Enterprise Manufacturing Intelligence Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431283 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Enterprise Manufacturing Intelligence Market Size

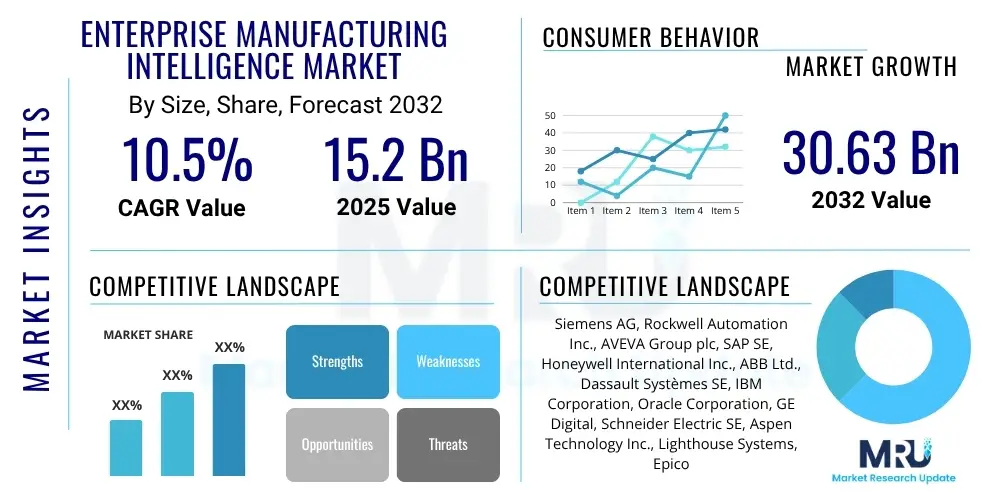

The Enterprise Manufacturing Intelligence Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2025 and 2032. The market is estimated at USD 15.2 Billion in 2025 and is projected to reach USD 30.63 Billion by the end of the forecast period in 2032.

Enterprise Manufacturing Intelligence Market introduction

The Enterprise Manufacturing Intelligence (EMI) market encompasses a specialized category of software solutions and services designed to collect, aggregate, analyze, and visualize data from various manufacturing operations across an enterprise. This robust system provides a holistic view of production processes, quality control, asset performance, and overall operational efficiency, enabling manufacturers to make data-driven decisions. EMI solutions integrate disparate data sources such as SCADA, MES, ERP, and IoT devices, transforming raw data into actionable insights for continuous improvement.

The core product within this market involves advanced analytical platforms that offer functionalities like real-time dashboards, reporting, predictive analytics, and prescriptive guidance. Major applications span across optimizing production schedules, enhancing product quality and compliance, improving equipment utilization through predictive maintenance, and streamlining supply chain operations. By consolidating crucial manufacturing data, EMI helps organizations identify bottlenecks, reduce waste, and improve resource allocation, leading to significant operational enhancements.

The primary benefits of adopting EMI include increased operational efficiency, reduced manufacturing costs, enhanced product quality, improved regulatory compliance, and greater agility in responding to market demands. Key driving factors propelling this market forward are the pervasive adoption of Industry 4.0 initiatives, the escalating demand for real-time operational visibility, the imperative for digital transformation across manufacturing sectors, and the growing competitive landscape necessitating optimized production processes and faster time-to-market.

Enterprise Manufacturing Intelligence Market Executive Summary

The Enterprise Manufacturing Intelligence market is experiencing robust growth, driven by a global push towards digitalization and smart factory initiatives. Business trends indicate a significant shift towards cloud-based EMI solutions, offering enhanced scalability and accessibility, particularly for multi-site and geographically dispersed manufacturing operations. There is also a growing emphasis on integrating advanced analytics, artificial intelligence, and machine learning capabilities into EMI platforms to unlock deeper insights and enable predictive and prescriptive actions, moving beyond mere historical reporting. This trend is shaping the competitive landscape, fostering innovation, and prompting solution providers to offer more comprehensive and integrated platforms.

Regional trends highlight the Asia Pacific (APAC) region as a key growth engine, fueled by rapid industrialization, expansion of manufacturing bases, and government support for digital transformation in countries like China, India, and Japan. North America and Europe, while more mature markets, continue to demonstrate strong adoption rates due to advanced technological infrastructure, high labor costs necessitating automation, and stringent regulatory environments demanding meticulous operational oversight. These regions are leading in the adoption of cutting-edge EMI functionalities, including AI-driven insights and digital twin integration, further solidifying their market positions.

Segment trends reveal that the software component continues to dominate the market share, with a growing demand for specialized modules tailored for specific industry verticals and functionalities such as quality management and asset performance management. The services segment, encompassing implementation, consulting, and support, is also projected for substantial growth as manufacturers require expert assistance in deploying and optimizing complex EMI systems. Deployment trends show a clear acceleration in the adoption of cloud-based EMI solutions over traditional on-premises deployments, reflecting a broader industry migration towards flexible, scalable, and cost-effective cloud infrastructure for managing manufacturing data and operations.

AI Impact Analysis on Enterprise Manufacturing Intelligence Market

Common user questions regarding AI's impact on the Enterprise Manufacturing Intelligence Market frequently revolve around how artificial intelligence enhances decision-making, improves operational efficiency, and facilitates predictive capabilities. Users are keen to understand the practical applications of AI in areas such as quality control, maintenance, and process optimization, while also expressing concerns about data privacy, integration complexities, and the skills gap required to leverage these advanced technologies effectively. The overarching themes include the desire for deeper, more autonomous insights, the potential for significant cost reductions, and the transformation of traditional manufacturing workflows into more intelligent, self-optimizing systems. Users expect AI to move EMI beyond descriptive analytics to truly prescriptive and adaptive intelligence.

- AI enhances predictive maintenance by analyzing sensor data to anticipate equipment failures, reducing downtime.

- It enables advanced quality control by identifying anomalies and defects in real-time, improving product consistency.

- AI optimizes production processes through machine learning algorithms that identify inefficiencies and suggest improvements.

- It facilitates autonomous operations by enabling machines to learn and adapt, leading to self-optimizing manufacturing lines.

- AI improves decision-making by providing prescriptive insights based on complex data analysis, guiding strategic and tactical choices.

- It supports energy optimization by identifying patterns in energy consumption and suggesting adjustments to reduce waste.

- AI streamlines supply chain synchronization by forecasting demand more accurately and optimizing inventory levels.

DRO & Impact Forces Of Enterprise Manufacturing Intelligence Market

The Enterprise Manufacturing Intelligence market is significantly shaped by a confluence of drivers, restraints, and opportunities that collectively determine its growth trajectory and adoption rates. A primary driver is the accelerating trend of Industry 4.0 adoption, pushing manufacturers to integrate advanced technologies for digital transformation, where EMI serves as a crucial backbone for data centralization and analysis. The escalating need for operational efficiency, cost reduction, and improved resource utilization in a highly competitive global manufacturing landscape further propels the demand for EMI solutions. Additionally, the increasing complexity of modern manufacturing processes, coupled with the imperative for real-time visibility into production performance and stringent regulatory compliance requirements, are powerful forces driving market expansion.

However, several restraints impede the market's full potential. The high initial investment required for implementing sophisticated EMI systems, including hardware, software, and integration costs, can be a significant barrier for small and medium-sized enterprises (SMEs). Data interoperability challenges, stemming from disparate systems and legacy infrastructure across factories, often complicate the seamless integration of EMI solutions. Concerns regarding cybersecurity, data privacy, and intellectual property protection also pose considerable hurdles, as manufacturing data is highly sensitive. Furthermore, a persistent shortage of skilled personnel capable of deploying, managing, and interpreting insights from advanced EMI platforms limits adoption in some regions.

Despite these challenges, substantial opportunities exist for market growth and innovation. The deepening integration of EMI with emerging technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and Digital Twin technology promises to unlock unprecedented levels of insight and automation, creating new value propositions. The growing preference for cloud-based EMI solutions offers scalability, reduced infrastructure costs, and enhanced accessibility, particularly attractive to SMEs and enterprises seeking greater agility. Moreover, the expanding focus on sustainability and green manufacturing practices presents an opportunity for EMI to play a pivotal role in optimizing energy consumption and reducing waste. Finally, the underserved market of SMEs represents a vast potential customer base that can be tapped with more accessible and cost-effective EMI offerings.

Segmentation Analysis

The Enterprise Manufacturing Intelligence market is comprehensively segmented across various dimensions to provide a granular understanding of its structure and growth dynamics. These segments reflect the diverse ways in which EMI solutions are consumed, deployed, applied, and adopted across different industrial verticals, offering crucial insights into market trends and future opportunities. Analyzing these segments helps stakeholders understand specific market demands, technological preferences, and the varying levels of maturity across different user groups, allowing for targeted product development and market strategies. Each segment plays a vital role in shaping the overall market landscape and contributes distinctly to its growth trajectory.

- By Component

- Software: Includes core EMI platforms, analytics modules, reporting tools, and visualization interfaces.

- Services: Encompasses consulting, implementation, training, maintenance, and support services.

- By Deployment Model

- On-premises: Solutions installed and operated within the client's internal infrastructure.

- Cloud-based: Hosted on remote servers and accessed via the internet, offering scalability and flexibility.

- By Application

- Process Optimization: Focuses on improving manufacturing workflows and efficiency.

- Quality and Compliance Management: Ensures product quality standards and adherence to regulations.

- Asset and Performance Management: Monitors and optimizes equipment utilization and lifespan.

- Production Monitoring and Tracking: Provides real-time visibility into production status and progress.

- Inventory and Supply Chain Management: Optimizes material flow and stock levels.

- Other Applications: Includes energy management, workforce management, and environmental monitoring.

- By Industry Vertical

- Automotive: For vehicle production, assembly, and component manufacturing.

- Food and Beverage: For process optimization, quality control, and traceability.

- Chemicals: For batch processing, safety, and regulatory compliance.

- Pharmaceuticals and Life Sciences: For stringent quality control, validation, and regulatory adherence.

- Metals and Mining: For operational efficiency in raw material processing and extraction.

- Electronics and Semiconductors: For high-volume, high-precision manufacturing.

- Aerospace and Defense: For complex assembly, quality assurance, and traceability.

- Oil and Gas: For process monitoring, asset performance, and safety in operations.

- Other Manufacturing Industries: Including textiles, packaging, and industrial machinery.

Value Chain Analysis For Enterprise Manufacturing Intelligence Market

The value chain for the Enterprise Manufacturing Intelligence market involves a sophisticated interplay of various stakeholders, spanning from technology development to end-user implementation and ongoing support. At the upstream level, the chain begins with core technology providers responsible for developing foundational components such as advanced analytics engines, big data platforms, IoT connectivity solutions, and specialized software modules. These entities lay the groundwork by offering the technological infrastructure and capabilities necessary for EMI solutions to function effectively, often involving research and development in areas like AI, machine learning, and cloud computing. Hardware manufacturers also form a crucial part of the upstream segment by providing the necessary sensors, industrial control systems, and data acquisition devices that feed information into EMI platforms.

Moving downstream, the value chain extends to solution integrators and specialized consulting firms that play a pivotal role in customizing, deploying, and integrating EMI systems within complex manufacturing environments. These partners bridge the gap between generic software offerings and the unique operational requirements of individual manufacturers, ensuring seamless data flow and functionality across diverse legacy systems and modern infrastructure. The distribution channel is multifaceted, comprising direct sales forces of large software vendors, value-added resellers (VARs) who offer tailored solutions, and strategic partners who often combine EMI with other enterprise software like ERP or MES to provide comprehensive digital transformation packages. Indirect channels, through a network of channel partners, also contribute significantly to market reach, especially for smaller or niche solution providers.

The final stage of the value chain involves the end-users – manufacturing companies across various industries – who procure, implement, and leverage EMI solutions to enhance their operational intelligence. Post-implementation, the value chain continues with ongoing support, maintenance, and upgrade services provided by the original software vendors or their certified partners. This comprehensive support ensures that EMI systems remain effective, up-to-date, and continue to deliver sustained value. The efficiency of this value chain is critical for the widespread adoption and successful implementation of EMI solutions, highlighting the importance of collaboration and strong partnerships between technology providers, integrators, and end-users to drive innovation and deliver maximum benefit.

Enterprise Manufacturing Intelligence Market Potential Customers

The potential customers for Enterprise Manufacturing Intelligence solutions are diverse and encompass a broad spectrum of manufacturing entities, ranging from large multinational corporations with complex global operations to agile small and medium-sized enterprises (SMEs) seeking to optimize their production processes. Essentially, any organization involved in the physical production of goods, irrespective of their scale or specific industry vertical, stands to benefit significantly from adopting EMI. These end-users are typically production managers, plant operators, quality assurance professionals, supply chain managers, and C-suite executives who require granular, real-time insights into manufacturing performance to make informed decisions.

Industries such as automotive, pharmaceuticals, food and beverage, chemicals, electronics, metals and mining, and aerospace and defense represent major buyer segments due to their inherent complexity, high volume production, stringent quality requirements, and regulatory pressures. Companies in these sectors are constantly striving to improve operational efficiency, reduce waste, enhance product quality, ensure compliance, and achieve greater agility in response to market demands. The drive for digital transformation and the adoption of Industry 4.0 paradigms are primary motivators for these potential customers to invest in EMI, as it serves as a foundational technology for achieving smart factory objectives and unlocking competitive advantages in a globalized market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 15.2 Billion |

| Market Forecast in 2032 | USD 30.63 Billion |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, Rockwell Automation Inc., AVEVA Group plc, SAP SE, Honeywell International Inc., ABB Ltd., Dassault Systèmes SE, IBM Corporation, Oracle Corporation, GE Digital, Schneider Electric SE, Aspen Technology Inc., Lighthouse Systems, Epicor Software Corporation, Parsec Automation Corp., PSI Metals GmbH, InfinityQS International Inc., MPDV Mikrolab GmbH, Werum IT Solutions GmbH, TrakSYS by Parsec |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Enterprise Manufacturing Intelligence Market Key Technology Landscape

The Enterprise Manufacturing Intelligence market is underpinned by a rapidly evolving technological landscape, leveraging a suite of advanced tools and platforms to deliver its core functionalities. Central to EMI is the effective utilization of Big Data Analytics, which involves processing vast volumes of diverse manufacturing data from various sources to uncover patterns, correlations, and trends that drive actionable insights. This capability is complemented by robust Internet of Things (IoT) technologies, which enable the pervasive collection of real-time data from shop floor machinery, sensors, and operational equipment, forming the bedrock of EMI's data-driven approach. The integration of IoT allows for continuous monitoring and remote data acquisition, essential for comprehensive operational visibility.

Cloud Computing plays a transformative role in the EMI market by providing scalable, flexible, and cost-effective infrastructure for data storage, processing, and application hosting. Cloud-based EMI solutions facilitate easier deployment, maintenance, and accessibility, enabling manufacturers to scale their intelligence capabilities without significant upfront capital investment in on-premises hardware. Furthermore, the incorporation of Machine Learning (ML) and Artificial Intelligence (AI) algorithms is increasingly prevalent, moving EMI beyond descriptive analytics to predictive and prescriptive capabilities. These AI/ML components allow systems to learn from historical data, anticipate future outcomes like equipment failures or quality deviations, and even suggest optimal courses of action, fostering a more proactive and autonomous manufacturing environment.

Additionally, the EMI landscape extensively utilizes Digital Twin technology, creating virtual replicas of physical assets, processes, or entire factories. These digital twins receive real-time data from their physical counterparts, allowing for sophisticated simulations, performance monitoring, and predictive analysis in a virtual environment before implementing changes in the real world. Integration with existing Manufacturing Execution Systems (MES) and Supervisory Control and Data Acquisition (SCADA) systems is also crucial, as EMI layers on top of these operational technologies to aggregate and analyze their data, providing a higher-level view of enterprise-wide manufacturing performance. These intertwined technologies collectively empower EMI platforms to deliver comprehensive operational intelligence and drive continuous improvement across the manufacturing value chain.

Regional Highlights

The global Enterprise Manufacturing Intelligence market exhibits distinct growth patterns and adoption rates across various key regions, influenced by industrial development, technological readiness, economic conditions, and regulatory environments. Each region contributes uniquely to the market's overall dynamics, reflecting different stages of digital transformation and manufacturing priorities. Understanding these regional nuances is critical for market players to tailor their strategies and investments effectively.

- North America: Characterized by early adoption of advanced manufacturing technologies, robust R&D investment, and a strong presence of key EMI vendors. The region benefits from a mature industrial base and a high demand for operational efficiency and automation, particularly in automotive, aerospace, and pharmaceutical sectors.

- Europe: Driven by initiatives like Industry 4.0 and smart factory mandates, emphasizing sustainable manufacturing, circular economy principles, and stringent quality standards. Germany, France, and the UK are leading adopters, focusing on process optimization and regulatory compliance.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, expanding manufacturing bases (e.g., China, India, Southeast Asia), and increasing government support for digital transformation. Cost optimization and production scalability are key drivers, with significant investments in new smart factories.

- Latin America: An emerging market for EMI, with growing awareness and adoption in industries such as automotive, food and beverage, and mining. Economic development and the need to enhance global competitiveness are driving factors, though infrastructure and investment challenges persist.

- Middle East and Africa (MEA): Showing nascent but significant growth, particularly in oil and gas, petrochemicals, and diversified manufacturing sectors. Governments are investing in economic diversification and industrial modernization, creating opportunities for EMI solutions focused on asset performance and operational visibility.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Enterprise Manufacturing Intelligence Market.- Siemens AG

- Rockwell Automation Inc.

- AVEVA Group plc

- SAP SE

- Honeywell International Inc.

- ABB Ltd.

- Dassault Systèmes SE

- IBM Corporation

- Oracle Corporation

- GE Digital

- Schneider Electric SE

- Aspen Technology Inc.

- Lighthouse Systems

- Epicor Software Corporation

- Parsec Automation Corp.

- PSI Metals GmbH

- InfinityQS International Inc.

- MPDV Mikrolab GmbH

- Werum IT Solutions GmbH

- TrakSYS by Parsec

Frequently Asked Questions

What is Enterprise Manufacturing Intelligence (EMI)?

Enterprise Manufacturing Intelligence (EMI) is a software-driven approach that collects, aggregates, and analyzes data from various manufacturing operations across an entire enterprise. It provides real-time visibility and actionable insights into production performance, quality, asset utilization, and compliance, enabling data-driven decision-making for continuous improvement.

How does EMI benefit manufacturers?

EMI offers significant benefits, including increased operational efficiency, reduced manufacturing costs, enhanced product quality, improved regulatory compliance, and greater agility in responding to market demands. It helps identify bottlenecks, optimize processes, predict equipment failures, and streamline the supply chain.

What are the key components of an EMI system?

Key components typically include data acquisition and integration modules (connecting to MES, SCADA, ERP, IoT), a centralized data repository, advanced analytics and reporting tools, real-time dashboards for visualization, and often modules for predictive analytics or AI-driven insights. Services for implementation and support are also integral.

Is cloud deployment common for EMI solutions?

Yes, cloud deployment is increasingly common for EMI solutions. Cloud-based EMI offers enhanced scalability, reduced infrastructure costs, greater flexibility, and improved accessibility, making it particularly attractive for manufacturers with multiple sites or those seeking a more agile and modern IT infrastructure.

How does EMI relate to Industry 4.0?

EMI is a foundational element of Industry 4.0. It provides the necessary framework for data collection, analysis, and intelligent decision-making that characterizes smart factories. By integrating data from connected devices and systems, EMI enables the real-time operational intelligence required for concepts like predictive maintenance, adaptive manufacturing, and autonomous operations inherent to Industry 4.0.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager