Fire Tube Low Temperature Industrial Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429449 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Fire Tube Low Temperature Industrial Boiler Market Size

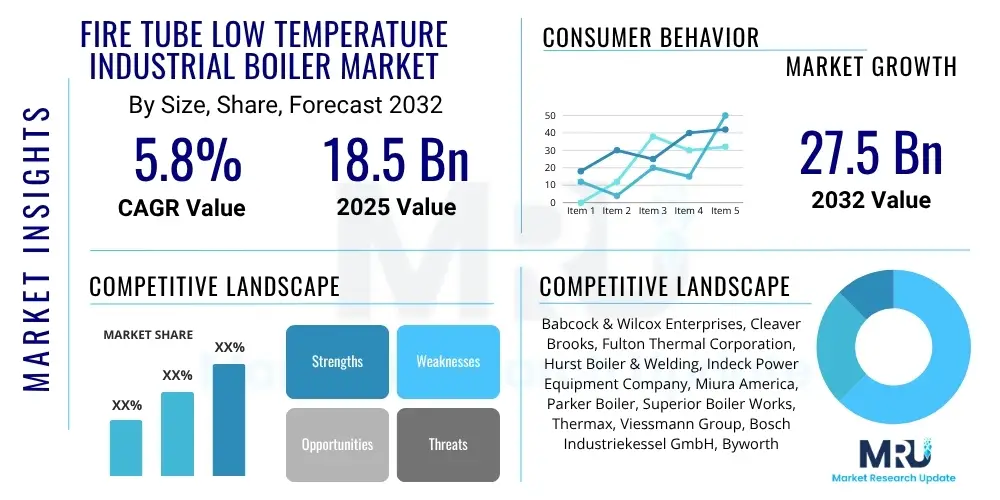

The Fire Tube Low Temperature Industrial Boiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at $18.5 Billion in 2025 and is projected to reach $27.5 Billion by the end of the forecast period in 2032.

Fire Tube Low Temperature Industrial Boiler Market introduction

The Fire Tube Low Temperature Industrial Boiler Market encompasses a critical segment of industrial heating solutions, providing efficient and reliable steam or hot water for various operational needs at moderate temperatures. These boilers are specifically designed to handle a range of industrial applications where process heat is required below the superheated steam threshold, offering a cost-effective and energy-efficient alternative to high-temperature systems. Their robust construction, typically featuring a cylindrical shell with tubes carrying hot gases, ensures durability and ease of maintenance, making them a cornerstone technology in the industrial sector. The market is primarily driven by the ongoing industrialization in emerging economies and the increasing emphasis on energy conservation and emission reduction globally, necessitating the adoption of more efficient heating equipment.

Fire tube boilers are characterized by their design where combustion gases pass through tubes surrounded by water, facilitating efficient heat transfer. Low temperature industrial boilers, specifically, operate below 250 degrees Fahrenheit for hot water or at pressures up to 15 psi for steam, making them ideal for applications not requiring extremely high temperatures or pressures. Major applications span across diverse industries including food and beverage processing, pharmaceuticals, chemical manufacturing, textiles, and heating ventilation and air conditioning (HVAC) for large commercial and institutional buildings. These boilers are valued for their operational simplicity, quick response to load changes, and comparatively lower capital expenditure than more complex boiler systems, contributing significantly to their market penetration across various industrial segments.

The benefits derived from deploying fire tube low temperature industrial boilers are multifaceted, extending from enhanced energy efficiency due to optimized combustion and heat recovery systems, to reduced operational costs through lower fuel consumption and maintenance requirements. They also contribute to environmental sustainability by allowing for lower emissions when integrated with modern combustion technologies and alternative fuels. Driving factors include the continuous expansion of manufacturing capacities worldwide, the escalating demand for process heating in numerous industrial processes, and the implementation of stringent environmental regulations that favor energy-efficient and cleaner burning boiler technologies. Furthermore, technological advancements in control systems and material science are consistently improving the performance and longevity of these boilers, reinforcing their market position.

Fire Tube Low Temperature Industrial Boiler Market Executive Summary

The Fire Tube Low Temperature Industrial Boiler market is poised for significant expansion, driven by accelerating industrialization and modernization initiatives across various global economies. Key business trends indicate a shift towards modular designs, smart boiler technologies, and solutions tailored for specific industrial processes, emphasizing customization and operational flexibility. Manufacturers are increasingly integrating IoT and AI into boiler systems to enhance efficiency, facilitate predictive maintenance, and enable remote monitoring, thereby optimizing performance and reducing downtime for end-users. Strategic partnerships and mergers and acquisitions are also prevalent as companies seek to consolidate market share and leverage technological synergies to offer more comprehensive solutions to their diverse customer base.

Regionally, Asia Pacific is expected to maintain its dominance due to rapid industrial growth in countries like China and India, coupled with increasing investments in manufacturing infrastructure. North America and Europe are witnessing a trend towards the replacement of aging boiler fleets with newer, more energy-efficient models that comply with stricter environmental standards, focusing on sustainability and emission reductions. Segment-wise, the market is primarily driven by the demand for natural gas-fired boilers due to their cleaner burning characteristics and widespread availability, although biomass and hybrid fuel options are gaining traction as industries seek diversified and sustainable energy sources. The application segment continues to be led by process heating in sectors such as food and beverage, chemical, and pharmaceutical, all demanding reliable and consistent low-temperature heat.

AI Impact Analysis on Fire Tube Low Temperature Industrial Boiler Market

User inquiries regarding AI's influence on the Fire Tube Low Temperature Industrial Boiler market frequently revolve around its potential to revolutionize operational efficiency, predictive maintenance capabilities, and overall energy management. Users are keen to understand how AI can move beyond basic automation to offer intelligent diagnostics, real-time optimization of combustion processes, and proactive identification of potential system failures, thereby minimizing downtime and extending asset lifespans. There is also significant interest in AI's role in optimizing fuel consumption, integrating with renewable energy sources, and ensuring compliance with increasingly stringent environmental regulations, showcasing a collective expectation for smarter, more sustainable, and autonomous boiler operations that enhance both economic and ecological outcomes.

- AI driven predictive maintenance extends boiler lifespan and reduces unscheduled downtime.

- Real time combustion optimization through AI algorithms improves fuel efficiency and reduces emissions.

- AI enhanced control systems allow for precise temperature and pressure regulation, adapting to fluctuating industrial demands.

- Remote monitoring and diagnostics powered by AI offer significant operational cost savings and faster troubleshooting.

- Integration of AI with IoT sensors enables comprehensive data analysis for proactive system management and performance benchmarking.

- AI facilitates better energy management by predicting load requirements and optimizing boiler output, reducing overall energy consumption.

- Improved safety protocols are achieved through AI based anomaly detection, identifying potential hazards before they escalate.

- AI assists in regulatory compliance by automatically logging operational data and suggesting adjustments to meet emission standards.

DRO & Impact Forces Of Fire Tube Low Temperature Industrial Boiler Market

The Fire Tube Low Temperature Industrial Boiler Market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces shaping its trajectory. Key drivers include the relentless pace of global industrialization, particularly in developing economies, which consistently fuels demand for efficient process heating solutions. Additionally, increasingly stringent environmental regulations, mandating lower emissions and higher energy efficiency, compel industries to invest in modern, optimized boiler systems. The growing preference for natural gas as a cleaner fuel source also acts as a significant catalyst, expanding the adoption of compatible fire tube boilers. These factors collectively push for continuous innovation and market growth.

Conversely, several restraints temper the market's growth potential. The substantial initial capital investment required for new industrial boiler installations can be a barrier for small and medium sized enterprises. Fluctuations in raw material prices, particularly for steel and other critical components, can impact manufacturing costs and, consequently, end-product pricing. Furthermore, the rise of alternative heating technologies, such as electric boilers or heat pumps in certain applications, presents a competitive challenge, potentially limiting the market share of traditional fire tube boilers. A lack of awareness or slow adoption of advanced technologies in some regions also hinders faster market penetration.

Despite these challenges, the market is rich with opportunities. The burgeoning demand from emerging markets, coupled with infrastructure development, offers vast untapped potential. Opportunities also arise from the increasing focus on customization and modular boiler solutions that can be tailored to specific industrial requirements, enhancing their appeal. Integrating fire tube boilers with smart technologies, such as IoT and AI for predictive maintenance and energy optimization, represents a lucrative avenue for innovation and market differentiation. The overall impact forces, including the bargaining power of buyers driven by product differentiation and the competitive landscape, alongside the threat of substitutes and new entrants, necessitate continuous innovation and strategic positioning for market players to thrive.

Segmentation Analysis

The Fire Tube Low Temperature Industrial Boiler market is comprehensively segmented to provide a detailed understanding of its diverse components and drivers. These segmentations are critical for market players to identify specific niches, tailor product offerings, and develop targeted marketing strategies. The market can be broadly categorized based on the type of fuel used, the boiler capacity, the specific application areas, and the end-use industries. Each segment exhibits unique growth dynamics and demand patterns, influenced by factors such as regional energy policies, industrial development, and technological preferences.

- By Fuel Type

- Natural Gas Fired Boilers: Dominant due to cleaner combustion and extensive infrastructure.

- Oil Fired Boilers: Used in regions with abundant oil supply or as backup.

- Biomass Fired Boilers: Growing segment driven by sustainability goals and waste utilization.

- Electric Boilers: Niche applications, often where carbon emissions are strictly regulated or electricity is cheaper.

- Hybrid Boilers: Combining multiple fuel types for flexibility and efficiency.

- By Capacity

- Small Capacity Boilers (Less than 10 MMBtu/hr): Used in smaller facilities or for auxiliary heating.

- Medium Capacity Boilers (10 MMBtu/hr to 50 MMBtu/hr): Common across various industrial plants.

- Large Capacity Boilers (More than 50 MMBtu/hr): Deployed in heavy industries requiring significant process heat.

- By Application

- Process Heating: Essential for chemical processing, food and beverage, pharmaceuticals.

- Space Heating: For large commercial and industrial buildings.

- Hot Water Generation: Utilized in various sanitation and industrial cleaning processes.

- Sterilization: Critical in healthcare and pharmaceutical industries.

- By End User Industry

- Food and Beverage Industry: For cooking, pasteurization, and cleaning.

- Chemical Industry: For reaction processes, distillation, and heating.

- Pharmaceutical Industry: For sterilization, drying, and process heating.

- Textile Industry: For dyeing, drying, and finishing processes.

- Pulp and Paper Industry: For drying and processing.

- Other Industries: Including automotive, metallurgy, and plastics.

Value Chain Analysis For Fire Tube Low Temperature Industrial Boiler Market

The value chain for the Fire Tube Low Temperature Industrial Boiler market is a complex ecosystem, beginning with the upstream activities of raw material sourcing and component manufacturing, extending through the production and assembly phases, and culminating in downstream distribution, installation, and comprehensive after-sales services. Upstream analysis involves the procurement of essential raw materials such as various grades of steel, insulation materials, refractory linings, and specialized components like burners, pumps, and control systems. Suppliers of these materials and components play a crucial role in determining the quality, cost efficiency, and lead times for boiler manufacturers. Strategic partnerships with reliable suppliers are paramount to ensure consistent product quality and to mitigate supply chain risks, especially for specialized parts.

The midstream segment of the value chain focuses on the design, manufacturing, and assembly of the boilers. This stage involves significant engineering expertise, advanced fabrication techniques, and quality control processes to ensure the boilers meet industry standards and specific customer requirements. Manufacturers often invest heavily in research and development to innovate designs, improve energy efficiency, and integrate smart technologies. Downstream activities involve the distribution channel, which can be direct or indirect. Direct sales are common for large industrial clients requiring custom solutions and direct technical support, often involving specialized sales teams and engineers from the manufacturer. Indirect distribution, on the other hand, relies on a network of authorized distributors, agents, and engineering, procurement, and construction (EPC) contractors who manage sales, installation, and commissioning for a broader customer base, including smaller industries and commercial facilities.

The distribution channel is pivotal in ensuring market reach and efficient delivery of products and services. Direct channels provide greater control over customer relationships and service quality, while indirect channels offer broader market penetration and localized support. Post-sales services, including installation, maintenance, repair, and spare parts supply, constitute a critical part of the downstream value chain, significantly influencing customer satisfaction and long-term loyalty. Companies that offer comprehensive service packages and proactive maintenance solutions tend to build stronger customer relationships and secure recurring revenue streams. The efficiency and reliability of these services are often as important as the boiler's initial performance, driving the overall perceived value and competitive advantage in the market.

Fire Tube Low Temperature Industrial Boiler Market Potential Customers

The Fire Tube Low Temperature Industrial Boiler Market serves a broad spectrum of end-users across various industrial and commercial sectors, all of whom require reliable and efficient sources of low-temperature steam or hot water for their operations. These potential customers primarily include manufacturing facilities that utilize process heat for heating, drying, curing, or sterilization purposes. Industries such as food and beverage, pharmaceuticals, chemicals, and textiles are prominent consumers, relying on these boilers for critical production stages that demand consistent and controlled thermal energy. For instance, food processing plants need boilers for cooking, pasteurization, and cleaning, while pharmaceutical companies require sterile steam for manufacturing processes and equipment sterilization.

Beyond traditional manufacturing, the market also targets large commercial and institutional establishments, including hospitals, universities, hotels, and office complexes, which often require extensive space heating, domestic hot water, and air conditioning systems. These end-users prioritize energy efficiency and operational reliability to manage their substantial heating demands and reduce utility costs. Furthermore, agricultural sectors, such as greenhouses and livestock farms, increasingly adopt low-temperature boilers for environmental control and specific processing needs. The diversity in end-user requirements necessitates manufacturers to offer a range of capacities, fuel types, and customizable features to cater effectively to this broad customer base. The emphasis on energy savings and environmental compliance is a common thread that drives purchasing decisions across all these potential customer segments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $18.5 Billion |

| Market Forecast in 2032 | $27.5 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Babcock & Wilcox Enterprises, Cleaver Brooks, Fulton Thermal Corporation, Hurst Boiler & Welding, Indeck Power Equipment Company, Miura America, Parker Boiler, Superior Boiler Works, Thermax, Viessmann Group, Bosch Industriekessel GmbH, Byworth Boilers, Cochran, John Thompson Boilers, Unilux, Mitsubishi Heavy Industries, Kawasaki Heavy Industries, Alfa Laval, Danfoss, Atlas Copco |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fire Tube Low Temperature Industrial Boiler Market Key Technology Landscape

The Fire Tube Low Temperature Industrial Boiler market is continuously evolving through significant technological advancements aimed at enhancing efficiency, reducing environmental impact, and improving operational reliability. A primary area of focus is on advanced combustion technologies, which include low NOx (nitrogen oxide) burners and optimized air-to-fuel ratio controls. These innovations are crucial for achieving cleaner emissions and meeting increasingly stringent environmental regulations, while simultaneously maximizing fuel efficiency. Furthermore, the integration of waste heat recovery systems, such as economizers and preheaters, is becoming standard practice, allowing for the capture and reuse of heat from flue gases, significantly boosting the overall thermal efficiency of the boiler system and reducing fuel consumption.

Another pivotal technological trend involves the increasing adoption of digital controls and automation. Modern fire tube boilers are equipped with sophisticated programmable logic controllers (PLCs) and distributed control systems (DCS) that enable precise monitoring and control of various operational parameters, from water levels and steam pressure to combustion rates and safety interlocks. These smart control systems facilitate remote operation, fault diagnosis, and predictive maintenance, thereby minimizing manual intervention, reducing downtime, and optimizing performance. The proliferation of IoT (Internet of Things) sensors further enhances this capability, allowing for real-time data collection and analysis, which can be leveraged for continuous process improvement and energy management.

Moreover, material science plays a significant role in improving the durability and performance of these boilers. The use of advanced alloys and corrosion-resistant materials for boiler tubes and pressure vessels extends the lifespan of the equipment and reduces maintenance frequency, especially when dealing with aggressive feed water or fuel types. Innovations in insulation materials also contribute to reducing heat losses, thereby increasing energy efficiency. The continuous drive towards modular designs and factory-assembled units is simplifying installation processes, reducing on-site construction time, and ensuring higher quality control. These technological enhancements collectively contribute to making fire tube low temperature industrial boilers more competitive, sustainable, and integral to modern industrial operations.

Regional Highlights

- North America: Characterized by a strong emphasis on modernizing aging infrastructure and adopting highly efficient, low emission boiler technologies. Stringent environmental regulations in the United States and Canada drive demand for advanced fire tube boilers.

- Europe: Focuses on decarbonization and energy transition, leading to increased adoption of biomass-fired and electric low temperature boilers, especially in countries with robust renewable energy policies like Germany and the UK.

- Asia Pacific (APAC): Dominates the market due to rapid industrialization, particularly in China, India, and Southeast Asian nations. High demand from manufacturing, food processing, and chemical industries fuels significant growth and new installations.

- Latin America: Exhibits steady growth driven by industrial development and investments in infrastructure, particularly in countries like Brazil and Mexico. The market here is moderately fragmented with a mix of local and international players.

- Middle East and Africa (MEA): Emerging market with growing investments in oil and gas, manufacturing, and commercial sectors. Demand is rising for robust boilers capable of operating in diverse climatic conditions, often driven by infrastructure projects in Saudi Arabia and UAE.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fire Tube Low Temperature Industrial Boiler Market.- Babcock & Wilcox Enterprises

- Cleaver Brooks

- Fulton Thermal Corporation

- Hurst Boiler & Welding

- Indeck Power Equipment Company

- Miura America

- Parker Boiler

- Superior Boiler Works

- Thermax

- Viessmann Group

- Bosch Industriekessel GmbH

- Byworth Boilers

- Cochran

- John Thompson Boilers

- Unilux

- Mitsubishi Heavy Industries

- Kawasaki Heavy Industries

- Alfa Laval

- Danfoss

- Atlas Copco

Frequently Asked Questions

What is a fire tube low temperature industrial boiler?

A fire tube low temperature industrial boiler is a type of boiler where hot combustion gases pass through tubes, which are surrounded by water within a larger shell. It is designed to produce steam at low pressures (typically up to 15 psi) or hot water at temperatures generally below 250 degrees Fahrenheit, making it ideal for process heating, space heating, and hot water generation in various industrial and commercial applications.

Which industries are the primary users of these boilers?

Primary users include the food and beverage industry for cooking and pasteurization, the pharmaceutical industry for sterilization and drying, chemical manufacturing for process heating, textile production for dyeing and finishing, and the HVAC sector for large building heating. These boilers provide essential thermal energy for a wide range of critical industrial processes.

What are the key advantages of fire tube low temperature industrial boilers?

Key advantages include high energy efficiency, particularly with modern designs and waste heat recovery systems, reduced operational costs due to lower fuel consumption and maintenance, robust and compact design, ease of operation, quick response to load changes, and comparatively lower initial capital investment compared to more complex high-pressure systems. They also contribute to environmental sustainability through lower emissions when using cleaner fuels.

How do environmental regulations impact the market for these boilers?

Environmental regulations significantly impact the market by driving demand for more energy-efficient and low emission boiler technologies. Stricter standards on NOx, CO, and particulate matter emissions compel industries to invest in advanced combustion systems, such as low NOx burners, and to consider cleaner fuel types like natural gas or biomass. This regulatory pressure encourages innovation and the replacement of older, less compliant boilers.

What role does digitalization and IoT play in the Fire Tube Low Temperature Industrial Boiler Market?

Digitalization and IoT are transforming the market by enabling advanced monitoring, control, and predictive maintenance. IoT sensors collect real-time data on boiler performance, which can be analyzed by digital control systems and AI to optimize combustion, improve fuel efficiency, and anticipate potential equipment failures. This leads to reduced downtime, lower operational costs, and enhanced overall system reliability and safety.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager