Electrical Discharge Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427251 | Date : Oct, 2025 | Pages : 239 | Region : Global | Publisher : MRU

Electrical Discharge Machine Market Size

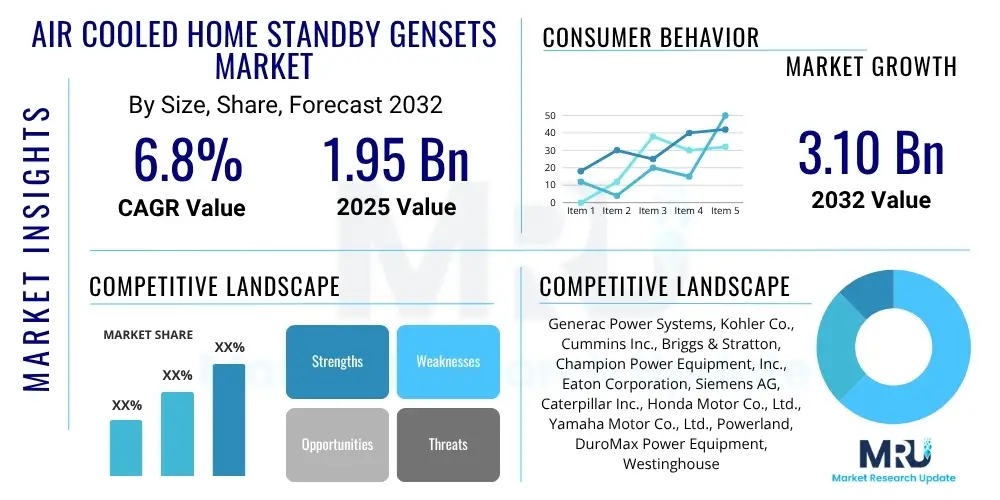

The Electrical Discharge Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 3.2 billion in 2025 and is projected to reach USD 5.7 billion by the end of the forecast period in 2032.

Electrical Discharge Machine Market introduction

The Electrical Discharge Machine (EDM) market encompasses specialized non-traditional machining processes that utilize electrical discharges to erode material from a workpiece. This method is particularly effective for fabricating complex geometries and machining hard-to-cut materials that are challenging or impossible to process with conventional methods. EDM technologies are essential for industries requiring extreme precision and intricate designs, offering solutions for material removal irrespective of the materials hardness, provided it is electrically conductive.

The primary products within this market include Wire EDM, Sinker (or Ram) EDM, and Hole Drilling EDM, each tailored for specific applications. Major applications span critical sectors such as aerospace and defense, automotive manufacturing, medical device production, and the highly demanding die and mold making industry. The benefits of EDM include superior surface finish, minimal mechanical stress on the workpiece due to no direct tool contact, and the capability to produce high-tolerance components. Key driving factors for market growth include the escalating demand for miniaturization, the widespread adoption of advanced materials like superalloys and composites in various industries, and the continuous need for high-precision, complex part manufacturing.

Electrical Discharge Machine Market Executive Summary

The Electrical Discharge Machine market is experiencing robust expansion driven by global industrial modernization and increasing demand for precision manufacturing. Business trends indicate a strong shift towards automation and integration of EDM systems with advanced CAD/CAM software, enhancing productivity and reducing lead times. Manufacturers are focusing on developing intelligent machines capable of real-time monitoring and adaptive control, aligning with Industry 4.0 principles. Furthermore, sustainability is emerging as a critical consideration, with efforts directed towards optimizing energy consumption and managing dielectric fluids more efficiently, influencing product development and operational strategies across the industry.

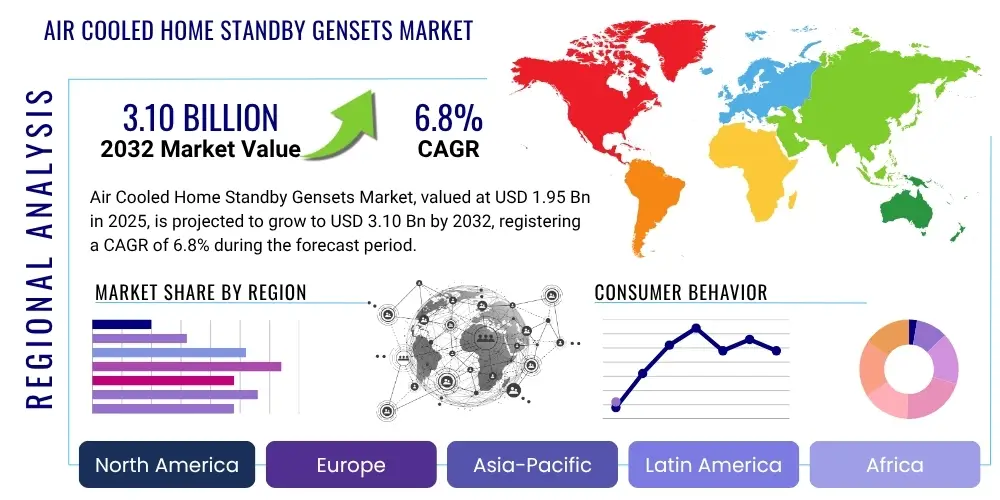

Regionally, Asia-Pacific remains the largest and fastest-growing market, primarily fueled by rapid industrialization, burgeoning electronics manufacturing, and a strong automotive sector in countries like China, Japan, and South Korea. North America and Europe continue to hold significant market shares, characterized by a mature industrial base, high investment in R&D, and demand for advanced manufacturing solutions in aerospace and medical device industries. Emerging economies in Latin America and the Middle East are also contributing to market growth, driven by investments in infrastructure and manufacturing capabilities. Segment trends highlight the increasing demand for Wire EDM for intricate cutting and Sinker EDM for highly detailed mold cavities, reflecting specialized industry needs.

AI Impact Analysis on Electrical Discharge Machine Market

The integration of Artificial Intelligence (AI) is poised to revolutionize the Electrical Discharge Machine market by significantly enhancing operational efficiency, predictive maintenance capabilities, and precision. Common user questions about AIs impact on EDM often revolve around how AI can optimize machining parameters, predict equipment failures, and ensure consistent part quality. Users are also concerned with the evolving role of human operators in an increasingly automated environment, questioning if AI will lead to job displacement or skill transformation. Expectations for AI in EDM primarily focus on achieving higher levels of automation, reducing downtime through proactive maintenance, and enabling the fabrication of more complex and intricate designs with unprecedented accuracy and repeatability.

AI algorithms can analyze vast datasets from EDM processes, including current, voltage, gap distance, and electrode wear, to identify optimal machining strategies and predict potential issues before they escalate. This predictive capability translates into significant reductions in machine downtime and improvements in overall equipment effectiveness. Furthermore, AI-driven systems can adapt machining parameters in real-time, optimizing performance for varying materials and geometries, thereby achieving superior surface finishes and tighter tolerances. The synergy between AI and EDM not only boosts productivity but also facilitates innovation in design and material processing, making previously impossible manufacturing tasks feasible.

- Enhanced Predictive Maintenance: AI analyzes sensor data to predict machine component failures and optimize maintenance schedules, reducing unplanned downtime.

- Optimized Machining Parameters: AI algorithms recommend or automatically adjust parameters such as pulse on/off times, gap voltage, and flushing pressure for improved efficiency and surface quality.

- Real-time Quality Control: AI-powered vision systems monitor the machining process, detecting defects or deviations from specifications in real-time, ensuring consistent output.

- Automated Process Planning: AI assists in generating optimal tool paths and machining sequences, significantly reducing setup times and programming efforts.

- Adaptive Control: AI systems can learn from past operations and adapt machining strategies to variations in material properties or environmental conditions, ensuring robust performance.

- Reduced Electrode Wear: AI predicts electrode wear patterns, allowing for proactive adjustments or replacements, extending tool life and maintaining precision.

- Data-driven Design Optimization: AI analyzes machining outcomes to provide feedback for product design improvements, enabling more manufacturable and complex geometries.

DRO & Impact Forces Of Electrical Discharge Machine Market

The Electrical Discharge Machine markets trajectory is shaped by a confluence of driving forces, inherent restraints, and emerging opportunities, all underpinned by significant impact forces. Key drivers include the escalating global demand for high-precision components across various industries, the increasing complexity of part geometries, and the growing adoption of hard-to-machine materials that conventional methods struggle with. The continuous drive towards automation and advanced manufacturing technologies, often linked with Industry 4.0 initiatives, further propels the market forward. Simultaneously, the market faces restraints such as the substantial initial capital investment required for EDM equipment, the ongoing costs associated with maintenance and specialized dielectric fluids, and environmental concerns regarding the disposal of these fluids. A persistent shortage of skilled labor capable of operating and maintaining advanced EDM systems also poses a challenge.

Opportunities within the EDM market are abundant, particularly in the realm of miniaturization, where EDM is crucial for producing micro-components with extreme accuracy. The integration of EDM with additive manufacturing (hybrid manufacturing) opens new avenues for creating intricate parts with internal features. Emerging economies, driven by industrial expansion, present untapped markets for EDM technology, while advancements in material science continually create new applications for EDM. Technological advancements, such as improved power supplies and adaptive control systems, act as primary impact forces, continuously refining EDM capabilities. Regulatory environments concerning environmental protection and workplace safety also exert significant influence, prompting innovation in fluid management and machine design. Economic shifts, including global manufacturing trends and supply chain dynamics, further dictate market demand and investment patterns.

Segmentation Analysis

The Electrical Discharge Machine market is comprehensively segmented to provide a detailed understanding of its diverse landscape and to identify specific areas of growth and opportunity. This segmentation allows stakeholders to analyze market trends based on different characteristics, including the type of EDM technology employed, the end-user industries utilizing these machines, and the specific applications for which EDM is deployed. Such granular analysis is crucial for strategic planning, product development, and targeted marketing efforts, enabling manufacturers and service providers to cater to distinct market needs and to capitalize on emerging niches effectively.

Understanding these segments reveals the underlying dynamics of market demand, technological preferences, and industry-specific requirements. For instance, the demand for Wire EDM often correlates with industries requiring intricate cutting paths, while Sinker EDM is critical for mold and die making. Similarly, growth in the aerospace sector will directly impact the demand for EDM machines capable of processing high-performance alloys. This structured approach to market segmentation provides a clear framework for assessing market performance and forecasting future trajectories within the complex and technologically driven EDM industry.

- By Type:

- Wire EDM (WEDM)

- Sinker EDM (Ram EDM)

- Hole Drilling EDM

- By End-User Industry:

- Aerospace and Defense

- Automotive

- Medical

- Die and Mold

- Electronics

- Energy

- Others (e.g., Tool and Die, Jewelry)

- By Application:

- High-Precision Machining

- Micro-Machining

- Prototyping

- Complex Geometry Machining

- Hard Material Processing

Electrical Discharge Machine Market Value Chain Analysis

The value chain of the Electrical Discharge Machine market encompasses a series of interconnected activities that add value to the final product, from raw material sourcing to end-user utilization. Upstream activities involve the acquisition and processing of raw materials such as specialized metals for electrodes (e.g., copper, graphite), components for power supplies, servo motors, filtration systems, and dielectric fluids. Key upstream players include material suppliers, component manufacturers, and software developers who provide essential programming tools and control systems. The quality and innovation at this stage directly impact the performance and reliability of the final EDM machine. Efficient sourcing and strong supplier relationships are critical for managing costs and ensuring a consistent supply of high-quality components.

Midstream activities primarily involve the design, manufacturing, and assembly of the EDM machines themselves. This stage requires significant investment in research and development to incorporate advanced technologies like CNC integration, adaptive control systems, and energy-efficient designs. Downstream activities focus on the distribution, sales, and post-sales support, including installation, training, maintenance, and spare parts supply. Distribution channels are typically a mix of direct sales by manufacturers, especially for large industrial clients, and indirect channels through a network of distributors and resellers who cater to smaller and medium-sized enterprises (SMEs). The effectiveness of the distribution network and the quality of after-sales service are crucial for customer satisfaction and market penetration, ensuring that the machines are properly supported throughout their operational life cycle.

Electrical Discharge Machine Market Potential Customers

Potential customers for Electrical Discharge Machine products are predominantly businesses operating within sectors that demand high-precision manufacturing, intricate designs, and the ability to process extremely hard or delicate materials. The die and mold making industry represents a significant end-user segment, relying on EDM for creating complex tooling, molds, and dies with exacting tolerances for applications across consumer goods, automotive, and electronics. The aerospace and defense sector is another critical customer base, requiring EDM for manufacturing turbine blades, structural components, and specialized parts from superalloys that must meet stringent performance and safety standards.

The automotive industry utilizes EDM extensively for producing engine components, transmission parts, and stamping dies, where precision and durability are paramount. The medical device industry, with its stringent requirements for biocompatibility and miniaturization, increasingly turns to EDM for fabricating implants, surgical instruments, and micro-components with exceptional accuracy and surface finish. Furthermore, the electronics sector leverages EDM for creating connectors, semiconductor components, and intricate circuitry. Other diverse end-users include the energy sector for power generation components, and general manufacturing shops specializing in custom parts or prototyping, all seeking the unique capabilities of EDM to overcome manufacturing challenges.

Electrical Discharge Machine Market Key Technology Landscape

The Electrical Discharge Machine market is characterized by a dynamic and evolving technology landscape, constantly driven by the need for higher precision, faster processing speeds, and greater automation. Central to this landscape is the advancement of Computer Numerical Control (CNC) systems, which provide precise, multi-axis control over electrode movement and workpiece positioning, enabling the creation of extremely complex geometries. Modern EDM machines integrate sophisticated power supplies, often utilizing pulse generators that deliver highly controlled electrical discharges, optimizing material removal rates and surface finish while minimizing electrode wear. These power supplies are critical for achieving the desired metallurgical properties on the workpiece surface and for processing a wide range of conductive materials.

Innovations in electrode materials and design are also crucial, with advancements in graphite, copper, and tungsten carbide electrodes extending tool life and improving machining efficiency. The development of advanced dielectric fluids, alongside more efficient filtration and recirculation systems, addresses both performance and environmental concerns by enhancing flushing capabilities and reducing waste. Furthermore, the integration of real-time monitoring and adaptive control systems, often leveraging sensor technology and data analytics, allows for automatic adjustments to machining parameters. This capability ensures consistent process stability and optimal performance. Automated tool changers, wire threading systems, and robotic workpiece loading/unloading further enhance the autonomy and productivity of EDM systems, aligning with the principles of smart manufacturing and Industry 4.0, while ensuring the market remains at the forefront of precision engineering.

Regional Highlights

- Asia Pacific: Dominates the global market, driven by robust growth in manufacturing sectors across China, Japan, South Korea, and India. High demand for EDM in automotive, electronics, and die & mold industries, coupled with significant investments in industrial automation and precision engineering, fuels regional expansion.

- North America: A mature market with consistent demand from the aerospace & defense, medical device, and automotive sectors. Focus on advanced manufacturing, R&D, and adoption of high-precision, automated EDM solutions.

- Europe: Characterized by strong industrial bases in Germany, Italy, Switzerland, and the UK. High demand from the automotive, machinery, and medical industries, with a strong emphasis on technological innovation, energy efficiency, and high-quality production standards.

- Latin America: An emerging market exhibiting steady growth, primarily influenced by expanding automotive and general manufacturing industries in Brazil and Mexico. Increasing foreign investments and industrialization initiatives are boosting the adoption of EDM technologies.

- Middle East & Africa: A nascent but growing market, propelled by diversification efforts in industrial sectors, particularly in the automotive and aerospace industries in countries like South Africa and the UAE. Investments in infrastructure and manufacturing capabilities contribute to gradual market penetration.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electrical Discharge Machine Market.- GF Machining Solutions

- Makino Inc.

- Sodick Co. Ltd.

- Mitsubishi Electric Corporation

- ONA Electroerosion S.A.

- Exeron GmbH

- Accutex Technologies Co. Ltd.

- CHMER EDM

- FANUC Corporation

- Belmont Technologies Inc.

Frequently Asked Questions

What is Electrical Discharge Machining (EDM)?

Electrical Discharge Machining (EDM) is a non-traditional manufacturing process that utilizes precisely controlled electrical discharges, or sparks, to erode material from an electrically conductive workpiece. This method allows for the creation of complex shapes and intricate details in hard materials that are difficult or impossible to machine with conventional tools, without any direct mechanical contact between the tool and the workpiece.

Which industries primarily use EDM technology?

EDM technology is predominantly utilized in industries requiring high-precision machining of complex geometries and hard materials. Key sectors include aerospace and defense for superalloy components, automotive for engine parts and molds, medical for implants and surgical instruments, and the die and mold industry for intricate tooling. The electronics sector also relies on EDM for manufacturing precise components.

What are the main types of EDM machines available?

The primary types of EDM machines are Wire EDM (WEDM), Sinker EDM (also known as Ram or Plunge EDM), and Hole Drilling EDM. Wire EDM uses a continuously fed thin wire as an electrode to cut intricate two-dimensional shapes. Sinker EDM uses a pre-shaped electrode to form three-dimensional cavities. Hole Drilling EDM is specialized for rapidly creating small, deep holes with high precision.

How does AI impact the efficiency of EDM processes?

AI significantly enhances EDM efficiency by enabling predictive maintenance, optimizing machining parameters in real-time, and improving quality control. AI algorithms analyze operational data to forecast potential machine failures, recommend optimal settings for various materials and designs, and monitor the process for defects, leading to reduced downtime, improved precision, and higher productivity.

What are the key advantages of using EDM over conventional machining methods?

The key advantages of EDM include its ability to machine extremely hard or exotic conductive materials irrespective of their hardness, produce intricate and complex geometries with high precision, and achieve superior surface finishes. EDM also eliminates mechanical stress on the workpiece due as there is no direct contact between the tool and material, reducing the risk of material distortion or damage.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager