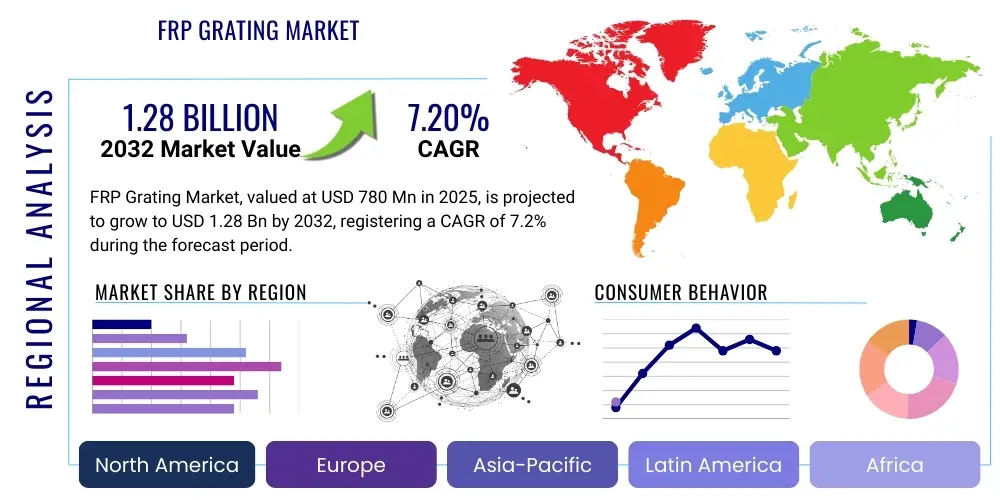

FRP Grating Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427282 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

FRP Grating Market Size

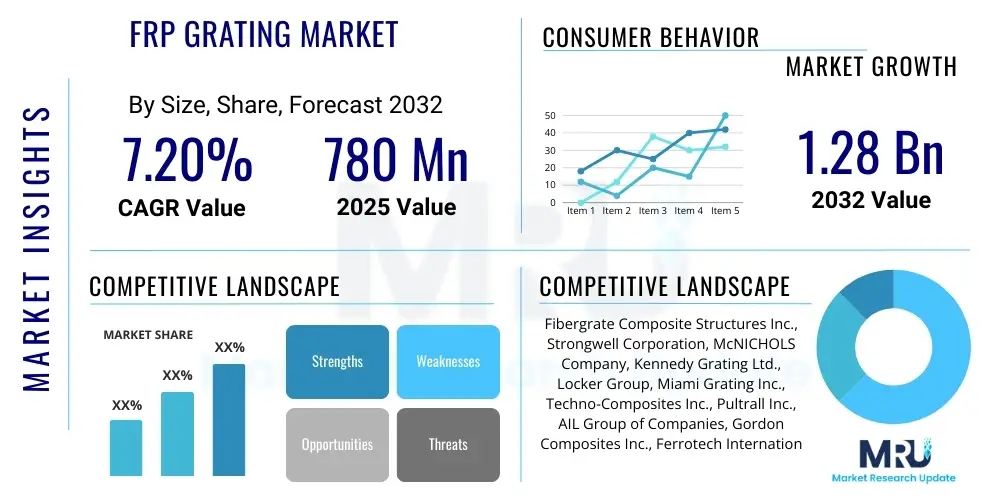

The FRP Grating Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2025 and 2032. The market is estimated at $780 million in 2025 and is projected to reach $1.28 billion by the end of the forecast period in 2032. This robust growth is primarily driven by the increasing demand for durable, corrosion-resistant, and low-maintenance materials across various industrial and commercial applications, offering a superior alternative to traditional materials like steel and concrete in challenging environments.

FRP Grating Market introduction

The Fiber Reinforced Polymer (FRP) Grating market encompasses the manufacturing, distribution, and application of composite gratings made from thermosetting resins and reinforcing fibers. These gratings are engineered for high performance in corrosive environments, offering an exceptional combination of strength, chemical resistance, fire retardancy, and anti-slip properties. The product description highlights their lightweight nature, ease of installation, and long operational lifespan, which significantly reduces maintenance costs compared to metallic or concrete alternatives.

Major applications for FRP grating span a diverse range of industries, including chemical processing plants, oil and gas refineries, wastewater treatment facilities, marine vessels and offshore platforms, power generation, and various construction and infrastructure projects. Their versatility allows for use in walkways, platforms, trench covers, stair treads, and catwalks, where safety and durability are paramount. The inherent benefits, such as non-conductivity, impact resistance, and ergonomic comfort, make FRP grating a preferred choice in demanding industrial settings.

The markets expansion is fundamentally driven by several critical factors. These include increasing industrialization, particularly in emerging economies, a growing global emphasis on infrastructure development and rehabilitation, stringent safety regulations promoting the use of non-corrosive and slip-resistant materials, and a rising awareness regarding the long-term cost-effectiveness and environmental advantages of FRP solutions over traditional materials. The escalating need for durable materials in highly corrosive and demanding environments, coupled with the ongoing replacement of aging infrastructure, further propels market growth.

FRP Grating Market Executive Summary

The FRP Grating Market is experiencing dynamic business trends, characterized by a heightened focus on product innovation, sustainability, and customized solutions to meet specific industry requirements. Manufacturers are increasingly investing in advanced resin systems and fiber technologies to enhance performance attributes such as flame retardancy, UV resistance, and structural integrity. The market also observes a shift towards automated production processes and digital design tools, which improve manufacturing efficiency and product consistency, leading to more competitive offerings and expanded application possibilities across various end-use sectors.

Regional trends indicate strong growth trajectories in Asia-Pacific, propelled by rapid industrialization, extensive infrastructure development projects, and significant investments in the chemical and wastewater treatment sectors, particularly in countries like China and India. North America and Europe also maintain substantial market shares, driven by the ongoing replacement of aging infrastructure, strict environmental regulations, and a mature industrial base that continuously adopts advanced material solutions. These regions demonstrate a consistent demand for high-performance FRP products in critical applications such as offshore platforms, power plants, and chemical processing units.

Segmentation trends highlight the increasing demand for both molded and pultruded FRP gratings, with each type serving distinct application needs. Molded gratings are favored for their bi-directional strength and ease of fabrication, while pultruded gratings offer superior unidirectional strength and span capabilities. The market also observes significant growth in specific end-use segments such as the food and beverage industry, where hygiene and corrosion resistance are crucial, and the renewable energy sector, particularly in wind and solar farms. This diverse application landscape underscores the versatility and adaptability of FRP grating solutions in addressing a wide array of industrial challenges.

AI Impact Analysis on FRP Grating Market

User inquiries into the impact of Artificial Intelligence on the FRP Grating market predominantly revolve around optimizing manufacturing processes, enhancing product quality control, streamlining supply chain management, and facilitating predictive maintenance. Users are keenly interested in how AI can contribute to more efficient material utilization, reduce waste, and improve overall operational efficiency within FRP grating production facilities. There is a strong expectation that AI will lead to more precise material formulation, advanced structural design, and real-time monitoring of production lines, ultimately resulting in superior product performance and reduced manufacturing costs.

Furthermore, concerns and expectations often touch upon AIs potential in predictive analytics for equipment maintenance, thereby minimizing downtime and extending the lifespan of machinery used in FRP grating production. Users also envision AI playing a significant role in market analysis, demand forecasting, and inventory management, providing manufacturers with deeper insights to make informed business decisions. The overarching theme is that AI will introduce a new era of intelligence and automation, transforming the traditional manufacturing paradigms of the FRP Grating industry into more agile, responsive, and technologically advanced operations.

- AI optimizes manufacturing processes through real-time data analysis, leading to enhanced efficiency and reduced waste.

- Predictive maintenance enabled by AI minimizes equipment downtime and prolongs the lifespan of production machinery.

- AI-driven quality control systems ensure higher product consistency and detect defects with greater accuracy.

- Advanced AI algorithms can facilitate the design and simulation of complex FRP grating structures, optimizing performance.

- Supply chain management benefits from AI-powered forecasting and logistics optimization, improving material flow and delivery times.

- Market intelligence and trend analysis leveraging AI offer manufacturers strategic advantages in product development and market positioning.

DRO & Impact Forces Of FRP Grating Market

The FRP Grating market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, all shaped by significant impact forces. Key drivers include the escalating global demand for corrosion-resistant materials in harsh industrial environments, particularly within chemical processing, oil & gas, and wastewater treatment sectors. Growing infrastructure development projects worldwide, coupled with the need to replace aging conventional material infrastructure, further propel market expansion. The emphasis on worker safety, leading to the adoption of non-conductive, anti-slip, and lightweight materials, also acts as a significant market impetus.

Conversely, the market faces several restraints. The relatively higher initial cost of FRP grating compared to traditional materials like steel or concrete can deter adoption, especially in price-sensitive markets or for projects with limited budgets. A lack of comprehensive awareness and standardized specifications in certain developing regions also poses a challenge to widespread market penetration. Competition from established conventional materials, which have a longer history of use and familiarity among contractors and engineers, requires continuous educational efforts and demonstration of long-term value from FRP manufacturers.

Opportunities for growth are abundant, particularly in emerging economies where industrialization and urbanization are on the rise, creating new demand for durable construction materials. Research and development in advanced composite formulations, including bio-based resins and novel fiber reinforcements, present avenues for product differentiation and enhanced performance. The increasing focus on sustainable and environmentally friendly construction solutions also positions FRP gratings favorably, given their long lifespan and minimal maintenance requirements. External impact forces such as economic growth, technological advancements in composite manufacturing, fluctuating raw material prices, and evolving regulatory landscapes significantly shape the markets trajectory, requiring continuous adaptation from industry players.

Segmentation Analysis

The FRP Grating market is extensively segmented to reflect its diverse product offerings, manufacturing processes, and applications across various industries. This segmentation provides a granular view of market dynamics, enabling stakeholders to understand specific demand patterns, identify niche opportunities, and tailor their strategies effectively. Key segmentation criteria typically include the type of resin used, the fiber reinforcement employed, the manufacturing process adopted, the specific application areas, and the end-use industries served, each with distinct growth drivers and market characteristics.

Analyzing these segments allows for a deeper understanding of market preferences and technological advancements. For instance, different resin types offer varying levels of chemical resistance and fire retardancy, catering to distinct industrial requirements. Similarly, the choice between molded and pultruded gratings depends on the structural needs and performance expectations of an application. The end-use industry segmentation highlights the critical sectors that rely on FRP gratings for their operational integrity, safety, and longevity, showcasing the products versatility and indispensable role in modern industrial infrastructure.

- By Resin Type: Polyester, Vinyl Ester, Phenolic, Isophthalic, and others.

- By Fiber Type: E-glass Fiber, Carbon Fiber, Basalt Fiber, and others.

- By Manufacturing Process: Molded Grating, Pultruded Grating.

- By Application: Walkways, Platforms, Stair Treads, Trench Covers, Cable Tray Covers, Others.

- By End-Use Industry: Chemical Processing, Oil & Gas, Wastewater Treatment, Marine, Construction, Power Generation, Food & Beverage, Mining, Pharmaceutical, Pulp & Paper, Electrical & Electronics.

FRP Grating Market Value Chain Analysis

The value chain for the FRP Grating market begins with the upstream analysis, which primarily focuses on the sourcing and supply of critical raw materials. This includes manufacturers of various thermosetting resins such as polyester, vinyl ester, and phenolic, as well as suppliers of reinforcing fibers like E-glass, carbon fiber, and basalt fiber. Additionally, the upstream segment involves providers of specialized additives, pigments, and catalysts essential for achieving specific product characteristics like UV resistance, fire retardancy, and desired coloration. The quality and cost-effectiveness of these raw materials significantly influence the final products performance and market price.

Moving through the value chain, manufacturing and fabrication form the core transformation stage. Here, raw materials are processed using advanced techniques such as molding and pultrusion to create the finished FRP grating products. This stage involves significant investment in machinery, quality control, and skilled labor to ensure products meet stringent industry standards and client specifications. Manufacturers often specialize in either molded or pultruded gratings, or offer a comprehensive range, leveraging specific process advantages to cater to diverse application needs and structural requirements.

The downstream analysis primarily concerns the distribution channels and the end-users. Distribution channels are varied, encompassing direct sales from manufacturers to large industrial clients, a network of specialized distributors, and increasingly, online sales platforms for smaller projects or specific product lines. Direct sales are common for large-scale, customized projects where technical consultation is crucial. Distributors play a vital role in reaching a broader customer base, offering local inventory, and providing installation support. The end-users, including chemical plants, oil refineries, construction companies, and municipal water treatment facilities, represent the final consumption point, driving demand based on their specific operational needs and regulatory compliance requirements.

FRP Grating Market Potential Customers

Potential customers for FRP Grating products encompass a broad spectrum of industries and organizations that require durable, corrosion-resistant, and safe flooring or structural solutions in challenging environments. The primary end-users are typically found in sectors where exposure to chemicals, moisture, high temperatures, or electrical hazards is common. These include large-scale industrial facilities suchating chemical processing plants, where FRP gratings are essential for walkways, platforms, and trench covers due to their exceptional chemical resistance and non-conductive properties, ensuring worker safety and long-term operational integrity.

Another significant customer segment includes the oil and gas industry, both onshore and offshore, where FRP gratings provide robust and low-maintenance solutions for platforms, mezzanines, and catwalks, resisting the harsh conditions of saltwater, corrosive gases, and petroleum by-products. Wastewater treatment facilities and municipal waterworks are also major buyers, leveraging FRPs resistance to biological and chemical degradation in constantly wet and corrosive environments, enhancing the lifespan of their infrastructure and reducing replacement costs. The marine sector, encompassing shipyards, docks, and offshore structures, relies on FRP for its lightweight, anti-slip, and non-corrosive characteristics.

Beyond heavy industry, the construction sector utilizes FRP gratings for architectural features, pedestrian bridges, and structural elements in environments where traditional materials would quickly degrade or require extensive maintenance. Power generation plants, including nuclear, thermal, and renewable energy facilities, employ FRP for its non-conductive properties and resistance to various environmental stressors. Furthermore, industries like food and beverage, pharmaceuticals, and mining also represent key customer bases, seeking FRP solutions that meet stringent hygiene standards, withstand aggressive cleaning agents, or endure abrasive conditions, respectively, underscoring the products widespread applicability and essential role in diverse operational contexts.

FRP Grating Market Key Technology Landscape

The key technology landscape of the FRP Grating market is characterized by continuous innovation in manufacturing processes, material science, and automation, aiming to enhance product performance, reduce production costs, and expand application possibilities. A foundational technology is the development and refinement of thermosetting resin systems, including polyester, vinyl ester, and phenolic resins, each engineered for specific chemical resistance, fire retardancy, and mechanical properties. Advances in resin chemistry enable manufacturers to produce gratings that can withstand increasingly aggressive corrosive agents and extreme temperatures, meeting stringent industry specifications and regulatory requirements for specialized applications.

Alongside resin advancements, fiber reinforcement technologies play a crucial role. While E-glass fiber remains predominant, ongoing research into carbon fiber and basalt fiber reinforcements offers enhanced strength-to-weight ratios, improved stiffness, and superior performance in high-stress applications. The development of hybrid fiber systems, combining the benefits of different fiber types, allows for tailor-made grating solutions optimized for specific load-bearing capacities and environmental exposures. These innovations in material composition directly translate into more durable, lighter, and longer-lasting FRP grating products, extending their applicability across diverse industrial sectors.

Manufacturing processes themselves are subject to significant technological advancements. Pultrusion and molding (especially compression molding and resin transfer molding) are core technologies, but automation and process control systems are continually being integrated to improve consistency, speed, and cost-efficiency. Advanced curing systems, such as UV or electron beam curing, are explored to accelerate production cycles and reduce energy consumption. Furthermore, the adoption of digital design tools, Finite Element Analysis (FEA) for structural integrity, and 3D printing for prototyping are transforming how FRP gratings are designed, tested, and customized, leading to more complex geometries and optimized performance characteristics for highly specialized industrial demands.

Regional Highlights

- North America: This region maintains a significant market share, driven by robust infrastructure spending, the presence of mature oil & gas and chemical industries, and stringent safety and environmental regulations. The ongoing replacement of aging traditional infrastructure with durable FRP solutions contributes substantially to market growth.

- Europe: Characterized by an established industrial base, particularly in chemical manufacturing and wastewater treatment, Europe shows consistent demand for FRP gratings. Strict European Union directives regarding worker safety and environmental protection further fuel the adoption of these advanced composite materials.

- Asia-Pacific: Emerging as the fastest-growing market, the Asia-Pacific region benefits from rapid industrialization, extensive infrastructure development projects in countries like China and India, and a burgeoning manufacturing sector. Increased investment in chemical processing and water treatment facilities drives strong demand.

- South America: This region experiences steady growth, primarily influenced by developing infrastructure, expansion in the mining and resource extraction industries, and increasing investments in industrial facilities. The need for resilient materials in often remote and challenging environments boosts FRP grating adoption.

- Middle East & Africa: Significant investments in oil & gas exploration and production, large-scale construction projects, and water desalination plants are key drivers in this region. The extreme environmental conditions (high temperatures, salinity) make FRP gratings an ideal choice for long-term durability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the FRP Grating Market.- Fibergrate Composite Structures Inc.

- Strongwell Corporation

- McNICHOLS Company

- Kennedy Grating Ltd.

- Locker Group

- Miami Grating Inc.

- Techno-Composites Inc.

- Pultrall Inc.

- AIL Group of Companies

- Gordon Composites Inc.

- Ferrotech International Pvt. Ltd.

- Hebecomp GmbH

- FRP Grating Manufacturer Co. Ltd.

- Safeguard Technology Inc.

- Composite Engineering Inc.

Frequently Asked Questions

What is FRP Grating and what are its primary advantages?

FRP Grating, or Fiber Reinforced Polymer Grating, is a structural material made from composite thermosetting resins and reinforcing fibers. Its primary advantages include exceptional corrosion resistance, high strength-to-weight ratio, non-conductivity, slip resistance, low maintenance, and a significantly longer lifespan compared to traditional materials like steel or concrete in harsh environments.

In which industries is FRP Grating most commonly utilized?

FRP Grating is extensively utilized across various demanding industries such as chemical processing, oil & gas, wastewater treatment, marine, power generation, and general industrial construction. It is preferred in environments where corrosive agents, electrical hazards, or the need for lightweight, durable flooring and platforms are critical.

How does FRP Grating compare to traditional materials like steel or concrete?

FRP Grating offers superior corrosion resistance, is lighter, non-conductive, and requires less maintenance than steel. Compared to concrete, FRP is significantly lighter, more resistant to chemical attack, and easier to install, making it a more cost-effective and safer long-term solution in many industrial and commercial applications.

What are the key factors driving the growth of the FRP Grating market?

Key growth drivers include increasing global industrialization and infrastructure development, a growing emphasis on worker safety and environmental regulations, the demand for durable and low-maintenance materials in corrosive environments, and the ongoing replacement of aging traditional infrastructure with advanced composite solutions that offer superior performance and longevity.

What should one consider when selecting FRP Grating for an application?

When selecting FRP Grating, key considerations include the specific corrosive agents present, required load-bearing capacity, desired flame retardancy, slip resistance needs, UV exposure, resin type (e.g., polyester, vinyl ester for chemical resistance), fiber reinforcement, and the manufacturing process (molded for bi-directional strength, pultruded for span capabilities).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- FRP Grating Market Size Report By Type (Molded FRP Grating, Pultruded FRP Grating), By Application (Stair Treads, Platforms, Covers, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Pultruded FRP Grating Market Statistics 2025 Analysis By Application (Walkways, Stair Treads, Docks), By Type (10-30mm, 31-50mm, Above 50mm), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager