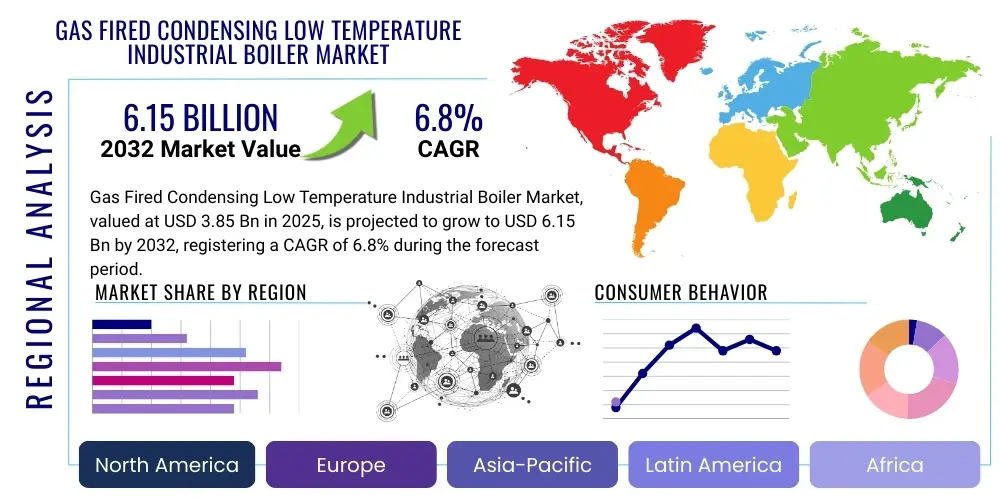

Gas Fired Condensing Low Temperature Industrial Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427554 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Gas Fired Condensing Low Temperature Industrial Boiler Market Size

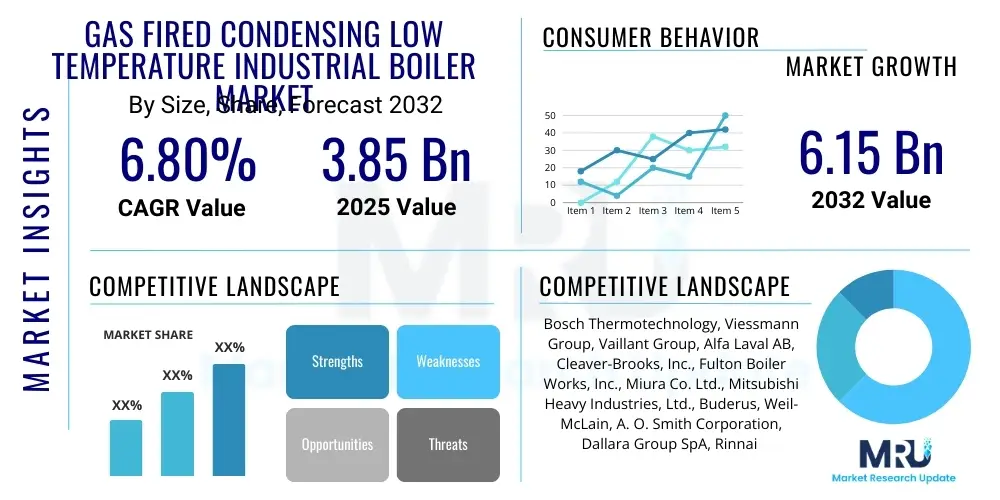

The Gas Fired Condensing Low Temperature Industrial Boiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 3.85 Billion in 2025 and is projected to reach USD 6.15 Billion by the end of the forecast period in 2032. This significant growth is primarily driven by global decarbonization efforts, stringent environmental regulations, and the increasing demand for energy-efficient industrial heating solutions across various sectors. The market expansion reflects a crucial shift towards sustainable industrial practices, where operational efficiency and reduced carbon footprints are paramount for businesses seeking long-term viability and compliance with international standards.

Gas Fired Condensing Low Temperature Industrial Boiler Market introduction

The Gas Fired Condensing Low Temperature Industrial Boiler Market is experiencing robust growth driven by the escalating demand for energy-efficient and environmentally responsible heating solutions in industrial applications. These boilers represent a technological advancement over traditional industrial boilers, utilizing latent heat from exhaust gases to preheat incoming water, thereby significantly improving thermal efficiency. This innovative design reduces fuel consumption and minimizes greenhouse gas emissions, aligning with global sustainability objectives and increasingly stringent regulatory frameworks aimed at combating climate change.

These sophisticated industrial boilers are predominantly characterized by their ability to operate at lower return water temperatures, which maximizes the condensation of water vapor in the flue gas. This process allows for the recovery of energy that would otherwise be lost up the chimney, resulting in efficiencies that can exceed 90% on a higher heating value basis. Their design typically incorporates advanced combustion control systems, modulating burners, and durable heat exchangers engineered to withstand the corrosive condensate, ensuring longevity and reliable performance in demanding industrial environments.

Major applications for gas fired condensing low temperature industrial boilers span a wide array of sectors including food and beverage processing, pharmaceuticals, chemical manufacturing, textile production, and various other industrial processes requiring reliable steam or hot water for heating, sterilization, or drying. The primary benefits include substantial reductions in operational costs due to lower fuel consumption, improved energy security, and compliance with environmental standards such as those related to NOx and CO2 emissions. Key driving factors encompass rising natural gas availability and affordability in some regions, government incentives for energy-efficient technologies, and corporate sustainability initiatives aiming to reduce carbon footprints and enhance brand reputation.

Gas Fired Condensing Low Temperature Industrial Boiler Market Executive Summary

The Gas Fired Condensing Low Temperature Industrial Boiler Market is witnessing dynamic business trends, characterized by a strong emphasis on smart boiler technologies and integrated energy management systems. Manufacturers are increasingly incorporating IoT capabilities, remote monitoring, and predictive maintenance features into their offerings, transforming boilers from standalone units into intelligent components of a broader industrial ecosystem. This shift is driven by industrial clients seeking enhanced operational visibility, optimized performance, and minimized downtime, directly impacting the demand for more sophisticated and connected boiler solutions that offer real-time data and analytics for proactive decision-making.

Regionally, the market exhibits varied growth trajectories influenced by disparate regulatory landscapes, industrial development phases, and energy cost structures. Europe leads in adoption due to pioneering environmental regulations and a mature industrial base keen on efficiency upgrades, while Asia-Pacific presents the most significant growth opportunities, propelled by rapid industrialization, expanding manufacturing sectors, and increasing awareness of energy conservation, particularly in countries like China and India. North America also shows steady growth, primarily driven by replacement demand for aging infrastructure and retrofits aimed at improving energy efficiency and meeting new emission standards.

In terms of segmentation, the market is predominantly influenced by boiler capacity and end-use industry. High-capacity boilers are experiencing substantial demand from large-scale manufacturing and power generation facilities, while smaller and medium-capacity units find widespread application in commercial and light industrial settings. The food and beverage, chemical, and pharmaceutical industries remain significant end-users due to their continuous need for precise temperature control and hygienic process heating. Technological advancements, particularly in burner design, heat recovery, and control systems, continue to drive product differentiation and competitive strategies among key market players, shaping the future landscape of industrial heating.

AI Impact Analysis on Gas Fired Condensing Low Temperature Industrial Boiler Market

The integration of Artificial Intelligence (AI) into the Gas Fired Condensing Low Temperature Industrial Boiler Market is profoundly reshaping operational efficiencies, maintenance protocols, and energy management strategies. Users are keenly interested in how AI can move beyond basic automation to deliver truly intelligent systems that predict failures, optimize fuel consumption in real-time based on varying load demands, and autonomously adjust to environmental factors. The primary concerns revolve around the cybersecurity implications of connected systems, the complexity of implementation, and the need for skilled personnel to manage and interpret AI-driven insights, alongside the expectation for demonstrable returns on investment through reduced operational costs and enhanced reliability.

- AI-powered predictive maintenance drastically reduces unscheduled downtime by analyzing sensor data to forecast potential equipment failures, enabling proactive servicing and part replacement before critical issues arise.

- Real-time combustion optimization using AI algorithms precisely controls air-to-fuel ratios, maximizing thermal efficiency and significantly lowering natural gas consumption and associated operational costs.

- Intelligent load management systems leverage AI to adapt boiler output to fluctuating industrial demand, preventing over-firing or under-firing, thus improving energy efficiency and extending equipment lifespan.

- Enhanced safety protocols are achieved through AI monitoring of operational parameters, immediately identifying anomalies or hazardous conditions and initiating automated shutdown procedures or alerts to prevent incidents.

- Remote monitoring and diagnostic capabilities are vastly improved with AI, allowing operators to oversee boiler performance from any location, troubleshoot issues, and receive intelligent recommendations, reducing the need for on-site inspections.

- AI contributes to superior environmental performance by optimizing combustion processes to minimize the emission of nitrogen oxides (NOx) and carbon monoxide (CO), helping industries meet stringent regulatory limits.

- Through machine learning, AI systems continuously learn from operational data, refining their control strategies over time to achieve ever-higher levels of efficiency and reliability, making the boilers self-improving assets.

DRO & Impact Forces Of Gas Fired Condensing Low Temperature Industrial Boiler Market

The Gas Fired Condensing Low Temperature Industrial Boiler Market is significantly influenced by a confluence of drivers, restraints, and opportunities that collectively shape its trajectory and impact forces. A primary driver is the increasing global focus on decarbonization and the urgent need to mitigate climate change, compelling industries to adopt more energy-efficient and low-emission heating solutions. Government mandates and incentives, such as carbon pricing, emission trading schemes, and subsidies for green technologies, further accelerate the transition towards condensing boilers. Additionally, the rising cost of conventional fuels and the operational savings offered by high-efficiency condensing units incentivize businesses to invest in these advanced systems, making them an economically viable and environmentally responsible choice for modern industrial facilities.

Despite the compelling advantages, the market faces notable restraints. The initial capital investment required for installing gas fired condensing low temperature industrial boilers is often higher than that for traditional boiler systems, which can be a significant barrier for small and medium-sized enterprises (SMEs) with limited budgets. Furthermore, the complexity of retrofitting existing industrial infrastructure to accommodate these advanced systems, including potential modifications to flue gas exhaust systems and condensate drainage, can lead to additional costs and operational disruptions. A lack of comprehensive awareness regarding the long-term benefits and payback periods among some potential end-users also acts as a restraint, hindering broader market penetration and adoption, especially in emerging economies where traditional boiler technologies are still prevalent.

Conversely, significant opportunities exist for market expansion and innovation. The ongoing advancements in smart boiler technologies, integrating features such as IoT connectivity, AI-driven controls, and remote diagnostics, present avenues for enhanced performance, predictive maintenance, and seamless integration into larger industrial automation systems. The growing demand for district heating and cooling networks, particularly in urban areas, offers a new application frontier for large-scale condensing boiler installations. Moreover, the increasing adoption of natural gas as a cleaner transitional fuel in many regions, coupled with the potential for these boilers to utilize renewable natural gas (RNG) or hydrogen blends in the future, positions them favorably for sustained growth and evolution within the broader energy transition landscape, attracting significant investments and fostering continuous technological innovation.

Segmentation Analysis

The Gas Fired Condensing Low Temperature Industrial Boiler Market is comprehensively segmented to provide granular insights into its diverse components and application areas. This segmentation helps in understanding the varied demands from different industrial sectors and capacity requirements, allowing manufacturers to tailor their product offerings and market strategies effectively. Analyzing these segments reveals key trends in adoption patterns, technological preferences, and regional concentrations, painting a detailed picture of the markets structure and future growth potential across its numerous facets. The classifications primarily revolve around the operational scale, specific industrial needs, and the core components that define these advanced heating systems, providing a multi-dimensional view of market dynamics.

- By Capacity:

- Small Capacity Boilers (up to 5 MW): Typically used in light industrial applications, commercial buildings, and smaller manufacturing plants requiring moderate heating loads.

- Medium Capacity Boilers (5 MW - 20 MW): Suited for medium-scale industrial processes, district heating plants, and larger manufacturing facilities with significant heat demands.

- Large Capacity Boilers (above 20 MW): Employed in heavy industrial sectors such as chemical processing, power generation, large food and beverage complexes, and municipal heating networks.

- By End-Use Industry:

- Food and Beverage: For sterilization, cooking, drying, and general process heating, demanding high efficiency and reliability.

- Chemical and Petrochemical: Critical for process heating, reaction temperature control, and steam generation in complex chemical syntheses.

- Pharmaceuticals: Requires precise temperature control and sterile steam for manufacturing, sterilization, and environmental conditioning.

- Manufacturing (General): Used in various processes including curing, drying, metal treatment, and space heating in factories.

- Power Generation: For supplementary heating, combined heat and power (CHP) applications, and auxiliary systems within power plants.

- Textile: Essential for dyeing, drying, and finishing processes which require substantial and consistent heat supply.

- Pulp and Paper: Utilized in drying, pulping, and various paper-making operations that are highly energy-intensive.

- Others: Includes district heating, commercial buildings, agriculture, and other sectors with significant heat requirements.

- By Component:

- Burners: Key for efficient combustion and fuel-air mixing, often incorporating modulating or low-NOx technologies.

- Heat Exchangers: Critical for heat transfer and enabling condensation, typically made from corrosion-resistant materials.

- Control Systems: Advanced PLCs and digital controllers for automation, safety, and optimization of boiler operation.

- Pumps: Circulation pumps for water flow within the boiler system and distribution to end-use applications.

- Valves and Fittings: Essential for regulating flow, pressure, and safety within the boiler and piping network.

- Condensate Recovery Systems: Designed to manage and often neutralize the acidic condensate for safe disposal or reuse.

- Flue Gas Systems: Components for safe and efficient exhaust of flue gases, including stacks and fans.

- Sensors and Actuators: For monitoring various parameters like temperature, pressure, and flow, and for executing control commands.

Gas Fired Condensing Low Temperature Industrial Boiler Market Value Chain Analysis

The value chain for the Gas Fired Condensing Low Temperature Industrial Boiler Market is a complex network involving multiple stakeholders, from raw material suppliers to end-users, each contributing to the products final delivery and lifecycle. Upstream activities commence with the sourcing of essential raw materials such as specialized steels, alloys, and non-ferrous metals for heat exchangers and boiler shells, alongside electronic components for advanced control systems, and insulation materials. Key suppliers in this stage include specialized metal fabricators, burner manufacturers, pump and valve producers, and control system developers, whose quality and innovation directly influence the boilers performance and efficiency. Strong relationships with these upstream partners are crucial for ensuring a steady supply of high-quality components and incorporating the latest material and technological advancements into boiler design and manufacturing.

Midstream activities involve the intricate processes of boiler design, manufacturing, assembly, and quality assurance. Leading boiler manufacturers invest heavily in research and development to enhance thermal efficiency, reduce emissions, and integrate smart technologies. This stage includes precision engineering, welding, hydrostatic testing, and the integration of sophisticated control systems and safety features. Manufacturing often takes place in highly automated facilities, leveraging advanced production techniques to ensure the boilers meet stringent international standards for performance, safety, and environmental compliance. After manufacturing, boilers undergo rigorous testing before being packaged and prepared for distribution to various markets globally, emphasizing robust logistics and supply chain management.

Downstream activities encompass the distribution, installation, commissioning, operation, and maintenance of the boilers. Distribution channels are varied, including direct sales to large industrial clients, partnerships with engineering, procurement, and construction (EPC) firms, and extensive networks of authorized distributors and value-added resellers. Direct sales are often preferred for highly customized or large-scale projects, allowing for closer client engagement. Indirect channels, through distributors and local partners, facilitate wider market reach and provide localized support, installation services, and after-sales maintenance. Post-installation, ongoing support, including preventive maintenance, spare parts supply, and diagnostic services, is crucial for ensuring optimal boiler performance and longevity, often provided by the original equipment manufacturers (OEMs) or certified service providers, forming a critical part of the long-term customer relationship and value proposition.

Gas Fired Condensing Low Temperature Industrial Boiler Market Potential Customers

The potential customer base for Gas Fired Condensing Low Temperature Industrial Boilers is expansive and diverse, encompassing a wide array of industrial and commercial sectors that require efficient and reliable sources of process heat or space heating. Industries with continuous, high-demand heat loads are prime candidates, particularly those operating in environments where energy costs are a significant operational expenditure and environmental compliance is rigorously enforced. These end-users are primarily motivated by the substantial operational cost savings derived from enhanced fuel efficiency, the environmental benefits of reduced greenhouse gas emissions, and the opportunity to achieve or maintain regulatory compliance, thereby future-proofing their operations against evolving energy policies and carbon taxation.

Key sectors include the food and beverage industry, which utilizes boilers for cooking, pasteurization, sterilization, and cleaning processes, demanding consistent and hygienic steam or hot water. The chemical and petrochemical industries rely on these boilers for reaction heating, distillation, and drying, where precise temperature control and reliability are paramount for product quality and safety. Similarly, pharmaceutical manufacturers require high-purity steam for sterilization, humidification, and various other critical processes within their production facilities. These industries represent a core segment due to their intensive energy consumption and strict regulatory requirements for process control and emissions.

Beyond these heavy process industries, other significant end-users include general manufacturing facilities, textile mills for dyeing and drying, pulp and paper plants for drying and pulping, and district heating networks that serve multiple residential and commercial buildings from a central plant. Commercial establishments such as large hotels, hospitals, universities, and shopping centers also present substantial potential, particularly when seeking to upgrade their HVAC systems for improved energy efficiency and reduced operating costs. The growing trend towards sustainable building management and corporate social responsibility initiatives further expands the customer base, as more organizations prioritize greener technologies and systems to align with their environmental objectives.

Gas Fired Condensing Low Temperature Industrial Boiler Market Key Technology Landscape

The technological landscape of the Gas Fired Condensing Low Temperature Industrial Boiler Market is characterized by continuous innovation aimed at maximizing energy efficiency, minimizing environmental impact, and enhancing operational intelligence. At the core of these advancements is the sophisticated condensing technology itself, which involves specialized heat exchangers designed to extract latent heat from the flue gases by cooling them below their dew point. These heat exchangers are typically constructed from corrosion-resistant materials like stainless steel or aluminum alloys to withstand the acidic condensate, significantly improving overall thermal efficiency compared to non-condensing counterparts and directly contributing to lower fuel consumption and reduced emissions, a critical performance metric for industrial users.

Further technological advancements include highly efficient modulating burners that precisely match boiler output to the actual heat demand, preventing short cycling and optimizing combustion efficiency across a wide load range. These burners often incorporate low-NOx (nitrogen oxide) technologies to minimize harmful emissions, aligning with increasingly stringent environmental regulations globally. Advanced combustion control systems, often leveraging microprocessors and sophisticated algorithms, play a crucial role in maintaining optimal air-to-fuel ratios, dynamically adjusting based on sensor feedback to ensure complete and clean combustion, which is vital for both efficiency and environmental performance. These controls also integrate safety interlocks and diagnostic capabilities, enhancing operational reliability.

The market is also witnessing a significant integration of smart technologies, including the Internet of Things (IoT) and artificial intelligence (AI), transforming boilers into connected, intelligent assets. IoT sensors gather real-time data on operational parameters such as temperature, pressure, flow rates, and flue gas composition, which can be transmitted to cloud-based platforms for analysis. AI algorithms process this data to provide predictive maintenance insights, identify potential inefficiencies, and recommend optimal operational settings, allowing for remote monitoring, diagnostics, and even autonomous adjustments. This integration enhances operational visibility, enables proactive problem-solving, and contributes to unprecedented levels of energy management and system uptime, representing a pivotal shift towards smart, self-optimizing industrial heating solutions.

Regional Highlights

- Europe: This region stands as a pioneer in adopting gas fired condensing low temperature industrial boilers, largely due to stringent environmental regulations, ambitious decarbonization targets, and high energy costs. Countries like Germany, the UK, and the Netherlands have robust markets driven by government incentives for energy efficiency, a mature industrial base requiring modern upgrades, and a strong focus on reducing carbon footprints.

- North America: The market here is primarily propelled by the replacement of aging boiler infrastructure, the increasing availability of natural gas, and evolving energy efficiency standards. The United States and Canada are seeing steady growth as industries seek to modernize facilities, reduce operational expenses, and comply with state and federal emission limits, with a growing emphasis on smart boiler technologies.

- Asia-Pacific: Representing the fastest-growing market, Asia-Pacifics expansion is fueled by rapid industrialization, burgeoning manufacturing sectors in countries like China, India, and Southeast Asia, and increasing environmental awareness. While initial adoption rates might vary, government policies promoting cleaner industrial production and energy conservation are accelerating the shift towards more efficient boiler technologies.

- Latin America: This region shows nascent but promising growth, driven by industrial expansion, particularly in countries like Brazil and Mexico, coupled with a push for energy efficiency in commercial and industrial sectors. The market is influenced by foreign investments in manufacturing and the increasing need for reliable and cost-effective heating solutions as infrastructure develops.

- Middle East and Africa: Growth in this region is more selective, primarily concentrated in industrial hubs and oil & gas operations, as well as in areas with expanding commercial infrastructure. The availability of natural gas and growing environmental regulations, particularly in wealthier Gulf Cooperation Council (GCC) countries, are key drivers, alongside the need to optimize energy consumption in diverse industrial applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gas Fired Condensing Low Temperature Industrial Boiler Market.- Bosch Thermotechnology

- Viessmann Group

- Vaillant Group

- Alfa Laval AB

- Cleaver-Brooks, Inc.

- Fulton Boiler Works, Inc.

- Miura Co. Ltd.

- Mitsubishi Heavy Industries, Ltd.

- Buderus (part of Bosch)

- Weil-McLain (a division of The Marley-Wylain Company)

- A. O. Smith Corporation

- Dallara Group SpA

- Rinnai Corporation

- Lochinvar LLC

- Raypak, Inc.

Frequently Asked Questions

What are the primary benefits of investing in a gas fired condensing low temperature industrial boiler?

Investing in a gas fired condensing low temperature industrial boiler offers significant advantages, primarily including substantial reductions in energy consumption due to their high thermal efficiency, often exceeding 90%. This directly translates to lower operational costs through decreased natural gas usage. Additionally, these boilers lead to a reduced carbon footprint and lower NOx emissions, aiding in compliance with environmental regulations and bolstering corporate sustainability initiatives. Their advanced control systems also contribute to enhanced reliability and precise temperature management for various industrial processes.

How does condensing technology improve the efficiency of industrial boilers?

Condensing technology achieves higher efficiency by recovering latent heat from the exhaust flue gases, which would otherwise be lost up the chimney. As the hot flue gases pass through a secondary heat exchanger, their temperature is lowered below the dew point of the water vapor present. This causes the water vapor to condense, releasing its latent heat back into the boilers return water. By capturing this additional energy, the boiler utilizes more of the fuels energy content, leading to a significant boost in overall thermal efficiency and reduced fuel consumption compared to traditional non-condensing boilers.

What types of industries are best suited for gas fired condensing low temperature industrial boilers?

Gas fired condensing low temperature industrial boilers are ideally suited for a wide range of industries that require continuous and efficient process heating or space heating. Key sectors include food and beverage processing, pharmaceuticals, chemical manufacturing, textile production, and general manufacturing. These industries often have high demands for steam or hot water for cooking, sterilization, drying, and other critical processes. Their suitability stems from the boilers ability to deliver consistent performance, high efficiency, and environmental compliance, which are crucial for these energy-intensive operations.

What is the typical lifespan and maintenance requirement for these advanced boilers?

The typical lifespan of a well-maintained gas fired condensing low temperature industrial boiler can range from 15 to 25 years, comparable to or even exceeding traditional industrial boilers, thanks to robust construction and corrosion-resistant materials. Maintenance requirements are generally structured around preventive schedules, which include regular inspections of the heat exchanger for scaling or corrosion, burner tuning for optimal combustion, and checks on the control systems, pumps, and valves. The integration of smart diagnostics and predictive maintenance technologies is increasingly simplifying and optimizing these maintenance routines, reducing downtime and extending operational longevity.

Are there any specific regulatory considerations for installing and operating these boilers?

Yes, the installation and operation of gas fired condensing low temperature industrial boilers are subject to various regulatory considerations, which vary by region and country. These typically include compliance with local and national building codes, boiler safety standards (e.g., ASME codes in North America, PED in Europe), and environmental regulations pertaining to air emissions (NOx, CO2) and condensate disposal. Many regions offer incentives or mandate specific efficiency levels and emission limits for industrial equipment, making condensing boilers a preferred choice for meeting or exceeding these standards. It is crucial for operators to consult local authorities and ensure full adherence to all applicable guidelines.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager