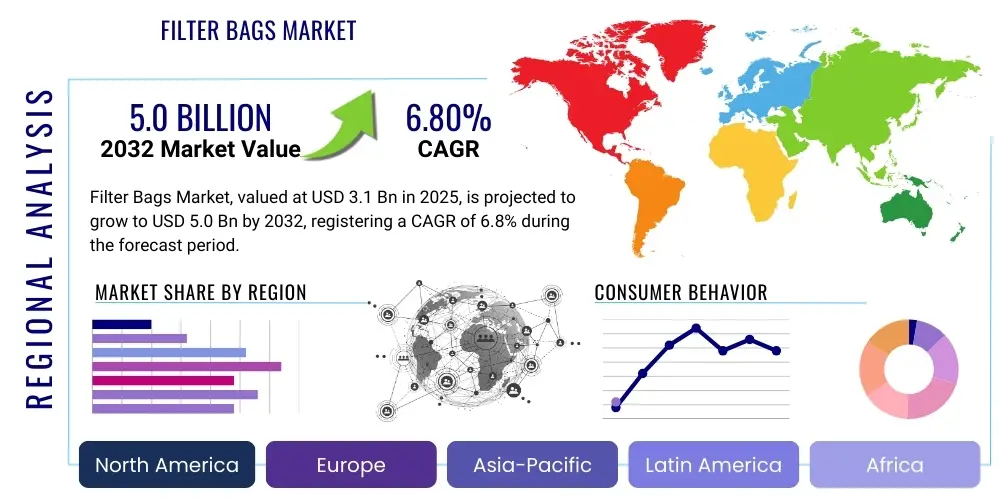

Filter Bags Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427663 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Filter Bags Market Size

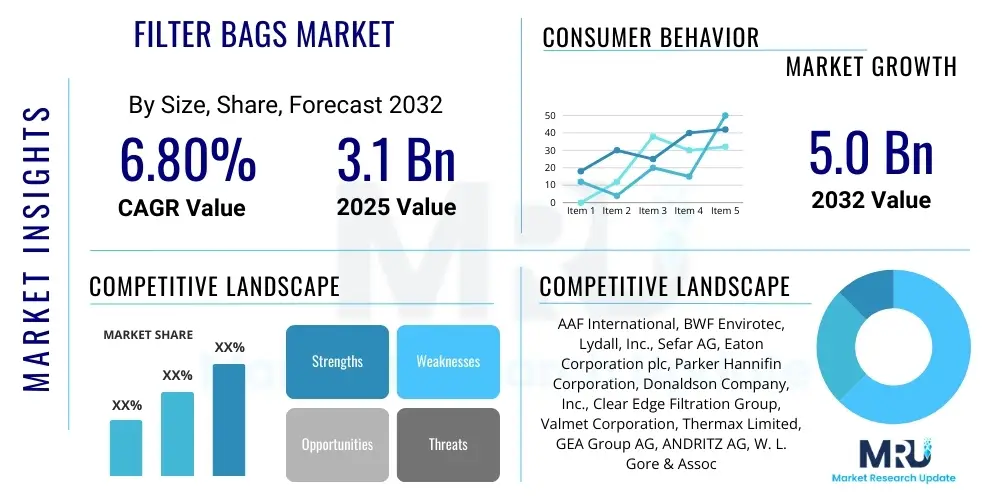

The Filter Bags Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 3.1 billion in 2025 and is projected to reach USD 5.0 billion by the end of the forecast period in 2032.

Filter Bags Market introduction

Filter bags are essential industrial components designed to efficiently separate solid particulate matter from liquid or gas streams. Their critical role spans various sectors, ensuring operational efficiency, environmental compliance, and product purity. These bags are engineered to capture contaminants ranging from fine dust particles to larger sediment, playing a pivotal part in maintaining clean air and water, as well as protecting machinery from abrasive wear and tear, thereby extending equipment lifespan.

Product descriptions highlight their construction from diverse materials such as polyester, polypropylene, nylon, aramid, PTFE, and fiberglass, chosen based on the specific operating conditions like temperature, chemical compatibility, and the size of particulates to be filtered. They are manufactured in various configurations, including sewn or welded designs, and are specifically tailored for applications requiring either high-efficiency dust collection or meticulous liquid filtration, offering robust and reliable performance.

Major applications of filter bags include industrial dust collection systems in cement plants, power generation facilities, and mining operations, as well as air pollution control systems in chemical and pharmaceutical manufacturing. In liquid filtration, they are indispensable for wastewater treatment, food and beverage processing, and chemical refining. The primary benefits include high filtration efficiency, cost-effectiveness, durability, and a significant contribution to environmental protection by reducing emissions and ensuring cleaner discharge, which collectively drive their increasing adoption across global industries.

Filter Bags Market Executive Summary

The Filter Bags Market is characterized by dynamic business trends, including a pronounced shift towards high-performance filtration media and customized solutions, driven by an increasing demand for superior efficiency, extended product lifespan, and enhanced resistance to harsh industrial environments. Manufacturers are increasingly investing in advanced automation technologies and adopting sustainable manufacturing practices to meet stringent regulatory requirements and consumer expectations for eco-friendly products.

Regionally, the market exhibits robust growth in the Asia-Pacific area, fueled by rapid industrialization, burgeoning infrastructure development, and a heightened awareness of environmental pollution, particularly in emerging economies like China and India. Concurrently, mature markets in North America and Europe are experiencing growth primarily driven by stringent environmental protection regulations, continuous technological advancements in filtration materials, and a focus on upgrading existing industrial facilities with more efficient systems.

Segmentation trends indicate a growing demand for specialized filter bags designed for critical applications such as high-temperature filtration, corrosive chemical processing, and ultra-fine particle capture. The liquid filtration segment, especially within pharmaceutical and food and beverage industries, is witnessing significant expansion due to the increasing need for sterile and contaminant-free processes, necessitating advanced and certified filtration media. The market overall reflects a strong emphasis on innovation to address complex industrial filtration challenges effectively.

AI Impact Analysis on Filter Bags Market

Common user questions regarding AIs impact on the Filter Bags Market primarily explore how artificial intelligence can optimize filtration processes, predict maintenance needs, and enhance material development. Users are keen to understand how AI can extend the operational lifespan of filter bags, reduce unplanned downtime, and ensure consistent filtration quality through intelligent monitoring and data analytics. The key themes emerging from these inquiries include the potential for AI to drive predictive maintenance strategies, improve operational efficiency, facilitate the design of smarter filter materials, and provide more accurate quality control, ultimately addressing concerns related to operational costs, environmental performance, and system reliability.

- Predictive maintenance and lifespan optimization of filter bags through AI-driven analytics, reducing unexpected failures.

- Enhanced filtration efficiency and process optimization via real-time data analysis and adaptive control systems.

- Development of smart filter materials with embedded sensors for self-monitoring and performance feedback, leading to more responsive filtration solutions.

- Automated fault detection and diagnostic systems for filtration units, minimizing manual inspection and expediting issue resolution.

- Improved supply chain management and inventory optimization for filter bag replacement, leveraging AI for demand forecasting.

- Personalized and highly efficient filtration solutions based on specific industrial requirements and dynamic operating conditions, tailored by AI.

- Enhanced quality control and assurance in filter bag manufacturing through AI-powered inspection systems.

DRO & Impact Forces Of Filter Bags Market

The Filter Bags Market is primarily driven by the escalating pace of industrialization across developing economies and the increasingly stringent global environmental regulations concerning air and water pollution. These regulations compel industries to adopt advanced filtration solutions to comply with emission standards and ensure responsible waste management. Additionally, continuous technological advancements in material science and manufacturing processes are yielding filter bags with enhanced durability, higher filtration efficiency, and improved resistance to harsh operating conditions, thereby expanding their applicability and appeal.

However, the market faces significant restraints, including the inherent volatility in the prices of raw materials such as polyester, polypropylene, and specialized fibers, which can directly impact manufacturing costs and consumer pricing, potentially affecting profit margins. Furthermore, the initial capital investment required for installing advanced and large-scale industrial filtration systems, including the cost of compatible filter bags, can be substantial, posing a barrier to entry or upgrade for smaller enterprises. The pervasive availability of alternative filtration technologies, each with specific advantages and disadvantages, also presents a competitive challenge to the filter bags segment.

Significant opportunities for market expansion exist in the burgeoning industrial sectors of emerging economies, where infrastructure development and manufacturing growth are creating new demands for efficient filtration. The increasing global emphasis on sustainability and circular economy principles is also driving the demand for eco-friendly and recyclable filter bag options. Moreover, the integration of IoT (Internet of Things) and smart technologies into filter bags, enabling real-time performance monitoring and predictive maintenance, represents a key growth avenue, promising enhanced operational efficiency and reduced downtime for end-users.

Segmentation Analysis

The Filter Bags Market is comprehensively segmented across several critical dimensions, providing a detailed understanding of its diverse applications, material requirements, and end-user landscapes. These segmentations are crucial for analyzing market dynamics, identifying specific growth areas, and developing targeted strategies. The market is typically categorized by the material used in manufacturing the bags, their specific design or type, the broad application areas they serve, and the various end-use industries that constitute their primary customer base. This granular approach allows for a precise evaluation of demand patterns and technological advancements within each niche.

Understanding these segments helps manufacturers tailor their product offerings to meet specific industrial demands, from high-temperature resistant materials for power generation to chemically inert options for pharmaceutical processing. The differentiation between dust collector bags and liquid filter bags, for instance, highlights the distinct engineering requirements for air versus fluid filtration. Similarly, analyzing demand from sectors like cement, mining, or food and beverage reveals industry-specific needs and regulatory drivers that shape market growth. This detailed segmentation aids in strategic planning and market forecasting.

- By Material: Polyester, Polypropylene, Nylon, Aramid, PTFE, Fiberglass, PPS (Polyphenylene Sulfide), P84 (Polyimide), Acrylic, Others (e.g., Ryton, Cotton).

- By Type: Dust Collector Bags (for pulse-jet, reverse air, shaker collectors), Liquid Filter Bags (for open and closed systems), Specialty Filter Bags (for specific industrial processes).

- By Application: Air Filtration (Industrial Dust Collection, HVAC Systems, Air Pollution Control, Emission Reduction), Liquid Filtration (Wastewater Treatment, Food & Beverage Processing, Chemical Processing, Pharmaceutical Manufacturing, Oil & Gas).

- By End-Use Industry: Cement Industry, Power Generation (Thermal Power Plants), Chemical Industry, Food & Beverage Industry, Pharmaceutical Industry, Mining Industry, Metallurgy, Water & Wastewater Treatment, Incineration Plants, Automotive, Agriculture, Others.

Filter Bags Market Value Chain Analysis

The value chain for the Filter Bags Market begins with the upstream analysis, involving the sourcing and procurement of diverse raw materials. This critical stage includes suppliers of synthetic fibers such as polyester, polypropylene, aramid, and PTFE, as well as specialized coating materials and finishing agents. The quality and specific characteristics of these raw materials directly impact the performance, durability, and filtration efficiency of the final product, making strategic supplier relationships and quality control paramount at this initial phase of the value chain.

Moving through the manufacturing process, these raw materials are transformed into various woven or non-woven filter media. This stage involves advanced textile manufacturing techniques, including spinning, weaving, felting, and often, specialized treatments like calendaring, singeing, or membrane lamination to achieve desired pore sizes, surface finishes, and chemical resistances. The subsequent fabrication process meticulously cuts, sews, or welds these media into specific bag configurations, ensuring precise dimensions, reinforced seams, and appropriate sealing mechanisms to meet stringent industrial specifications and prevent bypass leakage.

The downstream analysis focuses on the distribution and sales channels, which involve manufacturers either selling directly to large industrial end-users or through a network of specialized distributors, resellers, and increasingly, online B2B platforms. Post-sale services, including technical support, installation guidance, maintenance recommendations, and efficient replacement programs, are integral to customer satisfaction and loyalty, completing the comprehensive value chain and ensuring optimal performance throughout the product lifecycle. Both direct sales to large corporations and indirect sales through a network of specialized filtration product distributors are crucial for market penetration.

Filter Bags Market Potential Customers

Potential customers for filter bags encompass a broad spectrum of industrial sectors that are fundamentally reliant on efficient separation of particulate matter from air or liquids. These end-users are primarily organizations that either generate significant amounts of dust, fumes, or aerosols as part of their production processes, or those that require the meticulous purification of liquid streams for product quality, operational integrity, or environmental compliance. Key buyers include manufacturing facilities striving to meet stringent regulatory standards for air emissions and wastewater discharge, industries seeking to protect sensitive machinery from abrasive particulate contamination, and sectors where product purity and clarity are paramount.

Specific industries demonstrating high and consistent demand include the cement industry, where filter bags are vital for controlling dust emissions from kilns and grinding mills; the power generation sector, particularly coal-fired plants, which utilize filter bags extensively for flue gas desulfurization and particulate removal; and the chemical processing industry, where they are used for both air pollution control and liquid product separation. Additionally, the food and beverage industry relies on filter bags for clarification processes, while pharmaceutical manufacturers use them for sterile filtration and particulate control in cleanroom environments.

Furthermore, mining operations, where dust suppression is crucial for worker safety and environmental protection, represent a significant customer segment. Municipal and industrial wastewater treatment plants are also substantial consumers, employing filter bags for solid-liquid separation to meet discharge standards and protect downstream equipment. These diverse customers consistently prioritize filter bags that offer high efficiency, extended lifespan, robust resistance to harsh operating conditions, and overall cost-effectiveness, seeking solutions that enhance operational uptime, reduce maintenance overheads, and contribute positively to environmental sustainability. Their selection criteria often hinge on material compatibility, temperature resistance, and specific filtration micron ratings.

Filter Bags Market Key Technology Landscape

The Filter Bags Markets technological landscape is continuously advancing, driven by an imperative for enhanced filtration efficiency, extended operational lifespan, and improved adaptability to increasingly challenging industrial environments. A cornerstone of this evolution is the development of advanced synthetic and composite materials, which include innovations like nanofiber media and specialized membrane laminations. These materials offer superior sub-micron particle retention capabilities, improved dust cake release properties, and enhanced airflow characteristics compared to conventional filter media, allowing for more effective and energy-efficient filtration processes.

Surface treatment technologies represent another critical area of innovation, with various chemical coatings and physical finishes being applied to filter media. These treatments impart essential properties such as oleophobicity (oil repellency), hydrophobicity (water repellency), and enhanced chemical resistance, making filter bags suitable for a wider array of demanding industrial applications, including those involving aggressive chemicals or high moisture content. Such advancements also significantly improve the cleanability of filter bags, contributing to longer service intervals and reduced operational costs.

Emerging technologies are increasingly focused on integrating smart features into filter bags and filtration systems. This includes the incorporation of embedded sensors for real-time monitoring of key performance indicators such as pressure drop, temperature, and filter integrity. This data enables predictive maintenance strategies, allowing operators to optimize filter bag replacement cycles, minimize unplanned downtime, and ensure consistent filtration performance. Furthermore, advancements in automated manufacturing processes are enhancing the consistency and quality of filter bag production, facilitating the creation of complex designs and customized solutions efficiently, thereby contributing to more sustainable and highly optimized industrial operations.

Regional Highlights

- North America: Characterized by stringent environmental protection regulations and a high adoption rate of advanced filtration technologies across industries such as power generation, chemical processing, and manufacturing. The region focuses on energy efficiency and sustainable solutions.

- Europe: Driven by robust EU directives on air quality and emission control, leading to continuous innovation in filter media and a strong emphasis on sustainability and circular economy principles within its mature industrial base. Germany, France, and the UK are key markets.

- Asia-Pacific: The fastest-growing market due to rapid industrialization, significant infrastructure development, and increasing awareness of air and water pollution, particularly in China, India, and Southeast Asian countries. Massive investments in manufacturing and power sectors fuel demand.

- Latin America: Experiencing growth in its industrial sector, notably in mining, oil and gas, and food and beverage processing. The region is witnessing increased adoption of industrial filtration solutions to meet growing environmental compliance and operational efficiency needs.

- Middle East & Africa: Marked by significant expansion in the oil & gas, petrochemicals, and construction sectors, driving a substantial demand for efficient air and liquid filtration solutions for process optimization and environmental management in these resource-rich economies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Filter Bags Market.- AAF International (Daikin Industries, Ltd.)

- BWF Envirotec

- Lydall, Inc. (now part of Unifrax)

- Sefar AG

- Eaton Corporation plc

- Parker Hannifin Corporation

- Donaldson Company, Inc.

- Clear Edge Filtration Group

- Valmet Corporation

- Thermax Limited

- GEA Group AG

- ANDRITZ AG

- W. L. Gore & Associates, Inc.

- DuPont de Nemours, Inc.

- TDC Filter Manufacturing, Inc.

Frequently Asked Questions

What are the primary functions of filter bags in industrial settings?

Filter bags are essential industrial components designed to efficiently separate solid particulate matter from liquid or gas streams. Their primary functions include air pollution control in manufacturing, product recovery, process purification in chemical and food industries, and wastewater treatment, ensuring operational efficiency, machinery protection, and adherence to environmental compliance standards across various sectors.

How do material types influence the selection of filter bags for specific applications?

Material types, such as polyester, polypropylene, aramid, or PTFE, significantly influence filter bag selection by offering distinct properties crucial for different applications. Each material provides specific resistance to temperature, chemical exposure, abrasion, and hydrolysis, while also influencing filtration efficiency and service life, making their choice critical for optimal performance in diverse industrial environments.

What are the key advantages of using filter bags compared to other filtration methods?

Key advantages of filter bags include their high filtration efficiency, cost-effectiveness, and remarkable versatility across a wide range of industrial applications. They offer superior dust cake release characteristics, can handle high flow rates with minimal pressure drop, and are relatively easy to install and replace, making them a preferred choice for many demanding industrial filtration challenges requiring robust and reliable solid-liquid or solid-gas separation.

How often should filter bags be inspected and replaced to maintain optimal performance?

The inspection and replacement frequency for filter bags are highly dependent on operational conditions, the type and concentration of particulate matter, air or liquid flow rates, and specific regulatory requirements. Regular monitoring of the pressure differential across the bag, adherence to manufacturer guidelines, and analyzing system performance trends are crucial for determining optimal replacement schedules, preventing system failures, and consistently maintaining filtration efficiency and system integrity.

What emerging trends are shaping the future of the Filter Bags Market?

Emerging trends in the Filter Bags Market include the development of smart filter bags with integrated sensors for real-time performance monitoring and predictive maintenance, a growing emphasis on sustainable and eco-friendly materials with improved recyclability, and advancements in nanofiber and membrane technology for ultra-high filtration efficiency. Customization, high-performance solutions for challenging industrial environments, and the integration of IoT for operational optimization are also key trends shaping the markets future trajectory.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager