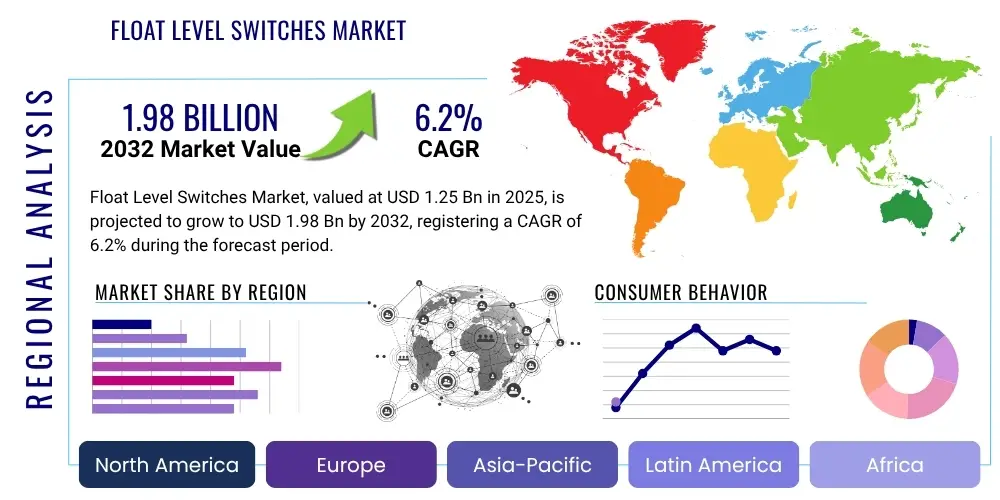

Float Level Switches Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429900 | Date : Nov, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Float Level Switches Market Size

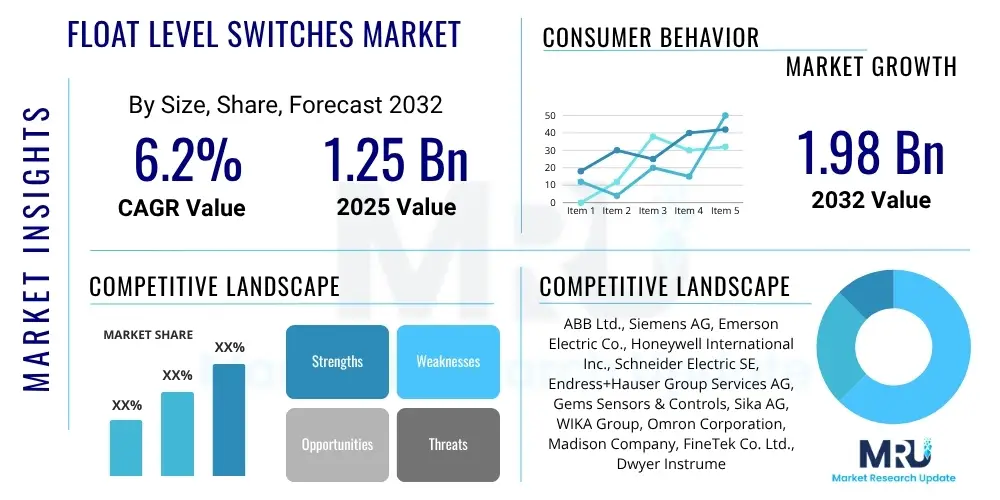

The Float Level Switches Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2025 and 2032. The market is estimated at USD 1.25 Billion in 2025 and is projected to reach USD 1.98 Billion by the end of the forecast period in 2032.

Float Level Switches Market introduction

Float level switches are crucial devices engineered for reliable and precise liquid level detection across a multitude of industrial and commercial applications. These robust sensors operate on a simple yet effective principle: a buoyant float rises or falls with the liquid level, triggering a switch mechanism when a predefined point is reached. Their widespread adoption is attributed to their inherent simplicity, mechanical reliability, and cost-effectiveness, making them indispensable in managing fluid processes ranging from basic tank overflow prevention to complex automation sequences in manufacturing plants.

The product encompasses various designs, including vertical and horizontal mount types, and can be constructed from diverse materials such as stainless steel, plastics, and exotic alloys, to withstand specific process conditions like high temperatures, corrosive chemicals, or sanitary requirements. Key benefits of utilizing float level switches include enhanced operational safety by preventing spills and equipment damage, improved process efficiency through automated control, and significant cost savings by minimizing manual intervention and material waste. Their low power consumption and long operational lifespan further contribute to their appeal.

Major applications span industries such as water and wastewater treatment, oil and gas, chemicals, food and beverage, pharmaceuticals, and HVAC systems, where accurate liquid level control is paramount for safety, quality, and operational integrity. The market is primarily driven by the escalating demand for industrial automation, the imperative for stringent process control and safety regulations, increasing investments in water infrastructure, and the expansion of manufacturing capabilities worldwide, particularly in emerging economies. These factors collectively underscore the vital role float level switches play in modern industrial environments.

Float Level Switches Market Executive Summary

The Float Level Switches Market is experiencing dynamic growth, driven by an accelerating trend towards industrial automation and the critical need for efficient process control across various sectors. Business trends highlight a significant shift towards smart, integrated solutions that offer enhanced connectivity and data analytics capabilities, moving beyond basic level detection to predictive maintenance and optimized operational workflows. Manufacturers are increasingly focusing on developing robust, customizable, and maintenance-friendly float switches that can withstand harsh industrial environments, addressing specific industry requirements for material compatibility, pressure, and temperature ratings. Furthermore, there is a growing emphasis on energy efficiency and sustainable manufacturing practices, influencing the design and material selection of new products.

Regionally, the Asia Pacific (APAC) region is poised for substantial growth, fueled by rapid industrialization, burgeoning infrastructure development, and increasing foreign direct investment in manufacturing and processing industries. Countries like China, India, and Southeast Asian nations are investing heavily in water treatment plants, chemical industries, and oil and gas exploration, thereby propelling the demand for reliable level sensing solutions. North America and Europe, while mature markets, continue to demonstrate steady growth, primarily driven by the modernization of existing industrial facilities, stringent environmental regulations, and a strong focus on advanced automation technologies and IoT integration. Latin America and the Middle East and Africa (MEA) are also emerging as key growth areas, with significant investments in oil and gas, mining, and water management projects.

Segment-wise, the market sees robust demand for switches made from stainless steel due to their durability and resistance to corrosion, particularly in chemical and food and beverage applications. The mechanical float level switch segment maintains a dominant share owing to its simplicity and cost-effectiveness, though there is a rising adoption of magnetic and ultrasonic variants for more complex and non-contact applications. End-use industries such as water and wastewater treatment, oil and gas, and chemicals remain the largest consumers, with increasing penetration in HVAC, pharmaceuticals, and power generation sectors. The trend towards miniaturization and wireless connectivity is also influencing product development, enabling easier installation and remote monitoring, thereby expanding the applicability of float level switches in diverse operational contexts.

AI Impact Analysis on Float Level Switches Market

Common user questions regarding AI's impact on the Float Level Switches Market often revolve around how traditional mechanical sensors can integrate with advanced intelligence, whether AI will replace or augment existing technology, and what benefits such integration could offer in terms of predictive maintenance, operational efficiency, and data-driven decision-making. Users are keen to understand if AI can make these devices "smarter" by enabling self-diagnosis, optimizing performance, and providing real-time insights into process anomalies beyond simple on/off signals. There is also interest in how AI can enhance the reliability and longevity of these devices by predicting failures and scheduling maintenance proactively, as well as its role in reducing human error and enhancing safety in critical applications. The overarching theme is the transformation from reactive monitoring to proactive, intelligent management of liquid levels.

- Enhanced Predictive Maintenance: AI algorithms can analyze historical data from float switches, alongside other process variables, to predict potential failures, optimize maintenance schedules, and reduce unexpected downtime, moving beyond simple failure detection.

- Optimized Process Control: AI can integrate data from float switches with other sensor inputs to provide a holistic view of process conditions, enabling more sophisticated and adaptive control strategies for liquid levels, improving efficiency and resource utilization.

- Real-time Anomaly Detection: Machine learning models can identify unusual patterns in float switch behavior or related liquid level dynamics, flagging deviations that might indicate leaks, blockages, or other critical issues before they escalate, enhancing operational safety.

- Improved Data Analytics: AI platforms can aggregate and analyze vast amounts of data generated by float switches across multiple assets, providing actionable insights into system performance, efficiency, and areas for process optimization at scale.

- Integration with IoT and Industry 4.0: AI acts as the intelligence layer for IoT-enabled float switches, facilitating seamless communication with central control systems, cloud platforms, and other smart devices, enabling a truly connected industrial environment.

- Automated Calibration and Diagnostics: Future AI-driven systems may enable float switches to self-calibrate or run diagnostic checks autonomously, reducing the need for manual intervention and ensuring sustained accuracy over time.

DRO & Impact Forces Of Float Level Switches Market

The Float Level Switches Market is shaped by a confluence of driving forces, restraining factors, and emerging opportunities, all interacting to define its growth trajectory. Key drivers include the relentless expansion of industrial automation across manufacturing, process industries, and infrastructure development, necessitating precise and reliable liquid level control. The escalating global demand for water and wastewater treatment, driven by population growth and urbanization, significantly boosts the adoption of these switches in municipal and industrial applications. Furthermore, stringent regulatory requirements for environmental protection and worker safety in sectors like chemicals and oil and gas compel industries to invest in advanced and reliable level sensing solutions to prevent spills, overflows, and ensure operational integrity. The simplicity, cost-effectiveness, and proven reliability of float switches continue to make them a preferred choice for many standard applications, underpinning their steady market expansion.

However, the market also faces notable restraints. The increasing competition from advanced alternative level sensing technologies, such as ultrasonic, radar, and capacitance level sensors, which offer non-contact measurement and higher accuracy in certain complex applications, presents a challenge to the traditional float switch market. High initial costs associated with installing advanced, multi-point float switch systems or integrating them into existing complex automation architectures can deter smaller enterprises. Moreover, the lack of skilled personnel capable of installing, calibrating, and maintaining sophisticated level sensing equipment in certain developing regions poses an operational hindrance. Specific process conditions, such as highly viscous liquids, turbulent flows, or crystallizing media, can also impact the reliability and require frequent maintenance of mechanical float switches, prompting users to explore alternative solutions.

Opportunities for growth are abundant, particularly in the realm of technological integration and market expansion. The integration of float level switches with Industry 4.0 technologies, including the Internet of Things (IoT), wireless connectivity, and AI-driven analytics, presents a significant avenue for innovation, enabling remote monitoring, predictive maintenance, and enhanced process optimization. Emerging markets in Asia Pacific, Latin America, and Africa, characterized by burgeoning industrialization and infrastructure development, offer untapped potential for market penetration. Furthermore, the development of customized and specialized float switches, designed to meet the unique requirements of niche applications such as marine, aerospace, and renewable energy sectors, can open new revenue streams. The increasing focus on energy efficiency and sustainable practices also creates opportunities for float switches that contribute to reduced waste and optimized resource management. These opportunities, coupled with ongoing technological advancements, are expected to fuel the market's long-term expansion and evolution.

Segmentation Analysis

The Float Level Switches Market is comprehensively segmented to provide a detailed understanding of its diverse landscape and to identify key trends across various product attributes, materials, operational principles, and end-use applications. This segmentation enables manufacturers and stakeholders to pinpoint specific market niches, develop targeted product offerings, and devise effective market entry strategies. By analyzing these distinct segments, insights into consumer preferences, technological adoption patterns, and regional demand variations can be garnered, facilitating strategic decision-making and fostering innovation within the market.

- By Type

- Mechanical Float Level Switches

- Magnetic Float Level Switches

- Optical Float Level Switches

- Conductivity Float Level Switches

- Cable Float Level Switches

- By Material

- Stainless Steel

- Plastics (PP, PVC, Nylon)

- Brass

- Exotic Alloys

- By End-Use Industry

- Water and Wastewater Treatment

- Oil and Gas

- Chemicals

- Food and Beverage

- Pharmaceuticals

- Power Generation

- HVAC (Heating, Ventilation, and Air Conditioning)

- Marine

- Automotive

- Others (Mining, Pulp & Paper)

- By Operation

- Normally Open (NO)

- Normally Closed (NC)

- SPDT (Single Pole Double Throw)

- By Mounting Type

- Vertical Mount

- Horizontal Mount

Value Chain Analysis For Float Level Switches Market

The value chain for the Float Level Switches Market encompasses a series of interconnected activities, beginning with the sourcing of raw materials and culminating in the delivery of the final product to the end-user. Upstream analysis highlights the critical role of raw material suppliers, including manufacturers of high-grade metals such as stainless steel and brass, various plastics (e.g., polypropylene, PVC, nylon), and specialized electronic components for wiring, connectors, and switch mechanisms. These suppliers provide the foundational elements that dictate the durability, chemical compatibility, and overall performance of the float switches. Quality control at this stage is paramount, as substandard materials can significantly impact the product's reliability and lifespan, particularly in corrosive or high-pressure environments. Strategic partnerships with reliable material suppliers are essential for ensuring consistent quality and cost-effectiveness in production.

Midstream activities involve the core manufacturing processes, including precision molding, machining, assembly of components, and rigorous testing. Manufacturers often leverage advanced automation and quality assurance protocols to ensure that each float switch meets industry standards and application-specific requirements. This stage also includes the development of innovative designs, incorporating features such as multiple switching points, adjustable levels, and compatibility with various communication protocols. Research and development plays a crucial role here, driving the evolution of new materials, miniaturization, and integration of smart technologies. Manufacturing capabilities, including economies of scale and specialized production lines, contribute significantly to competitive pricing and market responsiveness, allowing companies to cater to a broad spectrum of customer demands, from simple on/off switches to complex multi-level sensing units.

Downstream analysis focuses on the distribution channels and end-user engagement. Float level switches reach end-users through a combination of direct sales, indirect sales via distributors, and increasingly, through online platforms. Direct sales channels are often employed for large industrial clients or projects requiring custom solutions, allowing for direct communication and tailored support. Indirect channels, through a network of specialized industrial distributors, offer broader market reach, localized inventory, and technical support for smaller businesses and varied applications. System integrators also form a crucial part of the downstream segment, incorporating float switches into larger automation systems. The presence of robust after-sales services, technical support, and accessible spare parts is vital for maintaining customer satisfaction and fostering long-term relationships, ensuring the continued operational efficiency of the deployed level switches.

Float Level Switches Market Potential Customers

Potential customers for float level switches span a wide array of industries and sectors, primarily driven by the universal need for reliable liquid level monitoring and control in various processes. Industrial manufacturers constitute a significant segment, encompassing sectors like chemicals, pharmaceuticals, food and beverage, and power generation. In these environments, float switches are critical for managing tank levels, ensuring process safety, preventing overflows or dry-runs in reactors, mixing vessels, and storage tanks. Their robust construction and compatibility with diverse liquids, from corrosive acids to potable water, make them an ideal solution for maintaining operational efficiency and adhering to stringent safety and quality standards across these manufacturing facilities. The continuous operation of these plants relies heavily on automated level control to minimize downtime and optimize resource utilization.

Utility companies and municipal corporations represent another large customer base, particularly within the water and wastewater treatment sector. Here, float level switches are extensively used in lift stations, clarifiers, reservoirs, and pumping systems to manage water levels, control pump operations, and prevent flooding or equipment damage. Their ability to operate reliably in harsh outdoor environments and contaminated water applications is highly valued. The need for precise level monitoring in water distribution networks, irrigation systems, and effluent treatment plants makes these entities consistent buyers of float level switches. Additionally, the increasing global focus on sustainable water management and the modernization of aging water infrastructure further solidify this customer segment's importance, driving demand for both new installations and replacement units that offer enhanced durability and accuracy.

Beyond traditional industrial and municipal applications, float level switches find significant demand in HVAC systems for monitoring condensate pans and cooling towers, in the marine industry for bilge pumps and fuel tanks, and in the automotive sector for fluid reservoirs and engine cooling systems. Building management systems utilize them for leak detection and maintaining levels in sumps and hot water tanks. Emerging applications also include renewable energy projects, such as solar thermal systems and small-scale hydro, where fluid level management is crucial for efficient operation. Furthermore, the agricultural sector employs them for irrigation control and managing levels in storage tanks for fertilizers and pesticides. This broad spectrum of end-users, each with unique requirements for accuracy, material compatibility, and environmental resilience, underscores the pervasive utility and diverse market for float level switches.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.25 Billion |

| Market Forecast in 2032 | USD 1.98 Billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, Emerson Electric Co., Honeywell International Inc., Schneider Electric SE, Endress+Hauser Group Services AG, Gems Sensors & Controls, Sika AG, WIKA Group, Omron Corporation, Madison Company, FineTek Co. Ltd., Dwyer Instruments Inc., Flowline Inc., Rechner Sensors, KROHNE Messtechnik GmbH, Balluff GmbH, Baumer Holding AG, Sapcon Instruments Pvt. Ltd., Nanjing Bota Technology Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Float Level Switches Market Key Technology Landscape

The Float Level Switches Market, while fundamentally relying on mechanical principles, has significantly evolved through the integration of advanced technologies to enhance performance, durability, and connectivity. Key technological advancements include the use of sophisticated materials engineering, where specialized plastics like PVDF and PEEK, alongside various grades of stainless steel and exotic alloys, are employed to withstand extreme temperatures, pressures, and highly corrosive chemicals, thus broadening their application scope. Miniaturization has also been a significant trend, allowing for the development of compact float switches suitable for small tanks and confined spaces, without compromising on reliability. Furthermore, the integration of magnetic and reed switch technologies ensures hermetically sealed designs, which prevents liquid ingress and extends operational life, particularly in sensitive or hazardous environments where electrical isolation is critical.

Beyond material science and mechanical design, the technological landscape is increasingly shaped by advancements in electronics and digital communication. Modern float level switches are often designed with integrated microcontrollers for precise signal processing and enhanced diagnostics, allowing for configurable switching points and hysteresis. The incorporation of wired (e.g., HART, Modbus) and wireless communication capabilities (e.g., LoRaWAN, Zigbee) enables seamless integration into larger industrial control systems and IoT platforms, facilitating remote monitoring, data logging, and predictive maintenance. This connectivity transforms traditional on/off devices into intelligent sensors that contribute valuable data to overall process optimization strategies. For instance, smart float switches can now communicate their operational status, remaining lifespan, or even report on the consistency of the fluid being monitored.

Emerging technologies continue to push the boundaries of float switch capabilities. Research and development efforts are focused on improving self-diagnostic features, allowing switches to autonomously detect and report internal faults, minimizing false alarms and ensuring higher operational uptime. There is also a growing interest in self-cleaning mechanisms for applications involving viscous or fouling liquids, which would significantly reduce maintenance requirements. The convergence of float switch technology with artificial intelligence (AI) and machine learning (ML) is beginning to enable more sophisticated data analysis for process anomalies and predictive analytics, moving beyond simple level detection to provide actionable insights for process control and asset management. These innovations are not only enhancing the reliability and accuracy of float level switches but also positioning them as integral components within the evolving framework of smart factories and Industry 4.0.

Regional Highlights

- North America: This region represents a mature yet robust market for float level switches, characterized by high adoption rates in well-established industries such as oil and gas, chemicals, and water and wastewater treatment. Demand is driven by stringent safety regulations, the modernization of existing industrial infrastructure, and a strong emphasis on automation and digital transformation. The United States and Canada are key contributors, with ongoing investments in smart factory initiatives and advanced process control systems, fostering a consistent need for reliable level sensing technologies. Innovation in sensor technology and IoT integration also originates significantly from this region.

- Europe: The European market demonstrates steady growth, propelled by stringent environmental regulations, a strong focus on sustainable industrial practices, and significant investments in water management and renewable energy sectors. Countries like Germany, the UK, and France are leading in adopting sophisticated automation solutions across their manufacturing and processing industries. The emphasis on high-quality, durable, and energy-efficient products, coupled with a push towards Industry 4.0, ensures sustained demand for advanced float level switches that comply with strict regional standards and contribute to operational excellence.

- Asia Pacific (APAC): APAC is anticipated to be the fastest-growing market for float level switches, driven by rapid industrialization, urbanization, and massive infrastructure development projects, particularly in China, India, Japan, and Southeast Asian countries. Expanding manufacturing capabilities, increasing investments in water and wastewater treatment facilities, chemical plants, and power generation units are significant growth drivers. The region benefits from a large consumer base and government initiatives supporting industrial growth and environmental protection, leading to substantial demand for basic to advanced level control solutions.

- Latin America: This region is experiencing moderate growth, primarily fueled by expanding industrial sectors such as mining, oil and gas, and food and beverage processing, particularly in Brazil, Mexico, and Argentina. Investments in infrastructure development and the increasing need for efficient process control systems in emerging economies are contributing to market expansion. While a significant portion of demand is for cost-effective and robust solutions, there is also a growing interest in integrating more advanced level sensing technologies to improve operational efficiency and safety in industrial plants.

- Middle East and Africa (MEA): The MEA market for float level switches is characterized by significant investments in the oil and gas industry, water desalination plants, and chemical production facilities. Countries like Saudi Arabia, UAE, and South Africa are key markets. The region's arid climate drives substantial demand for efficient water management solutions, including float switches for reservoirs, treatment plants, and irrigation systems. Ongoing industrial diversification efforts and large-scale construction projects are also contributing to the increasing adoption of level sensing technologies to enhance operational safety and resource management across various critical applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Float Level Switches Market.- ABB Ltd.

- Siemens AG

- Emerson Electric Co.

- Honeywell International Inc.

- Schneider Electric SE

- Endress+Hauser Group Services AG

- Gems Sensors & Controls

- Sika AG

- WIKA Group

- Omron Corporation

- Madison Company

- FineTek Co. Ltd.

- Dwyer Instruments Inc.

- Flowline Inc.

- Rechner Sensors

- KROHNE Messtechnik GmbH

- Balluff GmbH

- Baumer Holding AG

- Sapcon Instruments Pvt. Ltd.

- Nanjing Bota Technology Co. Ltd.

Frequently Asked Questions

What is a float level switch and how does it function?

A float level switch is a mechanical or magnetic device designed to detect a specific liquid level within a tank or container. It operates using a buoyant float that rises or falls with the liquid. When the float reaches a predetermined level, it activates a switch (typically a reed switch or a microswitch) through a direct mechanical linkage or magnetic force, sending an electrical signal to a control system. This signal can then be used to turn pumps on or off, activate alarms, or trigger other control actions to maintain desired liquid levels, ensuring process safety and efficiency.

What are the primary advantages of using float level switches?

Float level switches offer several key advantages, including high reliability due to their simple and robust mechanical design, making them less prone to electronic failures. They are generally cost-effective compared to more complex level sensing technologies, providing excellent value. Installation and operation are straightforward, requiring minimal calibration. Furthermore, they consume very little power, contributing to energy efficiency. Their versatility in terms of material construction allows them to be used in diverse applications, from potable water to corrosive chemicals, ensuring long-term performance and minimizing maintenance requirements.

In which industries are float level switches most commonly applied?

Float level switches are widely utilized across a broad spectrum of industries where precise liquid level monitoring and control are essential. Prominent sectors include water and wastewater treatment for managing pump operations and tank levels, the oil and gas industry for storage tanks and process vessels, and the chemical industry for corrosive fluid containment. They are also crucial in food and beverage processing for hygienic tank management, pharmaceuticals for sterile liquid control, HVAC systems for condensate and chiller levels, and power generation for boiler water levels and cooling systems. Their adaptability makes them indispensable in various manufacturing and process automation scenarios.

What materials are typically used to construct float level switches?

The selection of materials for float level switches is critical and depends heavily on the specific application's chemical compatibility, temperature, and pressure requirements. Common materials include various grades of stainless steel (e.g., 304, 316) for chemical resistance and durability, and plastics such as polypropylene (PP), polyvinyl chloride (PVC), and nylon for lighter applications and corrosive environments. More specialized materials like PVDF, PEEK, or exotic alloys are used for highly aggressive chemicals or extreme temperature and pressure conditions. Brass is also utilized for general-purpose applications. The choice of material directly impacts the switch's longevity, reliability, and suitability for its intended operational context.

What factors should be considered when selecting a float level switch?

Selecting the appropriate float level switch requires careful consideration of several factors. Firstly, the characteristics of the liquid, including its density, viscosity, temperature, pressure, and chemical compatibility, are paramount for material selection. Secondly, the mounting type (vertical or horizontal) and available space within the tank or vessel are important for installation. Thirdly, the number of switching points required (single or multi-point) and the electrical output specifications (normally open, normally closed, SPDT) need to match the control system. Environmental conditions, such as vibration or hazardous area classifications, also play a role. Lastly, cost-effectiveness, reliability, and ease of maintenance are practical considerations for optimal selection.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager