, performance, efficiency, and safety of EVs. As global demand for electric vehicles continues to surge, driven by environmental concerns, technological advancements, and supportive government policies, the importance of robust and efficient thermal management systems has become paramount. Proper temperature control prevents overheating or overcooling, both of which can significantly degrade component life and compromise vehicle operation.

The core product in this market includes a range of components such as heat pumps, chillers, radiators, fluid pumps, valves, sensors, and advanced control units that work in conjunction to maintain optimal operating temperatures. Major applications span across passenger electric cars, commercial electric vehicles like buses and trucks, and specialized electric vehicles. The benefits derived from advanced thermal management systems are extensive, including extended battery lifespan, improved vehicle range, faster charging capabilities, enhanced safety by preventing thermal runaway, and optimal performance of electric drivetrains and power converters under varying environmental conditions. The driving factors for this market's expansion are directly tied to the accelerating adoption of electric vehicles worldwide, continuous innovations in battery technology necessitating precise thermal control, and increasingly stringent performance and safety standards.

As the EV industry matures, the focus shifts from merely managing temperature to intelligently optimizing thermal energy. This involves waste heat recovery, zonal cooling, and predictive thermal control, which are becoming standard features in next-generation EVs. The complex interplay of various thermal loads within an EV demands an integrated and sophisticated approach to thermal management, pushing manufacturers to invest heavily in research and development for more efficient, compact, and cost-effective solutions. The market is also seeing a trend towards modular and highly integrated thermal management units that simplify assembly and enhance overall system reliability, further driving its growth trajectory.

Electric Vehicle Thermal Management System Market Executive Summary

The Electric Vehicle Thermal Management System Market is experiencing dynamic growth, propelled by the global transition towards sustainable transportation and the relentless pursuit of enhanced EV performance. Key business trends indicate a strong emphasis on the integration of smart technologies, including artificial intelligence and machine learning, to enable predictive and adaptive thermal management. Manufacturers are also prioritizing lightweight and compact designs to minimize vehicle weight and maximize efficiency, alongside the adoption of eco-friendly refrigerants and advanced liquid cooling techniques. There is a growing inclination towards modular and integrated thermal systems that can efficiently manage heat across batteries, motors, and cabin, simplifying vehicle architecture and reducing production costs. Strategic collaborations between EV manufacturers and thermal system suppliers are becoming common, fostering innovation and accelerating market development.

From a regional perspective, Asia-Pacific dominates the market, largely driven by the high volume of EV production and sales in countries like China, Japan, and South Korea. This region benefits from robust government support, significant investments in battery manufacturing, and a large consumer base. Europe is another significant growth hub, fueled by stringent emission regulations, substantial consumer incentives for EV adoption, and a strong focus on advanced automotive R&D in nations such as Germany, Norway, and the United Kingdom. North America is also witnessing rapid expansion, characterized by increasing EV demand, substantial infrastructure development, and the emergence of innovative domestic EV manufacturers. Emerging markets in Latin America, the Middle East, and Africa are showing nascent interest and potential, albeit with slower adoption rates due to infrastructure and cost barriers.

Segmentation trends highlight the increasing importance of Battery Thermal Management Systems (BTMS) as the cornerstone of EV performance, with liquid cooling solutions being the most prevalent and effective method. Passenger vehicles continue to hold the largest market share, but the commercial vehicle segment, including electric buses and trucks, is projected to exhibit significant growth due to increasing urbanization and logistics electrification efforts. Within cooling types, active cooling mechanisms, particularly liquid-based systems, are preferred for their superior efficiency and control. The market is also seeing a rise in integrated thermal management modules that combine functions for batteries, motors, and cabin climate control, optimizing energy use and reducing overall system complexity. These trends underscore a market that is continually evolving, driven by technological advancements and the imperative for sustainable mobility solutions.

AI Impact Analysis on Electric Vehicle Thermal Management System Market

User inquiries regarding AI's impact on Electric Vehicle Thermal Management Systems frequently center on how AI can optimize energy efficiency, extend battery life, enhance safety, and enable more intelligent system control. Common questions explore AI's role in predictive maintenance, real-time adaptive thermal management, and its ability to process complex data to anticipate thermal loads. There is significant interest in how AI can move thermal systems beyond reactive control to proactive, intelligent management, thereby improving overall EV performance and reliability. Users are keen to understand the practical benefits, potential challenges related to data requirements, and the future outlook for autonomous thermal management solutions in EVs. The collective expectation is that AI will unlock new levels of optimization and efficiency, making EVs even more practical and desirable.

- AI enables predictive thermal management by analyzing driving patterns, environmental conditions, and battery state-of-health data to anticipate thermal loads and proactively adjust cooling or heating.

- Optimized energy consumption results from AI algorithms determining the most energy-efficient strategies for thermal regulation, minimizing parasitic losses and maximizing vehicle range.

- Real-time adaptive control is achieved as AI continuously monitors system parameters and makes instantaneous adjustments to fluid flow rates, fan speeds, and compressor operations for optimal temperature maintenance.

- Enhanced fault detection and diagnostics are provided by AI, which can identify anomalies in thermal system performance, predict potential failures, and alert drivers or service centers before critical issues arise.

- Improved battery state-of-health (SOH) and lifespan estimation are direct benefits, as AI-driven thermal control ensures the battery operates within its ideal temperature window, slowing down degradation processes.

- Integration with overall vehicle energy management systems allows AI to prioritize energy usage between propulsion, cabin comfort, and thermal management, balancing performance with efficiency.

- Personalized thermal comfort for occupants can be achieved through AI learning individual preferences and adjusting cabin climate control dynamically, potentially reducing overall energy expenditure.

- Facilitation of faster and safer charging is possible as AI monitors battery temperature during charging and precisely manages cooling to prevent overheating, accelerating the process without compromising safety.

DRO & Impact Forces Of Electric Vehicle Thermal Management System Market

The Electric Vehicle Thermal Management System Market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form the impact forces shaping its trajectory. The primary driver is the exponential growth in electric vehicle sales worldwide, spurred by increasing environmental consciousness, stringent emission regulations, and supportive government incentives. As more consumers adopt EVs, the demand for sophisticated thermal management to enhance battery life, range, and safety directly escalates. Advancements in battery technology, particularly the shift towards higher energy density cells and ultra-fast charging capabilities, inherently necessitate more robust and precise thermal control solutions, further fueling market expansion. Additionally, the growing consumer expectation for improved EV performance, longer range, and faster charging cycles puts pressure on manufacturers to integrate cutting-edge thermal management systems, making them indispensable for competitive differentiation.

However, several restraints pose challenges to the market's growth. The high initial cost associated with advanced thermal management systems, especially those incorporating heat pumps and complex liquid cooling circuits, can add to the overall price of electric vehicles, potentially hindering mass adoption in cost-sensitive markets. The inherent complexity of integrating diverse thermal components—for battery, motor, power electronics, and cabin—into a compact and efficient system presents significant engineering challenges, leading to prolonged development cycles and increased R&D expenses. Furthermore, the reliance on certain critical raw materials for components like heat exchangers and sensors, coupled with potential supply chain vulnerabilities, can impact production and pricing stability. Infrastructure limitations, particularly in emerging economies, concerning widespread access to efficient charging stations that necessitate rapid battery cooling, also indirectly restrain the uptake of advanced thermal solutions.

Despite these challenges, substantial opportunities exist for market participants. The continuous research and development into next-generation battery technologies, such as solid-state batteries, promises to revolutionize thermal management requirements, opening avenues for innovative cooling and heating solutions. The increasing integration of vehicle-to-grid (V2G) and vehicle-to-home (V2H) technologies will require sophisticated thermal control to manage bidirectional energy flows and potential heat generation during grid interaction. Moreover, the development of lightweight and compact thermal system designs using advanced materials (e.g., composites, advanced aluminum alloys) offers opportunities to reduce overall vehicle weight and improve energy efficiency. Smart city initiatives and the growth of shared mobility services are expected to drive the demand for durable and high-performing electric vehicles, thereby increasing the market for robust thermal management systems. The expansion into emerging EV markets, with their unique climatic and regulatory conditions, also presents untapped growth potential for adaptable thermal solutions.

Segmentation Analysis

The Electric Vehicle Thermal Management System Market is comprehensively segmented across various dimensions to provide a granular understanding of its intricate dynamics and growth vectors. This segmentation is crucial for identifying specific market needs, technological preferences, and regional variations in adoption. The diverse categories include segmentation by component, cooling type, vehicle type, propulsion type, and sales channel, each reflecting distinct aspects of the EV ecosystem. Each segment presents unique growth trajectories and technological requirements driven by evolving EV architectures, regulatory frameworks, and consumer preferences. The intricate interplay between these segments is vital for understanding market dynamics and forecasting future innovations in thermal management, allowing stakeholders to tailor strategies and product development to specific niche requirements and overarching industry trends.

- By Component

- Battery Thermal Management System (BTMS): Focuses on maintaining optimal battery temperature for longevity, performance, and safety. Includes cold plates, chillers, fluid pumps, and control units.

- Cabin Thermal Management System: Regulates the interior temperature of the vehicle for passenger comfort and energy efficiency. Often utilizes heat pumps and HVAC systems.

- Motor Thermal Management System: Ensures the electric motor operates within its ideal temperature range to prevent overheating and maintain efficiency. Involves cooling jackets and fluid circulation.

- Power Electronics Thermal Management System: Manages heat generated by inverters, converters, and onboard chargers to ensure reliable operation of critical electrical components.

- By Cooling Type

- Active Cooling: Involves energy expenditure to remove heat.

- Liquid Cooling: Utilizes refrigerants or coolants circulated through dedicated channels (cold plates, radiators) for highly efficient heat transfer, dominant in high-performance EVs.

- Air Cooling: Uses ambient air or forced air circulation, generally simpler and less effective for high power density components, often found in smaller battery packs or auxiliary systems.

- Refrigerant-based Cooling: Employs vapor compression cycles (similar to AC systems) to actively cool components, highly effective for rapid cooling.

- Passive Cooling: Relies on natural heat transfer mechanisms without active energy input.

- Phase Change Material (PCM): Utilizes materials that absorb and release latent heat during phase transitions (solid to liquid) to buffer temperature fluctuations.

- Heat Sinks: Conducts heat away from components through fins or extended surfaces, dissipating it into the surrounding environment.

- Active Cooling: Involves energy expenditure to remove heat.

- By Vehicle Type

- Passenger Cars: The largest segment, covering a wide range of sedans, SUVs, and hatchbacks.

- Commercial Vehicles: Includes electric buses, trucks, vans, and other heavy-duty vehicles, a rapidly growing segment with demanding thermal requirements.

- By Propulsion Type

- Battery Electric Vehicles (BEV): Pure electric vehicles relying solely on battery power, requiring comprehensive thermal management for all components.

- Plug-in Hybrid Electric Vehicles (PHEV): Vehicles with both an electric motor and an internal combustion engine, requiring integrated thermal solutions for both power sources and the battery.

- Fuel Cell Electric Vehicles (FCEV): Hydrogen-powered vehicles that generate electricity through a fuel cell, necessitating thermal management for the fuel cell stack and associated components.

- By Sales Channel

- OEM (Original Equipment Manufacturer): Sales directly to vehicle manufacturers for integration into new vehicles.

- Aftermarket: Sales of components and systems for replacement, upgrades, or repairs after the initial vehicle purchase.

Value Chain Analysis For Electric Vehicle Thermal Management System Market

The value chain for the Electric Vehicle Thermal Management System Market is characterized by a multi-tiered structure, encompassing a range of activities from raw material sourcing to final product distribution and aftermarket services. At the upstream end, the value chain begins with the procurement of essential raw materials such as aluminum, copper, specialized plastics, advanced refrigerants, and various rare earth metals for sensors and electronic components. These materials are then supplied to component manufacturers who specialize in producing intricate parts like heat exchangers, fluid pumps, valves, compressors, fans, and sophisticated electronic control units. These specialized suppliers often leverage advanced manufacturing processes and precision engineering to meet the stringent quality and performance requirements of the automotive industry. The complexity of these components necessitates deep expertise and specialized production facilities, forming a critical foundation for the entire market.

Moving downstream, these manufactured components are integrated into sub-systems and complete thermal management modules by Tier-1 automotive suppliers. These suppliers, often large global corporations, act as crucial intermediaries, designing, assembling, and testing comprehensive thermal solutions tailored to the specific needs of various Electric Vehicle (EV) manufacturers. Their role involves extensive R&D, system integration, and rigorous validation to ensure that the thermal management systems meet performance, safety, and durability standards set by the OEMs. Further down the chain, these integrated systems are then supplied directly to Electric Vehicle manufacturers, who incorporate them into the final vehicle assembly. This direct relationship between Tier-1 suppliers and EV OEMs is paramount, facilitating collaborative design and optimizing the integration process within the vehicle's architecture. The efficiency of this collaboration directly impacts the overall performance and cost-effectiveness of the finished electric vehicle.

The distribution channel primarily operates through direct sales from Tier-1 suppliers to Original Equipment Manufacturers (OEMs) for new vehicle production, which forms the dominant part of the market. For the aftermarket segment, components and repair kits are distributed through a network of specialized automotive parts distributors, independent garages, and authorized service centers. This indirect channel caters to replacement needs, upgrades, and maintenance throughout the vehicle's lifecycle. Direct sales ensure tight integration and customization, while indirect channels provide accessibility and support for a growing installed base of electric vehicles. The interplay between these upstream and downstream activities, coupled with efficient distribution, is crucial for market efficiency, responsiveness to technological changes, and ultimately, the widespread adoption of advanced thermal management systems in electric vehicles.

Electric Vehicle Thermal Management System Market Potential Customers

The primary potential customers for Electric Vehicle Thermal Management Systems are the manufacturers of electric vehicles themselves, ranging from established automotive giants to innovative startups specializing in electric mobility. These Original Equipment Manufacturers (OEMs) require sophisticated thermal solutions for their passenger cars, commercial vehicles (buses, trucks, vans), and even specialized electric vehicles. Leading global EV manufacturers such as Tesla, BYD, Volkswagen, General Motors, Ford, Hyundai, BMW, and Mercedes-Benz consistently seek advanced and efficient thermal management systems to ensure the optimal performance, extended range, and safety of their diverse EV lineups. Emerging players like Rivian, Lucid Motors, Nio, and XPeng also represent significant potential customers, often pushing for cutting-edge, integrated solutions that can differentiate their products in a competitive market. The demand from these OEMs is driven by regulatory pressures, consumer expectations for performance, and the continuous evolution of battery technology.

Beyond traditional EV manufacturers, battery pack manufacturers, such as CATL, LG Energy Solution, Panasonic, and Samsung SDI, also represent a crucial segment of potential customers. While often integrated directly into OEM supply chains, these companies develop the core energy storage units and require robust thermal management solutions that are tightly integrated with their battery designs. Ensuring the thermal stability of battery cells and modules is paramount for preventing thermal runaway, maximizing energy throughput, and extending the operational life of the battery pack, which is often the most expensive component of an EV. Consequently, partnerships and direct sales to these battery specialists are vital for thermal management system providers looking to embed their technologies early in the EV design process. The expertise of these battery manufacturers in thermal engineering also influences the requirements and specifications for external thermal management solutions.

Furthermore, Tier-1 automotive suppliers, who often act as system integrators, are also key potential customers. Companies like BorgWarner, Dana Inc., Mahle, Gentherm, and Hanon Systems design and supply entire modules or sub-systems to EV OEMs. They frequently source specialized components for thermal management (e.g., specific pumps, valves, heat exchangers) from other expert manufacturers to integrate into their larger offerings. Therefore, companies providing these specialized, high-performance components find a significant customer base within these Tier-1 suppliers. Lastly, the burgeoning market for electric commercial vehicles, including heavy-duty trucks and buses from manufacturers like Daimler, Volvo, and Proterra, presents a rapidly growing customer segment with unique and stringent thermal management demands due to heavier loads, longer duty cycles, and often more extreme operating conditions. These diverse customer bases underscore the wide applicability and critical importance of advanced thermal management systems across the entire electric vehicle industry.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.5 Billion |

| Market Forecast in 2032 | USD 19.3 Billion |

| Growth Rate | 22.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BorgWarner Inc., Dana Inc., Mahle GmbH, Gentherm Inc., Hanon Systems, Denso Corporation, Robert Bosch GmbH, Continental AG, Valeo S.A., Schaeffler AG, Modine Manufacturing Company, Marelli, Webasto SE, Sanhua Holding Group, Grayson Thermal Systems, VOSS Automotive GmbH, Sumitomo Electric Industries, Ltd., LG Energy Solution, CATL, Thermamax GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electric Vehicle Thermal Management System Market Key Technology Landscape

The Electric Vehicle Thermal Management System Market is undergoing rapid technological evolution, driven by the need for enhanced efficiency, compactness, and adaptability to new battery chemistries and vehicle architectures. One of the most prominent technologies is advanced liquid cooling, particularly through the use of precisely engineered cold plates and micro-channel heat exchangers. These systems offer superior heat transfer capabilities compared to air cooling, enabling more precise temperature control for high-power battery packs and electric motors, crucial for achieving faster charging times and maintaining peak performance under strenuous conditions. Liquid cooling systems often incorporate optimized fluid dynamics and intelligent pump controls to maximize efficiency while minimizing energy consumption. The move towards distributed cooling loops and integrated modules that manage multiple thermal loads simultaneously is also a significant trend, reducing complexity and improving overall system packaging.

Heat pump systems represent another pivotal technological advancement, offering bidirectional functionality for both heating and cooling. Unlike traditional resistive heaters, heat pumps efficiently transfer thermal energy, significantly reducing the energy required for cabin heating in colder climates and improving the overall range of electric vehicles. Modern heat pumps are designed for high efficiency across a wide range of ambient temperatures and can often recover waste heat from the powertrain or battery to warm the cabin, thus optimizing energy usage. Furthermore, the integration of Phase Change Materials (PCMs) is gaining traction, especially for passive thermal management. PCMs absorb or release latent heat during their phase transition, acting as a thermal buffer to smooth out temperature fluctuations within battery packs, extending their lifespan and improving performance, particularly during rapid charging or discharging cycles.

Beyond hardware, the role of Artificial Intelligence (AI) and Machine Learning (ML) in predictive thermal control is transforming the market. These intelligent algorithms analyze a multitude of data points, including driving patterns, ambient temperature, battery state-of-charge, and historical performance, to anticipate thermal loads and proactively optimize cooling or heating strategies. This predictive capability not only enhances efficiency but also contributes to proactive maintenance and extends the operational life of critical EV components. Other key technologies include advanced sensors and actuators for precise monitoring and control, lightweight materials (such as high-strength aluminum alloys and composites) to reduce vehicle mass, and the development of refrigerants with lower Global Warming Potential (GWP) to meet environmental regulations. The continuous innovation across these technological fronts is essential for the sustained growth and effectiveness of electric vehicle thermal management systems.

Regional Highlights

- Asia Pacific: This region stands as the undisputed leader in the Electric Vehicle Thermal Management System Market, largely propelled by the booming EV manufacturing and sales in China, Japan, and South Korea. Government initiatives, substantial investments in battery production, and a rapidly expanding charging infrastructure create a fertile ground for market expansion. China, in particular, drives a significant portion of this growth with its aggressive EV adoption policies and a vast domestic market for both passenger and commercial electric vehicles. The emphasis on high-performance and long-range EVs in this region further stimulates demand for sophisticated and efficient thermal management solutions.

- Europe: The European market is experiencing robust growth, primarily fueled by stringent environmental regulations, ambitious decarbonization targets, and strong consumer demand for electric vehicles, particularly in countries like Germany, Norway, France, and the UK. The region is a hub for automotive innovation and R&D, leading to the development and adoption of advanced thermal management technologies, including sophisticated heat pump systems and integrated cooling solutions. Government incentives and a well-established automotive supply chain contribute significantly to the market's continuous expansion across the continent.

- North America: North America is witnessing substantial growth in the EV thermal management market, driven by increasing consumer awareness, federal and state-level incentives for EV purchases, and significant investments in charging infrastructure. The presence of major EV manufacturers and a growing ecosystem of startups actively contributes to technological advancements and market penetration. The demand for powerful and long-range electric trucks and SUVs, especially in the United States, places a premium on highly efficient and reliable thermal management systems capable of handling demanding performance requirements and diverse climatic conditions.

- Latin America, Middle East, and Africa (MEA): These regions represent emerging markets for EV thermal management systems, characterized by nascent but growing interest in electric mobility. While adoption rates are currently lower compared to developed regions, increasing environmental awareness, governmental efforts to promote sustainable transportation, and foreign investments are gradually stimulating market growth. Challenges related to charging infrastructure and higher initial EV costs are being addressed, paving the way for future expansion. The unique climatic conditions in some MEA countries, with extreme temperatures, also highlight the critical need for robust thermal management solutions tailored to specific regional requirements.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electric Vehicle Thermal Management System Market.- BorgWarner Inc.

- Dana Inc.

- Mahle GmbH

- Gentherm Inc.

- Hanon Systems

- Denso Corporation

- Robert Bosch GmbH

- Continental AG

- Valeo S.A.

- Schaeffler AG

- Modine Manufacturing Company

- Marelli

- Webasto SE

- Sanhua Holding Group

- Grayson Thermal Systems

- VOSS Automotive GmbH

- Sumitomo Electric Industries, Ltd.

- LG Energy Solution

- CATL

- Thermamax GmbH

Frequently Asked Questions

Why is thermal management crucial for electric vehicles?

Thermal management is paramount for electric vehicles because it directly impacts the performance, safety, and longevity of key components like batteries, electric motors, and power electronics. Maintaining optimal operating temperatures prevents overheating, which can lead to battery degradation, reduced power output, decreased efficiency, and even thermal runaway incidents. Conversely, ensuring components do not operate in excessively cold conditions is equally vital, as cold temperatures can reduce battery capacity, slow charging rates, and diminish motor efficiency. Effective thermal control extends the lifespan of expensive EV components, maximizes vehicle range, ensures faster and safer charging, and guarantees consistent performance under various environmental conditions, making it a foundational element of EV reliability and user experience.

What are the primary types of EV thermal management systems?

The primary types of EV thermal management systems are broadly categorized into active and passive cooling methods, often integrated within a comprehensive system. Active cooling systems include liquid cooling, which circulates coolants through cold plates and heat exchangers to efficiently dissipate heat from high-power components, and refrigerant-based cooling, utilizing vapor compression cycles for precise and rapid temperature regulation, often found in heat pump systems. Air cooling, a simpler active method, uses fans to circulate ambient air. Passive cooling systems involve technologies like Phase Change Materials (PCMs), which absorb and release latent heat to buffer temperature fluctuations, and traditional heat sinks that dissipate heat through conduction and convection. Modern EVs increasingly employ sophisticated integrated systems that combine these methods, such as heat pumps that manage thermal energy for both the battery and cabin climate control.

How does thermal management impact EV battery life and performance?

Thermal management profoundly impacts EV battery life and performance by ensuring the battery operates within its ideal temperature window. Batteries are highly sensitive to temperature extremes; consistently operating at elevated temperatures accelerates chemical degradation, leading to a permanent loss of capacity and power over time, thus shortening the battery's overall lifespan. Conversely, very cold temperatures can temporarily reduce available capacity, increase internal resistance, and slow down charging rates. Effective thermal management prevents these detrimental effects by actively cooling the battery during strenuous operation or fast charging, and warming it in cold conditions, thereby preserving the battery's state-of-health, maximizing energy efficiency, enabling consistent power delivery, and extending its useful life for thousands of charge cycles. This directly translates to greater vehicle range and sustained performance for the owner.

What role do heat pumps play in modern EV thermal management?

Heat pumps play a transformative role in modern EV thermal management by offering a highly efficient, bidirectional solution for both heating and cooling. Unlike traditional resistive heaters that generate heat by consuming a significant amount of electrical energy directly from the battery, heat pumps efficiently transfer thermal energy from one area to another. In cold weather, they extract heat from the ambient air or other vehicle components (like the motor) and transfer it to the cabin, drastically reducing energy consumption for heating and thereby extending the EV's range. In warmer conditions, they reverse the process to cool the cabin or battery. Modern EV heat pumps are often integrated into a sophisticated system that can also recover waste heat from the powertrain to further optimize energy usage, providing superior comfort with significantly less energy draw compared to conventional systems.

What are the emerging trends in EV thermal management technology?

Emerging trends in EV thermal management technology are focused on increasing efficiency, integration, and intelligence. One key trend is the advancement of integrated thermal management modules, which combine the cooling and heating functions for the battery, motor, power electronics, and cabin into a single, compact unit, simplifying vehicle architecture and reducing overall weight. The adoption of Artificial Intelligence and Machine Learning for predictive thermal control is another significant development, enabling systems to anticipate thermal loads based on driving patterns and environmental conditions, optimizing energy use proactively. Furthermore, there is a growing interest in Phase Change Materials (PCMs) for passive thermal buffering, advanced fluid dynamics and micro-channel designs for enhanced liquid cooling efficiency, and the development of more environmentally friendly refrigerants with lower global warming potential. The industry is also exploring zonal thermal management, allowing precise temperature control for specific areas of the vehicle independently, further enhancing comfort and efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager