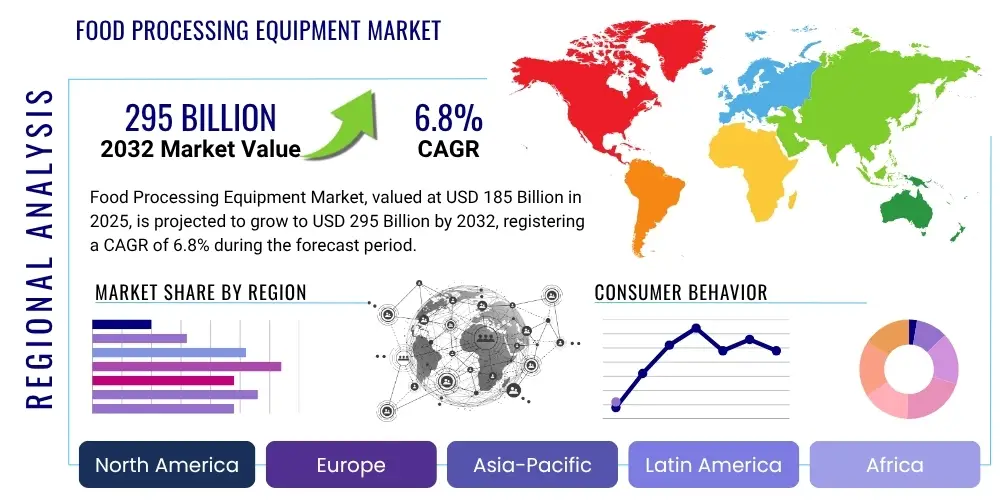

Food Processing Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429078 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Food Processing Equipment Market Size

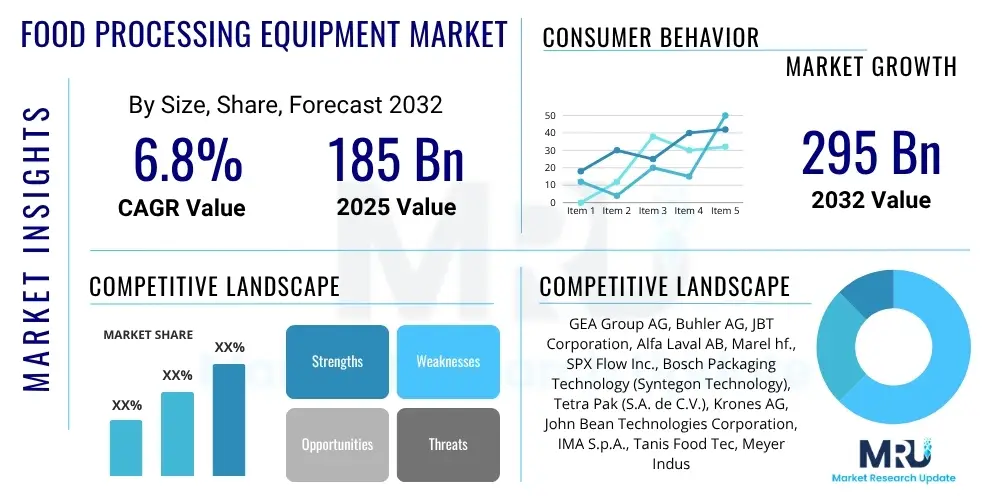

The Food Processing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 185 Billion in 2025 and is projected to reach USD 295 Billion by the end of the forecast period in 2032.

Food Processing Equipment Market introduction

The Food Processing Equipment Market encompasses a wide array of machinery and systems utilized in the transformation of raw agricultural products into marketable food items, suitable for consumption by humans or animals. This sophisticated equipment plays a pivotal role across various stages of food production, from initial cleaning and preparation to advanced processing, preservation, packaging, and quality control. The primary objective is to enhance food safety, extend shelf life, improve nutritional value, and create diverse food products that meet evolving consumer demands and regulatory standards. The market is characterized by continuous innovation aimed at increasing efficiency, automation, and sustainability in food operations globally.

Product descriptions within this market span a broad spectrum, including but not limited to, machinery for sorting, washing, peeling, cutting, mixing, grinding, forming, cooking, cooling, freezing, drying, and pasteurizing. Specialized equipment caters to specific industries such as dairy, meat, beverages, bakery, and fruits and vegetables, ensuring optimal processing for each commodity. Major applications include the production of packaged foods, convenience meals, dairy products, processed meats, bakery and confectionery items, and a variety of beverages. The benefits derived from advanced food processing equipment are substantial, offering enhanced operational efficiency, reduced labor costs, consistent product quality, improved food safety through controlled environments, and the ability to scale production to meet increasing global demand.

Driving factors for the growth of this market are multifaceted, primarily fueled by the burgeoning global population and the consequent surge in demand for processed and packaged foods. Urbanization trends contribute significantly, as urban consumers often prefer convenient, ready-to-eat options. Furthermore, stringent food safety regulations imposed by governments and international bodies necessitate the adoption of modern, hygienic processing equipment. Technological advancements, particularly in automation, robotics, and smart systems, are further propelling market expansion by offering higher precision, reduced waste, and enhanced operational control across the food processing value chain. The increasing focus on sustainability and energy efficiency also drives demand for newer, eco-friendly equipment solutions.

Food Processing Equipment Market Executive Summary

The Food Processing Equipment Market is experiencing robust growth, primarily driven by a global shift towards processed and convenience foods, coupled with escalating demands for food safety and quality. Key business trends indicate a strong emphasis on automation, digital integration, and sustainable practices. Manufacturers are increasingly investing in advanced robotics, Artificial Intelligence (AI), and Internet of Things (IoT) solutions to enhance operational efficiency, reduce labor costs, and optimize production processes. Customization of equipment to meet specific client needs and specialized food categories, such as plant-based proteins or allergen-free products, represents a significant market dynamic. Mergers and acquisitions are also prevalent, as companies seek to expand their technological capabilities and market reach, fostering competitive landscapes that prioritize innovation and integrated solutions for complex food production challenges.

Regionally, the Asia Pacific (APAC) market is anticipated to dominate, largely due to rapid urbanization, increasing disposable incomes, and the expansion of the food and beverage industry in countries like China and India. North America and Europe continue to be strong markets, characterized by advanced technological adoption, high automation levels, and strict regulatory frameworks that necessitate cutting-edge equipment. Latin America, the Middle East, and Africa are emerging as high-growth regions, driven by industrialization, improving economic conditions, and the development of local food processing capabilities. These regions present significant opportunities for equipment manufacturers to introduce cost-effective and scalable solutions, catering to a diverse range of local food traditions and consumer preferences. Investment in cold chain infrastructure and efficient processing solutions is particularly critical in these developing markets.

Segmentation trends highlight a notable increase in demand for equipment in the bakery and confectionery, meat and poultry, and dairy sectors, reflecting changing dietary habits and the growing popularity of diverse food products. The beverage processing segment also shows sustained growth, driven by innovation in functional drinks and new product launches. Equipment type wise, processing equipment (e.g., mixers, grinders, ovens) and packaging equipment are experiencing significant demand, as they are crucial for both production and marketability. Furthermore, there is a rising trend in continuous processing technologies over traditional batch methods, offering enhanced efficiency and scalability for large-scale operations. The emphasis on hygienic design and easy-to-clean equipment is becoming paramount across all segments, ensuring compliance with global food safety standards and minimizing contamination risks throughout the production cycle.

AI Impact Analysis on Food Processing Equipment Market

User inquiries concerning AI's influence on the Food Processing Equipment Market frequently revolve around how this technology can revolutionize efficiency, food safety, and operational intelligence. Common questions include how AI can enhance automation, optimize production lines, enable predictive maintenance, ensure product quality, and contribute to sustainability efforts within food processing facilities. There is significant interest in AI's role in tasks such as sorting and grading, quality inspection, process control, and supply chain optimization. Users also express concerns regarding the initial investment costs associated with AI integration, the requirement for specialized technical expertise, potential job displacement, and the importance of data security and privacy within AI-driven systems. Overall, the prevailing expectation is that AI will usher in an era of smarter, more responsive, and highly efficient food processing operations, moving beyond traditional automation to truly intelligent systems capable of adaptive learning and autonomous decision-making in real-time.

- AI enhances predictive maintenance, reducing downtime and operational costs by forecasting equipment failures.

- Automated quality control systems, powered by AI vision, detect defects and inconsistencies with greater accuracy than human inspection.

- Process optimization through AI algorithms allows for real-time adjustment of parameters, maximizing yield and minimizing waste.

- AI-driven robotics improve precision in sorting, cutting, and packaging, particularly for delicate or variable food products.

- Enhanced traceability and food safety monitoring are achieved through AI analysis of data from sensors across the supply chain.

- AI aids in demand forecasting and inventory management, optimizing production schedules and reducing spoilage.

- Personalized product development and ingredient formulation can be accelerated by AI's ability to analyze vast data sets of consumer preferences and nutritional profiles.

- Energy efficiency is improved through AI-managed systems that optimize equipment usage based on load and demand.

- Worker safety can be enhanced by deploying AI in hazardous or repetitive tasks, reducing human exposure to risks.

DRO & Impact Forces Of Food Processing Equipment Market

The Food Processing Equipment Market is significantly influenced by a confluence of drivers, restraints, and opportunities that collectively shape its trajectory and impact forces. A primary driver is the burgeoning global population, which fuels an ever-increasing demand for processed, packaged, and convenience foods, particularly in emerging economies. Concurrent with this is the accelerating pace of urbanization, leading to lifestyle changes that favor ready-to-eat meals and pre-processed ingredients, thereby necessitating more sophisticated and efficient processing solutions. Furthermore, stringent global food safety regulations and evolving consumer awareness regarding product quality and hygiene compel manufacturers to adopt advanced equipment that ensures compliance and maintains high standards. Technological advancements, especially in automation, robotics, and sensor technologies, also act as powerful drivers, offering improved operational efficiency, reduced labor costs, and enhanced precision in food production.

However, the market faces significant restraints that temper its growth potential. High capital investment required for purchasing and installing advanced food processing equipment represents a major barrier, particularly for small and medium-sized enterprises (SMEs). The complexity and high cost associated with maintenance and spare parts for specialized machinery further exacerbate this challenge. Additionally, the availability of skilled labor to operate and maintain sophisticated equipment can be limited in certain regions, posing operational hurdles. Economic downturns or trade protectionist policies can also negatively impact market expansion by limiting investment in new facilities or equipment upgrades. Furthermore, the inherent variability in raw material quality and supply can pose challenges for automated systems, requiring adaptable and flexible machinery.

Opportunities within the Food Processing Equipment Market are abundant and diverse. The increasing demand for sustainable and eco-friendly processing solutions, driven by environmental concerns and corporate social responsibility initiatives, presents a significant avenue for innovation in energy-efficient and waste-reducing equipment. The growing trend of customization and personalization in food products, including plant-based alternatives and functional foods, creates new niches for specialized processing machinery. Emerging markets in Asia Pacific, Latin America, and Africa offer immense untapped potential for equipment manufacturers as their food processing industries mature and expand. Furthermore, the integration of Industry 4.0 technologies like IoT, AI, and Big Data analytics in smart factories provides opportunities for developing highly integrated and intelligent processing lines that can optimize production, predict maintenance needs, and enhance overall operational transparency and control. These opportunities are actively shaping the competitive landscape, pushing companies towards more innovative and value-added offerings.

Segmentation Analysis

The Food Processing Equipment Market is extensively segmented across various parameters to provide a detailed understanding of its dynamics, catering to the diverse needs of the food and beverage industry. These segmentations allow for a granular analysis of market trends, identifying growth pockets and specific demands across different product types, applications, modes of operation, and geographical regions. Understanding these segments is crucial for manufacturers to tailor their equipment offerings and for food producers to select the most appropriate machinery for their specific production goals, ensuring efficiency, compliance, and quality. The market's complexity necessitates a multi-dimensional approach to segmentation, reflecting the wide range of food products and processing methodologies.

- By Type:

- Processing Equipment (e.g., Mixers, Blenders, Grinders, Slicers, Cutters, Formers)

- Thermal Equipment (e.g., Ovens, Fryers, Freezers, Heat Exchangers, Pasteurizers, Sterilizers, Coolers)

- Packaging Equipment (e.g., Fillers, Sealers, Labelers, Wrappers, Cartoning Machines)

- Cleaning & Sorting Equipment (e.g., Washers, Dryers, Sorters, Separators)

- Material Handling Equipment (e.g., Conveyors, Palletizers, Robots)

- Baking Equipment (e.g., Proofers, Dividers, Rounders, Moulders)

- Extrusion Equipment

- Homogenizers

- Filtration Equipment

- Peeling & Coring Equipment

- By Application:

- Bakery & Confectionery

- Meat & Poultry

- Dairy Products

- Beverages (Alcoholic & Non-Alcoholic)

- Fruits & Vegetables

- Fish & Seafood

- Edible Oils & Fats

- Grains, Pasta & Cereals

- Pet Food

- Prepared Foods

- By Operation:

- Automatic

- Semi-Automatic

- Manual

- By Mode of Operation:

- Batch

- Continuous

Value Chain Analysis For Food Processing Equipment Market

The value chain for the Food Processing Equipment Market begins with extensive upstream analysis, focusing on the sourcing of raw materials and sophisticated components essential for machine fabrication. This includes sourcing high-grade stainless steel, advanced alloys, specialized plastics, and complex electronic components such as sensors, programmable logic controllers (PLCs), and human-machine interface (HMI) systems. Key upstream players include raw material suppliers, specialized component manufacturers, and technology providers who develop innovative automation and control systems. The quality and reliability of these upstream inputs directly impact the performance, durability, and technological sophistication of the final food processing equipment. Strong relationships with these suppliers are critical for maintaining product quality, managing costs, and ensuring a consistent supply chain in a highly technical manufacturing environment.

Moving downstream, the value chain encompasses the manufacturing and assembly of the diverse range of food processing equipment, followed by distribution and sales. Manufacturers invest significantly in research and development to design innovative machinery that meets evolving industry standards, efficiency requirements, and food safety regulations. Once produced, the equipment reaches end-users, primarily food and beverage manufacturers, through various distribution channels. These channels can be broadly categorized into direct and indirect methods. Direct distribution involves sales directly from the equipment manufacturer to the food processing company, often for large, custom-built, or highly specialized machinery, facilitating closer relationships and tailored support. This approach allows for direct feedback and more personalized service.

Indirect distribution involves intermediaries such as distributors, agents, and system integrators. These partners play a crucial role in reaching a broader customer base, particularly small and medium-sized enterprises (SMEs) that may not have direct access to large manufacturers. Distributors often provide localized sales, technical support, installation services, and after-sales maintenance, acting as vital links between equipment producers and end-users. The choice of distribution channel often depends on the type of equipment, target market, geographic reach, and the level of service required. Both direct and indirect channels are critical for market penetration and customer relationship management, ensuring that complex machinery is not only sold but also effectively implemented and maintained throughout its operational lifespan. The efficiency of these channels significantly impacts the market's overall reach and responsiveness to customer needs.

Food Processing Equipment Market Potential Customers

The potential customers and end-users of the Food Processing Equipment Market represent a diverse and extensive landscape, spanning the entire spectrum of the food and beverage industry. These buyers range from small-scale artisanal producers to multinational food conglomerates, all seeking machinery to enhance efficiency, ensure product quality, and meet regulatory standards. A primary segment of end-users includes large-scale food manufacturers involved in the mass production of various processed foods such as packaged snacks, ready meals, frozen foods, and canned goods. These entities require high-capacity, automated, and continuous processing lines to achieve economies of scale and maintain consistent output. Their purchasing decisions are often driven by factors like throughput, energy efficiency, integration capabilities with existing infrastructure, and long-term service support from equipment providers.

Medium-sized enterprises (SMEs) constitute another significant customer base, often specializing in particular product categories like dairy, meat, bakery, or beverages. These businesses typically seek flexible and scalable equipment solutions that can adapt to evolving production volumes and product innovations. Their focus is often on equipment that offers a balance between capital investment, operational costs, and the ability to produce high-quality, differentiated products. The rising trend of local and regional food brands further fuels demand from SMEs looking to modernize their facilities and expand their production capabilities while adhering to local market demands and specific processing requirements.

Beyond traditional food manufacturers, other potential customers include catering services, institutional kitchens (e.g., hospitals, schools, corporate cafeterias), and even the emerging sector of ghost kitchens and meal-kit providers. These entities require equipment that supports high-volume food preparation, ensures hygiene, and facilitates rapid production to meet tight deadlines. Furthermore, the growing pet food industry is a notable buyer, as it requires specialized processing equipment for kibble, wet food, and treats, often mirroring human food production standards for safety and quality. The broad applicability of food processing technology means that virtually any entity involved in transforming raw ingredients into consumable food products can be considered a potential customer for this market, underscoring its vast and multifaceted demand landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 185 Billion |

| Market Forecast in 2032 | USD 295 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GEA Group AG, Buhler AG, JBT Corporation, Alfa Laval AB, Marel hf., SPX Flow Inc., Bosch Packaging Technology (Syntegon Technology), Tetra Pak (S.A. de C.V.), Krones AG, John Bean Technologies Corporation, IMA S.p.A., Tanis Food Tec, Meyer Industries, Urschel Laboratories, TNA Australia Pty Ltd., Fristam Pumpen KG, Multivac Sepp Haggenmuller SE & Co. KG, Provisur Technologies, Reiser, Heat and Control Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Food Processing Equipment Market Key Technology Landscape

The Food Processing Equipment Market is undergoing a profound transformation driven by rapid advancements in technology, creating a landscape characterized by smart, interconnected, and highly efficient systems. The integration of Industry 4.0 paradigms, including the Internet of Things (IoT), Artificial Intelligence (AI), and robotics, is at the forefront of this evolution. IoT sensors embedded within processing equipment enable real-time data collection on various parameters such as temperature, pressure, humidity, and machine performance. This data is then analyzed by AI algorithms to optimize production processes, predict potential equipment failures through predictive maintenance, and ensure consistent product quality, moving beyond traditional reactive maintenance to proactive operational management.

Robotics and advanced automation are also pivotal in enhancing efficiency and precision across the food processing value chain. Collaborative robots (cobots) are increasingly being deployed for repetitive or hazardous tasks like picking, placing, packaging, and cleaning, working alongside human operators to improve productivity and reduce manual labor. These robotic systems are often equipped with advanced vision systems and machine learning capabilities, allowing them to adapt to variations in product size or shape, thereby minimizing waste and maximizing throughput. The shift towards automated and continuous processing lines reduces human intervention, significantly lowering the risk of contamination and improving overall food safety and hygiene standards within facilities.

Furthermore, cloud computing and Big Data analytics play a crucial role by providing the infrastructure for storing, processing, and analyzing vast amounts of operational data generated by smart equipment. This enables food manufacturers to gain deeper insights into their production processes, identify bottlenecks, and make data-driven decisions for continuous improvement. Blockchain technology is emerging as a critical tool for enhancing supply chain transparency and traceability, allowing for end-to-end tracking of food products from farm to fork, thereby bolstering consumer trust and facilitating rapid recall management in case of contamination. These interconnected technologies collectively contribute to the development of highly agile, resilient, and intelligent food processing ecosystems, capable of meeting the dynamic demands of the global food industry.

Regional Highlights

- North America: A mature market characterized by high adoption of automation, advanced food safety standards, and a strong demand for innovative convenience foods. The United States and Canada are leading in R&D and investment in smart factory technologies.

- Europe: Driven by stringent food safety regulations, sustainable processing trends, and a preference for high-quality, diverse food products. Countries like Germany, France, and Italy are key manufacturing hubs for sophisticated equipment.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid urbanization, increasing disposable incomes, and a burgeoning middle class demanding processed and packaged foods. China, India, and Japan are major contributors to market expansion.

- Latin America: Experiencing significant growth due to industrialization of the food sector, increasing foreign investment, and expanding domestic consumption. Brazil and Mexico are leading markets with increasing demand for modern processing solutions.

- Middle East and Africa (MEA): An emerging market with growing investments in food processing infrastructure to enhance food security and reduce reliance on imports. Saudi Arabia, UAE, and South Africa are key growth areas.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Food Processing Equipment Market.- GEA Group AG

- Buhler AG

- JBT Corporation

- Alfa Laval AB

- Marel hf.

- SPX Flow Inc.

- Bosch Packaging Technology (Syntegon Technology)

- Tetra Pak (S.A. de C.V.)

- Krones AG

- John Bean Technologies Corporation

- IMA S.p.A.

- Tanis Food Tec

- Meyer Industries

- Urschel Laboratories

- TNA Australia Pty Ltd.

- Fristam Pumpen KG

- Multivac Sepp Haggenmuller SE & Co. KG

- Provisur Technologies

- Reiser

- Heat and Control Inc.

Frequently Asked Questions

Analyze common user questions about the Food Processing Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the current estimated size of the Food Processing Equipment Market?

The Food Processing Equipment Market is estimated at USD 185 Billion in 2025, reflecting robust global demand for processed food products and increasing automation in the industry.

What are the primary drivers for the growth of the Food Processing Equipment Market?

Key drivers include rising global population, increasing demand for processed and convenience foods, stringent food safety regulations, rapid urbanization, and continuous technological advancements in automation and efficiency.

How does AI impact the Food Processing Equipment Market?

AI significantly impacts the market by enabling predictive maintenance, enhancing automated quality control, optimizing production processes, improving precision with robotics, and bolstering food safety and traceability through data analysis.

Which regions are leading in the adoption of food processing equipment?

Asia Pacific is the fastest-growing region, while North America and Europe remain mature markets with high adoption rates of advanced processing equipment, driven by technology and strict regulatory standards.

What types of equipment are included in the Food Processing Equipment Market?

The market encompasses a wide range of equipment including processing (mixers, grinders), thermal (ovens, freezers), packaging (fillers, sealers), cleaning & sorting, material handling, baking, extrusion, and homogenization equipment, among others.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Seafood Processing Equipment Market Size Report By Type (Finfish, Crustaceans, Mollusks, Others, , Gutting, Scaling, Skinning, Deboning, Filleting, Others), By Application (.), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Food Processing Equipment Market Size Report By Type (Processing, Pre-processing), By Application (Bakery & Confectionaries, Meat, Poultry, & Seafood , Beverage, Dairy , Fruit, Nut, & Vegetable, Grains, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Seafood Processing Equipment Market Size Report By Type (Crustaceans Processing Equipment, Fish Processing Equipment, Molluscs Processing Equipment, Others), By Application (Frozen Seafood, Smoked Seafood, Canned Seafood, Dried Seafood, Surimi Seafood, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager