Flexible Foam Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430133 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Flexible Foam Market Size

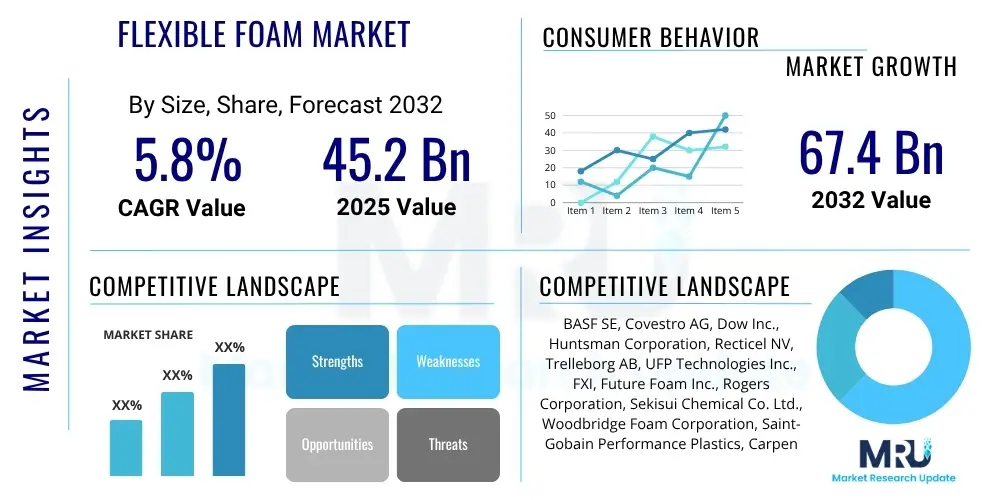

The Flexible Foam Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 45.2 billion in 2025 and is projected to reach USD 67.4 billion by the end of the forecast period in 2032.

Flexible Foam Market introduction

The Flexible Foam Market encompasses a diverse range of polymer-based materials characterized by their pliable and resilient nature. Primarily composed of polyurethane, but also including polyethylene, polypropylene, and EVA foams, these materials offer excellent cushioning, insulation, and shock absorption properties. Their open-cell or closed-cell structures allow for varied applications, making them indispensable across numerous industries.

Key applications for flexible foams span from comfort-oriented products like mattresses, furniture upholstery, and automotive seating to protective packaging, sound insulation in construction, and specialized medical devices. The inherent benefits of flexible foams, such as their lightweight nature, durability, thermal and acoustic insulation capabilities, and adaptability to various shapes, drive their widespread adoption. These advantages contribute significantly to enhanced product performance and user comfort in diverse end-use sectors.

The market is primarily driven by the escalating demand from the automotive industry for lightweight and comfortable interiors, the expanding global furniture and bedding sectors fueled by urbanization and increasing disposable incomes, and the growing need for efficient packaging solutions. Furthermore, advancements in foam technology, leading to improved performance characteristics and sustainable options, continue to propel market expansion, catering to evolving industry standards and consumer preferences.

Flexible Foam Market Executive Summary

The Flexible Foam Market is experiencing robust growth driven by sustained demand across key end-use industries such as automotive, furniture, bedding, and packaging. Business trends indicate a strong focus on product innovation, particularly in developing sustainable and bio-based foam solutions, alongside strategic mergers and acquisitions aimed at consolidating market share and expanding product portfolios. Manufacturers are increasingly investing in advanced production technologies to enhance efficiency and product quality, responding to the need for high-performance and environmentally friendly materials.

Regionally, Asia Pacific continues to emerge as the dominant and fastest-growing market, primarily due to rapid industrialization, increasing urbanization, and a burgeoning middle class in countries like China and India, which fuels demand in construction, automotive, and consumer goods sectors. North America and Europe also maintain significant market shares, characterized by a strong emphasis on technological advancement, stringent environmental regulations driving sustainability efforts, and a mature automotive and furniture industry landscape that demands premium quality foams.

Segment-wise, polyurethane flexible foam maintains its leading position due to its versatility and superior performance characteristics, widely adopted across almost all application areas. The furniture and bedding application segment remains the largest consumer, driven by continuous residential and commercial construction activities and evolving consumer preferences for comfort and ergonomic designs. The automotive segment also presents substantial growth, propelled by the increasing production of vehicles and the rising demand for lightweight components to improve fuel efficiency and enhance passenger comfort.

AI Impact Analysis on Flexible Foam Market

User queries regarding the impact of AI on the flexible foam market frequently center on themes of operational efficiency, quality control, sustainable manufacturing, and supply chain optimization. Key concerns include the initial investment costs for AI integration, the need for specialized skills, and data privacy. Expectations are high for AI to revolutionize various stages of foam production, from raw material management to finished product inspection, ultimately enhancing competitiveness and environmental compliance.

- AI driven process optimization enhances manufacturing efficiency and reduces waste by predicting optimal parameters.

- Predictive maintenance for machinery minimizes downtime and extends equipment lifespan in foam production facilities.

- Automated quality inspection systems improve consistency and detect defects with higher accuracy than manual methods.

- AI powered supply chain management optimizes inventory, logistics, and raw material procurement, mitigating price volatility.

- Generative design tools assist in developing novel foam structures with improved performance characteristics.

- Enhanced energy management in production lines through AI algorithms leads to lower operational costs and a reduced carbon footprint.

- Data analytics platforms provide insights into market trends, customer preferences, and production bottlenecks, informing strategic decisions.

- Robotics integrated with AI can handle hazardous tasks, improving worker safety and productivity in foam handling.

DRO & Impact Forces Of Flexible Foam Market

The Flexible Foam Market is significantly influenced by a dynamic interplay of driving forces, restraining factors, and emerging opportunities, all contributing to its overall impact and trajectory. Key drivers include the robust growth in end-use industries such as automotive, furniture, bedding, and construction, where flexible foams are essential for comfort, insulation, and protective applications. Additionally, increasing disposable incomes in developing regions, coupled with rapid urbanization, are fueling demand for upholstered products and better quality living spaces, thereby boosting foam consumption. Technological advancements leading to improved foam properties like enhanced durability, flame retardancy, and customized densities further propel market expansion.

Conversely, the market faces considerable restraints, primarily the volatile pricing of key raw materials like isocyanates and polyols, which are petroleum derivatives, leading to cost fluctuations and impacting profit margins for manufacturers. Environmental concerns regarding the disposal of conventional flexible foams and their non-biodegradable nature pose another significant challenge, driving regulatory pressures and consumer preference towards more sustainable alternatives. The emergence of alternative materials that offer similar functional properties at competitive prices also presents a restraint, potentially eroding market share.

Despite these challenges, substantial opportunities exist, particularly in the development and adoption of bio-based and recycled flexible foams, addressing environmental concerns and meeting sustainability goals. The increasing demand for lightweight and high-performance materials in electric vehicles and advanced aerospace applications offers new avenues for specialized foam products. Furthermore, expansion into untapped emerging markets and strategic collaborations for technological innovation are expected to unlock new growth potential, allowing the market to overcome existing hurdles and capitalize on evolving industrial needs.

Segmentation Analysis

The Flexible Foam Market is extensively segmented based on various criteria to provide a detailed understanding of its dynamics and growth prospects across different product types, applications, and end-use industries. This segmentation helps in identifying key market trends, competitive landscapes, and opportunities within specific niches. The primary types of flexible foams include polyurethane, polyethylene, polypropylene, and EVA foams, each possessing distinct properties suitable for particular applications.

Applications range from critical components in the automotive sector for seating and interior panels to comfort layers in furniture and bedding, insulation in building and construction, and protective solutions in packaging. The diverse end-use industries further categorize the market, highlighting the broad utility of flexible foams in residential, commercial, industrial, and specialized sectors. Each segment's growth is influenced by specific market drivers, technological advancements, and regulatory environments, contributing to the overall market's complex structure.

- By Type

- Polyurethane Flexible Foam

- Polyester Polyurethane Foam

- Polyether Polyurethane Foam

- Polyethylene Foam

- Polypropylene Foam

- EVA Foam

- Others (e.g., Natural Rubber Foam, Silicone Foam)

- Polyurethane Flexible Foam

- By Application

- Furniture and Bedding

- Automotive (Seating, Interiors, Headliners)

- Building and Construction (Insulation, Sealing)

- Packaging (Protective Packaging, Custom Cushions)

- Textile and Apparel (Interlining, Padding)

- Medical and Healthcare (Wound Dressings, Orthotics)

- Others (e.g., Sports and Leisure, Consumer Goods)

- By End-Use Industry

- Residential

- Commercial

- Industrial

- Institutional

Value Chain Analysis For Flexible Foam Market

The value chain for the flexible foam market begins with upstream activities, primarily involving the sourcing and production of critical raw materials. This stage is dominated by chemical manufacturers who supply essential components such as polyols, isocyanates (TDI, MDI), blowing agents, catalysts, and various additives like flame retardants, colorants, and stabilizers. The quality, availability, and cost of these raw materials significantly influence the overall production cost and performance of the final foam products. Key players in this segment include large petrochemical companies and specialty chemical manufacturers.

The midstream segment involves the core manufacturing process, where raw materials are chemically reacted to produce flexible foam. This includes both slabstock production, which yields large blocks of foam subsequently cut into desired shapes, and molded foam production, where foam is directly formed into specific shapes using molds. Foam manufacturers, ranging from global giants to regional specialists, apply various technologies and formulations to create foams with specific properties like density, hardness, resilience, and porosity. This stage also includes initial processing such as cutting, shaping, and sometimes lamination.

Downstream activities involve the further processing, distribution, and end-use integration of flexible foams. Converters and fabricators take the raw foam stock and transform it into finished components or products tailored for specific applications, such as cut foam for mattresses, molded automotive seats, or specialized packaging inserts. Distribution channels are varied, including direct sales to large original equipment manufacturers (OEMs) in industries like automotive and furniture, as well as indirect channels through a network of distributors and wholesalers who cater to smaller businesses, retailers, and diverse end-users. The efficiency of these distribution networks is crucial for timely delivery and market penetration across various geographical regions and application sectors, ensuring that the diverse needs of the global market are effectively met.

Flexible Foam Market Potential Customers

The potential customers for flexible foam products span a broad spectrum of industries, driven by the material's versatile properties such as cushioning, insulation, and shock absorption. The largest segment of buyers comprises manufacturers within the furniture and bedding industry, including mattress producers, upholstered furniture makers, and cushion manufacturers, who utilize flexible foams for comfort layers, support cores, and padding. These customers frequently require foams with specific densities, resilience, and durability to meet ergonomic and longevity standards for consumer products.

Another significant customer base is the automotive industry, where flexible foams are integral to vehicle interiors. This includes automotive OEMs and tier-1 suppliers who purchase foams for car seats, headliners, door panels, armrests, and sound insulation applications. The demand here is often for lightweight foams that contribute to fuel efficiency, along with properties such as flame retardancy, comfort, and noise vibration harshness (NVH) reduction. The building and construction sector also represents a key end-user group, requiring flexible foams for thermal insulation, soundproofing, sealing applications, and pipe insulation, driven by energy efficiency standards and building codes.

Furthermore, the packaging industry is a vital customer, utilizing flexible foams for protective packaging solutions for delicate electronics, industrial components, and consumer goods, ensuring product safety during transit. Other notable end-users include the textile and apparel industry for padding and interlinings, the medical and healthcare sector for wound dressings, orthotics, and patient positioning, and various consumer goods manufacturers for products ranging from sports equipment to toys. Each customer group has distinct requirements for foam properties, volumes, and delivery logistics, necessitating customized product offerings and supply chain solutions from flexible foam manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 45.2 Billion |

| Market Forecast in 2032 | USD 67.4 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Covestro AG, Dow Inc., Huntsman Corporation, Recticel NV, Trelleborg AB, UFP Technologies Inc., FXI, Future Foam Inc., Rogers Corporation, Sekisui Chemical Co. Ltd., Woodbridge Foam Corporation, Saint-Gobain Performance Plastics, Carpenter Co., Armacell International S.A., JSP Corporation, Toray Industries Inc., Zotefoams plc, INOAC Corporation, Evonik Industries AG. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flexible Foam Market Key Technology Landscape

The flexible foam market is continuously evolving with significant technological advancements aimed at enhancing performance, improving manufacturing efficiency, and addressing sustainability concerns. A foundational technology involves the sophisticated chemistry behind polyurethane foam production, encompassing precise control over polyol and isocyanate ratios, along with the selection of various catalysts, surfactants, and blowing agents. Innovations here focus on creating foams with tailored properties such as improved resilience, specific densities, enhanced flame retardancy, and superior thermal or acoustic insulation capabilities, critical for high-end applications in automotive and bedding industries.

Another crucial area of technological development lies in manufacturing processes. Advancements in continuous slabstock foaming, including variable pressure foaming (VPF) and CO2 blowing technologies, allow for better control over cell structure, reduced volatile organic compound (VOC) emissions, and more efficient resource utilization. For molded foams, innovations in tooling and injection techniques enable the production of complex shapes with higher precision and less material waste, particularly relevant for automotive seating and ergonomic furniture components. Robotics and automation are also increasingly integrated into production lines to enhance consistency, speed, and safety.

Furthermore, sustainability-driven technological innovations are gaining prominence. This includes the development of bio-based polyols derived from renewable resources like soy, castor oil, or algae, which reduce reliance on petrochemicals and lower the carbon footprint of flexible foams. Chemical and mechanical recycling technologies for post-consumer and post-industrial foam waste are also advancing, aiming to create a circular economy for foam products. The integration of smart additives and fillers for improved foam functionality, alongside digital tools for simulation and design, represents the cutting edge, enabling manufacturers to innovate rapidly and meet the stringent performance and environmental demands of a diverse global market.

Regional Highlights

- North America: This region showcases a mature market characterized by significant demand from the automotive, furniture, and construction sectors. Innovation in lightweight and durable foams, coupled with a focus on sustainable solutions, drives market expansion. The presence of major market players and robust R&D infrastructure contributes to its stable growth.

- Europe: Europe is a key market, driven by stringent environmental regulations and a strong emphasis on sustainability, leading to increased adoption of bio-based and recycled foams. The automotive and bedding industries are prominent consumers, with a rising demand for comfort and performance foams.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market due to rapid urbanization, increasing disposable incomes, and booming manufacturing sectors in countries like China, India, and Southeast Asian nations. High demand from construction, automotive, and furniture industries fuels this growth, alongside expanding industrialization.

- Latin America: This region exhibits steady growth, primarily influenced by improving economic conditions and increased foreign investments, leading to growth in construction and automotive manufacturing. There is a growing demand for cost-effective and versatile foam solutions across various applications.

- Middle East and Africa (MEA): The MEA region is experiencing growth driven by infrastructure development projects, increasing tourism, and a burgeoning population. Demand for flexible foams is particularly strong in the construction and furniture sectors, with a gradual shift towards modern and high-quality materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flexible Foam Market.- BASF SE

- Covestro AG

- Dow Inc.

- Huntsman Corporation

- Recticel NV

- Trelleborg AB

- UFP Technologies Inc.

- FXI

- Future Foam Inc.

- Rogers Corporation

- Sekisui Chemical Co. Ltd.

- Woodbridge Foam Corporation

- Saint-Gobain Performance Plastics

- Carpenter Co.

- Armacell International S.A.

- JSP Corporation

- Toray Industries Inc.

- Zotefoams plc

- INOAC Corporation

- Evonik Industries AG

Frequently Asked Questions

What are the primary applications of flexible foam?

Flexible foam is primarily used in furniture and bedding for comfort and support, in automotive interiors for seating and sound dampening, in building and construction for insulation and sealing, and in packaging for protective cushioning of goods during transit.

Which type of flexible foam holds the largest market share?

Polyurethane flexible foam consistently holds the largest market share due to its versatility, excellent cushioning properties, and adaptability across a wide range of applications, including furniture, automotive, and bedding.

How is sustainability influencing the flexible foam market?

Sustainability is driving innovation in the flexible foam market towards bio-based raw materials, enhanced recycling technologies, and foams with lower volatile organic compound (VOC) emissions, responding to environmental concerns and consumer demand for greener products.

What are the main drivers of growth for the flexible foam market?

Key growth drivers include increasing demand from the automotive industry for lightweight and comfortable interiors, expansion of the global furniture and bedding sectors, rising construction activities, and the growing need for efficient packaging solutions.

Which geographical region is expected to lead the flexible foam market?

The Asia Pacific region is projected to lead the flexible foam market in terms of both market size and growth rate, primarily driven by rapid industrialization, urbanization, and a burgeoning middle-class population in countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager