Galvanized Rigid Conduit Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430125 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Galvanized Rigid Conduit Market Size

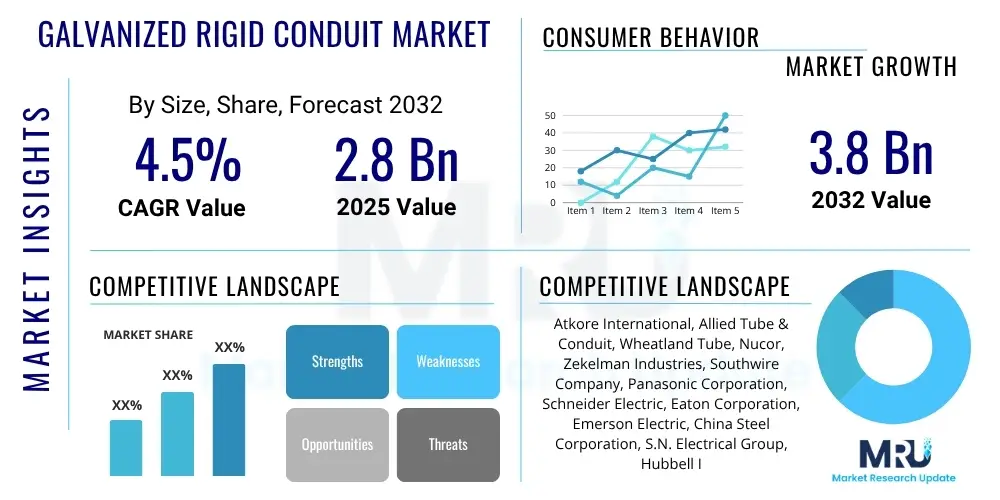

The Galvanized Rigid Conduit Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2025 and 2032. The market is estimated at USD 2.8 Billion in 2025 and is projected to reach USD 3.8 Billion by the end of the forecast period in 2032.

Galvanized Rigid Conduit Market introduction

The Galvanized Rigid Conduit (GRC) market plays a critical role in electrical infrastructure, providing robust protection for wiring in diverse environments. GRC is a heavy-gauge, hot-dip galvanized steel conduit that offers superior physical protection, corrosion resistance, and electromagnetic interference (EMI) shielding for electrical conductors. Its robust construction makes it an ideal choice for demanding commercial, industrial, and utility applications where durability and safety are paramount.

GRC is predominantly used to enclose and protect insulated electrical conductors and cables in structures, ensuring the safe and reliable transmission of power. Key applications span across commercial buildings, manufacturing facilities, power generation plants, water treatment facilities, and critical infrastructure projects such as bridges and tunnels. The inherent strength and integrity of GRC prevent mechanical damage, resist chemical degradation, and offer exceptional fire protection, which are crucial benefits in harsh operational settings.

The market growth for GRC is fundamentally driven by persistent global urbanization, escalating infrastructure development initiatives, and the implementation of stringent electrical safety codes. Expanding industrial sectors, a heightened focus on reliable power distribution, and the continuous need for upgrading aging electrical systems further propel demand. GRC's reputation for longevity and compliance with international safety standards solidifies its position as an indispensable component in modern electrical installations.

Galvanized Rigid Conduit Market Executive Summary

The Galvanized Rigid Conduit market is experiencing steady growth, propelled by resilient business trends such as escalating global construction activities, particularly in developing economies, and significant investments in infrastructure upgrades across mature regions. A growing emphasis on electrical safety and compliance with evolving building codes globally also fuels demand. Manufacturers are increasingly focusing on efficiency in production and supply chain optimization to meet these demands while navigating raw material price fluctuations.

Regional dynamics significantly influence the market landscape. Asia Pacific is emerging as a primary growth engine due to rapid urbanization, industrial expansion, and extensive public and private infrastructure projects. North America and Europe, while mature markets, continue to demonstrate stable demand, driven by renovation, maintenance, and modernization of existing electrical systems. Furthermore, stricter environmental and safety regulations in these regions often mandate the use of durable and protective conduits like GRC, contributing to sustained market traction.

Segment-wise, the market sees robust demand across industrial and commercial applications, where the protective qualities of GRC are indispensable for operational integrity and personnel safety. There is also a notable trend towards specialized GRC products, including those with enhanced corrosion resistance for marine or chemical environments, and pre-threaded options that streamline installation processes. This diversification in product offerings aims to cater to specific end-user requirements, optimizing both performance and installation efficiency.

AI Impact Analysis on Galvanized Rigid Conduit Market

The integration of Artificial Intelligence (AI) into the Galvanized Rigid Conduit market is primarily focused on optimizing manufacturing processes, enhancing supply chain efficiency, and improving product quality control, rather than directly altering the core product itself. Common user inquiries revolve around how AI can reduce production costs, predict maintenance needs for machinery, automate inspection processes, and streamline logistics. Users are keen to understand if AI can lead to more consistent product quality, faster delivery times, and more responsive manufacturing capabilities, ultimately impacting the cost-effectiveness and availability of GRC products.

While GRC is a physical product, the influence of AI is felt indirectly through its upstream and downstream applications. AI algorithms can analyze vast datasets from production lines to identify inefficiencies, predict equipment failures before they occur, and optimize energy consumption in galvanizing plants. This leads to more sustainable and cost-efficient manufacturing. Additionally, AI-driven demand forecasting can help manufacturers better manage inventory and raw material procurement, reducing waste and improving overall market responsiveness. The adoption of AI in quality assurance, such as visual inspection systems, ensures that GRC products consistently meet rigorous industry standards.

The long-term expectations from AI's impact include the potential for customized product lines based on real-time market data, more agile production cycles, and reduced lead times for orders. While GRC itself will remain a steel conduit, its journey from raw material to installation site is increasingly being influenced by intelligent systems designed to enhance efficiency and reliability. The overarching theme is the application of AI to create a smarter, more resilient, and more cost-effective manufacturing and supply chain ecosystem for vital construction materials like GRC.

- AI-powered predictive maintenance for manufacturing machinery

- Optimized supply chain and logistics through AI-driven forecasting

- Enhanced quality control with AI-based visual inspection systems

- Improved energy efficiency in galvanizing processes

- Data-driven demand forecasting for inventory management

- Automation of routine operational tasks in production

DRO & Impact Forces Of Galvanized Rigid Conduit Market

The Galvanized Rigid Conduit market is influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form its Impact Forces. Key drivers include significant global investments in infrastructure development, particularly in emerging economies where urbanization and industrialization are accelerating. Stringent electrical safety regulations and building codes across various regions mandate the use of durable, protective conduits like GRC, further boosting demand. The increasing focus on reliable and safe power distribution systems in commercial and industrial sectors also acts as a primary growth stimulant.

Conversely, several restraints impede market expansion. The volatile pricing of raw materials, primarily steel and zinc, directly impacts manufacturing costs and profit margins for GRC producers. The availability and increasing adoption of alternative conduit materials, such as PVC, EMT (Electrical Metallic Tubing), and FMC (Flexible Metal Conduit), offer competitive pricing and ease of installation in certain applications, potentially diverting market share from GRC. Furthermore, a shortage of skilled labor for complex electrical installations can slow down project timelines and, consequently, GRC demand.

Despite these challenges, substantial opportunities exist within the market. The global shift towards smart city initiatives and renewable energy projects, which require extensive and robust electrical infrastructure, presents new avenues for GRC applications. Developing economies offer untapped potential for market penetration as they continue to invest heavily in construction and industrialization. Additionally, advancements in manufacturing processes leading to more cost-effective or enhanced-performance GRC products, such as those with specialized corrosion coatings or pre-assembled fittings, could significantly expand market reach and application diversity.

Segmentation Analysis

The Galvanized Rigid Conduit market is meticulously segmented to provide a comprehensive understanding of its diverse landscape and to identify specific growth drivers and market dynamics across various categories. These segmentations are critical for stakeholders to pinpoint key areas of demand, understand competitive landscapes, and formulate targeted strategies, ensuring that product offerings align with distinct end-user requirements and application specificities. The market can be broadly categorized by type, diameter, application, and end-use industry, each offering unique insights into consumption patterns and growth trajectories.

Analyzing these segments allows for a granular view of the market's structure. For instance, segmentation by type, such as hot-dip galvanized versus electro-galvanized, highlights differences in corrosion resistance and cost implications. Diameter-based segmentation caters to varying wiring capacity and protection needs, from smaller commercial installations to heavy-duty industrial power lines. Application and end-use industry segmentations reveal the predominant sectors driving demand, from large-scale commercial constructions and manufacturing plants to utilities and critical infrastructure, offering a clearer picture of where GRC products are most vital and actively utilized across the globe.

- By Type:

- Hot-Dip Galvanized Rigid Conduit

- Electro-Galvanized Rigid Conduit

- By Diameter:

- 1/2 Inch to 1 Inch

- 1-1/4 Inch to 2 Inch

- 2-1/2 Inch to 4 Inch

- Above 4 Inch

- By Application:

- Commercial Construction

- Industrial Facilities

- Residential Construction

- Infrastructure (Utilities, Transportation, Communication)

- By End-Use Industry:

- Construction

- Manufacturing

- Power Generation & Distribution

- Oil & Gas

- Chemical

- Telecommunications

Value Chain Analysis For Galvanized Rigid Conduit Market

The value chain for the Galvanized Rigid Conduit market begins with upstream activities, primarily involving the sourcing of foundational raw materials. This stage is dominated by steel manufacturers and zinc suppliers, who provide the high-quality steel sheets or coils and the zinc required for the galvanization process. The cost, quality, and availability of these raw materials are critical determinants of the final product's competitiveness and are subject to global commodity market fluctuations. Robust relationships with reliable raw material providers are essential for maintaining stable production and pricing within the GRC market.

Midstream activities encompass the manufacturing and processing of GRC. This involves several key steps: steel tube formation, threading, and the crucial galvanization process where steel conduits are coated with a layer of zinc to provide corrosion resistance. Manufacturers often invest heavily in advanced machinery and quality control systems to ensure products meet stringent industry standards such as UL 6, ANSI C80.1, and CSA C22.2 No. 83. This stage also includes packaging and preparation for distribution, where efficiency and adherence to regulatory compliance are paramount for market acceptance and operational success.

Downstream activities involve the distribution, sales, and end-use of GRC products. Products move through various distribution channels, including direct sales to large contractors or utility companies, and indirect channels suchuting through a network of wholesalers, distributors, and electrical supply retailers. These channels facilitate market reach and provide logistical support to end-users such as electrical contractors, industrial facilities, and commercial developers. The effectiveness of these distribution networks, coupled with strong customer service and technical support, is vital for driving market penetration and ensuring product availability across diverse geographical regions and project types.

Galvanized Rigid Conduit Market Potential Customers

The primary potential customers and end-users of Galvanized Rigid Conduit products are diverse, spanning multiple sectors that require robust and reliable electrical wiring protection. These include a wide array of entities involved in construction, industrial operations, and public infrastructure development. Electrical contractors represent a significant segment, acting as direct buyers who incorporate GRC into their installation projects for commercial buildings, industrial plants, and residential complexes. Their purchasing decisions are often influenced by project specifications, regulatory compliance, and the need for durable, long-lasting solutions.

Beyond contractors, large industrial facilities such as manufacturing plants, chemical processing units, and oil & gas refineries are crucial end-users. These environments frequently expose electrical systems to harsh conditions, demanding the superior protection and corrosion resistance that GRC offers. Similarly, commercial building developers, particularly those undertaking large-scale projects like office complexes, shopping malls, and data centers, consistently specify GRC for its reliability, safety, and compliance with stringent building codes. The long-term maintenance benefits and fire protection capabilities are key considerations for these buyers.

Government agencies and utility companies also constitute substantial potential customers, especially for critical infrastructure projects. This includes applications in power generation and distribution networks, public transportation systems (railways, subways), bridges, tunnels, and water treatment plants. For these applications, the longevity, mechanical strength, and ability of GRC to withstand extreme environmental conditions are indispensable. Their procurement processes often involve stringent quality checks and adherence to national and international standards, ensuring that GRC products meet the highest levels of performance and safety for public sector use.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.8 Billion |

| Market Forecast in 2032 | USD 3.8 Billion |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atkore International, Allied Tube & Conduit, Wheatland Tube, Nucor, Zekelman Industries, Southwire Company, Panasonic Corporation, Schneider Electric, Eaton Corporation, Emerson Electric, China Steel Corporation, S.N. Electrical Group, Hubbell Incorporated, ABB Ltd., Legrand, Calpipe Industries, Pipelife International, Tenaris, Electri-Flex Company, King Metal Conduit |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Galvanized Rigid Conduit Market Key Technology Landscape

The technology landscape for the Galvanized Rigid Conduit market is continually evolving, driven by advancements aimed at enhancing product performance, manufacturing efficiency, and environmental sustainability. Core technologies revolve around the galvanization process itself, with manufacturers increasingly adopting advanced hot-dip galvanizing techniques that ensure a more uniform and durable zinc coating. Innovations in steel metallurgy also contribute to higher strength-to-weight ratios and improved corrosion resistance of the base steel tubing, extending the lifespan and application range of GRC products. Furthermore, advancements in robotic welding and forming technologies are optimizing the production process, leading to higher precision and reduced material waste.

Beyond the fundamental manufacturing processes, significant technological developments are observed in value-added features and installation methodologies. This includes the development of specialized coatings and interior linings for enhanced corrosion resistance in highly aggressive environments, such as those exposed to chemicals or saltwater. Pre-threading and integral coupling technologies are gaining traction, as they streamline installation, reduce labor costs, and improve connection integrity on job sites. These innovations cater to the growing demand for quicker and more efficient construction practices, reflecting a broader trend towards modular and pre-fabricated building solutions.

Moreover, the adoption of digital technologies is transforming GRC manufacturing and supply chain management. Advanced automation in quality control, utilizing vision systems and non-destructive testing, ensures adherence to stringent product specifications and safety standards. Enterprise Resource Planning (ERP) systems, integrated with real-time data analytics, optimize production scheduling, inventory management, and logistics, leading to greater operational transparency and responsiveness. While the core product remains a robust conduit, the technologies surrounding its production, enhancement, and delivery are continuously advancing to meet modern market demands for quality, efficiency, and sustainability.

Regional Highlights

- North America: A mature market characterized by significant infrastructure spending, ongoing maintenance, and upgrades of aging electrical systems. Strict adherence to safety standards and building codes drives consistent demand. The United States and Canada lead in consumption due to robust commercial and industrial construction.

- Europe: Exhibits steady demand fueled by renovation projects, industrial automation, and investments in renewable energy infrastructure. Germany, the UK, and France are key contributors, driven by stringent environmental and safety regulations requiring high-quality conduit solutions.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid urbanization, industrialization, and massive infrastructure development projects, particularly in countries like China, India, and Southeast Asian nations. Increased manufacturing activities and expanding construction sectors are primary market drivers.

- Latin America: An emerging market with growing opportunities due to increasing foreign direct investment in manufacturing and infrastructure. Brazil and Mexico are notable markets, driven by residential and commercial construction growth and modernization efforts.

- Middle East and Africa (MEA): Demonstrates significant growth, largely due to extensive construction projects in the GCC countries (Saudi Arabia, UAE) and investments in oil & gas, utilities, and diversified industrial sectors. Urban development and industrialization initiatives are key demand catalysts.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Galvanized Rigid Conduit Market.- Atkore International

- Allied Tube & Conduit (Zekelman Industries)

- Wheatland Tube

- Nucor

- Southwire Company

- Panasonic Corporation

- Schneider Electric

- Eaton Corporation

- Emerson Electric

- China Steel Corporation

- S.N. Electrical Group

- Hubbell Incorporated

- ABB Ltd.

- Legrand

- Calpipe Industries

- Pipelife International

- Tenaris

- Electri-Flex Company

- King Metal Conduit

- Anvil International

Frequently Asked Questions

What is Galvanized Rigid Conduit (GRC) and what are its primary uses?

Galvanized Rigid Conduit (GRC) is a heavy-gauge, hot-dip galvanized steel tubing primarily used for protecting electrical wiring in commercial, industrial, and utility installations. It provides superior mechanical protection, corrosion resistance, and electromagnetic interference (EMI) shielding for conductors.

Why is GRC preferred over other types of conduits in certain applications?

GRC is preferred for its exceptional durability, high strength, resistance to harsh environments, and fire protection capabilities. It is essential in demanding locations where physical impact, corrosive elements, or extreme temperatures are concerns, offering long-term reliability and safety compliance.

What factors are driving the growth of the GRC market?

Key growth drivers include increasing global infrastructure spending, rapid urbanization, stringent electrical safety regulations, and expanding industrial and commercial construction activities. The need for robust, long-lasting electrical systems in critical environments consistently fuels demand.

How do raw material prices impact the Galvanized Rigid Conduit market?

Raw material prices, particularly for steel and zinc, significantly influence GRC manufacturing costs. Volatility in these commodity markets can lead to price fluctuations for GRC products, affecting profit margins for manufacturers and procurement costs for buyers, potentially impacting market stability.

What are the main regional markets for Galvanized Rigid Conduit?

The primary regional markets for GRC include Asia Pacific (due to rapid development), North America (stable demand from infrastructure upgrades), Europe (renovation and industrial focus), Latin America (emerging construction), and the Middle East & Africa (large-scale development projects).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager