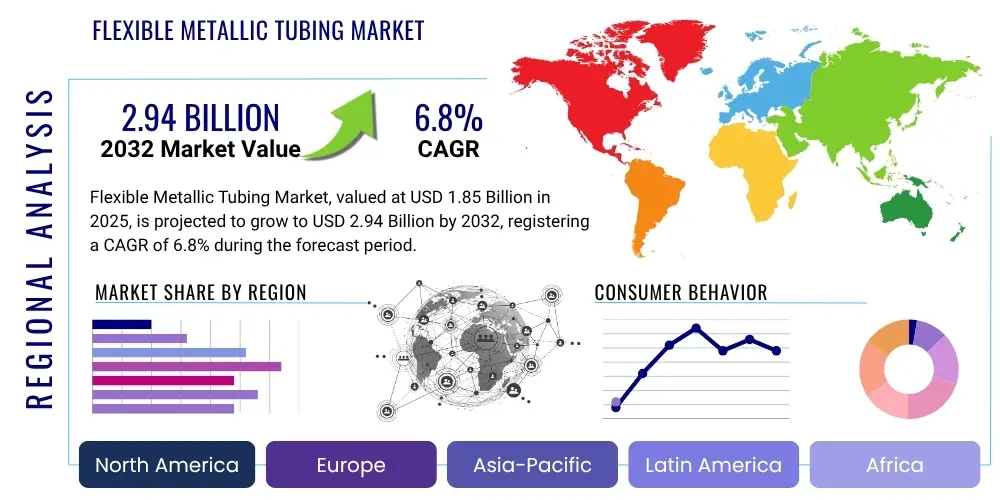

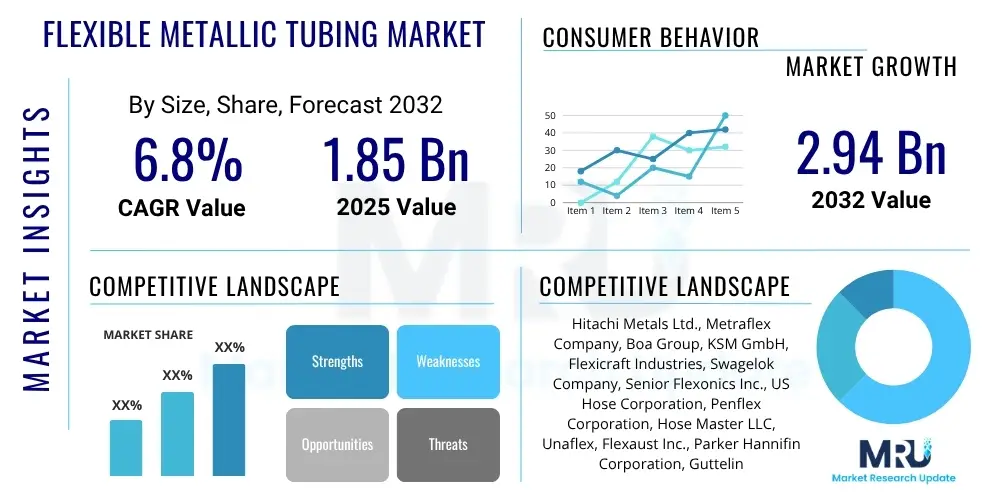

Flexible Metallic Tubing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429112 | Date : Oct, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Flexible Metallic Tubing Market Size

The Flexible Metallic Tubing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.85 Billion in 2025 and is projected to reach USD 2.94 Billion by the end of the forecast period in 2032.

Flexible Metallic Tubing Market introduction

The Flexible Metallic Tubing Market encompasses the manufacturing and distribution of specialized tubes crafted from various metals, designed to offer exceptional flexibility, durability, and resistance to extreme conditions. These crucial components are engineered to manage the transfer of fluids, gases, and granular materials under demanding operational pressures and temperatures, making them indispensable across a multitude of industrial applications. Their unique construction allows for significant bending and vibration absorption, attributes that rigid piping systems cannot provide, thereby addressing complex installation challenges and enhancing system longevity.

Flexible metallic tubing, often constructed from materials like stainless steel, bronze, Monel, or Inconel, features a corrugated or helical core, frequently reinforced with a braided wire mesh to boost pressure resistance and prevent elongation. This robust design ensures high performance in critical environments where safety and reliability are paramount. The product's inherent benefits include superior corrosion resistance, high temperature and pressure handling capabilities, excellent vibration dampening, and a long service life, reducing the need for frequent maintenance and replacement.

Key applications span diverse sectors such as oil and gas, chemical processing, automotive, aerospace, HVAC, and power generation, where they are utilized in exhaust systems, fuel lines, hydraulic systems, and cryogenic transfer lines. The market's growth is primarily driven by expanding industrial infrastructure, increasing demand for robust fluid and gas conveyance systems, stringent safety and environmental regulations mandating reliable components, and the continuous need for advanced materials in high-performance applications globally.

Flexible Metallic Tubing Market Executive Summary

The Flexible Metallic Tubing Market is experiencing robust expansion driven by global industrialization and a heightened focus on operational efficiency and safety across various sectors. Business trends indicate a strong emphasis on customization, with manufacturers increasingly developing application-specific tubing solutions that meet precise client requirements for pressure, temperature, and chemical compatibility. Automation in manufacturing processes is also gaining traction, leading to improved production efficiency, reduced costs, and enhanced product consistency, positioning companies to capitalize on scaling demand from emerging economies.

Regionally, Asia Pacific continues to dominate the market, propelled by rapid industrial development, significant infrastructure investments, and burgeoning manufacturing hubs in countries like China and India. North America and Europe demonstrate steady growth, fueled by stringent regulatory standards, technological advancements in end-use industries such as aerospace and automotive, and a continuous demand for advanced, high-performance materials. The Middle East and Africa are also emerging as key growth regions, primarily due to expansive oil and gas projects and ongoing urbanization efforts.

In terms of segments, stainless steel flexible metallic tubing leads the market due to its superior corrosion resistance and strength, finding extensive use across chemical, automotive, and general industrial applications. The aerospace and defense sector represents a high-value segment, demanding specialized tubing for critical systems, while the HVAC and construction industries drive consistent demand for flexible conduits in ventilation and utility routing. The trend towards lightweight and ultra-durable materials, coupled with increasing demand from the medical and food and beverage industries for hygienic transfer solutions, is expected to further diversify segment growth.

AI Impact Analysis on Flexible Metallic Tubing Market

User inquiries concerning AI's influence on the Flexible Metallic Tubing Market frequently revolve around optimizing manufacturing processes, enhancing product quality through predictive analytics, and improving supply chain efficiency. Common questions include how AI can streamline design and material selection, if it can predict tubing failures before they occur, and how AI-driven logistics might impact delivery times and cost. There is significant interest in AI's potential to introduce new levels of precision, reduce waste, and extend the lifespan of metallic tubing, moving beyond traditional methods to embrace smarter, more responsive operational frameworks.

The key themes emerging from this analysis center on the transformative potential of artificial intelligence to revolutionize every stage of the flexible metallic tubing lifecycle, from initial concept and design to manufacturing, quality control, and aftermarket services. Stakeholders are keen to understand how AI can enable more sophisticated defect detection, personalize product specifications on an unprecedented scale, and create more resilient and efficient supply chains in response to market fluctuations. Expectations are high for AI to not only optimize existing operations but also to unlock entirely new possibilities for innovation and competitive advantage within this specialized industrial sector.

- Predictive Maintenance: AI algorithms analyze sensor data from installed tubing systems to forecast potential failures, enabling proactive maintenance and significantly reducing unscheduled downtime.

- Enhanced Manufacturing Processes: AI-driven automation optimizes welding, braiding, and forming processes, leading to higher precision, reduced material waste, and increased production speed.

- Quality Control and Inspection: Machine vision systems powered by AI perform real-time, high-speed defect detection, ensuring stringent quality standards and minimizing human error in inspection.

- Design and Material Optimization: AI tools simulate various design parameters and material combinations, identifying optimal configurations for specific applications, enhancing performance and durability.

- Supply Chain Efficiency: AI predicts demand fluctuations, optimizes inventory levels, and streamlines logistics, improving lead times and reducing operational costs for tubing manufacturers and distributors.

DRO & Impact Forces Of Flexible Metallic Tubing Market

The Flexible Metallic Tubing Market is predominantly driven by continuous industrial expansion and significant investments in infrastructure projects globally. The increasing demand from critical sectors such as oil and gas, chemical processing, power generation, and automotive for durable, high-performance fluid and gas transfer solutions provides a strong impetus for market growth. Furthermore, the rising adoption of flexible metallic tubing in applications requiring vibration absorption, thermal expansion compensation, and protection against corrosive elements further fuels its market penetration. Stringent safety regulations and environmental compliance standards across various industries also necessitate the use of reliable, leak-proof, and fire-resistant tubing, boosting demand for high-quality flexible metallic products.

However, the market faces several restraints, including the volatility of raw material prices, particularly for metals like stainless steel and exotic alloys, which can significantly impact production costs and profit margins. Intense competition among existing manufacturers, coupled with the potential threat from alternative piping materials such as specialized plastics or composites, can exert downward pressure on pricing and market share. Additionally, the complex manufacturing processes involved in producing high-quality flexible metallic tubing, along with the need for specialized expertise and equipment, can pose barriers to entry for new players and limit innovation in some areas.

Opportunities for growth lie in emerging economies, where rapid industrialization and urbanization projects are creating substantial demand for robust infrastructure components. The increasing trend towards customization and specialized solutions for niche applications, such as medical devices or cryogenic systems, offers manufacturers avenues for product differentiation and premium pricing. Furthermore, advancements in material science, leading to the development of lighter, stronger, and more corrosion-resistant alloys, alongside the integration of smart manufacturing technologies, present significant potential for market expansion and innovation in the Flexible Metallic Tubing Market.

Segmentation Analysis

The Flexible Metallic Tubing Market is comprehensively segmented by various parameters to provide a detailed understanding of its dynamics and growth prospects across different categories. These segments include differentiation by the type of material used, the structural design of the tubing, its intended application across diverse industries, and the specific end-use sector where it finds deployment. This granular segmentation allows for a precise analysis of demand patterns, technological advancements, and competitive landscapes within each specialized niche, highlighting key areas of growth and market saturation.

- By Material

- Stainless Steel: Widely used for its excellent corrosion resistance, high strength, and temperature stability, primarily in chemical, automotive, and general industrial applications.

- Bronze: Valued for its good flexibility, vibration dampening properties, and compatibility with specific fluids, often utilized in steam and hot water applications.

- Monel: A nickel-copper alloy known for exceptional corrosion resistance in marine and chemical environments, as well as high strength at elevated temperatures.

- Inconel: A superalloy offering superior performance in extreme high-temperature and corrosive conditions, vital for aerospace, power generation, and furnace applications.

- Others: Includes materials like titanium, Hastelloy, and other specialized alloys used for highly specific and demanding applications requiring unique properties.

- By Type

- Corrugated Tubing: Features a series of parallel or spiral convolutions that provide flexibility and absorb vibration, commonly used in general industrial and HVAC applications.

- Annular Tubing: Characterized by evenly spaced, parallel convolutions, offering high flexibility and often used in critical applications requiring high pressure resistance.

- Helical Tubing: Designed with a continuous spiral convolution, providing excellent flexibility and good flow characteristics, often used in automotive exhaust and industrial transfer lines.

- Braided Tubing: Corrugated or helical tubing covered with an external wire braid (e.g., stainless steel), which enhances pressure containment and protects the core from abrasion.

- By Application

- Industrial: Broad category including general manufacturing, machinery, and equipment where fluid and gas transfer is critical under various conditions.

- Automotive: Used in exhaust systems, fuel lines, cooling systems, and hydraulic lines, demanding high flexibility, heat resistance, and vibration absorption.

- Aerospace and Defense: Critical for fuel, hydraulic, and pneumatic lines in aircraft and spacecraft, requiring lightweight, high-strength, and extreme temperature resistance.

- HVAC: Employed in air conditioning and heating systems for ducting, refrigerant lines, and vibration isolation, ensuring efficient and quiet operation.

- Construction: Used in flexible conduits for electrical wiring, plumbing, and structural expansion joints, providing durability and adaptability to architectural designs.

- Medical: Utilized in sterile environments for fluid transfer, gas delivery, and equipment connections, requiring biocompatibility and precision.

- Others: Includes applications in marine, railway, food and beverage processing, and specialized laboratory equipment.

- By End-Use Industry

- Oil and Gas: Extensive use in drilling, refining, and transportation for hydraulic lines, gas transfer, and high-pressure applications.

- Chemical: Critical for conveying corrosive chemicals, gases, and high-temperature fluids in processing plants, requiring chemical inertness and durability.

- Power Generation: Employed in steam lines, exhaust systems, and cooling water circuits for reliable performance under high temperature and pressure in power plants.

- HVAC: Essential for residential, commercial, and industrial climate control systems, ensuring efficient air and fluid circulation.

- Automotive: Integrated into vehicle manufacturing for various fluid and exhaust management systems.

- Food and Beverage: Used in hygienic transfer lines for processing and packaging, requiring non-contaminating and easy-to-clean materials.

- Others: Includes pharmaceuticals, metallurgy, electronics, and waste treatment industries.

Value Chain Analysis For Flexible Metallic Tubing Market

The value chain for the Flexible Metallic Tubing Market begins with the upstream procurement of specialized raw materials. This segment involves suppliers of various metals such as stainless steel alloys, bronze, Monel, Inconel, and other high-performance alloys. These raw material providers play a crucial role in determining the quality, cost, and availability of the foundational inputs. Key activities at this stage include sourcing, metallurgical processing, and ensuring compliance with industry standards and material specifications, which directly impacts the performance characteristics of the final tubing products.

Moving downstream, the value chain encompasses the manufacturing processes, which involve forming, corrugating, braiding, and welding the metal components into finished flexible tubing. Manufacturers then distribute these products through a combination of direct sales to large industrial clients and Original Equipment Manufacturers (OEMs), as well as through a network of indirect distribution channels. Indirect channels typically include specialized industrial distributors, wholesalers, and resellers who serve a broader base of smaller enterprises, maintenance, repair, and overhaul (MRO) operations, and various contractors. These distributors provide essential services such as inventory management, technical support, and localized delivery, effectively bridging the gap between manufacturers and diverse end-users across multiple geographies and industries.

Flexible Metallic Tubing Market Potential Customers

Potential customers for flexible metallic tubing are diverse and span across nearly all industrial and commercial sectors, driven by the critical need for reliable and adaptable fluid and gas conveyance systems. Major end-users include large-scale manufacturing operations in the automotive industry, which require tubing for exhaust systems, fuel lines, and hydraulic applications, and aerospace and defense contractors, who integrate these tubes into aircraft and spacecraft for fuel, hydraulic, and oxygen lines, demanding utmost precision and resilience. The chemical processing sector, facing highly corrosive and high-temperature environments, relies heavily on specialized flexible metallic tubing for safe and efficient material transfer, making them a significant customer segment.

Beyond heavy industry, the construction sector represents a consistent customer base, utilizing flexible conduits for electrical wiring protection, plumbing connections, and expansion joints in buildings and infrastructure projects. The HVAC industry frequently purchases flexible metallic tubing for refrigerant lines, ventilation systems, and vibration isolation, ensuring efficient and quiet operation in both commercial and residential settings. Additionally, emerging high-growth sectors such as medical device manufacturing and the food and beverage industry are increasingly adopting flexible metallic tubing for sanitary and precise transfer of sensitive materials, highlighting their expanding market reach and versatile application potential among a broad spectrum of buyers and end-users.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.85 Billion |

| Market Forecast in 2032 | USD 2.94 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hitachi Metals Ltd., Metraflex Company, Boa Group, KSM GmbH, Flexicraft Industries, Swagelok Company, Senior Flexonics Inc., US Hose Corporation, Penflex Corporation, Hose Master LLC, Unaflex, Flexaust Inc., Parker Hannifin Corporation, Gutteling, Technoflex, Pacific Hoseflex Pty Ltd, Zhejiang Tiangong Industrial Co. Ltd., Shandong Xinhongyu Metal Hose Co. Ltd., Alvenius Industrier AB, Hangzhou Huahong Flexible Tube Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flexible Metallic Tubing Market Key Technology Landscape

The Flexible Metallic Tubing Market is continually evolving with advancements in manufacturing technologies that aim to enhance product performance, durability, and cost-effectiveness. Key technologies employed include sophisticated hydroforming and roll forming techniques, which precisely shape the metal into corrugated or helical forms, ensuring consistent wall thickness and optimal flexibility. Advanced welding processes, such as TIG (Tungsten Inert Gas) welding and laser welding, are critical for creating robust, leak-proof seams that can withstand extreme pressures and temperatures, contributing significantly to the integrity and reliability of the tubing in demanding applications.

Furthermore, the integration of automated braiding machines has revolutionized the production of reinforced flexible metallic tubing, allowing for high-speed and uniform application of wire braiding. This not only boosts pressure resistance but also protects the core tubing from external abrasion and impact. Non-destructive testing (NDT) methods, including ultrasonic testing, radiographic inspection, and eddy current testing, are essential for ensuring the quality and structural integrity of finished products. Innovations in material science, particularly the development of new alloys with enhanced corrosion resistance, higher strength-to-weight ratios, and improved thermal properties, also play a pivotal role in expanding the application scope and performance capabilities of flexible metallic tubing across various industrial sectors.

Regional Highlights

The global Flexible Metallic Tubing Market exhibits distinct growth patterns and market characteristics across its major geographic regions. North America, a mature market, is characterized by significant demand from the aerospace, automotive, and oil and gas sectors, driven by rigorous industry standards and a focus on high-performance, durable solutions. The region benefits from substantial investments in infrastructure modernization and a strong emphasis on maintaining operational safety and efficiency in critical industrial applications.

Europe represents a robust market with consistent demand stemming from its advanced manufacturing base, particularly in the chemical, power generation, and general industrial sectors. The region's stringent environmental and safety regulations often necessitate the use of premium, certified flexible metallic tubing, fostering innovation and the adoption of high-quality products. There is a growing trend towards specialized and customized tubing solutions to meet the unique requirements of various European industries.

Asia Pacific stands out as the fastest-growing region, propelled by rapid industrialization, massive infrastructure development projects, and the expansion of manufacturing capabilities, especially in China, India, and Southeast Asian countries. The burgeoning automotive, construction, and electronics industries, coupled with increasing investments in power generation and petrochemicals, contribute significantly to the escalating demand for flexible metallic tubing in this dynamic region.

- North America: Driven by aerospace and defense, automotive, and a mature oil and gas industry; strong emphasis on safety standards and technological adoption.

- Europe: High demand from chemical, power generation, and general manufacturing sectors; stringent regulatory landscape promotes high-quality and specialized tubing.

- Asia Pacific (APAC): Fastest-growing market due to rapid industrialization, infrastructure development, and expanding manufacturing bases in China and India.

- Latin America: Emerging market with growth spurred by oil and gas exploration, mining activities, and increasing infrastructure investments.

- Middle East and Africa (MEA): Significant demand from large-scale oil and gas projects, infrastructure development, and urbanization initiatives; investments in industrial diversification.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flexible Metallic Tubing Market.- Hitachi Metals Ltd.

- Metraflex Company

- Boa Group

- KSM GmbH

- Flexicraft Industries

- Swagelok Company

- Senior Flexonics Inc.

- US Hose Corporation

- Penflex Corporation

- Hose Master LLC

- Unaflex

- Flexaust Inc.

- Parker Hannifin Corporation

- Gutteling

- Technoflex

- Pacific Hoseflex Pty Ltd

- Zhejiang Tiangong Industrial Co. Ltd.

- Shandong Xinhongyu Metal Hose Co. Ltd.

- Alvenius Industrier AB

- Hangzhou Huahong Flexible Tube Co. Ltd.

Frequently Asked Questions

What are the primary applications of flexible metallic tubing?

Flexible metallic tubing is predominantly used in industries requiring durable, high-performance solutions for conveying fluids, gases, or granular materials under varying conditions. Key applications include exhaust systems in automotive and marine sectors, fuel and hydraulic lines in aerospace and industrial machinery, chemical transfer in processing plants, and critical connections in HVAC systems for vibration isolation and refrigerant lines. Its adaptability to extreme temperatures, pressures, and corrosive environments makes it indispensable across diverse operational settings.

What materials are commonly used in flexible metallic tubing?

The most common materials for flexible metallic tubing include various grades of stainless steel, such as 304, 316, and 321, prized for their exceptional corrosion resistance and strength. Other frequently used metals are bronze, known for its flexibility and vibration dampening; Monel, a nickel-copper alloy, favored for its resistance to seawater corrosion; and Inconel, a superalloy, utilized in extreme high-temperature and highly corrosive environments. The selection of material depends heavily on the specific application's requirements for chemical compatibility, temperature range, and pressure rating.

How does flexible metallic tubing differ from rigid piping?

Flexible metallic tubing offers significant advantages over rigid piping, primarily its ability to absorb vibration, compensate for thermal expansion and contraction, and accommodate misalignment during installation. Unlike rigid pipes that require complex bends and fittings for changes in direction, flexible tubing can be routed easily, reducing installation time and costs. Its inherent flexibility also makes it ideal for dynamic applications where movement is constant, preventing stress fractures common in static rigid systems. While rigid piping is suited for fixed, straightforward installations, flexible tubing provides resilience and adaptability in challenging environments.

What factors influence the cost of flexible metallic tubing?

The cost of flexible metallic tubing is influenced by several factors. Firstly, the type and grade of metal used significantly impact pricing, with exotic alloys like Inconel being more expensive than standard stainless steel. Secondly, the complexity of the tubing's construction, including the degree of corrugation, the presence of a braided reinforcement layer, and overall diameter and length, affects manufacturing costs. Market fluctuations in raw material prices, specialized manufacturing processes like advanced welding, and compliance with stringent industry certifications also contribute to the final cost. Customization for specific applications can further elevate prices due to unique design and testing requirements.

What are the future trends in the flexible metallic tubing market?

Future trends in the flexible metallic tubing market indicate a strong move towards enhanced performance materials, including lightweight and high-strength alloys capable of operating under increasingly extreme conditions. There is a growing demand for customized solutions tailored to specific industry needs, alongside a focus on integrating smart technologies such as sensors for real-time monitoring and predictive maintenance. Sustainability initiatives are also driving the development of more eco-friendly production methods and recyclable materials. Additionally, automation and AI integration in manufacturing processes are expected to boost efficiency, improve quality control, and streamline supply chain management, fostering innovation across the market.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager