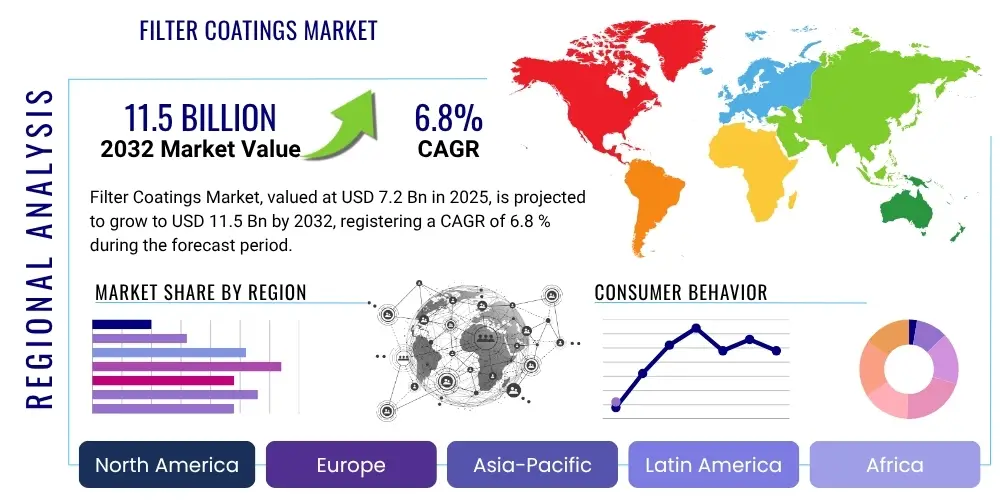

Filter Coatings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427976 | Date : Oct, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Filter Coatings Market Size

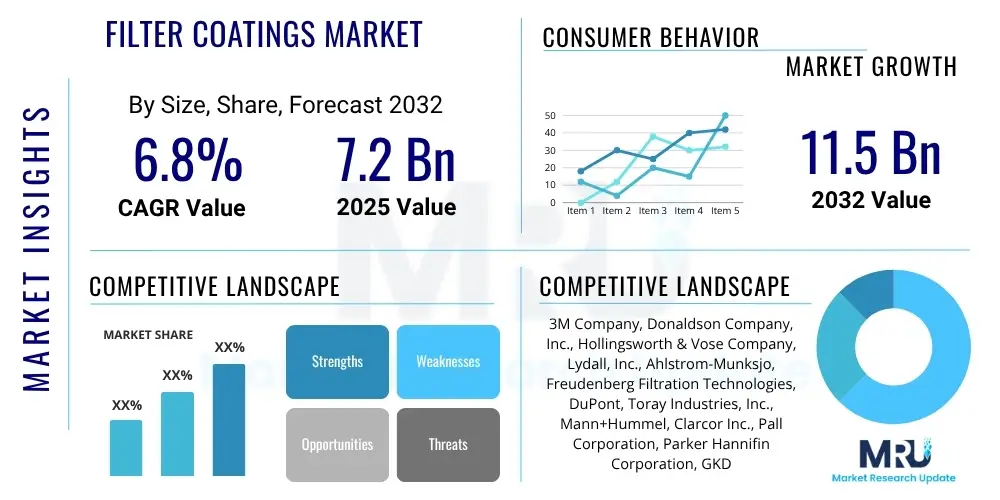

The Filter Coatings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 7.2 Billion in 2025 and is projected to reach USD 11.5 Billion by the end of the forecast period in 2032.

Filter Coatings Market introduction

The Filter Coatings Market encompasses a diverse range of specialized surface treatments applied to filter media to enhance their performance characteristics. These coatings are engineered to improve filtration efficiency, extend filter lifespan, impart specific functionalities such as hydrophobicity, oleophobicity, antimicrobial properties, or catalytic activity, and resist harsh operating conditions. Product descriptions vary widely, including polymer-based, ceramic-based, carbon-based, and metallic oxide coatings, each tailored for different applications and environmental challenges. Their primary function is to optimize the filtration process, whether for air purification, liquid separation, or gas treatment.

Major applications of filter coatings span across numerous industries, including automotive, HVAC, medical, industrial manufacturing, and water treatment. In the automotive sector, they enhance cabin air filters and engine air intake filters. For HVAC systems, they improve indoor air quality by capturing finer particulates and allergens. Industrial applications include dust collection, chemical processing, and cleanroom environments, where high-performance filtration is critical. The benefits of these coatings are substantial, including reduced energy consumption due to lower pressure drop, enhanced particle capture, protection against chemical degradation, and prevention of microbial growth.

Driving factors for market growth include escalating global concerns over air and water quality, stringent environmental regulations necessitating higher filtration standards, increasing industrialization and manufacturing activities worldwide, and the growing demand for advanced filtration solutions in emerging economies. The rising awareness about health impacts of pollutants, coupled with technological advancements in material science and coating application techniques, further propels the adoption of filter coatings across various end-use sectors, contributing to continuous market expansion.

Filter Coatings Market Executive Summary

The Filter Coatings Market is experiencing robust growth, driven by an convergence of evolving business trends, significant regional expansion, and the continuous innovation within product segments. Business trends indicate a strong shift towards sustainable and high-performance solutions, with manufacturers increasingly investing in R&D to develop eco-friendly coatings that offer enhanced efficiency and durability. There is also a notable trend towards customization, as industries demand coatings tailored to specific operational requirements and environmental challenges, fostering collaborations between coating suppliers and filter media manufacturers. The integration of smart manufacturing processes and automation in coating application is another key business driver, optimizing production costs and ensuring consistent quality.

Regional trends highlight Asia Pacific as a dominant and rapidly expanding market, fueled by rapid industrialization, urbanization, increasing air pollution levels, and stringent regulatory frameworks in countries like China and India. North America and Europe also maintain significant market shares, characterized by advanced industrial infrastructures, high adoption rates of premium filtration systems, and strong emphasis on environmental protection and public health. Latin America and the Middle East & Africa are emerging markets, showing considerable potential due to growing infrastructure development and rising awareness about industrial safety and environmental compliance, stimulating demand for advanced filter coating solutions.

Segment trends underscore the increasing preference for advanced materials and functional coatings. Polymer-based coatings, including PTFE and polyurethane, continue to hold a significant share due attributed to their versatility and chemical resistance. However, nanotechnology-enabled coatings, offering superior filtration efficiency and self-cleaning properties, are gaining traction rapidly. Application-wise, industrial filtration and HVAC systems remain major segments, while the automotive and medical sectors are poised for substantial growth due to increasing regulatory pressures and health consciousness. The demand for antimicrobial and antiviral coatings, particularly post-pandemic, has also seen a significant surge, reflecting evolving consumer and industrial needs for enhanced air purification and safety.

AI Impact Analysis on Filter Coatings Market

Users frequently inquire about how artificial intelligence can optimize the design and application of filter coatings, predict filter performance, and enhance manufacturing processes. Key themes revolve around the potential for AI to accelerate R&D cycles for novel coating materials, improve quality control during production, and enable predictive maintenance for filtration systems, ultimately leading to more efficient, durable, and cost-effective filtration solutions. Concerns often include the initial investment in AI infrastructure, data privacy, and the need for specialized expertise to implement and manage AI-driven systems effectively within this niche industry.

- AI can accelerate the discovery and optimization of new filter coating materials through machine learning algorithms that predict material properties and performance.

- AI-driven sensors and analytics can enable real-time quality control during the coating process, minimizing defects and ensuring consistent product quality.

- Predictive maintenance for filtration systems, powered by AI, can forecast filter lifespan and optimal replacement times, reducing downtime and operational costs.

- AI can optimize manufacturing parameters for coating application, leading to increased production efficiency and reduced material waste.

- Advanced AI models can simulate filter performance under various environmental conditions, aiding in product design and customization for specific applications.

DRO & Impact Forces Of Filter Coatings Market

The Filter Coatings Market is propelled by several key drivers, tempered by specific restraints, while presenting significant opportunities, all influenced by overarching impact forces. Drivers include the global emphasis on improving air and water quality, stringent environmental regulations pushing for higher filtration standards, the expansion of industrial manufacturing, and increasing awareness regarding the health benefits of superior air purification. These factors collectively stimulate the demand for advanced filter coating solutions that can meet evolving performance requirements and compliance mandates.

However, the market faces restraints such as the high initial cost associated with advanced coating technologies, which can deter adoption, particularly in price-sensitive markets. The complexity of developing application-specific coatings, coupled with intellectual property challenges and the need for specialized technical expertise, also limits market penetration. Furthermore, fluctuations in raw material prices and the energy-intensive nature of some coating processes pose economic challenges for manufacturers, potentially impacting profit margins and market growth trajectory.

Opportunities for growth are abundant, primarily through the development of nanotechnology-enabled coatings offering enhanced filtration efficiency and self-cleaning capabilities. The rising demand for smart filters integrated with IoT for real-time monitoring, and the advent of sustainable and bio-based coating materials, present significant avenues for innovation and market expansion. Penetration into emerging markets with rapidly industrializing economies and increasing environmental consciousness also offers substantial growth prospects for filter coating manufacturers seeking new revenue streams.

Impact forces on the market include evolving environmental protection policies and emission standards that continually reshape demand for high-performance filtration. Technological advancements in material science and coating application techniques directly influence product innovation and competitive landscapes. Global economic conditions affect industrial output and investment in filtration infrastructure, while health crises and public health awareness campaigns amplify the demand for advanced air and water purification technologies, accelerating market dynamics.

Segmentation Analysis

The Filter Coatings Market is comprehensively segmented based on various critical attributes including type, material, application, and end-use industry, providing a granular view of market dynamics and growth opportunities. This segmentation allows for a detailed analysis of specific product demands, technological trends, and regional consumption patterns, highlighting the diverse needs across different sectors. Each segment contributes uniquely to the market's overall trajectory, influenced by specific regulatory environments and operational requirements, enabling manufacturers to tailor their offerings effectively.

- By Type

- Polymer-based Coatings

- Ceramic-based Coatings

- Carbon-based Coatings

- Metallic Oxide Coatings

- Nanocoatings

- Others (e.g., Plasma Coatings)

- By Material

- PTFE

- Polyurethane

- Silicone

- Acrylic

- Fluoropolymers

- Activated Carbon

- Titanium Dioxide

- Silver Nanoparticles

- Others

- By Application

- Air Filtration

- Liquid Filtration

- Gas Filtration

- Oil/Fuel Filtration

- HVAC Systems

- Automotive Filters

- Industrial Process Filters

- Medical Filters

- Residential Filters

- Water & Wastewater Treatment

- Others (e.g., Food & Beverage)

- By End-Use Industry

- Automotive

- HVAC (Heating, Ventilation, and Air Conditioning)

- Industrial Manufacturing

- Healthcare & Pharmaceuticals

- Water & Wastewater Treatment

- Aerospace & Defense

- Chemical Processing

- Energy & Utilities

- Consumer Goods

- Others

Value Chain Analysis For Filter Coatings Market

The value chain for the Filter Coatings Market commences with upstream activities involving the sourcing and processing of raw materials. This includes specialty polymers, ceramic precursors, carbon materials, metallic oxides, and various additives from chemical manufacturers and material suppliers. Research and development plays a crucial role here, focusing on synthesizing novel compounds and optimizing existing materials for enhanced coating performance. Quality control and cost efficiency at this stage are paramount, as they directly impact the final product's attributes and market competitiveness. Upstream analysis also considers the geopolitical factors influencing raw material availability and pricing.

Moving downstream, the value chain progresses through the manufacturing of filter coatings, involving complex chemical formulation, mixing, and specialized application techniques such as spray coating, dip coating, or plasma deposition onto various filter media. This stage includes product development, testing, and scaling up production to meet market demand. Manufacturers often invest heavily in advanced equipment and process automation to ensure precision, consistency, and cost-effectiveness. The integration of sustainability practices, such as reducing waste and using environmentally friendly solvents, is also becoming increasingly important in downstream operations.

The distribution channel is multifaceted, encompassing both direct and indirect approaches. Direct distribution involves filter coating manufacturers selling directly to large original equipment manufacturers (OEMs) of filtration systems or major industrial end-users. This allows for customized solutions and closer client relationships. Indirect distribution leverages a network of distributors, wholesalers, and specialized agents who cater to a broader range of smaller businesses, regional markets, and MRO (Maintenance, Repair, and Operations) segments. These intermediaries provide logistical support, technical assistance, and localized market knowledge, expanding the reach of filter coating products.

Both direct and indirect channels play vital roles in market penetration and customer engagement. Direct sales often characterize segments requiring high technical expertise and custom formulations, while indirect sales are crucial for standard products and broader market access. The effectiveness of the distribution network is critical for timely delivery, inventory management, and providing technical support to end-users, thus influencing customer satisfaction and market share. Strong relationships with channel partners are essential for navigating market complexities and ensuring efficient product flow from production to end-use applications.

Filter Coatings Market Potential Customers

Potential customers for the Filter Coatings Market encompass a wide array of industries and end-users who rely on efficient and specialized filtration solutions for their operations and products. These include manufacturers of automotive vehicles, requiring advanced coatings for engine air and cabin air filters to meet stringent emission standards and enhance passenger comfort. HVAC system manufacturers represent another significant customer base, seeking coatings that improve air quality, prolong filter life, and reduce energy consumption in residential, commercial, and industrial buildings.

The industrial manufacturing sector is a cornerstone of demand, with industries such as chemical processing, pharmaceuticals, food and beverage, power generation, and mining all requiring high-performance filters to protect equipment, ensure product purity, and comply with environmental regulations. Companies in the water and wastewater treatment sector are also key buyers, utilizing coated filters for enhanced purification processes. Healthcare and medical device manufacturers are emerging as critical customers, demanding antimicrobial and biocompatible coatings for filters used in sensitive environments and medical equipment.

Beyond large industrial entities, the market also serves residential and commercial end-users indirectly through finished filter products. Companies providing maintenance, repair, and overhaul (MRO) services for industrial equipment and facilities also represent significant potential customers for replacement filters with advanced coatings. The breadth of applications underscores the diverse and substantial customer base driven by both regulatory compliance and the increasing imperative for operational efficiency and environmental responsibility.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 7.2 Billion |

| Market Forecast in 2032 | USD 11.5 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Donaldson Company, Inc., Hollingsworth & Vose Company, Lydall, Inc., Ahlstrom-Munksjo, Freudenberg Filtration Technologies, DuPont, Toray Industries, Inc., Mann+Hummel, Clarcor Inc., Pall Corporation, Parker Hannifin Corporation, GKD – Gebr. Kufferath AG, Porvair plc, Sefar AG, Saint-Gobain, Camfil, HVDS, Solvay S.A., BASF SE. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Filter Coatings Market Key Technology Landscape

The Filter Coatings Market is characterized by a dynamic and evolving technology landscape, with continuous advancements aimed at enhancing filtration performance, durability, and functionality. One of the most significant technological trends is the development and adoption of nanotechnology in coatings. Nanoparticles, such as titanium dioxide, silver, and carbon nanotubes, are integrated into filter media to impart properties like antimicrobial resistance, photocatalytic self-cleaning, and superior particle capture efficiency, even for ultrafine particulates. These nano-enabled coatings often create a larger surface area for filtration and can selectively target specific pollutants, representing a significant leap in filtration capabilities.

Another crucial area of innovation lies in smart coatings and functionalized surfaces. Researchers are developing coatings that can respond to environmental changes, such as pH or temperature variations, or coatings that incorporate embedded sensors for real-time monitoring of filter saturation or air quality. These "smart" filter coatings can potentially integrate with IoT systems, enabling predictive maintenance, optimized filter replacement schedules, and enhanced operational efficiency. The use of plasma treatment and atomic layer deposition (ALD) techniques is also gaining traction, allowing for precise control over coating thickness and uniformity, leading to filters with highly optimized pore structures and surface chemistries.

Furthermore, advancements in polymer science continue to drive innovation in traditional filter coatings. Development of novel fluoropolymers, silicones, and polyurethanes with enhanced chemical resistance, thermal stability, and mechanical strength ensures that filters can operate effectively in harsh industrial environments. Bio-based and environmentally friendly coating formulations are also a key focus, responding to increasing demand for sustainable solutions. These technologies collectively underscore a market driven by material science breakthroughs, process engineering refinements, and a strong push towards intelligent, high-performance, and ecologically responsible filtration solutions.

Regional Highlights

- North America: A mature market characterized by stringent environmental regulations, advanced industrial infrastructure, and high adoption of premium filtration solutions in HVAC, automotive, and industrial sectors. Significant R&D investments drive innovation.

- Europe: Similar to North America, with a strong focus on environmental protection, energy efficiency, and high-performance filtration in automotive, industrial, and medical applications. Germany, France, and the UK are key contributors.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by rapid industrialization, urbanization, increasing air pollution levels, and supportive government initiatives for cleaner environments in China, India, Japan, and South Korea.

- Latin America: An emerging market showing steady growth due to expanding industrial sectors, infrastructure development, and growing awareness of environmental and health issues, particularly in Brazil and Mexico.

- Middle East and Africa (MEA): Experiencing growth fueled by investments in industrial diversification, increasing construction activities, and rising demand for water treatment and air purification solutions in industrial and commercial sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Filter Coatings Market.- 3M Company

- Donaldson Company, Inc.

- Hollingsworth & Vose Company

- Lydall, Inc.

- Ahlstrom-Munksjo

- Freudenberg Filtration Technologies

- DuPont

- Toray Industries, Inc.

- Mann+Hummel

- Clarcor Inc.

- Pall Corporation

- Parker Hannifin Corporation

- GKD – Gebr. Kufferath AG

- Porvair plc

- Sefar AG

- Saint-Gobain

- Camfil

- HVDS

- Solvay S.A.

- BASF SE

Frequently Asked Questions

Analyze common user questions about the Filter Coatings market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are filter coatings?

Filter coatings are specialized surface treatments applied to filter media to enhance their performance, such as improving filtration efficiency, extending lifespan, or imparting specific functionalities like water repellency or antimicrobial properties.

Why are filter coatings important?

They are crucial for optimizing filtration processes, enabling filters to capture finer particles, resist harsh conditions, prevent microbial growth, and reduce pressure drop, leading to cleaner air/liquids and increased operational efficiency.

What are the primary applications of filter coatings?

Key applications include air filtration (HVAC, automotive, industrial), liquid filtration (water treatment, chemical processing), and gas filtration, serving industries like manufacturing, healthcare, and residential sectors.

What types of materials are used in filter coatings?

Common materials include polymers (e.g., PTFE, polyurethane, acrylic), ceramics, activated carbon, and metallic oxides, with nanotechnology (e.g., silver, titanium dioxide nanoparticles) increasingly used for advanced functionalities.

What is the market outlook for filter coatings?

The filter coatings market is projected for significant growth, driven by increasing global concerns over air and water quality, stricter environmental regulations, rapid industrialization, and continuous technological advancements in coating materials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager