Explosion-proof Lighting Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429922 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Explosion-proof Lighting Market Size

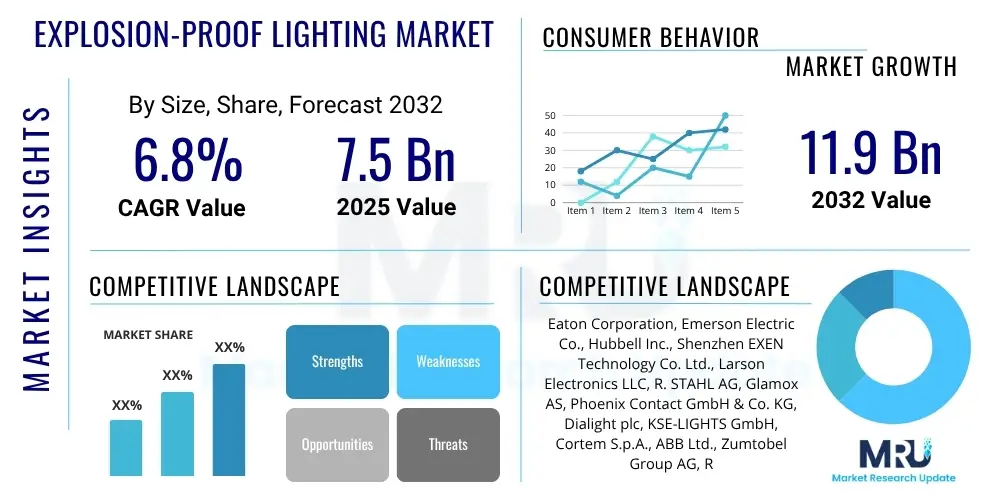

The Explosion-proof Lighting Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 7.5 billion in 2025 and is projected to reach USD 11.9 billion by the end of the forecast period in 2032.

Explosion-proof Lighting Market introduction

The Explosion-proof Lighting Market encompasses specialized illumination solutions designed to operate safely in environments containing flammable gases, vapors, combustible dust, or fibers. These hazardous locations, commonly found in industries such as oil and gas, mining, chemical, and pharmaceutical, pose significant risks of explosions if standard lighting equipment generates sparks, heat, or fails in other ways. The core product in this market is an explosion-proof light fixture, engineered to contain any internal explosion and prevent ignition of the surrounding hazardous atmosphere, or to operate at surface temperatures below the ignition temperature of the external hazardous material. These sophisticated lighting systems are critical for ensuring worker safety, operational continuity, and compliance with stringent international safety regulations.

Major applications for explosion-proof lighting span across diverse sectors where hazardous conditions are inherent. This includes offshore oil rigs, refineries, petrochemical plants, underground mines, grain processing facilities, paint spray booths, and pharmaceutical manufacturing sites. The primary benefits of implementing these lighting solutions are enhanced safety for personnel and assets, prevention of catastrophic industrial incidents, and reduced downtime due to equipment failure or regulatory non-compliance. These systems are typically robust, durable, and designed to withstand harsh industrial conditions, offering long operational lifespans and lower maintenance requirements compared to conventional lighting in such demanding environments. The increasing global focus on industrial safety, coupled with stringent regulatory frameworks and the expansion of hazardous industries, are key driving factors propelling the growth of this specialized market.

Furthermore, the continuous technological advancements in LED lighting, which offer superior energy efficiency, longer lifespans, and reduced heat emission, are significantly influencing market dynamics. These innovations allow for the development of more compact, powerful, and durable explosion-proof lighting fixtures that meet the evolving demands of various hazardous classified locations. The rising adoption of smart lighting solutions, integrating remote monitoring and control capabilities, also presents new opportunities for market expansion, enhancing operational efficiency and safety management. As industries increasingly prioritize worker well-being and environmental protection, the demand for reliable and high-performance explosion-proof lighting solutions is expected to maintain a robust upward trajectory.

Explosion-proof Lighting Market Executive Summary

The Explosion-proof Lighting Market is poised for significant expansion, driven by escalating safety mandates and industrial growth in hazardous environments worldwide. Business trends indicate a strong shift towards LED-based explosion-proof solutions, valued for their energy efficiency, durability, and reduced maintenance needs. Manufacturers are focusing on developing products that comply with global certification standards such as ATEX, IECEx, and UL, enabling broader market penetration and ensuring product integrity across diverse geographies. Strategic partnerships and mergers and acquisitions are also prominent, as companies seek to consolidate market share, expand technological capabilities, and strengthen distribution networks to serve a growing base of industrial clients. The market is also witnessing an increase in customization requests to meet specific operational requirements and environmental challenges, fostering innovation in product design and functionality.

Regional trends highlight the Asia Pacific as a rapidly growing market, propelled by expanding industrial infrastructure in countries like China and India, particularly in oil and gas, chemical, and manufacturing sectors. North America and Europe, while mature, continue to hold substantial market shares due to stringent safety regulations and ongoing investments in industrial upgrades and modernization projects. Emerging economies in Latin America, the Middle East, and Africa are also contributing to market growth, driven by increasing exploration and production activities in the energy sector. These regions present significant opportunities for market players to introduce advanced explosion-proof lighting technologies and establish robust supply chains, catering to a diverse range of industrial safety requirements and operational scales.

From a segmentation perspective, LED technology dominates the market due to its inherent advantages over traditional lighting types, including superior lumen output, extended operational life, and lower power consumption. The oil and gas sector remains the largest application area, given the volatile nature of its operations, necessitating stringent safety protocols and robust lighting solutions. However, other sectors like mining, chemical and pharmaceutical, and food and beverage processing are also experiencing substantial growth in the adoption of explosion-proof lighting as industrial automation and safety standards become more pervasive. Demand is particularly high for fixtures classified for Zone 1 and Zone 2 hazardous areas, indicating a strong focus on primary prevention and risk mitigation in highly combustible environments. This comprehensive growth across technologies, applications, and regions underscores the market's robust health and future potential.

AI Impact Analysis on Explosion-proof Lighting Market

Users are increasingly questioning how artificial intelligence will integrate with and enhance explosion-proof lighting systems, focusing on aspects like predictive maintenance, adaptive illumination, and remote diagnostics. Common themes revolve around the potential for AI to optimize energy consumption, improve operational safety through smart monitoring, and reduce the frequency of manual inspections in hazardous zones. There is significant interest in understanding how AI can enable these systems to become more autonomous, responsive to environmental changes, and capable of identifying potential risks before they escalate. Concerns often touch upon the complexity of integrating AI in safety-critical environments, data security, and the reliability of AI algorithms in potentially extreme operating conditions, while expectations are high for breakthroughs in efficiency, safety, and system longevity.

- AI can enable predictive maintenance by analyzing operational data from lighting fixtures, anticipating potential failures, and scheduling maintenance proactively, minimizing downtime and enhancing safety.

- Integration with smart sensors allows AI to adjust light intensity and color temperature based on real-time environmental conditions, improving visibility and worker comfort while optimizing energy use in hazardous areas.

- AI-powered analytics can monitor anomalies in lighting performance, heat signatures, or gas concentrations, providing early warnings of potential hazards and enabling rapid response to mitigate risks.

- Remote diagnostic capabilities leveraging AI algorithms allow for troubleshooting and performance optimization without physically entering hazardous zones, reducing exposure risks for maintenance personnel.

- AI can facilitate compliance and reporting by automating data collection on lighting system performance and environmental conditions, ensuring adherence to safety regulations and simplifying audit processes.

- Enhanced security features, through AI-driven anomaly detection in surveillance integrated with lighting, can identify unauthorized access or unusual activities in hazardous industrial settings.

- AI-driven optimization of power distribution networks for explosion-proof lighting can lead to significant energy savings and improved grid stability, especially in large industrial complexes.

DRO & Impact Forces Of Explosion-proof Lighting Market

The Explosion-proof Lighting Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, all contributing to its overall impact forces. Key drivers include stringent industrial safety regulations imposed by global and regional authorities, mandating the use of certified explosion-proof equipment in hazardous environments. The continuous expansion of industries like oil and gas, petrochemicals, mining, and chemical manufacturing, particularly in developing economies, further fuels demand. Additionally, technological advancements, especially in LED lighting, offering enhanced energy efficiency, longer lifespan, and superior durability compared to traditional lighting solutions, act as a strong impetus for market growth. Increased awareness among industrial operators regarding the benefits of workplace safety and the high costs associated with industrial accidents also serves as a crucial driver.

However, the market also faces notable restraints. The high initial investment cost associated with explosion-proof lighting systems, due to their specialized design, robust construction, and stringent certification requirements, can be a barrier for small and medium-sized enterprises (SMEs). The complexity of installation and maintenance, requiring specialized knowledge and trained personnel, also adds to operational costs. Furthermore, the fragmented nature of regulatory standards across different regions can create challenges for manufacturers in achieving universal compliance, potentially limiting market reach and increasing product development complexities. Economic slowdowns or volatility in key end-user industries, such as a decline in crude oil prices impacting oil and gas exploration, can also temporarily curb market growth.

Despite these challenges, substantial opportunities exist for market expansion and innovation. The growing trend of industrial automation and the adoption of smart factory concepts present avenues for integrating explosion-proof lighting with advanced control systems and IoT platforms, enhancing operational efficiency and predictive maintenance capabilities. The increasing demand for energy-efficient solutions drives innovation in product development, such as solar-powered explosion-proof lights for remote hazardous locations. Furthermore, the expansion into new application areas, including wastewater treatment plants, aerospace facilities, and specialized marine environments, offers untapped market potential. The continuous development of lighter, more compact, and more powerful explosion-proof lighting solutions will also unlock new market segments and drive adoption across various hazardous industrial settings, ensuring sustained market expansion throughout the forecast period.

Segmentation Analysis

The Explosion-proof Lighting Market is comprehensively segmented across various parameters, including product type, protection method, area type, and application, providing a detailed view of its intricate structure and diverse demands. This segmentation allows for a granular analysis of market dynamics, revealing specific growth drivers and emerging opportunities within each category. Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for end-users to select the most appropriate lighting solutions for their specific hazardous environments. The market exhibits distinct preferences and requirements across these segments, driven by technological advancements, regulatory mandates, and operational exigencies.

- By Type

- LED (Light Emitting Diode) Lighting

- Fluorescent Lighting

- Incandescent Lighting

- High-Intensity Discharge (HID) Lighting

- Other Types (e.g., Halogen)

- By Protection Method

- Flameproof/Explosion-proof Enclosure (Ex d)

- Intrinsic Safety (Ex i)

- Pressurization (Ex p)

- Increased Safety (Ex e)

- Oil Immersion (Ex o)

- Powder Filling (Ex q)

- Type N Protection (Ex n)

- By Area Type

- Hazardous Area

- Zone 0/Class I, Division 1 (Continuous presence of hazardous material)

- Zone 1/Class I, Division 1 (Likely presence of hazardous material during normal operation)

- Zone 2/Class I, Division 2 (Presence of hazardous material not likely during normal operation)

- Class II, Division 1 (Combustible dust likely)

- Class II, Division 2 (Combustible dust not likely)

- Class III, Division 1 (Ignitable fibers/flyings likely)

- Class III, Division 2 (Ignitable fibers/flyings not likely)

- Non-Hazardous Area (General purpose lighting in industrial settings adjacent to hazardous zones, often requiring robust industrial-grade solutions)

- Hazardous Area

- By Application/End-Use Industry

- Oil and Gas (Upstream, Midstream, Downstream)

- Mining (Coal, Metal, Non-Metal)

- Chemical and Pharmaceutical

- Manufacturing and Industrial Facilities

- Food and Beverage Processing

- Marine and Offshore

- Aerospace and Defense

- Power Generation

- Wastewater Treatment

- Others (e.g., Grain Processing, Paint Spray Booths)

- By Product Form

- Fixed Lighting (e.g., Bulkheads, High Bays, Floodlights, Linear Lights)

- Portable Lighting (e.g., Hand Lamps, Work Lights, Spotlights)

- Emergency Lighting

Value Chain Analysis For Explosion-proof Lighting Market

The value chain for the Explosion-proof Lighting Market is intricate, beginning with the upstream supply of raw materials and specialized components. This stage involves suppliers of high-grade metals like aluminum and stainless steel for housing, tempered glass for lenses, and advanced electronic components such as LED chips, drivers, and control modules. The stringent requirements for explosion-proof certification necessitate sourcing materials that meet specific thermal, mechanical, and electrical resistance standards. Upstream activities also include the research and development of new technologies and materials to enhance product performance, durability, and energy efficiency, ensuring compliance with evolving safety regulations and market demands.

Moving downstream, the value chain progresses through the manufacturing and assembly of explosion-proof lighting fixtures, followed by rigorous testing and certification processes by accredited bodies such as UL, ATEX, and IECEx. Manufacturers invest heavily in specialized facilities and expertise to design products that contain potential explosions or operate at safe surface temperatures. The distribution channel plays a critical role, encompassing both direct and indirect sales. Direct sales often involve large industrial clients or specific project tenders where manufacturers engage directly to provide customized solutions and technical support. Indirect channels typically involve a network of specialized industrial distributors, electrical wholesalers, and system integrators who have expertise in hazardous area equipment and provide broader market reach to diverse end-users, including SMEs.

After-sales services, including installation guidance, maintenance, and warranty support, constitute a crucial part of the downstream value chain, ensuring the long-term safety and performance of these critical lighting systems. Logistics and transportation, often involving specialized handling for industrial equipment, are also integral to delivering products to various global locations. The effectiveness of the value chain is highly dependent on strong collaboration between raw material suppliers, component manufacturers, finished product manufacturers, certification bodies, and distribution partners to deliver reliable, compliant, and cost-effective explosion-proof lighting solutions to end-users across hazardous industries worldwide, emphasizing safety and operational efficiency at every stage.

Explosion-proof Lighting Market Potential Customers

Potential customers for explosion-proof lighting products are primarily end-users operating in industries where flammable gases, vapors, combustible dusts, or ignitable fibers are present in quantities sufficient to create an explosion or fire hazard. These environments necessitate lighting equipment specifically designed and certified to prevent ignition. The largest segment of buyers typically includes operators in the oil and gas industry, encompassing upstream exploration and production facilities, midstream pipelines and storage terminals, and downstream refineries and petrochemical plants. These entities prioritize safety and regulatory compliance above all else, making explosion-proof lighting an indispensable part of their operational infrastructure. The continuous investment in new projects and the upgrading of existing facilities within this sector consistently drive demand for high-performance, durable lighting solutions.

Beyond the energy sector, other significant end-users include mining companies, particularly those involved in coal, metal, and non-metal mining, where methane gas and combustible dust are common hazards. Chemical and pharmaceutical manufacturers also represent a substantial customer base, given the handling of volatile organic compounds and fine powders in their production processes. Manufacturing and heavy industrial facilities that deal with solvents, paints, or fine particulate matter, such as automotive paint booths or grain processing plants, also require specialized explosion-proof illumination. Food and beverage processing plants, particularly those handling combustible dusts from ingredients like flour or sugar, are increasingly adopting these lights to ensure safety and hygiene while complying with ATEX and other regional safety standards for dust hazardous locations.

Furthermore, marine and offshore applications, including container ships, drilling rigs, and port facilities, require robust explosion-proof lighting capable of withstanding corrosive saltwater environments and hazardous gas presence. Power generation facilities, especially those utilizing fossil fuels or biomass, also constitute important buyers. As safety regulations become more globalized and enforcement strengthens, the customer base expands to any industrial facility where a risk assessment identifies a hazardous area classification, underscoring the universal applicability of these specialized lighting solutions for safeguarding personnel and assets in potentially volatile environments across a wide spectrum of industrial operations. This broad and diverse customer base underscores the critical and indispensable nature of explosion-proof lighting in modern industrial safety protocols.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 7.5 billion |

| Market Forecast in 2032 | USD 11.9 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Eaton Corporation, Emerson Electric Co., Hubbell Inc., Shenzhen EXEN Technology Co. Ltd., Larson Electronics LLC, R. STAHL AG, Glamox AS, Phoenix Contact GmbH & Co. KG, Dialight plc, KSE-LIGHTS GmbH, Cortem S.p.A., ABB Ltd., Zumtobel Group AG, Raytec Global, N.V. Philips, Ocean King Lighting Inc., ABL Lights, Appleton Group (Emerson), Thomas & Betts (ABB), Intertek Group plc (for certification services). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Explosion-proof Lighting Market Key Technology Landscape

The key technology landscape of the Explosion-proof Lighting Market is continuously evolving, primarily driven by advancements in illumination sources and improved methods of explosion protection. Light Emitting Diode (LED) technology stands as the dominant and most impactful innovation, offering significant advantages over traditional incandescent, fluorescent, and High-Intensity Discharge (HID) lamps. LEDs provide superior energy efficiency, consuming substantially less power while delivering higher lumen output. Their extended operational lifespan, often exceeding 50,000 to 100,000 hours, drastically reduces maintenance costs and the frequency of lamp replacements, which is particularly beneficial in hard-to-access hazardous zones. Furthermore, LEDs generate less heat, contributing to safer operation in environments where temperature control is critical, and their robust solid-state design enhances durability against vibration and impact, making them ideal for demanding industrial applications. The compact size of LED modules also allows for more flexible and innovative fixture designs.

Beyond the light source itself, advancements in explosion protection methods are equally crucial. Technologies like flameproof enclosures (Ex d), intrinsic safety (Ex i), and increased safety (Ex e) are continually being refined to meet stricter safety standards and accommodate new materials and designs. Flameproof enclosures are designed to contain an internal explosion and prevent its propagation to the external atmosphere, requiring robust mechanical construction and precise machining. Intrinsic safety focuses on limiting electrical and thermal energy to below ignition thresholds, making it suitable for instrumentation and control systems, and increasingly integrated with low-power LED systems. Increased safety techniques focus on preventing sparks and hot surfaces in normal operation, often involving enhanced insulation and spacing. Material science plays a vital role in developing lighter, stronger, and more corrosion-resistant alloys for housing and advanced optical materials for lenses that maintain integrity under extreme conditions.

Emerging technologies also include the integration of smart lighting features, leveraging IoT connectivity and sensor technology. This involves incorporating sensors for motion detection, ambient light levels, and even gas detection directly into explosion-proof fixtures. These smart features enable adaptive lighting, energy optimization through dimming or switching off lights in unoccupied areas, and real-time monitoring of environmental conditions. Wireless communication protocols, designed for hazardous areas, are facilitating remote control and diagnostics, enhancing safety management and operational efficiency. The development of modular designs and standardized interfaces is also gaining traction, allowing for easier upgrades, maintenance, and customization of explosion-proof lighting systems, further solidifying their indispensable role in industrial safety infrastructure.

Regional Highlights

- North America: This region maintains a significant market share due to mature oil and gas industries, stringent safety regulations (OSHA, NFPA), and continuous infrastructure investments. The U.S. and Canada are leading adopters, driven by refining, chemical processing, and a strong focus on worker safety.

- Europe: Europe is a highly regulated market, with ATEX directives being a primary driver for explosion-proof lighting adoption. Countries like Germany, the UK, and France show high demand, fueled by chemical, pharmaceutical, and manufacturing sectors, alongside a robust maritime industry.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, attributed to rapid industrialization, expanding oil and gas exploration in China, India, and Southeast Asia, and increasing emphasis on industrial safety standards. The region offers immense growth potential for manufacturers.

- Latin America: This region is experiencing growth driven by new oil and gas projects, particularly in Brazil and Mexico, and a burgeoning mining sector. Investments in industrial infrastructure and a growing awareness of international safety norms are key factors.

- Middle East and Africa (MEA): MEA is a crucial market due to its extensive oil and gas reserves and ongoing investments in extraction and processing facilities. Countries like Saudi Arabia, UAE, and Nigeria are significant contributors, with a strong focus on highly robust and reliable explosion-proof solutions for extreme environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Explosion-proof Lighting Market.- Eaton Corporation

- Emerson Electric Co.

- Hubbell Inc.

- Shenzhen EXEN Technology Co. Ltd.

- Larson Electronics LLC

- R. STAHL AG

- Glamox AS

- Phoenix Contact GmbH & Co. KG

- Dialight plc

- KSE-LIGHTS GmbH

- Cortem S.p.A.

- ABB Ltd.

- Zumtobel Group AG

- Raytec Global

- N.V. Philips

- Ocean King Lighting Inc.

- ABL Lights

- Appleton Group (an Emerson brand)

- Thomas & Betts (an ABB brand)

- Chalmit Lighting (a Hubbell company)

Frequently Asked Questions

What is explosion-proof lighting and where is it used?

Explosion-proof lighting refers to specialized light fixtures designed to safely operate in hazardous environments containing flammable gases, vapors, combustible dust, or ignitable fibers. These lights are engineered to prevent any internal spark or heat from igniting the external atmosphere. They are critically used in industries such as oil and gas, chemical and pharmaceutical manufacturing, mining, food processing, and marine environments to ensure worker safety and regulatory compliance.

What are the key differences between explosion-proof and ordinary lighting?

The primary difference lies in their design and certification for hazardous areas. Explosion-proof lighting features robust, sealed enclosures capable of containing an internal explosion or limiting surface temperatures below ignition points, preventing ignition of external flammable substances. Ordinary lighting lacks these protective features and would pose a severe fire or explosion risk in such environments, making them unsuitable and illegal for use in classified hazardous locations.

What certifications are important for explosion-proof lighting?

Key international and regional certifications include ATEX (for Europe), IECEx (international standard), and UL (Underwriters Laboratories, primarily for North America). These certifications ensure that the lighting fixtures have been tested and approved to meet stringent safety standards for use in specific hazardous classified locations, based on the type of hazardous material and its likelihood of presence.

Why is LED technology preferred in explosion-proof lighting?

LED technology is highly preferred due to its superior energy efficiency, consuming less power and offering significantly longer lifespans compared to traditional light sources. LEDs also generate less heat, which is crucial in hazardous environments, and their solid-state design makes them highly durable and resistant to vibration and impact, reducing maintenance and enhancing safety in demanding industrial applications.

What factors should be considered when selecting explosion-proof lighting?

Key factors include the specific hazardous area classification (e.g., Zone 1, Zone 2, Class I Division 1, Class II Division 2), the type of hazardous material present, required lumen output and beam angle, operational temperature range, energy efficiency, ease of installation and maintenance, and relevant international or local certifications. The fixture's durability, resistance to corrosion, and integration capabilities with smart systems should also be evaluated.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager