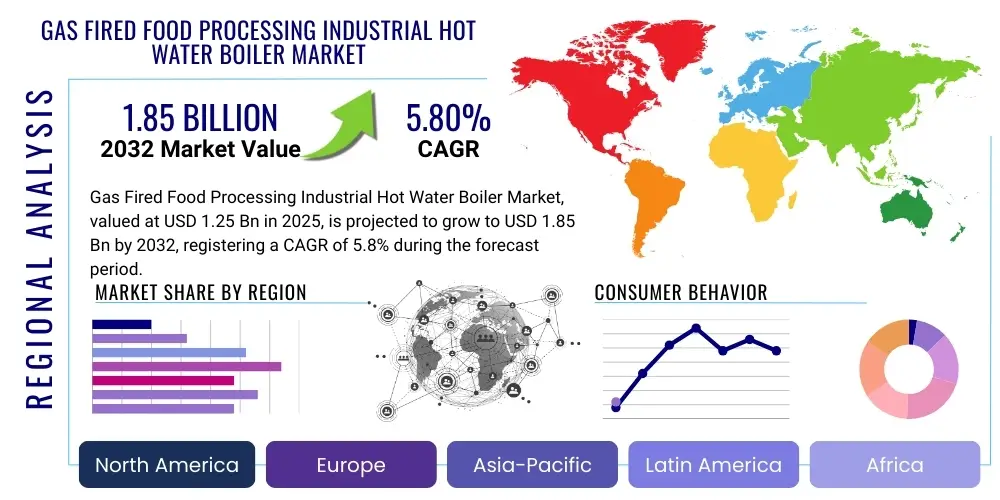

Gas Fired Food Processing Industrial Hot Water Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427711 | Date : Oct, 2025 | Pages : 239 | Region : Global | Publisher : MRU

Gas Fired Food Processing Industrial Hot Water Boiler Market Size

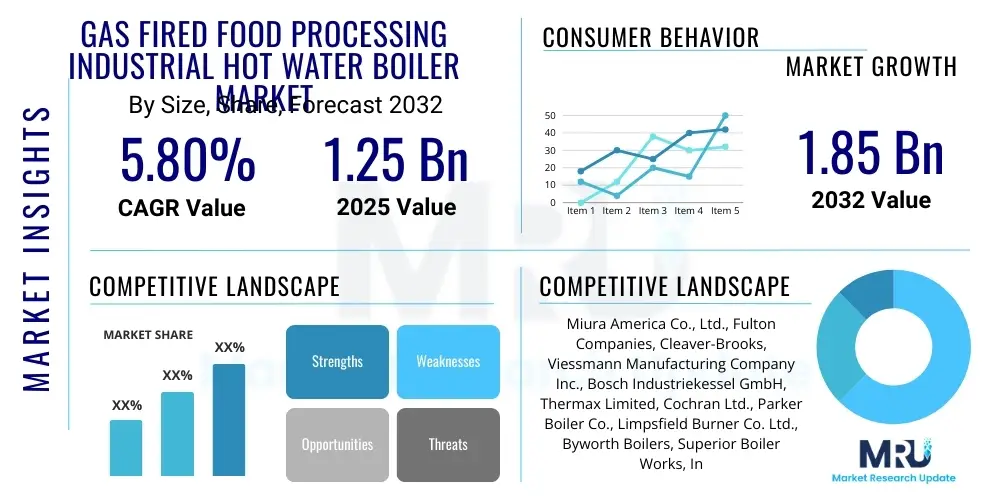

The Gas Fired Food Processing Industrial Hot Water Boiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 1.25 Billion in 2025 and is projected to reach USD 1.85 Billion by the end of the forecast period in 2032. This growth is primarily attributed to the increasing demand for processed food products globally, stringent food safety regulations necessitating precise temperature control, and the ongoing modernization of food processing infrastructure. The shift towards more sustainable and efficient energy sources also drives the adoption of natural gas-fired systems, favored for their lower emissions and operational costs compared to traditional fuel types.

Gas Fired Food Processing Industrial Hot Water Boiler Market introduction

The Gas Fired Food Processing Industrial Hot Water Boiler Market encompasses the design, manufacturing, distribution, and maintenance of specialized heating systems that utilize natural gas or liquefied petroleum gas (LPG) to generate hot water for various applications within the food processing industry. These boilers are critical for maintaining hygiene, pasteurization, sterilization, cooking, and various other thermal processes essential for food safety and quality. The product range includes a variety of capacities and designs, from compact units for small-scale operations to large industrial systems supporting extensive production lines. Key benefits include precise temperature control, enhanced energy efficiency, reduced operational costs due to the affordability and cleaner burning properties of natural gas, and compliance with increasingly strict environmental regulations. The market is driven by expanding global food production, technological advancements in boiler efficiency, and the imperative for food processors to optimize their energy consumption while adhering to high standards of sanitation and product consistency.

Gas Fired Food Processing Industrial Hot Water Boiler Market Executive Summary

The Gas Fired Food Processing Industrial Hot Water Boiler Market is experiencing robust expansion, propelled by significant business trends such as the escalating demand for convenience and processed foods, increasing automation in manufacturing, and a global pivot towards sustainable industrial practices. Food safety and quality assurance remain paramount, driving investments in advanced, reliable heating solutions. Regional trends indicate strong growth in Asia Pacific and North America, fueled by burgeoning populations, disposable incomes, and the modernization of food processing facilities, while Europe maintains a steady market due focused on efficiency upgrades and environmental compliance. Segment trends highlight a preference for high-capacity, modular, and intelligent boiler systems that offer superior energy efficiency and integration capabilities. Furthermore, the market is witnessing an intensified focus on digital controls, remote monitoring, and predictive maintenance solutions, reflecting the industrys broader digital transformation agenda and the continuous pursuit of operational excellence and reduced downtime.

AI Impact Analysis on Gas Fired Food Processing Industrial Hot Water Boiler Market

Users frequently inquire about how artificial intelligence can optimize the performance, efficiency, and maintenance of gas-fired industrial hot water boilers in food processing environments. Key themes revolve around leveraging AI for predictive maintenance to prevent costly downtime, optimizing fuel consumption through real-time data analysis, enhancing operational safety, and integrating boiler systems seamlessly within broader smart factory ecosystems. Concerns often include data security, the initial investment costs of AI implementation, and the need for specialized personnel to manage AI-driven systems. Expectations center on AIs ability to provide proactive insights, automate complex decision-making processes, and ultimately contribute to more sustainable and cost-effective food production. The overarching interest lies in transforming traditional boiler operations into intelligent, self-optimizing units capable of significant efficiency gains and improved reliability, thereby reducing operational overheads and improving product quality.

- AI-driven predictive maintenance scheduling reduces unplanned downtime and extends equipment lifespan by analyzing operational data patterns.

- Real-time fuel optimization through AI algorithms adjusts combustion parameters for maximum efficiency, lowering natural gas consumption and operating costs.

- Enhanced fault detection and diagnostics using machine learning quickly identifies anomalies, preventing major system failures and ensuring operational continuity.

- Integration with smart factory systems allows for centralized control and monitoring, optimizing energy usage across the entire food processing plant.

- Automated system calibration and performance tuning based on AI insights ensure boilers operate at peak efficiency under varying load conditions.

- Improved safety protocols through AI monitoring of operational parameters, identifying potential hazards before they escalate.

- Reduced environmental footprint by optimizing combustion processes, leading to lower emissions of greenhouse gases and pollutants.

- Facilitates remote monitoring and control, enabling operators to manage and troubleshoot boiler systems from any location, improving response times.

- Data analytics capabilities provide deep insights into energy consumption patterns, informing strategic decisions for future investments and process improvements.

- Supports regulatory compliance by maintaining optimal operating conditions and generating comprehensive performance reports automatically.

DRO & Impact Forces Of Gas Fired Food Processing Industrial Hot Water Boiler Market

The Gas Fired Food Processing Industrial Hot Water Boiler Market is primarily driven by the escalating global demand for processed and ready-to-eat foods, which necessitates advanced and reliable heating solutions for sterilization, pasteurization, and cooking. Stringent food safety and hygiene regulations worldwide compel food processors to invest in modern, precisely controlled hot water systems. The increasing focus on energy efficiency and sustainability further propels the adoption of natural gas boilers, given their lower operational costs and reduced carbon footprint compared to traditional fuel sources. However, restraints include the high initial capital investment required for these advanced boiler systems and the fluctuating prices of natural gas, which can impact long-term operational budgets. Opportunities lie in the technological advancements leading to more intelligent, connected, and energy-efficient boilers, as well as the expansion of food processing industries in emerging economies. Impact forces include intense competition among manufacturers, evolving environmental policies, and the rapid pace of digitalization transforming industrial equipment towards smart, interconnected systems, all of which shape market dynamics and dictate strategic investments by key players.

Segmentation Analysis

The Gas Fired Food Processing Industrial Hot Water Boiler Market is comprehensively segmented to provide a detailed understanding of its diverse applications, capacities, and technological attributes. This segmentation allows for precise market analysis, identifying key growth areas and niche opportunities across various end-user industries within the broader food processing sector. Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for investors to make informed decisions regarding market penetration and expansion strategies, ensuring that the specific demands of different operational scales and regulatory environments are met effectively.

- By Capacity:

- Small Capacity (Below 100 kW)

- Medium Capacity (100 kW to 1 MW)

- Large Capacity (Above 1 MW)

- By Type:

- Condensing Boilers

- Non-Condensing Boilers

- Fire Tube Boilers

- Water Tube Boilers

- By Application:

- Dairy Processing

- Meat and Poultry Processing

- Beverage Production

- Bakery and Confectionery

- Fruit and Vegetable Processing

- Seafood Processing

- Other Food Processing Applications (e.g., Prepared Meals, Snacks)

- By End-User:

- Small and Medium-sized Enterprises (SMEs)

- Large Enterprises

- By Component:

- Boiler Units

- Burners

- Control Systems

- Heat Exchangers

- Pumps and Valves

- Ancillary Equipment

Gas Fired Food Processing Industrial Hot Water Boiler Market Value Chain Analysis

The value chain for the Gas Fired Food Processing Industrial Hot Water Boiler Market begins with upstream activities involving the sourcing of raw materials such as steel, copper, insulation materials, and specialized components like burners, pumps, and control systems from various suppliers. These materials undergo manufacturing processes, including metal fabrication, assembly, and integration of heating elements and control mechanisms, followed by rigorous quality control and testing. Midstream activities encompass the distribution channels, which typically involve a mix of direct sales from manufacturers to large industrial clients, and indirect channels through authorized distributors, wholesalers, and specialized equipment dealers who provide regional access and technical support. Downstream activities involve installation services, commissioning, routine maintenance, spare parts supply, and comprehensive after-sales support to ensure optimal performance and longevity of the boiler systems within food processing plants. The interaction between these stages, including direct and indirect distribution channels, significantly influences market reach, customer satisfaction, and overall operational efficiency, underscoring the importance of robust supply chain management and collaborative partnerships across the entire ecosystem.

Gas Fired Food Processing Industrial Hot Water Boiler Market Potential Customers

Potential customers for Gas Fired Food Processing Industrial Hot Water Boilers primarily comprise a wide spectrum of entities within the food and beverage manufacturing sector, ranging from small-scale artisanal producers to large multinational corporations with extensive processing facilities. These end-users are driven by the need for efficient, reliable, and hygienically compliant hot water for critical processes such as pasteurization of dairy and beverages, sterilization of equipment, cooking of meat and poultry, blanching of vegetables, and various cleaning-in-place (CIP) and sterilization-in-place (SIP) operations. Specific buyer segments include dairy plants, breweries and distilleries, meatpacking facilities, bakeries, confectioneries, fruit and vegetable canneries, seafood processing units, and manufacturers of prepared meals and snack foods. The decision-making process for these buyers is heavily influenced by factors such as boiler capacity, energy efficiency, compliance with food safety standards (e.g., HACCP, FDA), maintenance costs, technological integration capabilities, and the availability of responsive after-sales service and technical support.

Gas Fired Food Processing Industrial Hot Water Boiler Market Key Technology Landscape

The key technology landscape of the Gas Fired Food Processing Industrial Hot Water Boiler Market is characterized by a continuous drive towards enhanced efficiency, reduced emissions, and smart operational capabilities. Modern boilers increasingly integrate advanced combustion technologies, such as low NOx burners and modulating burners, to achieve higher fuel efficiency and meet stringent environmental regulations by minimizing nitrogen oxide emissions. Condensing technology is widely adopted to recover latent heat from flue gases, significantly boosting thermal efficiency by up to 10-15% compared to non-condensing units. Control systems have evolved from basic thermostatic controls to sophisticated PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) based systems, offering precise temperature management, diagnostic capabilities, and remote monitoring. Furthermore, the integration of IoT (Internet of Things) sensors and cloud-based platforms is enabling real-time data analytics, predictive maintenance, and seamless connectivity with broader plant management systems, transforming traditional boilers into intelligent, networked assets. These technological advancements collectively contribute to optimized performance, improved safety, and substantial operational cost savings for food processing facilities.

Regional Highlights

- North America: A mature market driven by strict food safety regulations, ongoing modernization of aging infrastructure, and a strong emphasis on energy efficiency and automation in food processing plants. The United States and Canada are leading adopters of advanced boiler technologies.

- Europe: Characterized by stringent environmental policies and a focus on sustainable manufacturing. Demand is high for high-efficiency condensing boilers and systems with low emission profiles. Germany, the UK, France, and Italy are key contributors.

- Asia Pacific: The fastest-growing region, fueled by rapid industrialization, increasing population, rising disposable incomes, and a burgeoning processed food sector. China, India, Japan, and Australia are witnessing significant investments in new food processing facilities and boiler upgrades.

- South America: Experiencing steady growth due to increasing urbanization and the expansion of the food and beverage industry, particularly in countries like Brazil and Argentina. Focus is on improving production capabilities and efficiency.

- Middle East and Africa: An emerging market with growing investments in food processing infrastructure to enhance food security and diversify economies. Saudi Arabia, UAE, and South Africa are showing increasing demand for modern industrial boilers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gas Fired Food Processing Industrial Hot Water Boiler Market.- Miura America Co., Ltd.

- Fulton Companies

- Cleaver-Brooks

- Viessmann Manufacturing Company Inc.

- Bosch Industriekessel GmbH

- Thermax Limited

- Cochran Ltd.

- Parker Boiler Co.

- Limpsfield Burner Co. Ltd.

- Byworth Boilers

- Superior Boiler Works, Inc.

- Kawasaki Heavy Industries, Ltd.

- Atlantic Boiler Works Ltd.

- Clayton Industries

- John Thompson Boilers

Frequently Asked Questions

What are the primary benefits of using gas-fired hot water boilers in food processing?

Gas-fired hot water boilers offer several key advantages for food processing, including high thermal efficiency, precise temperature control essential for pasteurization and sterilization, lower operating costs due to the affordability of natural gas, and reduced environmental impact compared to fossil fuels, ensuring compliance with strict environmental and food safety regulations. Their clean combustion properties also minimize contamination risks within processing environments.

How do gas-fired boilers contribute to food safety and hygiene in processing plants?

Gas-fired boilers are crucial for food safety by providing consistent and precisely controlled hot water for critical processes such as sterilization of equipment, pasteurization of products to eliminate harmful bacteria, and effective cleaning-in-place (CIP) and sterilization-in-place (SIP) systems. This ensures hygienic operational environments, prevents cross-contamination, and meets rigorous regulatory standards, safeguarding product quality and consumer health.

What factors should be considered when selecting a gas-fired hot water boiler for a food processing facility?

Key factors for selecting a gas-fired hot water boiler include its capacity to meet peak demand, energy efficiency (e.g., condensing technology), compliance with local emissions and safety regulations, the level of automation and control features, ease of maintenance, and the total cost of ownership (TCO) including initial investment and operational expenses. Suitability for specific food processing applications and the availability of reliable after-sales support are also critical considerations.

Are there specific regulations governing the use of industrial hot water boilers in the food industry?

Yes, the food industry operates under strict regulations governing industrial hot water boilers. These include requirements from bodies like the FDA in the US, EFSA in Europe, and national safety and environmental agencies. Regulations typically cover boiler design, operational safety, emissions limits, energy efficiency standards, and water quality for process applications, necessitating regular inspections and adherence to industry-specific hygiene protocols and certifications.

How do smart technologies and IoT impact the efficiency of gas-fired hot water boilers in food processing?

Smart technologies and IoT significantly enhance boiler efficiency by enabling real-time performance monitoring, remote diagnostics, and predictive maintenance. This allows for proactive issue resolution, minimizes downtime, and optimizes fuel consumption through intelligent control algorithms that adjust operations based on demand and environmental conditions. Integration with broader plant management systems further optimizes energy usage across the entire facility, leading to substantial operational savings and improved reliability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager