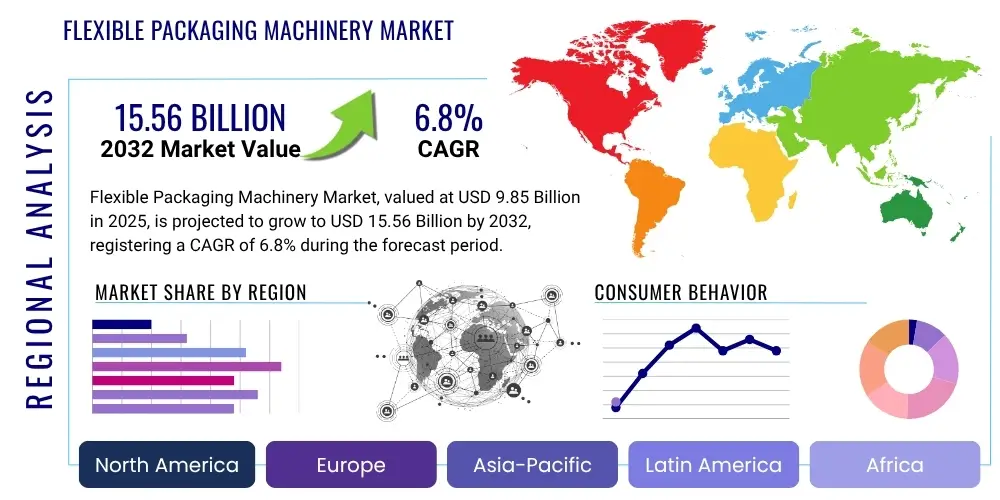

Flexible Packaging Machinery Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428884 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Flexible Packaging Machinery Market Size

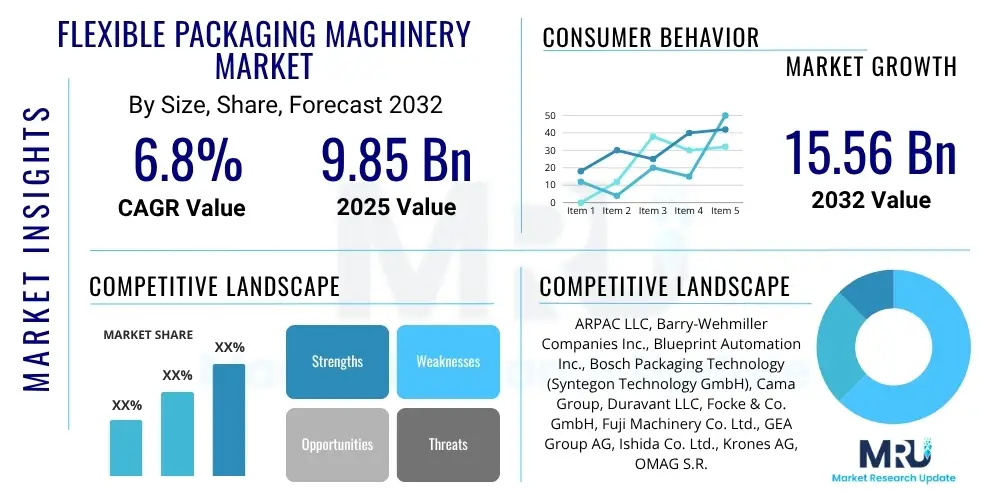

The Flexible Packaging Machinery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 9.85 Billion in 2025 and is projected to reach USD 15.56 Billion by the end of the forecast period in 2032.

Flexible Packaging Machinery Market introduction

The Flexible Packaging Machinery Market stands as a pivotal segment within the global manufacturing landscape, addressing the escalating demand for efficient, versatile, and sustainable packaging solutions across diverse industries. This market encompasses a wide array of specialized equipment designed to process and convert flexible materials like films, foils, paper, and laminates into various packaging formats, including pouches, bags, wraps, sachets, and flow wraps. These machines are instrumental in automating packaging processes, from forming and filling to sealing and labeling, thereby enhancing production speeds, reducing operational costs, and ensuring product integrity.

Key products within this domain include form-fill-seal (FFS) machines, which can be vertical (VFFS) or horizontal (HFFS), as well as dedicated pouch making machines, stretch wrapping machines, shrink wrapping machines, and ancillary equipment like weighers, feeders, and conveyors. These sophisticated machines are engineered for precision, speed, and adaptability, catering to specific product requirements and packaging material characteristics. They are critical for ensuring aseptic conditions, extending product shelf life, and facilitating attractive product presentation, which are paramount in competitive consumer markets.

The primary applications of flexible packaging machinery span across the food and beverage, pharmaceutical, personal care, cosmetics, and industrial product sectors. In the food industry, these machines are essential for packaging snacks, confectioneries, dairy products, and frozen foods, offering extended freshness and convenience. For pharmaceuticals, they provide sterile, tamper-evident packaging crucial for drug safety and compliance. The market's growth is predominantly driven by increasing consumer preference for convenient and single-serve packaging, the proliferation of e-commerce necessitating robust and lightweight packaging, rising disposable incomes in emerging economies, and a growing emphasis on sustainable and eco-friendly packaging materials and processes.

Flexible Packaging Machinery Market Executive Summary

The Flexible Packaging Machinery Market is undergoing a transformative period, characterized by significant innovation and strategic adaptations to meet evolving global demands. Business trends indicate a strong shift towards automation, intelligent machinery integrated with IoT, and the adoption of Industry 4.0 principles to enhance operational efficiency, reduce labor costs, and improve manufacturing precision. Manufacturers are increasingly focused on developing highly flexible and modular machines capable of handling diverse packaging formats and materials, addressing the growing need for customization and shorter product lifecycles. Furthermore, there is a pronounced emphasis on sustainability, driving demand for machinery compatible with recyclable, biodegradable, and compostable packaging films, aligning with global environmental objectives and consumer preferences for eco-conscious products.

Regionally, the Asia Pacific (APAC) market continues to dominate in terms of growth and adoption, fueled by rapid industrialization, expanding manufacturing capabilities, and a burgeoning consumer base with increasing disposable incomes, particularly in countries like China, India, and Southeast Asia. North America and Europe, while mature markets, are witnessing steady growth driven by technological advancements, stringent regulatory frameworks pushing for quality and safety, and significant investments in research and development for sustainable packaging solutions. Latin America and the Middle East & Africa are emerging as promising markets, spurred by infrastructural developments, urbanization, and a gradual increase in packaged goods consumption, presenting lucrative opportunities for market players seeking geographical expansion.

Segment-wise, the food and beverage industry remains the largest end-use segment, experiencing robust growth due to rising demand for convenience foods, processed items, and beverages. The pharmaceutical sector is also a critical segment, driven by strict regulatory requirements for product integrity and the increasing production of over-the-counter and prescription drugs. In terms of machine types, form-fill-seal (FFS) machines continue to hold a substantial market share, attributed to their versatility and efficiency in high-volume production. The market is also seeing increased traction in secondary packaging machinery and collaborative robots, further streamlining the entire packaging workflow and contributing to the overall market expansion.

AI Impact Analysis on Flexible Packaging Machinery Market

The integration of Artificial Intelligence (AI) into the Flexible Packaging Machinery Market is rapidly transforming manufacturing processes, addressing common user questions about enhancing efficiency, reducing downtime, and ensuring product quality. Users frequently inquire about AI's ability to optimize machine performance, predict maintenance needs, improve error detection, and adapt to varying production parameters. The overarching theme from user expectations revolves around AI's capacity to deliver smarter, more autonomous, and highly adaptable packaging solutions. This includes leveraging AI for real-time data analysis to inform operational decisions, minimizing material waste, and facilitating quicker changeovers between different product lines, thereby maximizing throughput and profitability for packaging operators.

- Enhanced Predictive Maintenance: AI algorithms analyze sensor data from machinery to predict potential failures before they occur, enabling proactive maintenance, reducing unexpected downtime, and extending equipment lifespan.

- Optimized Production Efficiency: AI-driven systems monitor and adjust machine parameters in real-time, such as speed, temperature, and pressure, to maintain optimal operating conditions, minimize material waste, and improve output consistency.

- Superior Quality Control: Vision systems powered by AI can detect minute defects in packaging materials or finished products at high speeds, significantly improving quality assurance and reducing the incidence of faulty items reaching the market.

- Adaptive Manufacturing: AI allows machinery to intelligently adapt to variations in product specifications or packaging materials, facilitating quicker changeovers and supporting mass customization without extensive manual reprogramming.

- Supply Chain Optimization: AI can be integrated into the broader supply chain to forecast demand, manage inventory for packaging materials, and optimize logistics, leading to more streamlined operations and cost savings.

- Energy Consumption Reduction: AI-driven systems can optimize energy usage by intelligently controlling machine components, contributing to more sustainable operations and lower utility costs.

- Robotics and Automation Integration: AI enhances the capabilities of robotic systems used in packaging, enabling them to perform complex tasks, collaborate with human operators, and handle delicate items with greater precision.

DRO & Impact Forces Of Flexible Packaging Machinery Market

The Flexible Packaging Machinery Market is profoundly shaped by a confluence of dynamic Drivers, Restraints, Opportunities, and broader Impact Forces that dictate its trajectory and competitive landscape. Key drivers include the ever-increasing global demand for packaged goods, particularly in food and beverage, pharmaceuticals, and personal care, fueled by urbanization, rising disposable incomes, and the convenience offered by flexible packaging. The rapid expansion of e-commerce channels also necessitates efficient and secure packaging solutions, thereby boosting the demand for advanced machinery. Moreover, the growing focus on automation and Industry 4.0 principles pushes manufacturers to invest in high-speed, integrated, and smart packaging equipment to optimize production workflows and reduce labor dependency.

However, the market faces several significant restraints. The substantial capital investment required for purchasing and installing sophisticated flexible packaging machinery can be a barrier for small and medium-sized enterprises (SMEs). Furthermore, the complexity of operating and maintaining these advanced machines necessitates a skilled workforce, which is often in short supply, particularly in developing regions. Fluctuations in raw material prices for packaging films and components, coupled with stringent and evolving regulatory standards related to food safety, pharmaceutical packaging, and environmental impact, add layers of complexity and cost pressures for manufacturers. Economic slowdowns or global supply chain disruptions can also adversely affect market growth by impacting consumer spending and manufacturing output.

Despite these challenges, numerous opportunities are poised to propel market expansion. Emerging economies in Asia Pacific, Latin America, and Africa present vast untapped markets with growing populations and increasing adoption of modern retail formats. The ongoing innovation in sustainable packaging materials, such as compostable and biodegradable films, offers a significant avenue for machinery manufacturers to develop compatible equipment and cater to environmentally conscious consumers and regulations. The integration of cutting-edge technologies like the Internet of Things (IoT), Artificial Intelligence (AI), and machine learning (ML) for predictive maintenance, quality control, and operational optimization represents a major growth opportunity. Additionally, the rising demand for customized and personalized packaging solutions drives the need for flexible, modular, and quick-changeover machinery, encouraging innovation and differentiation among market players. These impact forces collectively create a competitive environment where strategic adaptation to technological advancements and sustainability imperatives is crucial for long-term success.

Segmentation Analysis

The Flexible Packaging Machinery Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation allows for precise analysis of market trends, consumer behavior, and technological advancements across various product types, applications, and regional landscapes. The primary bases for segmentation typically include machine type, application (end-use industry), and functionality, each offering unique insights into market opportunities and challenges. Understanding these segments is crucial for stakeholders to tailor their product offerings, marketing strategies, and investment decisions effectively, ensuring they address the specific needs of different market niches.

- By Machine Type

- Form-Fill-Seal (FFS) Machines

- Vertical FFS (VFFS)

- Horizontal FFS (HFFS)

- Wrapping Machines

- Stretch Wrapping Machines

- Shrink Wrapping Machines

- Flow Wrapping Machines

- Pouch Making Machines

- Laminating Machines

- Slitting and Rewinding Machines

- Converting Machines

- Filling Machines

- Sealing Machines

- Cartoning Machines

- Palletizing Machines

- Other Packaging Machines

- Form-Fill-Seal (FFS) Machines

- By Application (End-Use Industry)

- Food and Beverage

- Dairy Products

- Meat, Poultry, and Seafood

- Snacks and Confectionery

- Baked Goods

- Fruits and Vegetables

- Beverages

- Other Food Products

- Pharmaceuticals

- Personal Care and Cosmetics

- Chemicals and Fertilizers

- Industrial Packaging

- Medical Devices

- Other Applications

- Food and Beverage

- By Automation Level

- Automatic

- Semi-Automatic

- By Output Speed

- Low Speed

- Medium Speed

- High Speed

- By Geography

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Flexible Packaging Machinery Market

The value chain for the Flexible Packaging Machinery Market encompasses a series of interconnected activities, beginning from the procurement of raw materials and components, moving through manufacturing and assembly, to distribution, sales, and after-sales support. This intricate network involves various stakeholders, each contributing to the final product and its delivery to the end-user. Understanding this value chain is crucial for identifying areas of efficiency, cost optimization, and potential competitive advantage, ensuring a robust and responsive supply ecosystem for the complex machinery involved in flexible packaging.

The upstream segment of the value chain involves the suppliers of essential raw materials and precision components. This includes providers of high-grade metals such as stainless steel and aluminum, electronic components like sensors, programmable logic controllers (PLCs), human-machine interfaces (HMIs), servo motors, and advanced control systems. Specialized component manufacturers also supply critical parts like custom gears, cutting blades, sealing mechanisms, and pneumatic or hydraulic systems. The quality and availability of these components directly impact the performance, reliability, and cost-effectiveness of the final packaging machinery, making strong supplier relationships and efficient sourcing strategies paramount for machinery manufacturers.

Further along the chain, the downstream segment primarily consists of packaging manufacturers and diverse end-user industries that directly utilize the machinery. Packaging companies, including converters and co-packers, procure these machines to produce flexible packaging materials or offer packaging services. The ultimate end-users are the companies in sectors such as food and beverage, pharmaceuticals, personal care, and industrial goods, which integrate this machinery into their production lines for packaging their products. The distribution channel plays a critical role in bridging the gap between machinery manufacturers and end-users. This can involve direct sales teams from manufacturers, a network of independent distributors and agents, or increasingly, digital platforms for showcasing and selling equipment. Both direct sales, offering a personalized approach and in-depth technical support, and indirect channels, providing broader market reach and localized service, are essential for comprehensive market penetration and customer satisfaction. After-sales support, including installation, training, maintenance, and spare parts supply, forms a vital component of the downstream value chain, ensuring optimal machine performance and customer loyalty.

Flexible Packaging Machinery Market Potential Customers

The Flexible Packaging Machinery Market serves a broad and diverse clientele, with its potential customers primarily comprising manufacturers across various industries that require efficient and reliable solutions for packaging their products in flexible formats. These end-users are driven by the need to protect their goods, extend shelf life, comply with regulatory standards, enhance brand appeal, and optimize logistics through lightweight and versatile packaging. The market's growth is inherently tied to the production volumes and packaging innovations within these customer segments, making a deep understanding of their unique requirements essential for machinery manufacturers.

The largest segment of potential customers is the food and beverage industry. This includes producers of snacks, confectioneries, baked goods, dairy products, meat, poultry, seafood, frozen foods, and beverages. These companies require high-speed, hygienic, and precise packaging machinery to handle a vast array of product types and textures, often with specific requirements for modified atmosphere packaging or vacuum sealing to preserve freshness and taste. The increasing consumer demand for convenience foods, single-serve portions, and on-the-go packaging formats further expands the customer base within this sector.

Another significant customer base lies within the pharmaceutical and medical device industries. These sectors demand machinery that adheres to stringent regulatory standards such as GMP (Good Manufacturing Practices), ensuring sterile, tamper-evident, and traceable packaging for medicines, medical disposables, and diagnostic kits. Precision, reliability, and validation capabilities are paramount for these customers. Additionally, the personal care and cosmetics industry, which includes manufacturers of lotions, shampoos, makeup, and other beauty products, represents a strong customer segment, driven by the need for visually appealing and functional flexible packaging that stands out on retail shelves. The chemicals and fertilizers, as well as various industrial product manufacturers, also constitute important, albeit often more specialized, customer groups for flexible packaging machinery, seeking durable and protective packaging solutions for their diverse range of goods.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 9.85 Billion |

| Market Forecast in 2032 | USD 15.56 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ARPAC LLC, Barry-Wehmiller Companies Inc., Blueprint Automation Inc., Bosch Packaging Technology (Syntegon Technology GmbH), Cama Group, Duravant LLC, Focke & Co. GmbH, Fuji Machinery Co. Ltd., GEA Group AG, Ishida Co. Ltd., Krones AG, OMAG S.R.L., PFM Packaging Machinery S.P.A., Premier Tech Ltd., Reiser (Handtmann Maschinenfabrik), Robert Bosch GmbH, Sacmi Imola S.C., Shibuya Corporation, Tecno Pack S.P.A., The Japan Steel Works Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flexible Packaging Machinery Market Key Technology Landscape

The Flexible Packaging Machinery Market is characterized by a rapidly evolving technological landscape, with innovations continuously driving improvements in efficiency, flexibility, and sustainability. Advanced automation lies at the core of this evolution, moving beyond basic robotics to fully integrated and intelligent systems that can perform complex tasks with minimal human intervention. This includes the widespread adoption of multi-axis servo drives and highly precise control systems, which enable faster speeds, greater accuracy, and quicker changeovers between different product formats or packaging materials, significantly boosting productivity and reducing downtime.

The advent of Industry 4.0 principles is profoundly impacting the market, with the proliferation of smart factories where packaging machinery is interconnected through the Internet of Things (IoT). This connectivity facilitates real-time data collection and analysis, allowing for predictive maintenance, remote diagnostics, and optimized operational parameters. Machine learning (ML) and Artificial Intelligence (AI) are being increasingly integrated to enhance quality control through advanced vision inspection systems, predict equipment failures, and enable adaptive manufacturing processes that can dynamically adjust to production variables, minimizing waste and ensuring consistent product quality.

Furthermore, the focus on sustainable packaging solutions is a major technological driver. Machinery manufacturers are innovating to develop equipment compatible with a broader range of eco-friendly materials, including compostable, biodegradable, and recycled content films. This involves advancements in heat sealing technologies, precise tension control for delicate films, and adaptable forming systems. Human-Machine Interfaces (HMIs) are becoming more intuitive and user-friendly, simplifying machine operation, troubleshooting, and data visualization. The integration of collaborative robots (cobots) is also gaining traction, enhancing safety and flexibility by allowing humans and robots to work together more efficiently on packaging lines, collectively shaping a more automated, intelligent, and sustainable future for the flexible packaging industry.

Regional Highlights

- North America: This region is a mature market characterized by high adoption of advanced automation technologies and a strong emphasis on smart packaging solutions. The United States and Canada are leading in research and development, particularly for sustainable packaging machinery and IoT integration. The market growth here is driven by the increasing demand for convenience foods, pharmaceuticals, and stringent quality control regulations, pushing manufacturers towards high-efficiency and precise equipment.

- Europe: Europe represents a significant market, distinguished by its strong focus on environmental sustainability and circular economy principles. Countries like Germany, Italy, and France are hubs for innovation in packaging machinery, developing advanced solutions that cater to recyclable, compostable, and bio-based packaging materials. High labor costs also drive the demand for fully automated and robot-integrated systems, maintaining a competitive edge through technological leadership and adherence to strict food safety and environmental standards.

- Asia Pacific (APAC): The APAC region is the fastest-growing market for flexible packaging machinery, fueled by rapid industrialization, expanding manufacturing sectors, and a burgeoning middle-class population with increasing purchasing power. Countries such as China, India, Japan, and South Korea are witnessing substantial investments in modern packaging infrastructure. The growth is particularly strong in the food and beverage and pharmaceutical industries, driven by urbanization and rising demand for packaged goods, leading to high-volume production requirements.

- Latin America: This region is an emerging market with significant growth potential, attributed to economic development, increasing foreign investments, and the modernization of its industrial sectors. Brazil and Mexico are key markets, showing rising demand for flexible packaging machinery in the food and beverage and personal care industries. As retail landscapes evolve and consumer preferences shift towards packaged products, the need for efficient and cost-effective packaging solutions is steadily growing.

- Middle East and Africa (MEA): The MEA region presents a developing market for flexible packaging machinery, driven by diversification efforts from oil-dependent economies, population growth, and increasing urbanization. Countries like UAE, Saudi Arabia, and South Africa are investing in expanding their manufacturing capabilities, particularly in food processing and consumer goods. While still relatively nascent, the market is expected to witness steady growth as local production increases and modern retail formats become more prevalent, creating opportunities for suppliers of robust and adaptable machinery.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flexible Packaging Machinery Market.- ARPAC LLC

- Barry-Wehmiller Companies Inc.

- Blueprint Automation Inc.

- Bosch Packaging Technology (Syntegon Technology GmbH)

- Cama Group

- Duravant LLC

- Focke & Co. GmbH

- Fuji Machinery Co. Ltd.

- GEA Group AG

- Ishida Co. Ltd.

- Krones AG

- OMAG S.R.L.

- PFM Packaging Machinery S.P.A.

- Premier Tech Ltd.

- Reiser (Handtmann Maschinenfabrik)

- Robert Bosch GmbH

- Sacmi Imola S.C.

- Shibuya Corporation

- Tecno Pack S.P.A.

- The Japan Steel Works Ltd.

Frequently Asked Questions

What are the primary growth drivers for the Flexible Packaging Machinery Market?

The market is primarily driven by the escalating global demand for packaged goods, particularly in the food and beverage and pharmaceutical sectors, coupled with the rapid expansion of e-commerce, increasing automation trends, and a growing emphasis on sustainable packaging solutions worldwide.

How is sustainability impacting the Flexible Packaging Machinery Market?

Sustainability is a critical driver, fostering innovation in machinery compatible with eco-friendly materials like recyclable, biodegradable, and compostable films. Manufacturers are developing equipment that minimizes material waste and energy consumption, aligning with environmental regulations and consumer demand for green packaging.

What role does automation play in the Flexible Packaging Machinery Market?

Automation is central to market growth, enhancing operational efficiency, increasing production speeds, and reducing labor costs. Advanced automation, including robotics, IoT, and AI, enables predictive maintenance, superior quality control, and flexible production capabilities for diverse packaging needs.

Which geographical region exhibits the highest growth potential in this market?

The Asia Pacific (APAC) region consistently shows the highest growth potential, driven by rapid industrialization, expanding consumer markets, increasing disposable incomes, and significant investments in manufacturing and processing industries across countries like China and India.

What are the main challenges faced by the Flexible Packaging Machinery Market?

Key challenges include high initial capital investment, the scarcity of skilled labor for operating and maintaining advanced machinery, fluctuations in raw material prices, and the need to comply with evolving and stringent global regulatory standards for product safety and environmental impact.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager