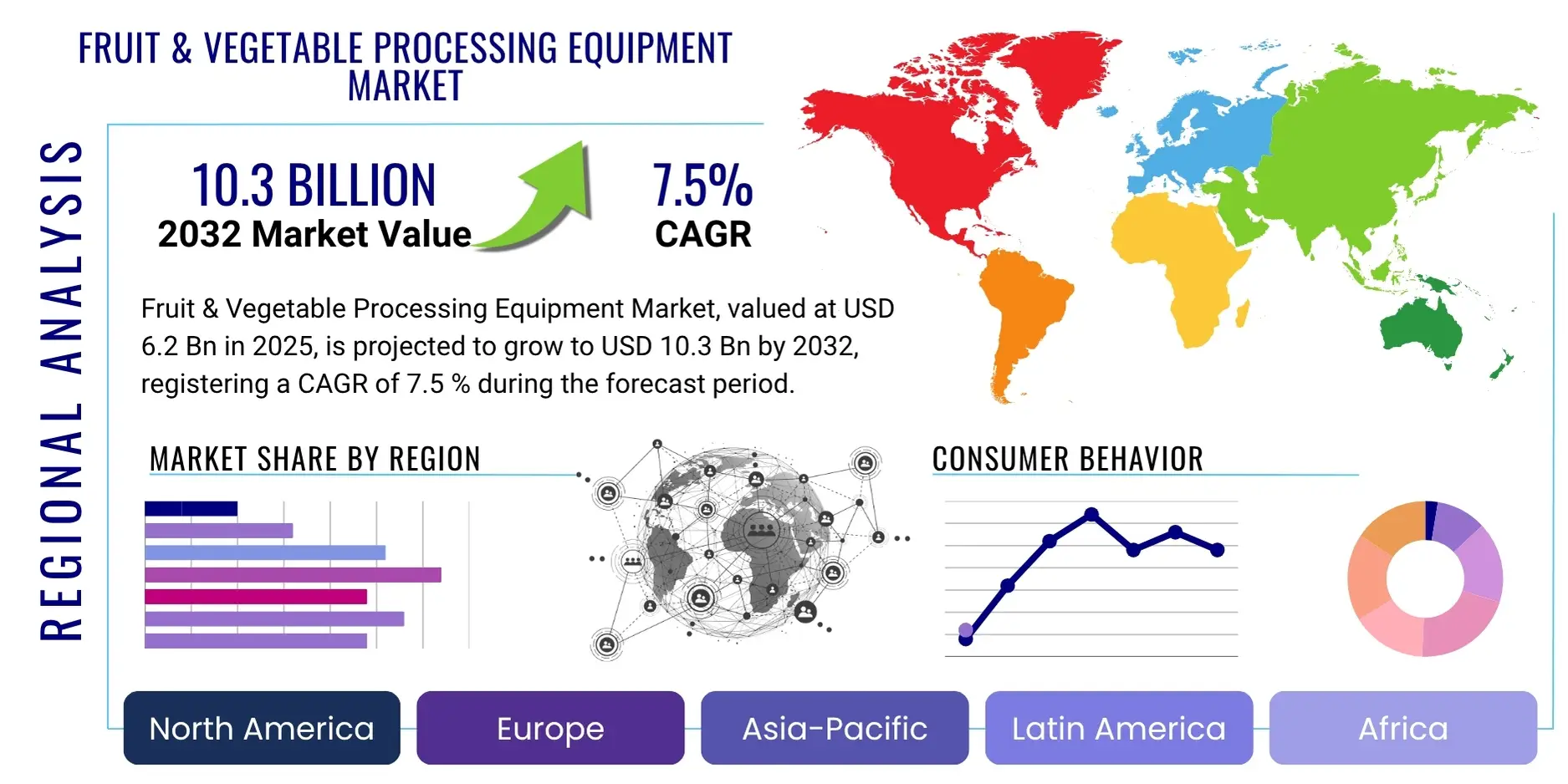

Fruit & Vegetable Processing Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428230 | Date : Oct, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Fruit & Vegetable Processing Equipment Market Size

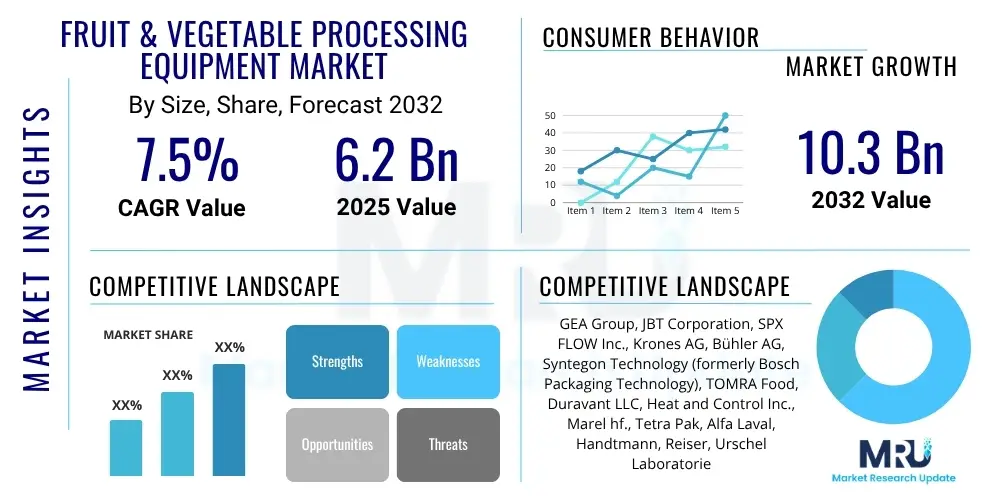

The Fruit & Vegetable Processing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2025 and 2032. The market is estimated at USD 6.2 billion in 2025 and is projected to reach USD 10.3 billion by the end of the forecast period in 2032.

Fruit & Vegetable Processing Equipment Market introduction

The Fruit & Vegetable Processing Equipment Market encompasses a wide range of machinery and systems designed to clean, sort, peel, cut, slice, blend, juice, dry, freeze, and package fruits and vegetables for various end-use applications. This equipment is crucial for maintaining food quality, extending shelf life, and improving processing efficiency across the food industry. Key products include washing and sorting machines, peeling and cutting equipment, juice extractors, blanchers, dryers, freezers, and packaging solutions. The primary applications span from large-scale commercial food processing plants to smaller-scale operations catering to niche markets, addressing the global demand for processed and semi-processed fruit and vegetable products. These applications are pivotal in creating convenience foods, beverages, canned goods, frozen meals, and dried snacks, directly impacting dietary patterns and consumption habits worldwide.

The widespread adoption of this equipment offers numerous benefits, including enhanced operational efficiency, reduced labor costs, improved product consistency, and adherence to stringent food safety and hygiene standards. By automating complex and labor-intensive processes, manufacturers can achieve higher throughput and greater precision, leading to superior product quality and reduced waste. Furthermore, advanced processing technologies enable the preservation of nutritional value and sensory attributes, meeting consumer expectations for wholesome and appealing food options. These benefits collectively contribute to the profitability and sustainability of food processing operations, providing a competitive edge in a dynamic market landscape. The ability to quickly and efficiently transform raw produce into value-added products is a cornerstone of modern food manufacturing.

Several driving factors underpin the robust growth of this market. Rapid urbanization and changing consumer lifestyles have spurred a significant increase in demand for convenient, ready-to-eat, and ready-to-cook fruit and vegetable products. Consumers are increasingly seeking processed foods that offer convenience without compromising on health or taste, propelling investment in advanced processing capabilities. Moreover, a growing awareness regarding food waste and the imperative for sustainable food systems is encouraging processors to adopt technologies that maximize yield and minimize spoilage. Technological advancements, particularly in automation, sensor-based sorting, and energy-efficient processing methods, are further stimulating market expansion. These innovations allow for greater precision, faster processing times, and lower operational costs, making modern equipment an attractive investment for food businesses looking to scale their operations and meet evolving market demands.

Fruit & Vegetable Processing Equipment Market Executive Summary

The Fruit & Vegetable Processing Equipment Market is experiencing dynamic growth driven by evolving consumer preferences for convenience foods, increasing demand for processed fruit and vegetable products, and a heightened focus on food safety and waste reduction. Business trends indicate a strong move towards automation and integration of smart technologies to enhance efficiency and productivity. Manufacturers are investing in advanced machinery that offers higher throughput, precise processing, and reduced operational costs, enabling them to meet the escalating global demand for value-added food items. There is also a growing emphasis on sustainable processing solutions, including energy-efficient equipment and technologies that minimize water usage and effluent discharge, reflecting a broader industry commitment to environmental responsibility. Furthermore, strategic partnerships and mergers among equipment manufacturers are becoming more common, aiming to consolidate market share and leverage synergistic capabilities to offer more comprehensive solutions to food processors.

Regionally, the market exhibits diverse growth patterns. Asia Pacific stands out as a dominant and rapidly expanding region, primarily due to its large population base, increasing disposable incomes, and the burgeoning food processing industry in countries like China and India. North America and Europe, while mature, continue to show steady growth, fueled by technological advancements, stringent food safety regulations, and a consistent demand for premium, high-quality processed food products. Latin America and the Middle East & Africa are emerging as significant growth frontiers, driven by expanding agricultural sectors, growing urbanization, and increasing foreign investments in food processing infrastructure. Each region presents unique opportunities and challenges, with local consumer preferences and regulatory frameworks playing a crucial role in shaping market dynamics. The localization of equipment design and service is becoming increasingly important for companies seeking to penetrate these diverse regional markets effectively.

Segmentation trends highlight the increasing demand for advanced processing technologies across various equipment types and applications. The sorting, cleaning, and washing equipment segment is witnessing substantial demand due to heightened food safety concerns and the need for rigorous quality control. Similarly, the packaging equipment segment is growing, driven by the need for extended shelf life and attractive product presentation. Automation is a key trend across all segments, with fully automatic machines gaining traction over semi-automatic and manual alternatives, particularly in large-scale industrial operations. Application-wise, the market is seeing robust growth in sectors like frozen foods, ready-to-eat meals, and beverages, reflecting the broader consumer shift towards convenient and time-saving food options. The ability to cater to diverse processing needs, from fresh-cut produce to highly processed ingredients, defines the success of equipment providers in this fragmented yet rapidly consolidating market.

AI Impact Analysis on Fruit & Vegetable Processing Equipment Market

Common user questions regarding AI's impact on the Fruit & Vegetable Processing Equipment Market revolve around how AI can enhance efficiency, reduce waste, improve product quality, and address labor shortages. Users are keenly interested in understanding the practical applications of AI in sorting, grading, defect detection, and predictive maintenance. There's also curiosity about the economic implications, such as potential cost savings and return on investment, and the challenges associated with integrating AI into existing infrastructure. Concerns often include the complexity of implementation, data privacy, and the need for specialized skills to operate and maintain AI-powered systems. Users also seek information on how AI can contribute to more sustainable processing practices and provide a competitive edge in a rapidly evolving industry, emphasizing smart factories and data-driven decision-making processes.

- Enhanced precision sorting and grading through computer vision and machine learning, significantly reducing manual labor and improving consistency.

- Predictive maintenance for equipment, anticipating failures and scheduling proactive repairs, thereby minimizing downtime and extending machine lifespan.

- Optimized processing parameters (e.g., temperature, pressure, cutting patterns) via AI algorithms, leading to improved product yield and energy efficiency.

- Advanced defect detection and foreign material removal, ensuring higher food safety standards and reducing product recalls.

- Robotics and automation integration for tasks like picking, packing, and palletizing, addressing labor shortages and improving operational speed.

- Real-time data analysis and process optimization, allowing for agile adjustments to production lines based on incoming raw material quality and output requirements.

- Development of smart processing lines capable of self-learning and adapting to variations in raw materials, reducing human intervention and errors.

- Improved supply chain visibility and traceability, from farm to fork, leveraging AI for better inventory management and recall readiness.

- Creation of new value-added products through AI-driven insights into consumer preferences and ingredient combinations.

DRO & Impact Forces Of Fruit & Vegetable Processing Equipment Market

The Fruit & Vegetable Processing Equipment Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities that collectively shape its growth trajectory and competitive landscape. Key drivers include the escalating global demand for processed foods, fueled by urbanization, evolving dietary habits, and the increasing need for convenience among consumers. Furthermore, a heightened focus on food safety, quality standards, and traceability across the supply chain compels processors to invest in advanced, automated equipment that ensures compliance and reduces contamination risks. Technological advancements, such as intelligent sensors, robotics, and automation, are also crucial drivers, enhancing efficiency, reducing labor costs, and improving product consistency. The imperative to minimize food waste throughout the processing chain provides another strong impetus for adopting efficient, high-yield machinery, aligning with global sustainability goals. These factors collectively create a robust environment for sustained market expansion, pushing innovation and investment in the sector.

However, the market also faces notable restraints. The high initial capital investment required for purchasing and installing sophisticated processing equipment can be a significant barrier for small and medium-sized enterprises (SMEs), limiting their adoption of advanced technologies. Operational costs, including energy consumption, maintenance, and the need for skilled labor to operate and manage complex machinery, further contribute to these restraints. Moreover, the stringent and evolving regulatory frameworks related to food processing, hygiene, and environmental compliance can pose challenges for manufacturers in terms of equipment design, material selection, and operational adjustments. Economic volatility and currency fluctuations can also impact raw material costs and equipment affordability, particularly for importers. These constraints necessitate careful financial planning and strategic resource allocation for market participants to navigate successfully and maintain competitiveness, often leading to a focus on long-term value and efficiency gains over immediate cost implications.

Despite these challenges, substantial opportunities exist within the market that promise future growth and innovation. Emerging economies, particularly in Asia Pacific, Latin America, and Africa, present vast untapped markets with rapidly expanding food processing industries and growing consumer bases. The rising adoption of advanced processing techniques, such as High-Pressure Processing (HPP) and Pulsed Electric Field (PEF) technologies, offers avenues for producing healthier, minimally processed products with extended shelf life. Customization and modular equipment solutions, tailored to specific processing needs and varying scales of operation, represent another significant opportunity to cater to a broader spectrum of clients. Furthermore, the increasing integration of Artificial intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) into processing equipment is poised to revolutionize operational intelligence, predictive maintenance, and overall plant efficiency. Sustainable processing methods, focusing on reduced water and energy consumption, also open doors for environmentally conscious innovation. These opportunities highlight the potential for market players to diversify their offerings, penetrate new geographies, and lead technological advancements in the fruit and vegetable processing sector.

Segmentation Analysis

The Fruit & Vegetable Processing Equipment Market is comprehensively segmented based on various critical attributes, providing a detailed view of its intricate structure and diverse application landscape. This segmentation allows for a nuanced understanding of market dynamics, enabling stakeholders to identify key growth areas, consumer preferences, and technological trends. The primary segmentation criteria typically include equipment type, level of operation, and end-use application. Each segment reflects distinct technological demands, operational efficiencies, and market values, influencing strategic decisions for manufacturers and processors alike. Understanding these divisions is crucial for product development, market positioning, and targeted sales efforts, ensuring that equipment solutions align with the specific needs of different processing environments and product categories within the broader food industry.

- By Equipment Type:

- Pre-processing Equipment (Washing, Sorting, Grading, Peeling, Destoning, Coring, Slicing, Dicing, Shredding)

- Processing Equipment (Blanching, Drying, Freezing, Pulping, Juicing, Concentrating, Extracting, Forming, Mixing, Cooling, Fermenting, Cutting, Mincing, Grinding)

- Packaging Equipment (Form-Fill-Seal Machines, Labeling Machines, Wrapping Machines, Capping Machines, Sealing Machines, Palletizers)

- Other Equipment (Storage Tanks, Conveyors, Pumps, Filters, Homogenizers, Sterilizers, Pasteurizers)

- By Operation:

- Automatic

- Semi-Automatic

- Manual

- By Application:

- Fresh-Cut Products

- Frozen Fruits & Vegetables

- Juices & Beverages

- Canned Fruits & Vegetables

- Jams, Jellies & Preserves

- Dried & Dehydrated Products

- Snacks & Confectionery

- Baby Food

- Sauces & Purees

- By End-User:

- Food Processing Plants

- Restaurants & Catering

- Supermarkets & Retail Chains

- Research & Development Institutes

- Hospitals & Institutions

Value Chain Analysis For Fruit & Vegetable Processing Equipment Market

The value chain for the Fruit & Vegetable Processing Equipment Market begins with upstream activities, primarily involving the sourcing and processing of raw materials such as steel, specialized alloys, plastics, and electronic components. Key upstream players include material suppliers, component manufacturers (e.g., motor manufacturers, sensor developers, control system providers), and software developers who create the operating systems and AI algorithms integrated into modern equipment. Research and development is also a critical upstream activity, focusing on innovation in processing technologies, material science, and automation to enhance equipment efficiency, hygiene, and durability. These foundational elements are essential for the quality, reliability, and performance of the final processing machinery, directly influencing the capabilities and competitiveness of equipment manufacturers. Strong relationships with these upstream suppliers are vital for ensuring consistent quality and managing supply chain risks, especially for specialized parts.

Moving downstream, the value chain encompasses the manufacturing, assembly, and distribution of the fruit and vegetable processing equipment. Equipment manufacturers design, fabricate, and assemble a wide array of machines, ranging from simple washing lines to complex, fully automated processing plants. This stage involves rigorous quality control, testing, and customization to meet specific client requirements. Post-manufacturing, the distribution channel plays a crucial role in delivering these complex machines to end-users. Direct distribution involves manufacturers selling directly to large food processing corporations or establishing their own sales and service networks. This approach allows for direct communication, custom solutions, and comprehensive after-sales support. Indirect distribution, on the other hand, involves working with third-party distributors, agents, and system integrators who have regional expertise and established networks, particularly beneficial for reaching smaller clients or penetrating new geographical markets. These distributors often provide local installation, training, and maintenance services, acting as an extension of the manufacturer's reach.

The final stages of the value chain involve the end-users and post-sales services. End-users are primarily food processing plants, but also include restaurants, catering services, and even agricultural cooperatives that undertake primary processing. These entities utilize the equipment to transform raw fruits and vegetables into various processed products. After-sales services, including installation, commissioning, maintenance, spare parts supply, technical support, and training, are critical components of the value chain, ensuring the longevity and optimal performance of the equipment. The quality of these services significantly impacts customer satisfaction and repeat business. The interplay between direct and indirect distribution channels often depends on market maturity, geographical reach, and the complexity of the equipment. Direct channels are preferred for highly customized or integrated solutions requiring extensive engineering support, while indirect channels facilitate broader market penetration for standardized products. This comprehensive value chain ensures that the equipment not only reaches the market but also remains operational and productive throughout its lifecycle, supporting the efficiency and profitability of the food processing industry.

Fruit & Vegetable Processing Equipment Market Potential Customers

Potential customers for Fruit & Vegetable Processing Equipment are predominantly diverse entities within the food and beverage industry, ranging from large multinational corporations to small-scale local businesses. The primary segment comprises large-scale industrial food processing plants that specialize in high-volume production of items such as frozen vegetables, fruit juices, canned goods, purees, jams, and ready-to-eat salads. These large-scale operators demand robust, high-capacity, and fully automated machinery capable of continuous operation, stringent hygiene standards, and integration with existing production lines. Their purchasing decisions are often driven by efficiency gains, labor cost reduction, product consistency, and compliance with global food safety regulations. These customers often require customized solutions and comprehensive after-sales service, including predictive maintenance and extensive technical support, to maximize their operational uptime and investment return.

Another significant customer segment includes medium-sized food processing units and regional food brands that cater to specific market niches or local consumer preferences. These businesses may focus on organic products, artisanal offerings, or culturally specific food items, requiring versatile and adaptable equipment that can handle smaller batches while maintaining quality and efficiency. They often seek semi-automatic or modular systems that can be scaled as their business grows, balancing initial investment costs with future expansion capabilities. The demand for equipment that supports sustainable practices and reduces waste is particularly strong within this segment, as many of these businesses emphasize ethical sourcing and environmentally friendly production methods. Customization and ease of operation are key considerations, as their workforce may not be as specialized as those in larger industrial settings.

Beyond traditional processing plants, the market extends to other end-users such as commercial kitchens, restaurants, catering services, and institutional food service providers like hospitals and schools. While their equipment needs are typically smaller in scale, they require reliable, easy-to-clean, and efficient machinery for tasks like fruit and vegetable preparation, juicing, and blending. Agricultural cooperatives and farms that engage in value-added processing of their produce before distribution also represent a growing customer base, seeking equipment to extend product shelf life and create new revenue streams. Additionally, research and development institutions and culinary schools invest in processing equipment for experimentation, product innovation, and training purposes. The diverse needs of these various end-users necessitate a broad product portfolio from equipment manufacturers, ranging from basic preparatory tools to sophisticated processing lines, each designed to optimize specific operations and deliver value to distinct customer profiles.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.2 Billion |

| Market Forecast in 2032 | USD 10.3 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GEA Group, JBT Corporation, SPX FLOW Inc., Krones AG, Bühler AG, Syntegon Technology (formerly Bosch Packaging Technology), TOMRA Food, Duravant LLC, Heat and Control Inc., Marel hf., Tetra Pak, Alfa Laval, Handtmann, Reiser, Urschel Laboratories Inc., Van Mark, Key Technology Inc., Finis B.V., G.M. Packaging Inc., Atlas Pacific Engineering Company Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fruit & Vegetable Processing Equipment Market Key Technology Landscape

The Fruit & Vegetable Processing Equipment Market is characterized by a rapidly evolving technological landscape, driven by the continuous need for enhanced efficiency, improved product quality, increased food safety, and reduced operational costs. Automation remains a foundational technology, with highly automated processing lines integrating various stages from receiving raw materials to final packaging, minimizing manual intervention and ensuring consistency. This includes advanced robotics for tasks such as picking, placing, cutting, and packing, which significantly boost throughput and address labor shortages. Sensor-based sorting technologies, utilizing optical sensors, hyperspectral imaging, and X-ray technology, are critical for precision sorting and grading, detecting subtle defects, foreign materials, and variations in quality that are imperceptible to the human eye, thereby enhancing product purity and safety.

Another prominent technological advancement is the integration of Artificial Intelligence (AI) and Machine Learning (ML) into processing equipment. These intelligent systems enable predictive maintenance by analyzing machine performance data to anticipate potential failures, thereby minimizing downtime and extending equipment lifespan. AI also optimizes processing parameters in real-time, adapting to variations in raw material quality and environmental conditions to maximize yield and energy efficiency. The Internet of Things (IoT) plays a crucial role by connecting various machines and sensors across the processing line, creating a network that collects and transmits vast amounts of data. This data is then analyzed to provide actionable insights for process optimization, remote monitoring, and improved traceability throughout the production cycle, fostering the development of smart factories and Industry 4.0 paradigms within the food processing sector.

Beyond automation and AI, innovative processing methods are also reshaping the market. High-Pressure Processing (HPP) and Pulsed Electric Field (PEF) technologies are gaining traction as non-thermal pasteurization alternatives, preserving the nutritional content, fresh taste, and natural texture of fruits and vegetables while extending shelf life and eliminating harmful microorganisms. Membrane filtration technologies are increasingly used for juice clarification and concentration, offering energy-efficient alternatives to traditional thermal methods. Additionally, advancements in sustainable processing solutions, such as water recycling systems, energy-efficient motors, and waste heat recovery units, are becoming standard features in modern equipment, aligning with global efforts to reduce the environmental footprint of food production. These diverse technological innovations collectively contribute to a more efficient, safe, and sustainable future for the fruit and vegetable processing industry, enabling manufacturers to meet increasingly complex consumer demands and regulatory requirements.

Regional Highlights

- North America: A mature market with high adoption of automated and advanced processing equipment, driven by stringent food safety regulations, significant demand for convenience foods, and technological innovation. Key countries include the United States and Canada, focusing on efficiency, labor cost reduction, and premium processed products.

- Europe: Characterized by strong emphasis on food quality, sustainability, and technological leadership, particularly in countries like Germany, France, Italy, and the UK. The region sees high demand for equipment supporting organic and minimally processed food trends, as well as solutions for reducing food waste and energy consumption.

- Asia Pacific (APAC): The fastest-growing region, fueled by large population bases, rising disposable incomes, rapid urbanization, and expanding food processing industries in countries like China, India, Japan, and Australia. Significant investments in infrastructure and increasing consumer demand for diverse processed fruit and vegetable products drive market expansion.

- Latin America: An emerging market with considerable growth potential, driven by expanding agricultural production and increasing investment in food processing capabilities, particularly in Brazil, Mexico, and Argentina. Focus is on enhancing processing efficiency and meeting export quality standards.

- Middle East & Africa (MEA): A developing market that is witnessing gradual growth due to increasing food security concerns, government initiatives to boost local food production, and foreign direct investments. Countries like South Africa, Saudi Arabia, and UAE are showing increasing adoption of modern processing technologies to cater to a growing urban population.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fruit & Vegetable Processing Equipment Market.- GEA Group

- JBT Corporation

- SPX FLOW Inc.

- Krones AG

- Bühler AG

- Syntegon Technology (formerly Bosch Packaging Technology)

- TOMRA Food

- Duravant LLC

- Heat and Control Inc.

- Marel hf.

- Tetra Pak

- Alfa Laval

- Handtmann

- Reiser

- Urschel Laboratories Inc.

- Van Mark

- Key Technology Inc.

- Finis B.V.

- G.M. Packaging Inc.

- Atlas Pacific Engineering Company Inc.

Frequently Asked Questions

Analyze common user questions about the Fruit & Vegetable Processing Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the current market size and projected growth rate for Fruit & Vegetable Processing Equipment?

The market is estimated at USD 6.2 billion in 2025 and is projected to reach USD 10.3 billion by 2032, growing at a Compound Annual Growth Rate (CAGR) of 7.5%.

What are the primary drivers fueling the growth of this market?

Key drivers include rising consumer demand for processed and convenience foods, increasing focus on food safety, technological advancements in automation and AI, and global efforts to reduce food waste.

How is AI impacting the Fruit & Vegetable Processing Equipment market?

AI is transforming the market through enhanced precision sorting, predictive maintenance, real-time process optimization, advanced defect detection, and integration with robotics to boost efficiency and product quality.

Which regions are significant for the Fruit & Vegetable Processing Equipment Market?

Asia Pacific is the fastest-growing region, while North America and Europe are mature markets with high adoption rates. Latin America and MEA are emerging with strong growth potential due to increasing investments.

What are the main types of equipment covered in this market?

The market encompasses pre-processing (washing, sorting, peeling), processing (blanching, drying, juicing, freezing), and packaging equipment, along with other auxiliary machinery like conveyors and pumps.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager