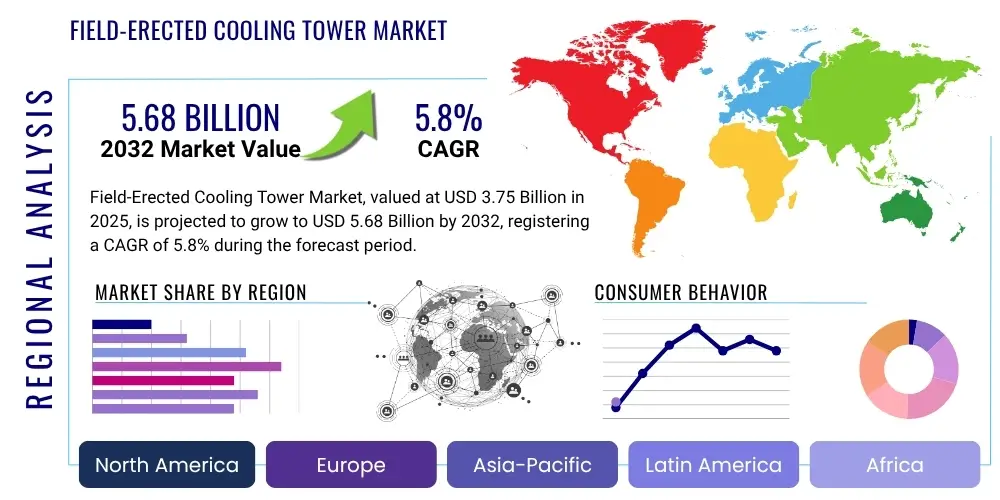

Field-Erected Cooling Tower Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428894 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Field-Erected Cooling Tower Market Size

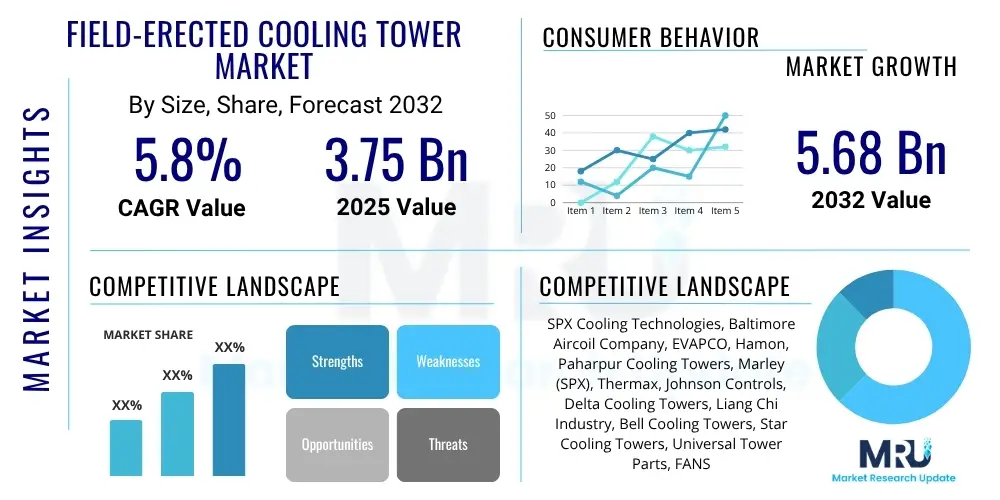

The Field-Erected Cooling Tower Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 3.75 billion in 2025 and is projected to reach USD 5.68 billion by the end of the forecast period in 2032.

Field-Erected Cooling Tower Market introduction

Field-erected cooling towers are large, custom-built heat rejection devices constructed on-site, primarily used in heavy industrial applications, power generation, and large commercial HVAC systems where pre-assembled units are insufficient or impractical due to size or performance requirements. These robust structures facilitate the dissipation of waste heat from industrial processes into the atmosphere, utilizing the evaporative cooling principle. Their customizability allows for precise adaptation to specific site conditions, capacity demands, and performance specifications, making them indispensable components in facilities requiring significant and continuous thermal management.

The product’s primary function is to cool circulating water that has absorbed heat from industrial machinery or HVAC systems, thus maintaining optimal operating temperatures and ensuring process efficiency. Major applications span across thermal power plants, petrochemical refineries, chemical processing units, steel mills, and large data centers, where efficient heat exchange is critical for operational stability and longevity of equipment. Key benefits include superior cooling capacity, enhanced durability due to robust construction materials, the ability to meet stringent environmental regulations through advanced water treatment and plume abatement technologies, and long operational lifespans with proper maintenance.

Driving factors for this market include the global increase in industrialization, particularly in emerging economies, leading to a rise in new facility constructions and expansions that necessitate large-scale cooling solutions. Furthermore, stringent environmental regulations regarding water usage and thermal discharge are prompting industries to invest in more efficient and sustainable cooling technologies, favoring field-erected units designed for optimal performance and resource conservation. The need to replace aging infrastructure and upgrade existing facilities with more technologically advanced and energy-efficient cooling systems also significantly contributes to market growth.

Field-Erected Cooling Tower Market Executive Summary

The Field-Erected Cooling Tower Market is experiencing significant momentum driven by robust industrial growth, particularly in developing regions, and a global emphasis on energy efficiency and sustainability. Business trends indicate a strong focus on customization and modularization within the field-erected segment, allowing for greater flexibility in design and construction to meet diverse industrial demands. There is also a growing adoption of advanced materials like fiber-reinforced polymer (FRP) and hybrid designs that offer enhanced durability, corrosion resistance, and reduced maintenance. Digitalization and automation are increasingly integrated into cooling tower operations, offering improved monitoring, control, and predictive maintenance capabilities, which are crucial for optimizing performance and extending asset lifespans.

Regional trends highlight Asia Pacific as a dominant and rapidly expanding market, fueled by extensive investments in power generation, manufacturing, and petrochemical industries across countries like China, India, and Southeast Asia. North America and Europe represent mature markets characterized by substantial replacement and retrofit activities, driven by the need to upgrade existing infrastructure to comply with evolving environmental standards and enhance energy efficiency. The Middle East and Africa, along with Latin America, are showing promising growth trajectories, propelled by new infrastructure projects and industrial expansions in sectors such as oil and gas, mining, and basic materials.

Segment trends reveal that counterflow cooling towers continue to be highly preferred due to their compact footprint and higher thermal efficiency, especially in space-constrained industrial environments. In terms of materials, concrete remains a staple for its structural integrity and longevity in harsh conditions, while FRP is gaining traction for its lightweight properties and corrosion resistance. The power generation sector consistently holds the largest share in end-use applications, followed by the chemical and petrochemical industries, demonstrating their critical reliance on high-capacity, reliable cooling solutions for continuous operations. The market is also seeing increased demand for plume abatement technologies and advanced water treatment systems to minimize environmental impact and optimize operational costs.

AI Impact Analysis on Field-Erected Cooling Tower Market

Common user inquiries regarding AI’s influence on the Field-Erected Cooling Tower Market often center on its ability to enhance operational efficiency, reduce maintenance costs, optimize energy consumption, and improve overall system reliability. Users are keen to understand how AI can facilitate predictive maintenance, automate control processes, and provide real-time performance insights to prevent downtime and extend asset life. Expectations include AI’s role in smart monitoring, adaptive cooling strategies, and integration with broader industrial IoT ecosystems, though concerns about implementation complexity, data security, and the return on investment for such advanced systems are also prevalent.

- Predictive maintenance through anomaly detection in operational data.

- Optimized energy consumption by dynamic fan and pump control based on ambient conditions and load.

- Real-time performance monitoring and fault diagnosis for proactive intervention.

- Automated water treatment chemical dosing based on continuous water quality analysis.

- Improved operational stability and efficiency through adaptive control algorithms.

- Enhanced safety by identifying potential equipment failures before they occur.

- Data-driven insights for long-term strategic planning and capital expenditure decisions.

DRO & Impact Forces Of Field-Erected Cooling Tower Market

The Field-Erected Cooling Tower Market is significantly shaped by a confluence of drivers, restraints, and opportunities, collectively forming its impact forces. Primary drivers include the ongoing global industrialization and urbanization, which necessitate increased power generation and manufacturing capacities, thereby escalating the demand for large-scale industrial cooling solutions. Stricter environmental regulations aimed at water conservation, energy efficiency, and reducing thermal pollution are compelling industries to invest in advanced, high-efficiency cooling towers. Furthermore, the imperative to replace or upgrade aging cooling infrastructure in mature industrial economies with more modern and sustainable systems provides a consistent demand impetus. The benefits of field-erected towers, such as their scalability, customization, and robust construction, align well with the demanding requirements of heavy industries.

However, the market also faces considerable restraints. The high initial capital expenditure associated with the design, construction, and installation of field-erected cooling towers can be a significant barrier for some investors, particularly for smaller projects or those with limited budgets. The complexity of these large-scale projects often leads to extended construction timelines and requires specialized engineering expertise, which can deter potential buyers seeking quicker deployment. Additionally, environmental concerns related to plume formation, noise pollution, and the aesthetic impact of large cooling towers can sometimes lead to public opposition or require additional abatement technologies, adding to the overall project cost and complexity.

Opportunities within the market largely stem from the development and adoption of smart cooling technologies, including IoT integration, AI-driven predictive maintenance, and advanced controls that enhance operational efficiency and reduce lifecycle costs. The growing focus on sustainable industrial practices presents avenues for innovative water-saving designs, hybrid wet/dry cooling solutions, and the use of eco-friendly materials. Expansion into emerging economies with rapid industrial growth, particularly in sectors like data centers, renewables manufacturing, and advanced materials, offers new market frontiers. The demand for retrofitting existing facilities with more efficient components and digital monitoring systems also represents a substantial opportunity, allowing industries to extend the life and improve the performance of their current cooling assets.

Segmentation Analysis

The Field-Erected Cooling Tower Market is comprehensively segmented across various parameters to provide a detailed understanding of its dynamics and cater to diverse industrial requirements. These segmentations typically include classifications by type, material of construction, cooling capacity, and the end-use industry, each reflecting distinct technological preferences, cost implications, and application demands. Understanding these segments is crucial for market players to tailor their offerings, develop targeted strategies, and identify niche growth opportunities within the expansive industrial cooling landscape. Each segment is influenced by factors such as operational environment, regulatory compliance, energy efficiency mandates, and capital investment budgets.

- By Type

- Crossflow

- Counterflow

- By Material of Construction

- Concrete

- Wood

- Fiber Reinforced Polymer (FRP)

- Hybrid (Concrete and FRP)

- Steel

- By Cooling Capacity

- Small (Up to 10,000 GPM)

- Medium (10,001 to 50,000 GPM)

- Large (Above 50,000 GPM)

- By End-Use Industry

- Power Generation (Thermal, Nuclear, Geothermal)

- Chemical and Petrochemical

- Oil and Gas

- Manufacturing (Steel, Cement, Food & Beverage)

- HVAC and Refrigeration (Large Commercial, Data Centers)

- Other Industrial (Mining, Pulp & Paper)

Value Chain Analysis For Field-Erected Cooling Tower Market

The value chain for the Field-Erected Cooling Tower Market begins with upstream activities involving the sourcing and processing of raw materials and the manufacturing of essential components. This stage includes suppliers of structural steel, concrete, timber, and various polymers for FRP panels, along with manufacturers specializing in fan assemblies, motors, pumps, heat exchange fill media, nozzles, and water treatment systems. Quality and cost-effectiveness at this foundational level directly influence the overall performance and longevity of the final product. Strong relationships with reliable suppliers ensure a consistent flow of high-quality materials and components, which is critical given the customized nature and large scale of field-erected projects.

Midstream activities primarily encompass the engineering, design, and construction phases. This segment is dominated by specialized cooling tower manufacturers, engineering, procurement, and construction (EPC) firms, and industrial contractors who possess the technical expertise to design custom solutions, manage complex project logistics, and perform on-site erection. The design phase involves intricate thermal calculations, structural engineering, and hydraulic analysis to ensure the cooling tower meets specific performance criteria and local regulatory standards. The construction phase is labor-intensive, requiring skilled trades for assembly and installation, often under challenging industrial site conditions. The integration of advanced manufacturing techniques for components and efficient on-site assembly processes are key competitive differentiators.

Downstream activities focus on the delivery, installation, commissioning, and crucially, post-sales services such as maintenance, repair, and upgrades. The distribution channel for field-erected cooling towers is primarily direct, with manufacturers and EPC firms engaging directly with large industrial end-users, power utilities, and government entities for specific project requirements. Indirect channels may involve specialized distributors for replacement parts or through consulting engineers who recommend specific brands during project design. Aftermarket services are vital for ensuring the sustained performance and extending the operational life of these significant capital assets, creating recurring revenue streams and strengthening customer loyalty through long-term service contracts and modernization programs. This entire chain emphasizes customization, technical expertise, and robust project management to deliver complex, high-performance cooling solutions.

Field-Erected Cooling Tower Market Potential Customers

Potential customers for field-erected cooling towers primarily comprise large-scale industrial and commercial entities that require substantial heat rejection capabilities for their continuous operations. These end-users are characterized by their need for custom-engineered, durable, and high-capacity cooling solutions that can withstand harsh operating environments and meet stringent performance specifications. The decision-making process for these buyers is typically driven by factors such as long-term operational costs, energy efficiency, regulatory compliance, reliability, and the ability to integrate with existing infrastructure. Their investments are often substantial, necessitating careful consideration of a cooling tower’s lifecycle cost, including initial capital outlay, maintenance, and energy consumption.

A significant segment of end-users comes from the power generation sector, including thermal, nuclear, and combined cycle power plants, which rely on cooling towers for efficient condenser cooling to maximize electricity output. The chemical and petrochemical industries represent another major customer base, requiring robust cooling solutions for various processes such as distillation, exothermic reactions, and gas compression. Similarly, oil and gas refineries utilize these towers for cooling process fluids in their complex operations, ensuring safety and efficiency. These industries often operate 24/7, making the reliability and durability of field-erected cooling towers paramount.

Beyond traditional heavy industries, the market extends to large manufacturing facilities across diverse sectors like steel, cement, pulp and paper, and food and beverage, all of which generate significant waste heat. Furthermore, the burgeoning demand for large-scale data centers, which require massive cooling capacities to maintain optimal server temperatures, is emerging as a critical growth area. These facilities prioritize energy efficiency and redundancy, making advanced field-erected cooling towers an attractive solution. Municipal water treatment plants and large district cooling systems also represent potential buyers, seeking efficient ways to manage process heat or provide cooling for extensive urban infrastructures.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.75 Billion |

| Market Forecast in 2032 | USD 5.68 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SPX Cooling Technologies, Baltimore Aircoil Company, EVAPCO, Hamon, Paharpur Cooling Towers, Marley (SPX), Thermax, Johnson Controls, Delta Cooling Towers, Liang Chi Industry, Bell Cooling Towers, Star Cooling Towers, Universal Tower Parts, FANS, Inc., Braden Manufacturing, Brentwood Industries, Tower Tech, Thermal Care, Flow Tech, United Blower. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Field-Erected Cooling Tower Market Key Technology Landscape

The Field-Erected Cooling Tower Market is continuously evolving with the integration of advanced technologies aimed at enhancing efficiency, reducing environmental impact, and extending operational lifespans. Central to this technological landscape is the adoption of highly efficient fill media designs, which maximize heat transfer surface area while minimizing airside pressure drop, thereby improving thermal performance and reducing energy consumption by fans. These media often incorporate anti-clogging features and are made from durable, corrosion-resistant materials like PVC or polypropylene. Another crucial technology involves the use of variable frequency drives (VFDs) for fan and pump motors, allowing for precise control of airflow and water flow based on cooling demand and ambient conditions, leading to significant energy savings and optimized performance during partial load operations.

Beyond core components, smart technologies are increasingly integrated into field-erected cooling towers. This includes the deployment of advanced sensor networks that monitor critical parameters such as water quality, temperature, flow rates, vibration levels, and fan motor health in real time. These sensors are often connected to Internet of Things (IoT) platforms, enabling remote monitoring, data logging, and sophisticated analytics. Predictive maintenance software, powered by AI and machine learning algorithms, analyzes this data to anticipate potential equipment failures, schedule maintenance proactively, and prevent costly downtime. This shift from reactive to proactive maintenance is a significant technological leap, improving reliability and operational efficiency.

Furthermore, innovations in materials science are contributing to the longevity and reduced maintenance requirements of cooling towers. This includes the wider adoption of fiber-reinforced polymer (FRP) components for structural elements, casing, and fan stacks due to their superior corrosion resistance, lightweight properties, and ease of fabrication compared to traditional materials like wood or steel. Plume abatement technologies, such as hybrid wet/dry sections, are also gaining traction to mitigate visible water vapor plumes, addressing environmental and aesthetic concerns, especially in urban or sensitive areas. Advanced water treatment solutions, including automated chemical dosing systems and filtration technologies, are being implemented to minimize biological growth, scaling, and corrosion, thereby enhancing the overall efficiency and lifespan of the cooling tower system and reducing make-up water demand.

Regional Highlights

- North America: This region represents a mature market characterized by a significant installed base of aging infrastructure. The demand is primarily driven by replacement projects, retrofits for efficiency upgrades, and stringent environmental regulations promoting water conservation and reduced energy consumption. The power generation, chemical, and petrochemical industries are key end-users, with a growing emphasis on smart cooling solutions and sustainable practices.

- Europe: Similar to North America, Europe is a mature market focused on efficiency, regulatory compliance, and modernization. Strict environmental policies, particularly concerning water usage and emissions, drive investment in advanced, low-plume, and water-efficient cooling tower designs. The region sees steady demand from power generation, heavy manufacturing, and the burgeoning data center sector, with a strong emphasis on lifecycle cost optimization and green technologies.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market, propelled by rapid industrialization, urbanization, and substantial investments in new infrastructure, particularly in China, India, and Southeast Asian nations. The region's expanding power generation capacity, burgeoning manufacturing sector, and growth in the chemical and petrochemical industries are primary demand drivers. While cost-effectiveness is a key factor, there is increasing adoption of advanced technologies for efficiency and environmental compliance.

- Latin America: This region is experiencing steady growth in the field-erected cooling tower market, fueled by expanding mining operations, oil and gas exploration, and investments in power generation infrastructure. Countries like Brazil, Mexico, and Chile are witnessing industrial development that necessitates large-scale cooling solutions. Market growth is also influenced by increasing foreign direct investment in manufacturing and processing industries.

- Middle East and Africa (MEA): The MEA region is a promising market driven by significant investments in oil and gas, petrochemicals, power generation, and large-scale construction projects. Economic diversification initiatives and infrastructure development in countries like Saudi Arabia, UAE, and Qatar are creating substantial demand. The region faces extreme climatic conditions, driving the need for robust, high-performance cooling towers capable of operating efficiently in high temperatures.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Field-Erected Cooling Tower Market.- SPX Cooling Technologies

- Baltimore Aircoil Company

- EVAPCO

- Hamon

- Paharpur Cooling Towers

- Marley (SPX)

- Thermax

- Johnson Controls

- Delta Cooling Towers

- Liang Chi Industry

- Bell Cooling Towers

- Star Cooling Towers

- Universal Tower Parts

- FANS, Inc.

- Braden Manufacturing

- Brentwood Industries

- Tower Tech

- Thermal Care

- Flow Tech

- United Blower

Frequently Asked Questions

What is a field-erected cooling tower?

A field-erected cooling tower is a large, custom-built heat rejection system constructed on-site to dissipate waste heat from industrial processes, power generation, or large HVAC systems into the atmosphere, primarily through evaporative cooling.

What are the main applications of field-erected cooling towers?

Key applications include power generation (thermal, nuclear), petrochemical processing, chemical manufacturing, oil and gas refineries, steel mills, and large-scale commercial HVAC systems and data centers.

How does efficiency impact the field-erected cooling tower market?

Efficiency is a critical driver, influencing energy consumption, operational costs, and environmental compliance. Industries prioritize highly efficient designs and technologies to reduce power usage, conserve water, and meet stringent regulatory standards.

What materials are commonly used in field-erected cooling towers?

Common materials include concrete for structural integrity, wood for some older designs, fiber-reinforced polymer (FRP) for corrosion resistance and durability, and steel for various components and sometimes structure. Hybrid designs often combine these materials.

What drives the demand for field-erected cooling towers?

Demand is driven by global industrialization, increasing power generation needs, the replacement and upgrade of aging infrastructure, and stricter environmental regulations emphasizing water conservation and energy efficiency in industrial processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager