Flexible Substrate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428855 | Date : Oct, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Flexible Substrate Market Size

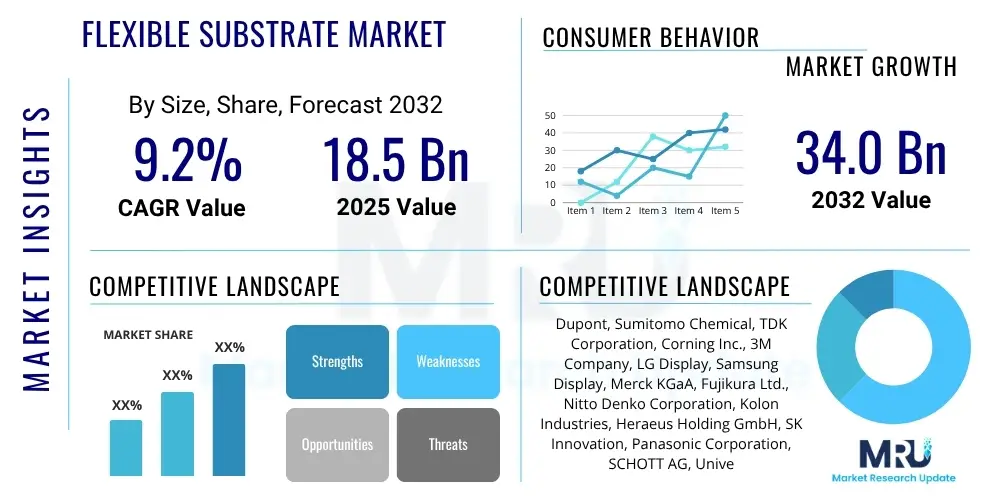

The Flexible Substrate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.2% between 2025 and 2032. The market is estimated at $18.5 Billion in 2025 and is projected to reach $34.0 Billion by the end of the forecast period in 2032.

Flexible Substrate Market introduction

The Flexible Substrate Market encompasses materials engineered to provide mechanical flexibility while maintaining essential electrical, thermal, or optical properties. These advanced materials, including flexible glass, plastic films like polyimide (PI) and polyethylene naphthalate (PEN), and metallic foils, serve as foundational components for a new generation of electronic and optical devices. They enable the development of products that are lightweight, thin, bendable, foldable, and even stretchable, moving beyond the rigid constraints of traditional electronics.

Major applications for flexible substrates are extensive and continuously expanding, spanning consumer electronics, automotive, healthcare, aerospace, and energy sectors. They are crucial for technologies such as flexible displays (OLEDs, e-paper), wearable devices, flexible batteries, smart sensors, RFID tags, and photovoltaic cells. The inherent benefits of flexible substrates, including their conformability to various surfaces, enhanced durability against impact, and reduced weight and form factor, drive their increasing adoption across diverse industries. The market is significantly propelled by several key factors: the relentless demand for miniaturized and portable electronic devices, the rapid expansion of the Internet of Things (IoT), advancements in flexible display technologies, and the growing integration of smart functionalities into everyday objects and industrial equipment.

Flexible Substrate Market Executive Summary

The Flexible Substrate Market is experiencing robust growth, driven by pervasive innovation in consumer electronics and the burgeoning demand for flexible and wearable technologies. Business trends indicate a strong focus on research and development, particularly in advanced materials like transparent polyimides and ultrathin glass, alongside improvements in manufacturing processes such as roll-to-roll fabrication to enhance cost-efficiency and scalability. Strategic collaborations between material suppliers, component manufacturers, and end-product developers are becoming increasingly common, aiming to accelerate product commercialization and address complex technical challenges. The market also sees significant investment in sustainable and eco-friendly flexible substrate solutions to align with global environmental mandates and consumer preferences.

Regionally, Asia Pacific continues to dominate the market due to its robust electronics manufacturing ecosystem, high consumer electronics adoption rates, and substantial government support for advanced material research. North America and Europe are also significant players, characterized by strong innovation hubs, significant R&D investments, and a growing demand for high-value applications in healthcare, automotive, and defense sectors. Emerging economies in Latin America and the Middle East and Africa are beginning to show promise, driven by increasing smartphone penetration and gradual industrialization, albeit from a lower base.

Segment-wise, polymer-based substrates, particularly polyimide, hold the largest market share due to their excellent thermal stability and mechanical properties, making them ideal for high-performance applications. However, flexible glass and metallic foils are gaining traction for specific uses requiring superior optical clarity or conductivity. Application segments such as flexible displays and wearables are primary growth engines, while novel areas like flexible sensors and biomedical devices present significant untapped opportunities. The market is also witnessing a trend towards multi-layer flexible substrates that integrate various functionalities, offering enhanced performance and versatility for complex electronic systems.

AI Impact Analysis on Flexible Substrate Market

User inquiries concerning AI's influence on the Flexible Substrate Market frequently center on how AI can optimize manufacturing processes, enable new applications, and streamline material development. Users are interested in whether AI can enhance the precision and efficiency of roll-to-roll fabrication, improve quality control through automated inspection, and accelerate the discovery of novel flexible materials with desired properties. There's also curiosity about AI's role in powering advanced flexible electronics, particularly in smart sensors and edge AI devices that leverage the unique characteristics of flexible substrates. Concerns often revolve around the complexity of integrating AI, data security, and the necessity for specialized expertise in material science and AI.

- AI can optimize material design and selection by simulating material properties and performance under various conditions, accelerating R&D cycles.

- AI-driven analytics can enhance manufacturing efficiency, predicting equipment failures, optimizing process parameters, and reducing waste in roll-to-roll production.

- Automated optical inspection systems powered by AI improve quality control for flexible substrates, identifying defects with higher accuracy and speed.

- AI enables advanced functionality in flexible sensors, allowing for real-time data analysis and predictive capabilities in wearable and IoT devices.

- AI algorithms can personalize flexible electronic designs and functions based on user data, leading to more adaptive and efficient products.

- The integration of AI at the edge, facilitated by flexible substrates, can lead to compact, low-power smart devices with on-device intelligence for various applications.

DRO & Impact Forces Of Flexible Substrate Market

The Flexible Substrate Market is shaped by a dynamic interplay of driving forces, significant restraints, and emerging opportunities, all contributing to its overall impact. Key drivers include the escalating demand for advanced consumer electronics that require thinner, lighter, and more durable components, coupled with the rapid proliferation of IoT devices and wearable technology. The inherent benefits of flexible substrates, such as their conformability, durability, and reduced form factor, are increasingly critical for next-generation product development across diverse sectors like automotive, healthcare, and aerospace.

However, the market faces notable restraints, primarily related to the high manufacturing costs associated with specialized flexible materials and complex processing techniques, which can hinder mass adoption in cost-sensitive applications. Technical challenges, such as ensuring long-term reliability, managing heat dissipation in tightly integrated flexible circuits, and overcoming material compatibility issues, also pose hurdles. Opportunities for growth are abundant, fueled by ongoing advancements in material science, the development of cost-effective roll-to-roll manufacturing methods, and the expansion into niche applications like flexible biomedical devices, smart packaging, and sustainable energy solutions. The continuous pursuit of enhanced performance, greater design freedom, and novel functionalities in electronic devices positions the market for sustained expansion.

The cumulative impact forces indicate a market in a robust growth phase, driven by technological innovation and evolving consumer preferences. While cost and technical complexities present challenges, significant investments in research and development, coupled with strategic collaborations and expanding application areas, are collectively propelling the market forward, ensuring its critical role in the future of electronics.

Segmentation Analysis

The Flexible Substrate Market is comprehensively segmented across various dimensions to provide granular insights into its complex dynamics. These segmentations are critical for understanding market structure, identifying growth opportunities, and assessing competitive landscapes. The primary segments typically include classification by material type, which differentiates between various polymer films, flexible glass, and metallic foils, each offering distinct properties for specific applications. Another key segmentation is by application, detailing the end-use sectors where flexible substrates are integrated, such as flexible displays, wearable electronics, flexible solar cells, and medical devices.

Further segmentation often considers the manufacturing process, distinguishing between roll-to-roll manufacturing, sheet-to-sheet processing, and other specialized fabrication techniques, reflecting the technological maturity and scalability. End-use industries also form a crucial segmentation, encompassing consumer electronics, automotive, healthcare, industrial, and aerospace, highlighting the diverse adoption patterns. These detailed breakdowns enable market participants to tailor their strategies, focusing on high-growth segments and addressing the unique requirements of different vertical markets.

- By Material Type

- Polymer Films

- Polyimide (PI)

- Polyethylene Naphthalate (PEN)

- Polyethylene Terephthalate (PET)

- Polycarbonate (PC)

- Other Polymers

- Flexible Glass

- Metallic Foils

- Stainless Steel

- Copper

- Aluminum

- Other Metals

- Paper

- Fabrics/Textiles

- Polymer Films

- By Application

- Flexible Displays (OLED, LCD, E-Paper)

- Flexible Batteries

- Flexible Sensors

- Flexible Printed Circuit Boards (FPCBs)

- Wearable Devices

- Flexible Solar Cells/Photovoltaics

- Medical & Healthcare Devices

- Smart Packaging & RFID Tags

- Automotive Electronics

- Consumer Electronics (Smartphones, Tablets)

- Aerospace & Defense

- LED Lighting

- Other Applications

- By End-Use Industry

- Consumer Electronics

- Automotive

- Healthcare

- Aerospace & Defense

- Energy

- Industrial

- Retail

- Other Industries

- By Manufacturing Process

- Roll-to-Roll Processing

- Sheet-to-Sheet Processing

- Printing (Inkjet, Screen, Gravure)

- Deposition Techniques

Value Chain Analysis For Flexible Substrate Market

The value chain for the Flexible Substrate Market begins with the upstream segment, which involves the sourcing and refinement of raw materials. This includes specialized polymers such as polyimides, PEN, and PET, along with high-purity glass, and various metallic foils like stainless steel and copper. Key players in this stage are chemical companies, material science innovators, and specialty glass manufacturers who develop and supply these foundational elements. The quality and specific properties of these raw materials are critical, directly influencing the performance and functionality of the final flexible substrate product. Innovations in material synthesis and formulation are essential to meet the evolving demands for transparency, heat resistance, and flexibility.

Moving further down the chain, the manufacturing and fabrication stage converts these raw materials into functional flexible substrates. This involves complex processes such as polymer film extrusion, thin-film deposition, chemical etching, and specialized surface treatments. Roll-to-roll processing is a particularly significant manufacturing method due to its high throughput and cost-efficiency for mass production. Manufacturers here focus on precision, uniformity, and scaling capabilities. Following this, the flexible substrates are integrated into various electronic components and devices. This downstream segment involves component manufacturers (e.g., FPCB manufacturers, display panel makers, sensor producers) who assemble, integrate, and test the flexible components into finished or semi-finished products.

Distribution channels for flexible substrates can be both direct and indirect. Direct sales typically occur for large-volume orders and specialized projects, where substrate manufacturers engage directly with major electronic device producers or automotive Tier 1 suppliers. Indirect channels involve distributors and value-added resellers who provide access to a broader customer base, including smaller manufacturers, R&D labs, and niche application developers. These distributors often offer customization services, inventory management, and technical support, playing a crucial role in market penetration and reaching diverse end-users. The efficiency of the entire value chain, from raw material sourcing to final product distribution, is paramount for market competitiveness and growth.

Flexible Substrate Market Potential Customers

The Flexible Substrate Market caters to a diverse range of potential customers, primarily comprising manufacturers across various high-technology and industrial sectors. These end-users are driven by the need to develop innovative products that offer enhanced form factors, improved durability, and novel functionalities not achievable with rigid electronics. A significant portion of the customer base resides within the consumer electronics industry, including major smartphone, tablet, laptop, and smart TV manufacturers who are constantly seeking to integrate flexible displays, batteries, and circuit boards into their next-generation devices. The push towards foldable phones, rollable displays, and lighter, more ergonomic gadgets directly fuels demand from this segment.

Beyond consumer electronics, the automotive industry represents a rapidly growing customer segment. As vehicles become increasingly smart and connected, there is a rising demand for flexible displays for dashboards, infotainment systems, and advanced driver-assistance systems (ADAS) sensors, along with flexible lighting solutions and heating elements. The healthcare sector is another critical customer, utilizing flexible substrates for wearable medical sensors, implantable devices, diagnostic patches, and smart drug delivery systems, where comfort, conformability, and biocompatibility are paramount. Additionally, the industrial sector, including manufacturers of IoT devices, smart packaging, and industrial sensors, leverages flexible substrates for their robust and adaptable nature in challenging environments. The aerospace and defense sectors also utilize these materials for lightweight, high-performance components in avionics and specialized equipment, further expanding the customer landscape for flexible substrate suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $18.5 Billion |

| Market Forecast in 2032 | $34.0 Billion |

| Growth Rate | 9.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dupont, Sumitomo Chemical, TDK Corporation, Corning Inc., 3M Company, LG Display, Samsung Display, Merck KGaA, Fujikura Ltd., Nitto Denko Corporation, Kolon Industries, Heraeus Holding GmbH, SK Innovation, Panasonic Corporation, SCHOTT AG, Universal Display Corporation, Dai Nippon Printing Co., Ltd., Shin-Etsu Chemical Co., Ltd., SEKISUI CHEMICAL CO., LTD., AU Optronics Corp. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flexible Substrate Market Key Technology Landscape

The Flexible Substrate Market is profoundly influenced by a dynamic and evolving technology landscape, centered around advancements in material science, manufacturing processes, and integration techniques. A critical technology is the development of advanced polymer films, particularly polyimide (PI) and polyethylene naphthalate (PEN), which offer exceptional thermal stability, mechanical strength, and chemical resistance, crucial for high-performance flexible electronics. Innovations in transparent polyimides and ultrathin flexible glass (e.g., Willow Glass) are also expanding the possibilities for flexible displays and optical components, offering superior optical clarity and barrier properties compared to traditional polymer films. Metallic foils, especially those made from stainless steel or copper, are gaining traction for applications requiring high electrical conductivity and robustness, particularly in flexible batteries and power circuitry.

Manufacturing process technologies are equally vital, with roll-to-roll (R2R) processing standing out as a transformative method. R2R enables continuous, high-volume production of flexible substrates and electronic components, significantly reducing manufacturing costs and increasing throughput compared to traditional batch processing. This includes various deposition techniques like physical vapor deposition (PVD) and chemical vapor deposition (CVD) adapted for flexible materials, as well as advanced printing technologies such as inkjet printing, screen printing, and gravure printing, which allow for the precise and cost-effective fabrication of circuits, sensors, and functional layers directly onto flexible surfaces. These printing methods are key for producing flexible hybrid electronics and smart labels.

Further technological advancements encompass encapsulation and barrier layer technologies, essential for protecting sensitive flexible electronic components from moisture, oxygen, and environmental degradation, thereby extending device lifespan and reliability. Integrated circuit design for flexible platforms, incorporating ultrathin chips and flexible interconnects, is also a rapidly evolving area. These technologies collectively enable the realization of increasingly complex, durable, and high-performance flexible electronic devices, pushing the boundaries of what is possible in areas such as wearable technology, IoT, and advanced display solutions, and continuously redefining product design and functionality.

Regional Highlights

- Asia Pacific: Dominates the flexible substrate market due to its robust electronics manufacturing base, high consumer electronics adoption, and significant investments in R&D and manufacturing infrastructure, particularly in countries like China, South Korea, Japan, and Taiwan.

- North America: A significant market characterized by strong innovation in flexible electronics, high demand for advanced medical devices, automotive electronics, and defense applications, supported by substantial R&D expenditure and a mature technological ecosystem.

- Europe: Exhibits steady growth driven by the automotive sector, medical technology advancements, and increasing adoption of flexible displays and sensors in industrial automation, with Germany, France, and the UK leading in research and application.

- Latin America: An emerging market with growing potential, influenced by increasing smartphone penetration, expanding consumer electronics manufacturing, and developing industrial infrastructure, though at a comparatively slower pace.

- Middle East and Africa (MEA): Shows gradual market expansion, primarily fueled by infrastructural development projects, increasing investment in smart cities, and a rising demand for consumer electronics, especially in urban centers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flexible Substrate Market.- Dupont

- Sumitomo Chemical

- TDK Corporation

- Corning Inc.

- 3M Company

- LG Display

- Samsung Display

- Merck KGaA

- Fujikura Ltd.

- Nitto Denko Corporation

- Kolon Industries

- Heraeus Holding GmbH

- SK Innovation

- Panasonic Corporation

- SCHOTT AG

- Universal Display Corporation

- Dai Nippon Printing Co., Ltd.

- Shin-Etsu Chemical Co., Ltd.

- SEKISUI CHEMICAL CO., LTD.

- AU Optronics Corp.

Frequently Asked Questions

What are flexible substrates?

Flexible substrates are thin, bendable materials, such as specialized polymers, ultrathin glass, or metallic foils, that serve as a base for flexible electronic and optical components, enabling products that are conformable, lightweight, and durable.

Which applications primarily drive the Flexible Substrate Market?

The market is primarily driven by flexible displays (OLEDs), wearable devices, flexible batteries, sensors for IoT, and advanced electronics in the automotive and healthcare sectors.

What are the main types of materials used for flexible substrates?

The main materials include polymer films (e.g., polyimide, PEN, PET), flexible glass, and metallic foils (e.g., stainless steel, copper).

What is the Compound Annual Growth Rate (CAGR) for the Flexible Substrate Market?

The Flexible Substrate Market is projected to grow at a CAGR of 9.2% between 2025 and 2032.

Which region holds the largest market share in flexible substrates?

Asia Pacific holds the largest market share due to its robust electronics manufacturing ecosystem and high consumer electronics adoption.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager