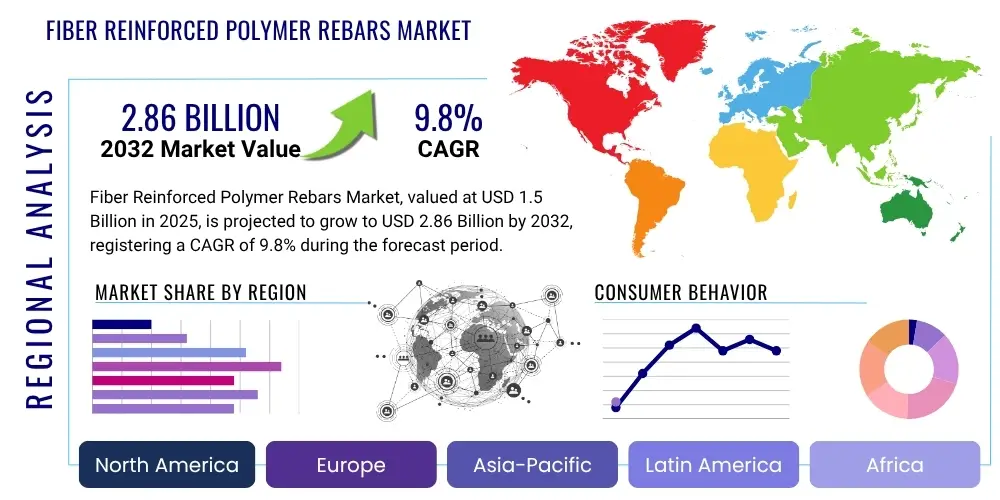

Fiber Reinforced Polymer Rebars Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429067 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Fiber Reinforced Polymer Rebars Market Size

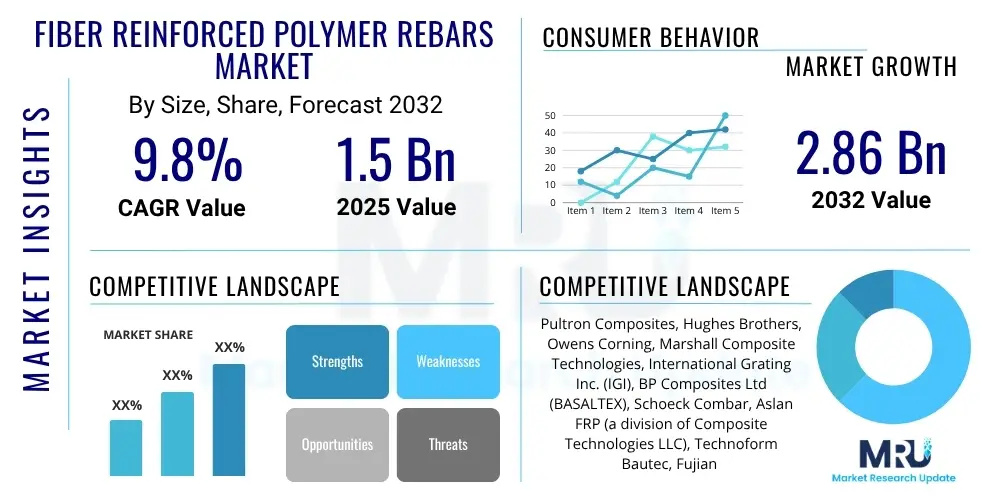

The Fiber Reinforced Polymer Rebars Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2025 and 2032. The market is estimated at USD 1.5 Billion in 2025 and is projected to reach USD 2.86 Billion by the end of the forecast period in 2032.

Fiber Reinforced Polymer Rebars Market introduction

The Fiber Reinforced Polymer (FRP) Rebars Market encompasses the production and application of advanced composite materials used as a non-corrosive alternative to traditional steel reinforcement in concrete structures. FRP rebars are typically made from high-strength fibers such as glass (GFRP), basalt (BFRP), or carbon (CFRP), embedded in a polymer resin matrix. These innovative materials offer superior performance characteristics, including exceptional corrosion resistance, high tensile strength, electromagnetic neutrality, and lightweight properties, making them ideal for challenging environments and specialized applications where steel is prone to degradation.

Major applications for FRP rebars span across critical infrastructure projects, including bridges, roads, marine structures, and tunnels, where resistance to saltwater, de-icing salts, and harsh chemicals is paramount. They are also increasingly adopted in building construction, specifically in hospitals, research facilities, and data centers that require non-magnetic materials, as well as in industrial applications like wastewater treatment plants and chemical processing facilities due to their chemical inertness. The inherent benefits of FRP rebars, such as extended service life, reduced maintenance costs, and improved structural integrity, are driving their adoption globally.

Key driving factors for market growth include escalating global infrastructure spending, particularly in coastal and seismic regions, and a growing emphasis on sustainable and resilient construction practices. The rising awareness among engineers and contractors regarding the long-term economic advantages and superior performance of FRP rebars over conventional steel is further accelerating market expansion. Furthermore, stringent environmental regulations and the push for greener building materials are positively influencing the demand for FRP reinforcement solutions.

Fiber Reinforced Polymer Rebars Market Executive Summary

The Fiber Reinforced Polymer Rebars Market is experiencing robust growth driven by the increasing global demand for durable, corrosion-resistant, and high-performance construction materials. Current business trends indicate a significant shift towards sustainable infrastructure development and rehabilitation projects, where the superior longevity and reduced lifecycle costs of FRP rebars offer a compelling alternative to steel. Manufacturers are focusing on expanding production capacities and investing in research and development to enhance material properties and cost-effectiveness. Strategic partnerships between raw material suppliers, rebar manufacturers, and construction firms are becoming prevalent, aiming to streamline supply chains and promote broader market acceptance.

Regionally, North America and Asia Pacific are leading the market, with substantial infrastructure investments fueling demand. North America benefits from a strong focus on upgrading aging infrastructure and implementing corrosion-resistant solutions, particularly in coastal areas and regions using de-icing salts. Asia Pacific's rapid urbanization, extensive new infrastructure projects, and increasing awareness of advanced construction materials are driving exponential growth. Europe is also showing steady adoption, influenced by strict environmental regulations and a focus on circular economy principles in construction, promoting materials with extended service life and lower environmental impact.

In terms of segments, Glass Fiber Reinforced Polymer (GFRP) rebars currently dominate the market due to their favorable balance of cost and performance, making them suitable for a wide range of applications. However, Basalt Fiber Reinforced Polymer (BFRP) rebars are gaining traction due to their higher temperature resistance and superior tensile strength, while Carbon Fiber Reinforced Polymer (CFRP) rebars, though premium-priced, are sought after for niche applications requiring extremely high strength-to-weight ratios. The application segment for infrastructure, including bridges and marine structures, remains the largest, but the building and industrial sectors are demonstrating significant growth potential as awareness of FRP benefits expands beyond traditional heavy civil engineering projects.

AI Impact Analysis on Fiber Reinforced Polymer Rebars Market

User inquiries concerning AI's influence on the Fiber Reinforced Polymer Rebars Market primarily revolve around questions of efficiency, material optimization, and predictive capabilities across the product lifecycle. Stakeholders are keen to understand how AI can enhance manufacturing processes, improve material design, and optimize supply chain management to reduce costs and increase quality. There is also significant interest in AI's role in predictive maintenance for FRP-reinforced structures and in supporting intelligent design for complex composite applications, addressing concerns about standardization and consistent performance.

The key themes emerging from user questions highlight expectations for AI to solve current challenges in FRP rebar adoption, such as initial cost barriers and complexity in custom design. Users anticipate AI will drive greater precision in quality control during manufacturing, enable more accurate market forecasting, and potentially assist in developing novel hybrid FRP compositions. Furthermore, there is an expectation that AI-driven data analysis will lead to a better understanding of long-term performance and durability, thereby fostering greater confidence and wider acceptance of FRP rebars in diverse construction projects.

- AI-driven optimization of pultrusion and filament winding processes for enhanced efficiency and reduced waste.

- Predictive analytics for raw material procurement and supply chain management, minimizing disruptions and optimizing inventory.

- AI-assisted material design for tailoring FRP rebar properties to specific application requirements, improving performance.

- Machine vision systems for automated quality control during manufacturing, ensuring consistent product standards.

- Development of smart structures incorporating FRP rebars with AI-powered sensors for real-time monitoring and predictive maintenance.

- AI algorithms for market trend analysis and demand forecasting, supporting strategic business decisions.

- Optimization of structural designs using AI to maximize the benefits of FRP rebars in complex engineering projects.

DRO & Impact Forces Of Fiber Reinforced Polymer Rebars Market

The Fiber Reinforced Polymer Rebars Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities that collectively shape its growth trajectory. Key drivers include the inherent superior properties of FRP rebars, such as their exceptional corrosion resistance, which makes them indispensable in environments aggressive to steel, including marine and coastal structures, roads exposed to de-icing salts, and chemical processing plants. The lightweight nature of FRP rebars contributes to easier handling and reduced transportation costs, while their high tensile strength offers comparable or superior structural performance to steel in many applications. Furthermore, significant global investments in infrastructure development and rehabilitation, coupled with growing awareness about the long-term economic and environmental benefits of durable construction materials, are propelling market expansion. The increasing adoption of green building initiatives and stringent regulations regarding material sustainability also favor FRP rebars.

However, the market faces several notable restraints. The primary impediment remains the higher initial cost of FRP rebars compared to conventional steel, which can deter adoption, especially in projects with tight budgetary constraints. Another significant challenge is the limited awareness and understanding among some engineers, contractors, and regulatory bodies regarding the design specifications, installation techniques, and overall performance characteristics of FRP materials. The absence of comprehensive, universally recognized design codes and standards for FRP composites across all regions can also hinder widespread acceptance, leading to slower integration into mainstream construction practices. Additionally, manufacturing complexities and the need for specialized equipment can limit production capacities and scalability for some manufacturers.

Despite these challenges, substantial opportunities exist for market growth. Emerging economies, particularly in Asia Pacific and Latin America, present vast untapped potential due to rapid urbanization and large-scale infrastructure projects. Technological advancements in composite materials, including the development of hybrid FRP rebars and novel resin systems, offer avenues for enhanced performance and cost reduction. The retrofitting and strengthening of existing infrastructure provide a significant niche market, where FRP rebars can extend the lifespan of aging structures. Moreover, increased research and development efforts aimed at reducing production costs, standardizing design guidelines, and educating the construction industry will be crucial in unlocking further market potential. The continuous innovation in manufacturing processes and the exploration of new application areas are poised to drive the market forward.

Segmentation Analysis

The Fiber Reinforced Polymer Rebars Market is segmented to provide a detailed understanding of its various components, categorized by material type, resin type, fiber type, application, end-use industry, and geographical region. This segmentation allows for precise analysis of market trends, growth drivers, and competitive landscapes within each specific sub-market, offering valuable insights for strategic planning and investment decisions. The diverse range of FRP rebar types and their tailored properties cater to a broad spectrum of construction needs, from general building applications to highly specialized infrastructure projects, reflecting the material's versatility and expanding utility.

- By Type:

- Glass Fiber Reinforced Polymer (GFRP) Rebars

- Basalt Fiber Reinforced Polymer (BFRP) Rebars

- Carbon Fiber Reinforced Polymer (CFRP) Rebars

- Aramid Fiber Reinforced Polymer (AFRP) Rebars

- By Resin Type:

- Polyester

- Vinyl Ester

- Epoxy

- Others (e.g., Polyurethane)

- By Fiber Type:

- Glass Fiber

- Basalt Fiber

- Carbon Fiber

- Aramid Fiber

- By Application:

- Bridges & Highway Structures

- Marine & Coastal Structures

- Building Construction (Residential, Commercial, Industrial)

- Water & Wastewater Treatment Plants

- Tunnels & Mining

- Electrical & Industrial Infrastructure

- Others (e.g., Agricultural, Medical Facilities)

- By End-Use Industry:

- Infrastructure

- Building & Construction

- Water & Wastewater Management

- Chemical Processing

- Transportation

- Others

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Fiber Reinforced Polymer Rebars Market

The value chain for the Fiber Reinforced Polymer Rebars Market begins with the upstream procurement of essential raw materials. This segment involves suppliers of various fiber types, including fiberglass, basalt fiber, and carbon fiber, as well as manufacturers of polymer resins such as vinyl ester, epoxy, and polyester, which serve as the matrix for the composite. Chemical additive suppliers, providing curing agents, initiators, and release agents, also form a critical part of the upstream activities. The quality and cost-effectiveness of these raw materials directly impact the final product's performance and price, making strong supplier relationships and consistent material sourcing vital for rebar manufacturers.

Moving downstream, the value chain encompasses the manufacturing process, primarily through pultrusion, where raw materials are pulled through a die and cured to form continuous rebars. After manufacturing, the products enter the distribution channels. These channels can be direct, where large FRP rebar manufacturers supply directly to major construction contractors or government infrastructure projects. This approach allows for customized orders, technical support, and direct communication, fostering strong client relationships. Indirect channels involve distributors, wholesalers, and specialized building material suppliers who cater to smaller projects, regional contractors, and retail customers, providing broader market reach and logistics support.

Finally, the value chain culminates with the end-users, which include a diverse range of clients such as civil engineering firms, building construction companies, marine construction specialists, precast concrete manufacturers, and industrial plant operators. The effectiveness of the distribution network, whether direct or indirect, is crucial for timely delivery and market penetration. Post-sales support, technical guidance, and adherence to project specifications are also critical components in establishing customer loyalty and driving repeat business. The entire chain emphasizes collaboration and efficiency to ensure high-quality FRP rebars reach diverse construction applications effectively.

Fiber Reinforced Polymer Rebars Market Potential Customers

The Fiber Reinforced Polymer Rebars Market caters to a diverse array of potential customers, primarily found within the broader construction and infrastructure sectors, seeking advanced material solutions for enhanced durability and performance. Government agencies and public works departments constitute a significant customer base, especially for large-scale infrastructure projects such as bridges, highways, tunnels, and marine structures. These entities prioritize materials that offer long-term resistance to corrosion from salt, chemicals, and moisture, thereby reducing lifecycle costs and maintenance requirements for public assets. Their demand is driven by the need to upgrade aging infrastructure and build new resilient facilities in challenging environmental conditions.

Private construction companies, including general contractors and specialized firms focusing on commercial, residential, and industrial buildings, also represent a substantial customer segment. Within this group, customers span from those involved in high-rise constructions where lightweight materials can offer logistical advantages, to those building specialized facilities like research laboratories, hospitals, or data centers where non-magnetic properties of FRP rebars are essential. The burgeoning demand for sustainable and green building practices further positions FRP rebars as an attractive option for these commercial and industrial developers aiming for higher environmental ratings and extended structural lifespans.

Furthermore, niche segments like wastewater treatment plants, chemical processing facilities, and precast concrete manufacturers are key buyers. Wastewater and chemical plants require materials with exceptional chemical resistance to withstand aggressive environments, making FRP rebars a superior choice over steel. Precast concrete manufacturers benefit from the lightweight nature of FRP, which simplifies handling and transportation of precast elements, while also offering a corrosion-free alternative for concrete components exposed to harsh conditions. These varied end-users underscore the broad applicability and growing acceptance of FRP rebars across a multitude of engineering and construction disciplines.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.5 Billion |

| Market Forecast in 2032 | USD 2.86 Billion |

| Growth Rate | CAGR 9.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Pultron Composites, Hughes Brothers, Owens Corning, Marshall Composite Technologies, International Grating Inc. (IGI), BP Composites Ltd (BASALTEX), Schoeck Combar, Aslan FRP (a division of Composite Technologies LLC), Technoform Bautec, Fujian Snowman Co., Ltd. (formerly Fibrwrap Construction), Fibergrate Composite Structures Inc., Zhejiang NaAo Composite Technology Co., Ltd., Sireg Geotech S.p.A., B&B FRP Manufacturing Inc., Creative Composites, Kodiak Fiberglass Rebar, Nanjing BoZhong Composites Co., Ltd., TUF-BAR (Pultrusion Technique Inc.), G.F.R.P. srl, Fibrolabs |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fiber Reinforced Polymer Rebars Market Key Technology Landscape

The technological landscape of the Fiber Reinforced Polymer Rebars Market is predominantly shaped by advanced manufacturing processes and ongoing innovations in material science aimed at enhancing performance, durability, and cost-effectiveness. The most widely adopted manufacturing technique is pultrusion, a continuous process where rovings of fibers are impregnated with a liquid resin, pulled through a heated die for curing, and then cut to desired lengths. This method allows for the production of high-strength, consistent profiles and is crucial for maintaining the structural integrity and uniformity of FRP rebars. Innovations in pultrusion technology focus on improving pulling speeds, optimizing resin impregnation, and developing more energy-efficient curing systems to reduce production costs and increase output.

Beyond pultrusion, other technologies play a role, particularly in specialized rebar geometries or applications. Filament winding, for instance, is used for producing hollow or curved FRP structures, though less common for standard straight rebars. Advancements in fiber technology, including the development of new grades of glass, basalt, and carbon fibers with improved strength-to-weight ratios and ductility, are continually pushing the performance boundaries of FRP rebars. Similarly, the evolution of polymer resin systems, such as vinyl esters and epoxies with enhanced chemical resistance, faster curing times, and improved adhesion to fibers, contributes significantly to the longevity and robustness of the final product.

Furthermore, the market benefits from ongoing research into surface treatment technologies, such as sand-coating or ribbed profiles, which are vital for improving the bond strength between FRP rebars and concrete. Quality control and assurance technologies, including non-destructive testing (NDT) methods and automated inspection systems, are becoming increasingly sophisticated to ensure the consistent high quality and performance of manufactured rebars. The integration of digital manufacturing tools and process automation is also gaining traction, aiming to streamline production, minimize human error, and facilitate customization, thereby supporting the broader adoption of FRP rebars in diverse construction applications.

Regional Highlights

- North America: This region is a significant market for FRP rebars, primarily driven by substantial government investments in infrastructure rehabilitation and new construction projects. The necessity to replace or strengthen aging bridges, roads, and marine structures, particularly in areas prone to chloride-induced corrosion from de-icing salts and saltwater, fuels demand. The U.S. and Canada are leading the adoption due to favorable regulatory support, growing awareness among civil engineers, and the presence of key industry players.

- Europe: The European market for FRP rebars is characterized by a strong emphasis on sustainable construction practices and stringent environmental regulations. Countries like Germany, the UK, and Scandinavian nations are progressively integrating FRP solutions into their infrastructure and building projects. The focus on reducing carbon footprints, extending structural lifespans, and minimizing maintenance costs aligns well with the benefits offered by FRP rebars, especially in coastal regions and critical infrastructure where durability is paramount.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market due to rapid urbanization, extensive infrastructure development, and increasing industrialization in economies such as China, India, Japan, and South Korea. Massive investments in transportation networks, commercial buildings, and smart cities are creating immense opportunities for FRP rebar manufacturers. The region's susceptibility to seismic activity and corrosive coastal environments further amplifies the need for resilient and advanced construction materials.

- Latin America: This region represents an emerging market for FRP rebars, with increasing investment in public works and infrastructure projects aimed at boosting economic growth and connectivity. Countries like Brazil, Mexico, and Argentina are gradually recognizing the long-term benefits of corrosion-resistant materials for coastal development, bridges, and industrial applications. While adoption is still in its early stages, growing awareness and the need for resilient infrastructure present significant growth potential.

- Middle East and Africa (MEA): The MEA market is driven by large-scale construction projects, particularly in the Gulf Cooperation Council (GCC) countries, focusing on oil and gas infrastructure, smart cities, and coastal developments. The harsh desert and marine environments, which accelerate the corrosion of steel, make FRP rebars an attractive alternative for ensuring structural longevity. Investment in new urban centers and economic diversification initiatives are key factors propelling the demand for high-performance construction materials in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fiber Reinforced Polymer Rebars Market.- Pultron Composites

- Hughes Brothers

- Owens Corning

- Marshall Composite Technologies

- International Grating Inc. (IGI)

- BP Composites Ltd (BASALTEX)

- Schoeck Combar

- Aslan FRP (a division of Composite Technologies LLC)

- Technoform Bautec

- Fujian Snowman Co., Ltd. (formerly Fibrwrap Construction)

- Fibergrate Composite Structures Inc.

- Zhejiang NaAo Composite Technology Co., Ltd.

- Sireg Geotech S.p.A.

- B&B FRP Manufacturing Inc.

- Creative Composites

- Kodiak Fiberglass Rebar

- Nanjing BoZhong Composites Co., Ltd.

- TUF-BAR (Pultrusion Technique Inc.)

- G.F.R.P. srl

- Fibrolabs

Frequently Asked Questions

What are Fiber Reinforced Polymer (FRP) Rebars?

FRP rebars are composite materials made from high-strength fibers (like glass, basalt, or carbon) embedded in a polymer resin matrix, used as a corrosion-resistant alternative to traditional steel reinforcement in concrete structures.

Why should I choose FRP rebars over traditional steel rebars?

FRP rebars offer superior corrosion resistance, are significantly lighter, non-magnetic, and boast high tensile strength, leading to extended structural lifespan and reduced maintenance, especially in harsh or sensitive environments.

What are the primary applications of FRP rebars?

Key applications include bridges, marine structures, roads exposed to de-icing salts, tunnels, wastewater treatment plants, and buildings requiring non-magnetic properties such as hospitals and research facilities.

What are the main challenges hindering the widespread adoption of FRP rebars?

The primary challenges include a higher initial cost compared to steel, a lack of comprehensive standardization across all regions, and limited awareness among some engineers and contractors regarding their design and installation.

Which regions are leading the growth in the Fiber Reinforced Polymer Rebars Market?

North America and Asia Pacific are currently leading the market due to significant infrastructure investments, a strong focus on durable construction, and rapid urbanization in countries like the U.S., Canada, China, and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager