Electron Microscope Sample Preparation Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429281 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Electron Microscope Sample Preparation Market Size

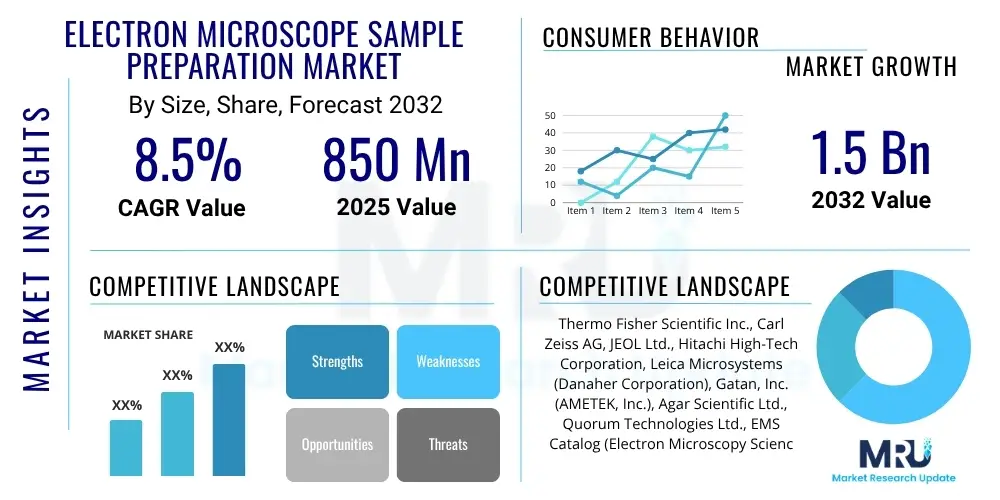

The Electron Microscope Sample Preparation Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 850 Million in 2025 and is projected to reach USD 1.5 Billion by the end of the forecast period in 2032.

Electron Microscope Sample Preparation Market introduction

The Electron Microscope Sample Preparation Market offers specialized instruments, consumables, and services essential for readying specimens for high-resolution imaging with Scanning Electron Microscopes (SEM), Transmission Electron Microscopes (TEM), and Focused Ion Beam (FIB) systems. This crucial process ensures samples are structurally stable, contamination-free, electrically conductive, and optimally thin or transparent, enabling accurate visualization and analysis of their ultrastructure and chemical composition at the nanoscale. Precision is paramount, as inconsistencies compromise image quality and data interpretability, highlighting its foundational role in advanced material science, biological research, and semiconductor analysis.

Key product categories include ultramicrotomes for ultrathin sectioning, ion milling instruments for precise material removal, sputter coaters for conductive layer deposition, and specialized cryo-preparation tools for biological samples. Consumables encompass electron microscopy grids, embedding resins, fixatives, stains, and various specimen holders, each designed for specific applications. Major applications span life sciences (cellular biology, pathology, virology, biotechnology), materials science (metals, polymers, ceramics, nanomaterials, composites), and the semiconductor industry (failure analysis, process control, R&D for microelectronics). These techniques collectively provide unparalleled spatial resolution, improved signal-to-noise ratios, minimized sample damage, and detailed analysis, facilitating groundbreaking discoveries and advancements in various fields.

The market's robust growth is primarily driven by continuous technological advancements in electron microscopy, which demand increasingly refined and specialized sample preparation methods to leverage the full capabilities of modern instruments. Escalating global investments in scientific research and development (R&D), particularly in emerging fields such as nanotechnology, biotechnology, and advanced materials, further fuel the demand for precise and efficient sample preparation solutions. The expanding need for sophisticated quality control, detailed failure analysis, and fundamental discovery across diverse high-tech industries solidifies the Electron Microscope Sample Preparation Market's indispensable position in modern scientific and industrial innovation, contributing significantly to both academic breakthroughs and commercial product development.

Electron Microscope Sample Preparation Market Executive Summary

The Electron Microscope Sample Preparation Market is undergoing robust expansion, driven by evolving business trends focusing on enhancing efficiency, reproducibility, and analytical depth across various applications. A significant trend is the increasing adoption of automated and semi-automated workflows, which are designed to minimize human variability, shorten preparation times, and accelerate throughput, a necessity for high-volume industrial applications and demanding research, such as cryo-electron microscopy (cryo-EM). Leading market players are strategically investing heavily in research and development to introduce innovative solutions, including integrated FIB-SEM systems for precise in-situ preparation and advanced vitrification devices for cryo-EM, ensuring their offerings meet the complex and evolving demands of modern electron microscopy. Strategic collaborations, mergers, and acquisitions are also prevalent, fostering co-development of specialized techniques and expanding market reach through combined expertise and distribution networks, thereby solidifying market positions and driving continuous innovation.

Geographically, North America and Europe retain substantial market shares, primarily due to their established scientific research infrastructures, extensive governmental and private sector R&D funding, and early adoption of advanced electron microscopy techniques. These regions host numerous leading academic institutions, major biotechnology and pharmaceutical companies, and advanced semiconductor manufacturing hubs, particularly in the United States, which collectively drive significant demand for sophisticated EM preparation solutions. Conversely, the Asia Pacific (APAC) region is emerging as a dynamic growth engine for the market, propelled by escalating governmental investments in science and technology, rapid industrialization, and expanding manufacturing sectors (especially in electronics and advanced materials). Nations like China, India, Japan, and South Korea are significantly increasing their research infrastructure and industrial production, leading to a sharp rise in EM adoption and, consequently, a robust demand for sophisticated sample preparation tools and consumables.

From a segmentation perspective, the consumables segment consistently holds a significant revenue share due to their recurrent purchase nature, directly correlating with increasing volumes of EM studies globally. Among specific techniques, advanced methods such as cryo-electron microscopy preparation are experiencing particularly rapid growth, fundamentally transforming structural biology by enabling unprecedented insights into biological macromolecules in their near-native state. Focused Ion Beam (FIB) milling techniques are also gaining substantial traction for their ability to perform precise, site-specific sample preparation for materials science and semiconductor failure analysis. End-user contributions are primarily from the life sciences and materials science sectors, which remain predominant revenue contributors. However, accelerating growth is also observed in the semiconductor and electronics industry, driven by the imperative for nanoscale defect detection, quality assurance, and the relentless pursuit of miniaturization in microchip fabrication, all of which are critically dependent on precise electron microscopy and its specialized sample preparation requirements.

AI Impact Analysis on Electron Microscope Sample Preparation Market

Users frequently inquire about the transformative potential of artificial intelligence within the intricate realm of electron microscope sample preparation. Common questions revolve around AI's capacity to automate traditionally manual and highly skill-dependent steps, thereby improving consistency, enhancing reproducibility, and ultimately elevating the quality of prepared samples for various EM applications. There is keen interest in AI's role in optimizing complex preparation parameters, such as ideal section thickness in ultramicrotomy, precise milling conditions in FIB, or optimal vitrification rates in cryo-EM, parameters that currently rely heavily on expert experience and trial-and-error. Users anticipate that AI could significantly mitigate human error, unlock new possibilities for difficult-to-prepare samples, and accelerate scientific discovery and industrial quality control by making EM analysis more efficient and accessible. Concerns often include the substantial initial investment costs, the necessity for specialized AI expertise, and ensuring robust data integrity and ethical considerations within this highly sensitive domain where precision is paramount.

- AI-driven automation of repetitive sample preparation tasks, such as automated grid loading and cryo-plunging, significantly reducing manual intervention and human error.

- Machine learning algorithms optimizing preparation parameters (e.g., thinning rates, coating thickness, freezing conditions) for different sample types, predicting ideal settings.

- Enhanced quality control and predictive analysis utilizing AI to identify and correct sample defects before imaging, allowing for immediate adjustments.

- Faster data acquisition and processing by integrating AI with image analysis pipelines, enabling immediate assessment of sample quality and guiding further preparation.

- Development of smart instruments capable of self-calibrating and adapting preparation protocols to different sample types or desired analytical outcomes.

- Advanced algorithms for reconstruction of 3D sample volumes from serial sections or tomographic data, improving accuracy and reducing post-processing time.

- Reduced need for extensive expert training by providing AI-guided workflows, intelligent troubleshooting, and virtual simulation tools for practicing complex techniques.

- Prediction of optimal cryo-EM grid conditions, including ice thickness and particle distribution, crucial for improving the efficiency and success rate of single-particle analysis.

DRO & Impact Forces Of Electron Microscope Sample Preparation Market

The Electron Microscope Sample Preparation Market is primarily driven by continuous technological advancements in electron microscopy, including the proliferation of higher-resolution instruments and specialized techniques like Cryo-EM and Focused Ion Beam (FIB)-SEM. These innovations necessitate increasingly specialized and precise sample preparation methods capable of preserving intricate details and presenting samples in their native states. Increasing research and development (R&D) activities across critical sectors such as life sciences, materials science, nanotechnology, and semiconductor manufacturing further fuel demand for high-resolution imaging and detailed structural analysis. The growing need for sophisticated quality control, failure analysis, and fundamental discovery across diverse high-tech industries, where electron microscopy provides unparalleled insights into nanoscale defects and material properties, also significantly contributes to market expansion. Rising global investments in academic and industrial research, coupled with government initiatives supporting scientific innovation, create a conducive environment for sustained market growth.

However, the market faces significant restraints, including the exceptionally high initial capital investment required for acquiring not only state-of-the-art electron microscopes but also their equally sophisticated and often expensive sample preparation equipment. This substantial financial barrier can be prohibitive for smaller research institutions or nascent companies, limiting broader market penetration. Compounding this challenge is the inherent complexity of many sample preparation workflows, which demand a high degree of technical expertise, extensive training, and often years of experience to master. This need for highly skilled personnel, coupled with the time-consuming and labor-intensive nature of many techniques, contributes to elevated operational costs and can hinder widespread adoption. Furthermore, the delicate nature of some samples and the persistent potential for introducing artifacts during the preparation process remain critical issues, necessitating continuous innovation in gentler and more reliable methods.

Despite these challenges, substantial opportunities exist within the Electron Microscope Sample Preparation Market that promise future growth. The burgeoning scientific and industrial landscape in emerging economies, particularly across Asia Pacific and parts of Latin America, presents significant untapped potential as these regions invest heavily in establishing advanced research infrastructures and industrial capabilities. The ongoing trend towards automation and the integration of artificial intelligence (AI) and machine learning (ML) algorithms into sample preparation workflows represents a transformative opportunity. These technologies can simplify complex processes, enhance reproducibility, reduce manual labor, and accelerate throughput, making EM more accessible and efficient. The development of correlative microscopy techniques, combining EM with light microscopy, also presents growth avenues. Furthermore, the relentless pursuit of understanding increasingly complex biological and material systems at the atomic scale will continue to drive innovation in this vital segment. Impact forces such as rapid technological obsolescence, stringent regulatory standards for biological sample handling, and global economic conditions influencing research funding directly affect market dynamics, requiring manufacturers to continuously innovate and adapt to evolving user needs and external pressures.

Segmentation Analysis

The Electron Microscope Sample Preparation Market is intricately segmented across various dimensions to provide a detailed understanding of its complex structure and diverse offerings. This comprehensive segmentation allows for a granular analysis of market trends, identifying key growth areas, competitive landscapes, and evolving customer needs within specific product categories, techniques, and end-user applications. Such an approach is essential for strategic planning, product development, and targeted marketing efforts, as the requirements for preparing biological samples fundamentally differ from those for advanced materials or semiconductor devices. The market's offerings are thus tailored to ensure optimal preparation for a wide range of analytical objectives, from visualizing cellular organelles to characterizing crystallographic defects, enabling researchers and industries to achieve the highest possible resolution and accuracy from their electron microscopy endeavors, thereby driving scientific and industrial progress.

- By Product: This segment differentiates between the capital equipment and the recurring consumables essential for EM sample preparation.

- Instruments: Comprises the sophisticated machinery integral to the preparation process.

- Ultramicrotomes: Devices for cutting extremely thin sections of biological and material samples.

- Ion Mills (Focused Ion Beam & Broad Ion Beam): Systems for precise material removal, thinning, and cross-sectioning.

- Sputter Coaters & Carbon Evaporators: Used to deposit conductive metallic or carbon layers on non-conductive samples.

- Critical Point Dryers: Equipment for drying delicate biological samples while preserving their ultrastructure.

- Plasma Cleaners: Devices for removing organic contamination from samples and specimen holders.

- Cryo-EM Sample Preparation Tools: Includes high-pressure freezers, automated plungers, and cryo-transfer systems for vitrifying biological specimens.

- Consumables: The expendable materials regularly purchased for ongoing preparation work.

- Grids: Fine mesh supports for holding prepared specimens (e.g., copper, carbon film grids).

- Embedding Resins: Materials for embedding samples to provide structural support for sectioning.

- Fixatives & Stains: Chemical agents used in biological preparation for preserving structure and enhancing contrast.

- Filaments & Apertures: Components of electron microscopes that require periodic replacement.

- Specimen Holders: Diverse holders designed for specific sample types and EM techniques.

- Freezing Agents & Cryo-Protectants: Used in cryo-preparation to prevent ice crystal formation.

- Instruments: Comprises the sophisticated machinery integral to the preparation process.

- By Technique: This segment categorizes the market based on the specific methodologies employed to prepare samples, each suited for different materials and analytical goals.

- Ultramicrotomy: Involves precise slicing of samples into nanometer-thick sections, including both room temperature and cryo-ultramicrotomy.

- Ion Milling: Utilizes beams of ions (e.g., argon, gallium) to precisely thin or etch samples, crucial for creating electron-transparent regions or cross-sections, encompassing Broad Ion Beam (BIB) and Focused Ion Beam (FIB) techniques.

- Cryo-Preparation: Techniques like high-pressure freezing and vitrification aim to rapidly freeze biological samples, preserving their native hydration and avoiding ice crystal damage, particularly vital for cryo-EM.

- Sputter Coating: A vacuum deposition technique to coat non-conductive samples with a thin layer of metal (e.g., gold, platinum) to prevent charging and enhance signal in SEM.

- Plasma Cleaning: Uses plasma to gently remove organic contaminants from samples and specimen holders, improving image quality and analytical accuracy.

- Critical Point Drying (CPD): A method to dry delicate biological specimens by replacing water with an intermediate fluid and then with liquid CO2, brought past its critical point to prevent surface tension collapse.

- Chemical Etching & Polishing: Chemical or electrochemical methods used primarily in materials science to selectively remove material or reveal specific microstructures.

- By End-User: This segment identifies the diverse industries and research sectors that are the primary consumers of EM sample preparation products and services.

- Life Sciences: Encompasses biotechnology & pharmaceutical companies, academic & government research institutes, and clinical & diagnostic laboratories using EM for cellular biology, virology, pathology, and drug discovery.

- Materials Science: Includes industries and research focused on metallurgy, polymers, ceramics, composites, and nanomaterials, where EM is essential for microstructural analysis, defect characterization, and material development.

- Semiconductors & Electronics: A crucial sector utilizing EM for failure analysis, process control, quality assurance, and R&D in microelectronics, integrated circuits, and advanced device fabrication.

- Industrial: Covers a broad range of applications in automotive, aerospace, forensics, environmental analysis, and manufacturing for quality control, failure investigation, and research.

Value Chain Analysis For Electron Microscope Sample Preparation Market

The value chain for the Electron Microscope Sample Preparation Market commences with upstream activities involving the meticulous sourcing and manufacturing of raw materials and precision components. This includes high-purity metals for grids, specialized optical and electronic elements for instruments, advanced polymers for embedding, and a wide array of high-grade chemical reagents and biological fixatives. These inputs are rigorously selected and undergo stringent quality control to meet the exacting standards required for electron microscopy applications, where even trace impurities can lead to significant artifacts. Intensive research and development (R&D) is a crucial upstream activity, where manufacturers, often collaborating with academic pioneers and scientific partners, invest heavily in developing novel sample preparation techniques and optimizing existing methodologies, driving innovation in solutions that address emerging scientific challenges and technological demands, such as cryo-EM advancements or automated sample processing.

Midstream activities focus on the manufacturing and assembly of the diverse product portfolio. This includes the intricate fabrication of sophisticated instruments like ultramicrotomes, ion mills, and cryo-preparation systems, requiring advanced engineering, precision machining, and cleanroom facilities. Concurrently, manufacturers produce a vast array of consumables, such as electron microscopy grids, specialized embedding resins, and biological fixatives. These manufacturing processes demand precision, reproducibility, and strict quality assurance to ensure that every component and consumable performs reliably under the demanding conditions of electron microscopy. The integration of advanced electronics, sophisticated software control systems, and ergonomic designs is also a key aspect of this stage, aimed at enhancing user experience, workflow efficiency, and the overall performance of the sample preparation solutions in a highly competitive landscape.

Downstream activities are primarily concerned with bringing these specialized products to the end-users and providing comprehensive post-sales support. Distribution channels typically employ a hybrid model: major manufacturers often utilize direct sales teams for their high-value, complex instrumentation, allowing for personalized technical consultation, tailored solutions, and direct customer relationships. This direct approach is essential for products requiring extensive installation, training, and ongoing specialized support. Simultaneously, a robust network of specialized distributors and resellers plays a crucial role in providing broader market access for both instruments and consumables, reaching a wider customer base globally and offering localized support and faster delivery. The ultimate end-users鈥攚hich include academic research institutions, biotechnology and pharmaceutical companies, materials science laboratories, and semiconductor manufacturers鈥攖hen integrate these products into their microscopy workflows. Post-sales services, encompassing professional installation, extensive user training, preventative maintenance contracts, calibration services, and rapid technical support, are indispensable for ensuring the optimal performance, longevity, and uptime of high-precision equipment, maximizing customer satisfaction and safeguarding the significant investments made by researchers and industries in advanced electron microscopy capabilities.

Electron Microscope Sample Preparation Market Potential Customers

The Electron Microscope Sample Preparation Market caters to a highly specialized and diverse customer base, primarily composed of entities engaged in advanced scientific research, industrial innovation, and quality control that necessitate nanoscale insights. A cornerstone customer segment is academic and government research institutions globally, including universities, national laboratories, and publicly funded research centers. These organizations are driven by the pursuit of fundamental scientific discovery across biology, chemistry, physics, and materials science, requiring a wide array of preparation techniques ranging from routine sectioning for cellular imaging to highly specialized cryo-preparation for structural biology, and precise thinning for advanced material characterization. They frequently invest in state-of-the-art EM facilities, demanding access to the latest instruments and a continuous supply of high-quality consumables to support their ongoing and often publicly funded research projects.

Another critically important customer segment is the life sciences industry, encompassing biotechnology and pharmaceutical companies, alongside clinical and diagnostic laboratories. In this sector, electron microscopy sample preparation is indispensable for drug discovery and development, where it aids in visualizing drug-target interactions, understanding cellular pathology, and characterizing nanoparticles for drug delivery. Pathologists rely on EM for ultrastructural diagnosis of diseases, while virologists utilize it to study viral morphology and infection mechanisms. The precision and detail offered by EM, facilitated by expert sample preparation, are crucial for validating findings from other analytical techniques and providing definitive structural evidence. These commercial entities require reliable, reproducible, and often high-throughput preparation solutions to meet rigorous research timelines and regulatory compliance standards.

Furthermore, the materials science and engineering sectors represent a substantial customer base, including industries focused on metallurgy, polymers, ceramics, advanced composites, and nanomaterials. Companies within these fields utilize electron microscopy for microstructural analysis, quality assurance of raw materials and finished products, failure analysis of components, and research into novel material properties. For instance, automotive and aerospace industries employ EM to characterize advanced alloys and composites, ensuring their structural integrity and performance under extreme conditions. The semiconductor and electronics industry forms another vital segment, where EM is essential for nanoscale defect analysis, process monitoring during the fabrication of integrated circuits, and the development of next-generation electronic devices. The imperative for miniaturization and flawless performance in microchips drives consistent demand for ultra-precise sample preparation techniques, such as focused ion beam (FIB) milling, to isolate specific regions of interest for subsequent high-resolution imaging. Other industrial applications like forensics and environmental analysis also contribute to the customer landscape, each with unique sample preparation challenges demanding tailored solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 850 Million |

| Market Forecast in 2032 | USD 1.5 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific Inc., Carl Zeiss AG, JEOL Ltd., Hitachi High-Tech Corporation, Leica Microsystems (Danaher Corporation), Gatan, Inc. (AMETEK, Inc.), Agar Scientific Ltd., Quorum Technologies Ltd., EMS Catalog (Electron Microscopy Sciences), Denton Vacuum LLC, SPI Supplies (Structure Probe, Inc.), Ted Pella, Inc., Cressington Scientific Instruments Ltd., Oxford Instruments plc, Bruker Corporation, Tescan Orsay Holding a.s., NanoScope Services, Inc., Delong Instruments, RMC Boeckeler, Microsocpy & Analysis. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electron Microscope Sample Preparation Market Key Technology Landscape

The electron microscope sample preparation market is shaped by a dynamic technological landscape, driven by increasingly sophisticated EM instruments and demands for higher resolution, throughput, and artifact-free analysis. A cornerstone of this evolution is the continuous refinement of focused ion beam (FIB) technology, often integrated with scanning electron microscopes (SEM) to form FIB-SEM systems. These hybrid instruments offer unparalleled capabilities for site-specific, precise material removal, creating electron-transparent lamellae for TEM analysis, and enabling comprehensive 3D reconstruction of complex microstructures and nanoscale devices. Advancements in ion beam sources, detector technology, and automation software within FIB platforms are constantly expanding their utility across materials science, geology, and semiconductor failure analysis.

Another pivotal area of innovation lies in cryo-electron microscopy (cryo-EM) sample preparation techniques, which have fundamentally transformed structural biology. Key technologies here include high-pressure freezing (HPF) and automated vitrification systems, which rapidly cool biological samples under high pressure or by plunging into liquid ethane. These methods preserve samples in their near-native, hydrated state without the formation of damaging ice crystals, allowing groundbreaking visualization of delicate macromolecules, viruses, and cellular organelles at atomic resolution. Furthermore, advancements in ultramicrotomy, including cryo-ultramicrotomy, are crucial for sectioning both biological and material samples into ultra-thin slices for TEM analysis, with innovations focusing on improved knife materials (e.g., diamond), precision motorized stages, and vibration isolation to achieve superior cutting quality and reproducibility, even for challenging soft or brittle specimens.

Beyond these, technological progress extends to ancillary but critical areas. Sputter coating and carbon coating technologies offer improved uniformity and adhesion for conductive layer deposition on non-conductive samples, essential for mitigating charging effects in SEM and enhancing signal-to-noise ratios. Plasma cleaning systems are increasingly sophisticated, utilizing various gas mixtures and controlled plasma environments to gently and effectively remove organic contamination from samples and specimen holders, thereby improving image quality and analytical accuracy for both SEM and TEM. The broader trend towards automation and integration of digital control systems across preparation instruments is paramount, encompassing automated parameter setting, robotic sample handling, and real-time feedback mechanisms. These advancements collectively reduce manual variability, significantly increase throughput, and simplify complex workflows, making advanced EM sample preparation more accessible and pushing the boundaries in nanoscale characterization and scientific discovery.

Regional Highlights

- North America: This region consistently dominates the Electron Microscope Sample Preparation Market, driven by its robust scientific research ecosystem, substantial investments in R&D by both government and private sectors, and the early adoption of cutting-edge microscopy technologies. The presence of numerous leading academic institutions, major biotechnology and pharmaceutical companies, and advanced semiconductor manufacturing hubs, particularly in the United States, fuels a continuous demand for sophisticated sample preparation solutions. The emphasis on innovation and the availability of significant research funding further solidify North America's position as a market leader, promoting the development and deployment of the latest EM preparation techniques and instruments.

- Europe: As a well-established market, Europe demonstrates strong growth, characterized by extensive academic research, significant governmental support for scientific endeavors, and a high concentration of key electron microscopy and sample preparation manufacturers. Countries such as Germany, the United Kingdom, and France are at the forefront of materials science, life sciences, and industrial research, leading to a sustained demand for advanced preparation techniques. European researchers are particularly active in fields like structural biology (cryo-EM) and advanced materials characterization, necessitating continuous innovation in sample preparation workflows and instruments.

- Asia Pacific (APAC): The Asia Pacific region is rapidly emerging as the fastest-growing market segment, propelled by escalating governmental investments in scientific and technological advancement, rapid industrialization, and the burgeoning expansion of manufacturing sectors, particularly in electronics, automotive, and advanced materials. Countries like China, Japan, India, and South Korea are significantly increasing their research infrastructure, establishing new universities and research institutes, and fostering strong domestic industries. This surge in R&D activities and industrial production translates into a sharp rise in the adoption of electron microscopy and, consequently, a robust demand for sophisticated sample preparation tools and consumables.

- Latin America: This region exhibits steady and promising growth, driven by increasing investments in scientific research and education, coupled with the development of industrial sectors. Countries such as Brazil, Mexico, and Argentina are gradually enhancing their research infrastructure and fostering collaborations with international scientific communities. The growing focus on materials characterization in mining and automotive industries, along with expanding biotechnology research, contributes to the demand for electron microscope sample preparation, albeit at a slower pace compared to more established regions.

- Middle East and Africa (MEA): The MEA region is showing gradual but consistent growth, primarily influenced by strategic governmental initiatives aimed at economic diversification through science, technology, and innovation. Countries like Saudi Arabia, the UAE, and South Africa are investing in establishing modern research facilities and industrial parks, attracting international scientific talent, and developing local expertise. This creates a nascent but growing demand for electron microscopy and its associated sample preparation techniques, particularly in oil and gas, materials research, and healthcare sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electron Microscope Sample Preparation Market.- Thermo Fisher Scientific Inc.

- Carl Zeiss AG

- JEOL Ltd.

- Hitachi High-Tech Corporation

- Leica Microsystems (Danaher Corporation)

- Gatan, Inc. (AMETEK, Inc.)

- Agar Scientific Ltd.

- Quorum Technologies Ltd.

- EMS Catalog (Electron Microscopy Sciences)

- Denton Vacuum LLC

- SPI Supplies (Structure Probe, Inc.)

- Ted Pella, Inc.

- Cressington Scientific Instruments Ltd.

- Oxford Instruments plc

- Bruker Corporation

- Tescan Orsay Holding a.s.

- NanoScope Services, Inc.

- Delong Instruments

- RMC Boeckeler

- Microsocpy & Analysis

Frequently Asked Questions

Analyze common user questions about the Electron Microscope Sample Preparation market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is electron microscope sample preparation and why is its precision crucial?

EM sample preparation involves transforming a specimen into a suitable form for high-resolution electron imaging. Precision is crucial because samples must be stable, clean, conductive, and often extremely thin to prevent artifacts, preserve native structures, and ensure optimal electron beam interaction, ultimately yielding accurate, high-contrast nanoscale images.

What are the most commonly utilized advanced techniques for EM sample preparation?

Common advanced techniques include ultramicrotomy for ultrathin sectioning of materials and biological samples, focused ion beam (FIB) milling for precise material removal, cryo-preparation (high-pressure freezing, vitrification) for preserving delicate biological structures in their native state, and sputter coating for conductive layer deposition on non-conductive samples, enhancing SEM image quality.

How is Artificial Intelligence (AI) expected to revolutionize EM sample preparation workflows?

AI is projected to revolutionize EM sample preparation by automating repetitive steps, optimizing complex parameters via machine learning, and enhancing real-time quality control to mitigate artifacts. This promises increased reproducibility, reduced human error, faster throughput, and lower skill barriers, making advanced EM more accessible and accelerating scientific discovery across various disciplines.

Which industries and research sectors are the primary end-users of EM sample preparation products?

Primary end-users include academic and government research institutions (life sciences, materials science, nanotechnology), biotechnology and pharmaceutical companies (drug discovery, pathology), materials science industries (polymers, metals, ceramics), and the semiconductor and electronics industry (failure analysis, R&D for microchips). Each relies on EM for critical nanoscale insights and quality control.

What are the key challenges in current electron microscope sample preparation, and how are they being addressed?

Key challenges involve high equipment costs, labor-intensive workflows, the need for specialized expertise, and the potential for introducing artifacts. These are being addressed through advancements in automation, AI integration for optimization and quality control, development of user-friendly interfaces, and continuous innovation in less invasive and more precise techniques like next-generation cryo-EM tools for improved efficiency and reliability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager