Epoxy Surface Coatings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430000 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Epoxy Surface Coatings Market Size

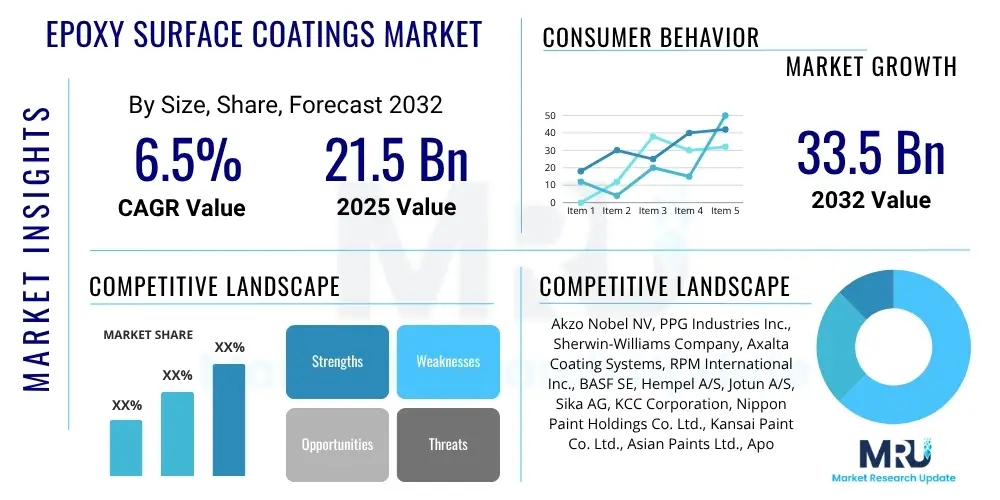

The Epoxy Surface Coatings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 21.5 billion in 2025 and is projected to reach USD 33.5 billion by the end of the forecast period in 2032.

Epoxy Surface Coatings Market introduction

The Epoxy Surface Coatings Market encompasses a wide range of protective and decorative coatings formulated using epoxy resins. These coatings are renowned for their exceptional adhesion, durability, chemical resistance, and high performance, making them indispensable across various industrial and commercial applications. Epoxy coatings are typically two-part systems consisting of an epoxy resin and a hardener, which react chemically to form a rigid, cross-linked polymer film, offering superior protection to surfaces against abrasion, corrosion, and chemical exposure.

Major applications for epoxy surface coatings span across flooring systems, protective coatings for industrial equipment, marine vessels, automotive components, and structural steel in construction. Their versatility allows for customization in terms of color, texture, and specific performance properties, such as anti-slip or anti-static features. The inherent benefits include enhanced surface longevity, reduced maintenance costs, improved aesthetics, and robust resistance to harsh environmental conditions, making them a preferred choice over traditional coating solutions in demanding environments.

Key driving factors for the growth of this market include rapid industrialization, particularly in emerging economies, increasing infrastructure development projects globally, and a growing emphasis on asset protection and longevity across diverse sectors. Furthermore, stringent regulatory requirements concerning industrial safety and environmental protection are fueling demand for high-performance and durable coating solutions that minimize the need for frequent recoating and repair.

Epoxy Surface Coatings Market Executive Summary

The global Epoxy Surface Coatings Market is poised for substantial growth, driven by robust expansion in end-use industries such as construction, automotive, marine, and industrial manufacturing. Business trends indicate a strong focus on sustainable and eco-friendly formulations, including low VOC (Volatile Organic Compound) and water-based epoxy coatings, in response to evolving environmental regulations and increasing consumer demand for safer products. Innovations in nanotechnology and smart coatings are also shaping the market, leading to products with enhanced properties like self-healing capabilities, improved anti-corrosion performance, and advanced thermal resistance. Strategic mergers, acquisitions, and collaborations among key players are prevalent, aimed at expanding product portfolios, enhancing technological capabilities, and strengthening market presence across various regions.

Regionally, Asia Pacific continues to dominate the market, largely due to rapid urbanization, significant infrastructure investments, and burgeoning manufacturing activities, particularly in countries like China and India. North America and Europe demonstrate mature markets characterized by stringent regulatory landscapes driving the adoption of advanced, high-performance, and environmentally compliant epoxy systems. Emerging markets in Latin America, the Middle East, and Africa are also expected to exhibit considerable growth, fueled by industrial development projects and increasing foreign investments in manufacturing and infrastructure sectors.

From a segmentation perspective, industrial applications, especially in protective coatings for heavy machinery, pipelines, and storage tanks, represent a significant share. The construction sector, driven by demand for durable and aesthetic flooring and wall coatings, is another major contributor. Additionally, the automotive and marine industries continue to rely heavily on epoxy coatings for corrosion protection and enhanced durability of vehicles and vessels. Future growth is anticipated in specialized segments like aerospace and electronics, where high-performance epoxy formulations are crucial for specific component protection and performance requirements.

AI Impact Analysis on Epoxy Surface Coatings Market

User inquiries concerning AI's influence on the Epoxy Surface Coatings Market frequently revolve around how artificial intelligence can optimize formulation, improve application processes, enhance quality control, and contribute to the development of novel materials. Key themes indicate user expectations for AI to streamline research and development, predict material performance more accurately, and enable predictive maintenance for coated assets. There is a strong interest in AI's role in creating more sustainable and efficient coating solutions, reducing waste, and improving the overall longevity and performance of epoxy-coated surfaces. Concerns often touch upon the initial investment costs, the complexity of integrating AI systems into existing manufacturing workflows, and the need for skilled personnel to manage these advanced technologies.

- AI driven formulation optimization for desired performance characteristics, reducing R&D cycles.

- Predictive analytics for raw material sourcing and supply chain management, minimizing disruptions.

- Enhanced quality control through AI powered visual inspection systems, detecting defects with high precision.

- Optimization of application processes (e.g., spray coating robots) for uniform thickness and reduced material waste.

- Development of smart coatings with AI integrated sensors for real time monitoring of coating integrity and performance.

- Predictive maintenance schedules for assets based on AI analysis of coating degradation, extending asset lifespan.

- Personalized coating solutions and customization based on specific client requirements and environmental conditions.

- Market trend analysis and demand forecasting using AI algorithms, informing production strategies.

DRO & Impact Forces Of Epoxy Surface Coatings Market

The Epoxy Surface Coatings Market is primarily driven by the escalating demand from various end-use industries, including building and construction, automotive, industrial, and marine. Rapid urbanization and industrialization in developing countries are leading to significant investments in infrastructure development, which in turn fuels the need for high-performance protective coatings. The superior properties of epoxy coatings, such as excellent adhesion, chemical resistance, abrasion resistance, and durability, make them highly desirable for extending the lifespan of assets and reducing maintenance costs, thus serving as a crucial driving force. Furthermore, continuous technological advancements in product formulation, including the development of low VOC and eco-friendly coatings, are broadening their application scope and attracting new market segments.

Despite the strong growth drivers, the market faces certain restraints. Volatility in the prices of raw materials, such as bisphenol A and epichlorohydrin, which are key components in epoxy resin production, significantly impacts manufacturing costs and profit margins. Strict environmental regulations pertaining to VOC emissions and hazardous substances pose challenges for manufacturers, necessitating continuous investment in research and development for compliant and sustainable product formulations. Additionally, the availability of alternative coating technologies, while not always offering the same performance profile, can introduce competitive pressures and limit market penetration in certain price-sensitive applications. The skilled labor required for proper application of some advanced epoxy systems also presents a constraint in certain regions.

Opportunities in the Epoxy Surface Coatings Market primarily lie in the increasing demand for sustainable and high-performance solutions, particularly in emerging economies. The development of smart coatings with functionalities like self-healing, anti-corrosion, and antimicrobial properties presents significant growth avenues. Furthermore, expansion into niche applications such as aerospace, electronics, and medical devices, where specialized epoxy coatings are crucial, offers lucrative prospects. Strategic collaborations and partnerships between raw material suppliers, coating manufacturers, and end-users can foster innovation and accelerate market penetration. The rising trend of renovation and repair activities in mature markets also provides a consistent demand for epoxy solutions. The impact forces influencing the market are multifaceted, encompassing global economic growth, which directly affects industrial output and construction spending, environmental regulations that shape product development and market acceptance, technological innovation driving new product introductions, and shifting consumer preferences towards durable and aesthetically pleasing finishes.

Segmentation Analysis

The Epoxy Surface Coatings Market is extensively segmented to reflect the diverse applications, formulations, and end-use industries that utilize these high-performance materials. This comprehensive segmentation allows for a granular understanding of market dynamics, growth drivers within specific niches, and the varying demands of different customer groups. The market can be broadly categorized by product type, application method, end-use industry, and resin type, each representing distinct characteristics and market opportunities. Understanding these segments is crucial for strategic planning, product development, and targeted marketing efforts by market participants.

- By Type:

- Water based Epoxy Coatings

- Solvent based Epoxy Coatings

- Powder Epoxy Coatings

- Solvent free Epoxy Coatings

- By Application:

- Flooring Coatings

- Wall Coatings

- Protective Coatings

- Adhesive Coatings

- Tank Linings

- Marine Coatings

- Automotive Coatings

- By End Use Industry:

- Building and Construction

- Industrial (Manufacturing, Oil and Gas, Power Generation)

- Automotive

- Marine

- Aerospace

- Electrical and Electronics

- Consumer Goods

- Others (e.g., Healthcare, Sports Facilities)

- By Resin Type:

- Bisphenol A based Epoxy Resins

- Novolac based Epoxy Resins

- Aliphatic Epoxy Resins

- Glycidyl Amine Epoxy Resins

- By Curing Agent:

- Amines

- Polyamides

- Anhydrides

- Thiols

- Others

Value Chain Analysis For Epoxy Surface Coatings Market

The value chain for the Epoxy Surface Coatings Market begins with the upstream segment, which primarily involves the procurement and processing of raw materials. Key raw materials include epoxy resins (derived from epichlorohydrin and bisphenol A), curing agents (such as amines, polyamides, and anhydrides), diluents, pigments, and various additives like fillers, flow modifiers, and stabilizers. Major chemical manufacturers and petrochemical companies form the backbone of this upstream segment, providing these essential components to coating formulators. The quality, availability, and cost fluctuations of these raw materials significantly impact the final product pricing and manufacturing efficiency of epoxy coatings.

Moving downstream, the value chain encompasses the manufacturing and formulation of epoxy coatings by specialized chemical companies and coating producers. These manufacturers develop a wide range of products tailored for specific applications and performance requirements. Following manufacturing, the products enter various distribution channels, which can be broadly categorized into direct and indirect sales. Direct distribution involves manufacturers selling directly to large industrial clients, major construction companies, or government agencies, often facilitated by a dedicated sales force and technical support team. This approach allows for direct communication, customization, and stronger client relationships, particularly for specialized or large-volume orders.

Indirect distribution involves leveraging a network of third-party distributors, wholesalers, and retailers to reach a broader customer base, including smaller contractors, individual applicators, and specialized retailers. This channel is crucial for market penetration in diverse geographical regions and for catering to smaller-scale projects. Online platforms are also emerging as significant distribution channels, offering convenience and broader reach. Ultimately, the end-users, such as construction companies, industrial manufacturers, automotive assembly plants, marine operators, and infrastructure developers, purchase and apply these coatings. The efficiency of this value chain, from raw material sourcing to end-user application, is critical for delivering high-quality, cost-effective epoxy surface coatings to the global market.

Epoxy Surface Coatings Market Potential Customers

The potential customers for epoxy surface coatings are incredibly diverse, spanning across nearly every major industrial and commercial sector due to the coatings' versatile protective and aesthetic properties. Building and construction companies represent a significant customer segment, utilizing epoxy coatings extensively for industrial and commercial flooring, wall protection in healthcare and food processing facilities, and protective coatings for concrete structures. Their demand is driven by the need for durable, easy-to-clean, and chemically resistant surfaces that can withstand heavy traffic and harsh conditions.

Industrial manufacturers, particularly those in heavy machinery, petrochemicals, power generation, and manufacturing plants, are crucial end-users. These industries rely on epoxy coatings for corrosion protection of equipment, pipelines, storage tanks, and structural steel, which are exposed to aggressive chemicals, high temperatures, and abrasive environments. The longevity and protective capabilities offered by epoxy coatings are paramount for ensuring operational efficiency and asset integrity in these demanding industrial settings.

Other significant customer segments include the automotive industry, which uses epoxy primers and coatings for vehicle components to enhance corrosion resistance and paint adhesion, and the marine industry, where epoxy coatings are vital for protecting ships, offshore platforms, and port infrastructure from saltwater corrosion and biofouling. Additionally, aerospace, electronics, and even consumer goods manufacturers seek specialized epoxy formulations for various applications, including electronic component encapsulation, aircraft fuselage protection, and durable finishes for household appliances. Infrastructure developers and maintenance contractors also form a substantial customer base, constantly requiring epoxy solutions for roads, bridges, public facilities, and renovation projects to ensure long-term durability and safety.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 21.5 billion |

| Market Forecast in 2032 | USD 33.5 billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Akzo Nobel NV, PPG Industries Inc., Sherwin-Williams Company, Axalta Coating Systems, RPM International Inc., BASF SE, Hempel A/S, Jotun A/S, Sika AG, KCC Corporation, Nippon Paint Holdings Co. Ltd., Kansai Paint Co. Ltd., Asian Paints Ltd., Apogee Enterprises Inc., National Paint Products, Covestro AG, DIC Corporation, Evonik Industries AG, Momentive Performance Materials Inc., Olin Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Epoxy Surface Coatings Market Key Technology Landscape

The Epoxy Surface Coatings Market is characterized by a dynamic technological landscape driven by continuous innovation aimed at enhancing performance, improving sustainability, and meeting evolving regulatory standards. A significant trend is the development of advanced formulation techniques that focus on reducing Volatile Organic Compounds (VOCs) and hazardous air pollutants (HAPs). This includes the widespread adoption of water-based, high-solids, and solvent-free epoxy systems, which offer environmental benefits without compromising on crucial properties like durability and chemical resistance. These technologies are critical for compliance with increasingly stringent environmental regulations globally, particularly in developed regions.

Furthermore, nanotechnology is playing an increasingly vital role in augmenting the properties of epoxy coatings. The incorporation of nanomaterials such as graphene, carbon nanotubes, and silica nanoparticles into epoxy formulations can significantly improve mechanical strength, scratch resistance, barrier properties against corrosion, and UV stability. This allows for the development of coatings that offer superior protection and extended service life, even in highly aggressive environments. Such advancements are particularly valuable in sectors like marine, aerospace, and industrial infrastructure where extreme conditions are prevalent.

Another emerging area is the development of smart coatings and functionalized epoxies. These innovative coatings integrate advanced functionalities such as self-healing capabilities, anti-fouling properties for marine applications, anti-microbial surfaces for healthcare and food processing, and active corrosion protection through embedded sensors or smart pigments. UV-curable epoxy systems are also gaining traction due to their rapid curing times, which translate into higher productivity and reduced energy consumption in industrial processes. These technological shifts are not only addressing performance demands but also contributing to more efficient and sustainable manufacturing and application processes across various end-use industries.

Regional Highlights

- North America: This region represents a mature yet robust market for epoxy surface coatings, driven by significant investment in infrastructure repair and maintenance, particularly in the United States and Canada. Stringent regulatory frameworks for environmental protection and industrial safety are fostering the adoption of advanced, high-performance, and low-VOC epoxy formulations. The automotive, construction, and manufacturing sectors are key consumers, with a consistent demand for durable and protective coatings. Technological advancements and the presence of major industry players further stabilize market growth.

- Europe: The European market for epoxy surface coatings is characterized by strong emphasis on sustainability and innovation. Countries like Germany, the UK, and France are leading in the adoption of eco-friendly and high-performance epoxy systems due to strict REACH regulations and a strong commitment to green building practices. The region's mature industrial base, coupled with renovation and refurbishment activities in the construction sector, ensures steady demand. Research and development activities focusing on smart coatings and nanotechnology integration are prominent here.

- Asia Pacific (APAC): Asia Pacific stands as the largest and fastest-growing market for epoxy surface coatings. This growth is primarily attributed to rapid industrialization, urbanization, and large-scale infrastructure projects in countries such as China, India, Japan, and South Korea. The expanding manufacturing sector, coupled with booming construction activities, especially in residential and commercial buildings, significantly fuels the demand for epoxy coatings. Increasing foreign investments and a growing middle class also contribute to the market expansion in this dynamic region.

- Latin America: The Latin American market for epoxy surface coatings is experiencing gradual but steady growth. Countries like Brazil, Mexico, and Argentina are witnessing increased industrial and construction activities, albeit with varying economic stability. Investments in oil and gas infrastructure, mining, and public works are driving the demand for protective epoxy coatings. The region presents opportunities for market players to expand their footprint as industrial development continues.

- Middle East and Africa (MEA): The MEA region is emerging as a promising market, primarily driven by substantial investments in construction, particularly in the Gulf Cooperation Council (GCC) countries, and ongoing oil and gas projects. Urban development, tourism infrastructure, and industrial expansion in countries like Saudi Arabia, UAE, and South Africa are creating a significant demand for high-performance epoxy coatings. Economic diversification efforts in these nations are further boosting the market for various industrial and architectural applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Epoxy Surface Coatings Market.- Akzo Nobel NV

- PPG Industries Inc.

- Sherwin-Williams Company

- Axalta Coating Systems

- RPM International Inc.

- BASF SE

- Hempel A/S

- Jotun A/S

- Sika AG

- KCC Corporation

- Nippon Paint Holdings Co. Ltd.

- Kansai Paint Co. Ltd.

- Asian Paints Ltd.

- Apogee Enterprises Inc.

- National Paint Products

- Covestro AG

- DIC Corporation

- Evonik Industries AG

- Momentive Performance Materials Inc.

- Olin Corporation

Frequently Asked Questions

What are the primary benefits of using epoxy surface coatings?

Epoxy surface coatings offer exceptional durability, superior chemical resistance, high adhesion, and abrasion resistance. They provide excellent protection against corrosion, enhance the aesthetic appeal of surfaces, and contribute to extended asset lifespan, significantly reducing maintenance costs in various demanding environments.

Which industries are the largest consumers of epoxy surface coatings?

The largest consumers of epoxy surface coatings include the building and construction industry (for flooring and protective applications), industrial manufacturing (for equipment and structural protection), automotive industry (for corrosion resistance), and the marine industry (for vessel protection).

How do environmental regulations impact the epoxy surface coatings market?

Environmental regulations, particularly those concerning VOC emissions and hazardous substances, significantly influence the market by driving demand for eco-friendly alternatives such as water-based, high-solids, and solvent-free epoxy coatings. Manufacturers must innovate to comply with these standards, pushing for more sustainable product development.

What technological advancements are shaping the future of epoxy coatings?

Key technological advancements include the integration of nanotechnology for enhanced mechanical and barrier properties, the development of smart coatings with self-healing or anti-corrosion functionalities, and the expansion of UV-curable and low-VOC formulations. These innovations aim to improve performance, efficiency, and environmental compliance.

What is the projected growth rate for the Epoxy Surface Coatings Market?

The Epoxy Surface Coatings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032, driven by increasing demand from diverse end-use industries and ongoing technological advancements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager