Gas Fired Water-Tube Food Processing Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430813 | Date : Nov, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Gas Fired Water-Tube Food Processing Boiler Market Size

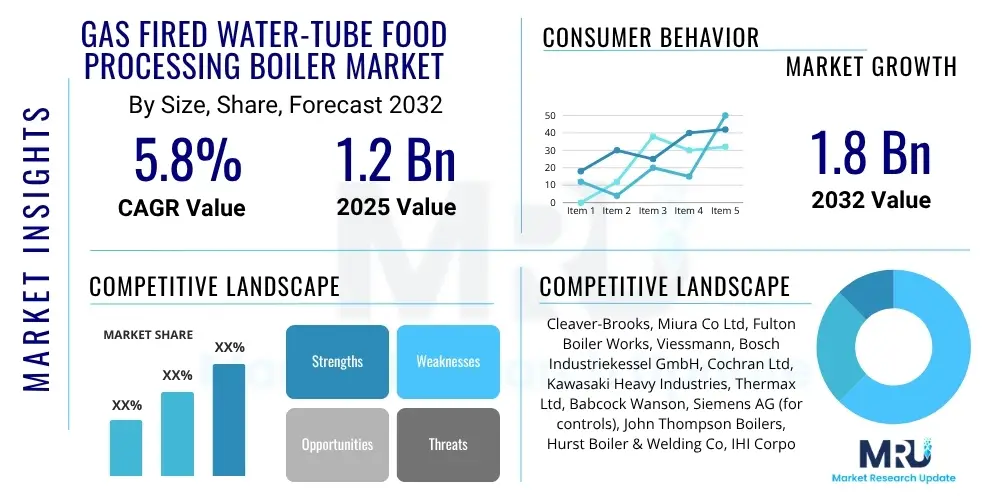

The Gas Fired Water-Tube Food Processing Boiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 1.2 Billion in 2025 and is projected to reach USD 1.8 Billion by the end of the forecast period in 2032.

Gas Fired Water-Tube Food Processing Boiler Market introduction

The Gas Fired Water-Tube Food Processing Boiler Market encompasses the manufacturing, distribution, and utilization of advanced boiler systems specifically designed for the demanding requirements of the food and beverage industry. These boilers are crucial for generating high-pressure steam and hot water, essential for various processing applications such as sterilization, cooking, pasteurization, distillation, and cleaning in food production facilities. The product description highlights their efficiency, rapid response to load changes, and ability to produce high-quality steam, making them ideal for operations where precise temperature control and hygiene are paramount. Major applications span across diverse sectors including dairy processing, beverage production, meat and poultry, confectionery, baked goods, and canned food manufacturing. The primary benefits derived from these systems include enhanced energy efficiency, reduced operational costs, lower environmental emissions compared to other fuel types, and compliance with stringent food safety and sanitation standards. Key driving factors for market growth include the increasing global demand for processed and packaged foods, rising focus on energy conservation and sustainable practices within industrial operations, and the continuous need for reliable, hygienic, and high-performance steam generation in food production.

Gas Fired Water-Tube Food Processing Boiler Market Executive Summary

The Gas Fired Water-Tube Food Processing Boiler Market is characterized by robust growth driven by evolving business trends, significant regional dynamics, and distinct segment trends. Business trends indicate a strong move towards automation, digitalization, and integration of IoT technologies for predictive maintenance and operational optimization. Manufacturers are increasingly focusing on modular designs, higher energy efficiency ratings, and systems that can integrate seamlessly with renewable natural gas or hydrogen blends, reflecting a broader industry shift towards sustainability and reduced carbon footprint. Mergers and acquisitions are also playing a role in market consolidation, aiming to leverage technological expertise and expand geographic reach. Regional trends highlight the Asia Pacific as a rapidly expanding market due to industrialization, increasing population, and escalating demand for processed foods, while North America and Europe maintain stable growth driven by replacement cycles, regulatory compliance, and technological upgrades. Latin America and the Middle East and Africa are emerging as promising markets with growing investments in food processing infrastructure.

Segment trends reveal a preference for medium to high capacity boilers to meet the scaling demands of large food processing plants. There is also a notable emphasis on boilers designed for higher pressure applications to facilitate faster and more effective sterilization processes. Applications within the dairy and beverage sectors continue to be dominant, but growth is also significant in the meat and poultry processing and confectionery industries, necessitating specialized boiler configurations. The market is also seeing innovation in terms of boiler materials and control systems to ensure maximum hygiene and operational safety, crucial for adherence to global food safety standards. These overarching trends collectively underscore a dynamic and evolving market landscape, where technological advancement, sustainability initiatives, and strategic regional expansion are key determinants of success.

AI Impact Analysis on Gas Fired Water-Tube Food Processing Boiler Market

Common user inquiries regarding AI's impact on the Gas Fired Water-Tube Food Processing Boiler Market frequently revolve around how artificial intelligence can enhance operational efficiency, reduce maintenance costs, improve safety protocols, and contribute to energy savings. Users are particularly interested in the practical applications of AI in real-time monitoring, predictive analytics for equipment failure, and optimization of combustion processes. There is also significant curiosity about how AI can assist in meeting stringent environmental regulations by optimizing emissions, alongside concerns about the initial investment required for AI integration and the potential for job displacement due to increased automation. Expectations are high for AI to transform boiler management from reactive to proactive, ensuring greater reliability and sustainability in food processing operations.

The integration of AI technologies is poised to revolutionize the operation and maintenance of gas-fired water-tube boilers in the food processing industry. AI algorithms can process vast amounts of operational data from sensors, including temperature, pressure, flow rates, and gas consumption, to identify patterns and anomalies that indicate potential inefficiencies or imminent failures. This capability shifts maintenance strategies from scheduled downtime to predictive maintenance, where repairs are performed only when necessary, significantly reducing unscheduled downtimes and extending the lifespan of critical components. Furthermore, AI can optimize fuel consumption by continuously adjusting combustion parameters based on real-time load demands and gas quality, leading to substantial energy savings and reduced greenhouse gas emissions. The sophisticated analytical power of AI also contributes to maintaining consistent steam quality and pressure, which is vital for the quality and safety of food products. As the food processing industry continues to seek ways to enhance productivity and sustainability, AI will become an indispensable tool for advanced boiler management.

- Predictive maintenance for reduced downtime and extended asset life.

- Real-time optimization of fuel consumption and combustion efficiency.

- Enhanced process control for consistent steam quality and pressure.

- Automated fault detection and diagnostic capabilities.

- Improved energy management and reduced operational costs.

- Data-driven insights for strategic operational improvements.

- Contribution to environmental compliance through optimized emissions.

- Remote monitoring and control capabilities for boiler systems.

DRO & Impact Forces Of Gas Fired Water-Tube Food Processing Boiler Market

The Gas Fired Water-Tube Food Processing Boiler Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, shaped by overarching impact forces. Key drivers include the relentless growth of the global food and beverage industry, fueled by increasing populations and changing dietary habits, which necessitates continuous investment in food processing infrastructure. The escalating demand for high-quality, safe, and hygienically processed food products further propels the adoption of efficient and reliable steam generation systems. Additionally, stringent regulatory frameworks related to food safety, environmental emissions, and energy efficiency compel food processors to upgrade to modern, compliant boiler technologies. Technological advancements in boiler design, control systems, and fuel efficiency also act as significant drivers, encouraging manufacturers to innovate and end-users to adopt newer, more effective solutions for their operational needs. The intrinsic benefits of natural gas, such as its cleaner combustion compared to other fossil fuels and its relatively stable supply in many regions, also make gas-fired boilers an attractive option for industrial applications, thereby driving market expansion.

However, the market faces several notable restraints. The substantial initial capital investment required for purchasing and installing high-capacity water-tube boilers can be a barrier for smaller food processing units or new entrants. Fluctuations in natural gas prices, influenced by geopolitical factors and supply chain disruptions, introduce an element of uncertainty and can impact operational costs for end-users. Stringent environmental regulations, while a driver for efficiency, can also act as a restraint by imposing complex compliance requirements and additional costs for emissions control equipment. The high maintenance costs associated with specialized boiler systems and the need for skilled labor for operation and servicing also pose challenges. Opportunities within the market are abundant, particularly in emerging economies where food processing industries are experiencing rapid growth and are in need of modern, efficient boiler solutions. The increasing adoption of smart technologies like IoT and AI for boiler management offers avenues for innovation and enhanced operational efficiency. Furthermore, the growing trend towards sustainable practices and the potential for integrating boilers with renewable natural gas or hydrogen blends present significant long-term growth opportunities for manufacturers willing to invest in green technologies. The continuous need for upgrading aging infrastructure in established markets also provides a consistent demand for new, energy-efficient gas-fired water-tube boilers.

- Drivers: Increasing global demand for processed foods, stringent food safety and hygiene regulations, focus on energy efficiency and sustainability, technological advancements in boiler design, favorable natural gas availability.

- Restraints: High initial capital investment, volatility in natural gas prices, complex regulatory compliance, high maintenance costs, skilled labor shortages.

- Opportunities: Expansion in emerging economies, integration of IoT and AI for smart boiler management, adoption of renewable natural gas, retrofitting and upgrading of aging boiler systems.

- Impact Forces: Global economic trends, environmental policies and regulations, technological innovation, geopolitical stability impacting energy supply, consumer demand for safe and quality food.

Segmentation Analysis

The Gas Fired Water-Tube Food Processing Boiler Market is meticulously segmented to provide a comprehensive understanding of its diverse components, allowing for targeted strategic planning and analysis. These segmentations typically categorize the market based on critical parameters such as boiler capacity, operating pressure, and various application areas within the food processing industry, as well as by geographical region. This granular approach helps in identifying key growth pockets, understanding competitive dynamics, and tailoring product offerings to specific end-user needs. By analyzing these segments, market participants can better understand the unique demands and challenges present in different parts of the market, from small-scale artisanal food producers to large multinational corporations, ensuring that solutions are both relevant and impactful. The segmentation also helps to delineate market trends influenced by technological maturity, regulatory environments, and economic development across different regions and industry sub-sectors.

- By Capacity:

- Low Capacity (Up to 10 tons/hour)

- Medium Capacity (10-50 tons/hour)

- High Capacity (Above 50 tons/hour)

- By Pressure:

- Low Pressure (Up to 15 bar)

- Medium Pressure (15-40 bar)

- High Pressure (Above 40 bar)

- By Application:

- Dairy Processing

- Beverage Production

- Meat and Poultry Processing

- Confectionery and Sweets

- Baked Goods and Cereals

- Canning and Preserving

- Other Food Processing (e.g., Oils and Fats, Seafood)

- By End-User:

- Large-scale Food Processors

- Small and Medium-sized Food Processors

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Gas Fired Water-Tube Food Processing Boiler Market

The value chain for the Gas Fired Water-Tube Food Processing Boiler Market encompasses a series of interconnected activities, beginning with the sourcing of raw materials and extending through manufacturing, distribution, installation, and after-sales service to the end-users in the food processing sector. Upstream analysis involves the procurement of high-quality components such as specialized steels, burner systems, control valves, pumps, heat exchangers, and automation modules from various suppliers. These components are critical for the boiler's performance, safety, and longevity, requiring manufacturers to maintain robust relationships with reliable vendors. The manufacturing phase involves design, fabrication, assembly, and rigorous testing of the boilers to meet specific industry standards and customer requirements. This stage is capital-intensive and demands significant engineering expertise to ensure the production of efficient and durable systems. The downstream analysis focuses on the end-users, primarily diverse food processing companies that rely on these boilers for critical operations like sterilization, cooking, and pasteurization, necessitating high levels of operational reliability and adherence to strict hygiene standards. The efficiency and performance of the boiler directly impact the quality and safety of their food products, making purchasing decisions highly strategic.

Distribution channels for gas-fired water-tube food processing boilers are multifaceted, catering to a global client base. Direct sales often occur for large, customized projects where manufacturers engage directly with major food processors, offering tailored solutions, installation support, and comprehensive after-sales services. This approach allows for closer collaboration and a deeper understanding of specific client needs. Indirect distribution channels involve a network of specialized distributors, agents, and engineering, procurement, and construction (EPC) contractors who play a crucial role in market penetration, especially in regions where manufacturers do not have a direct presence. These intermediaries often provide local expertise, logistical support, and initial technical assistance, broadening the reach of boiler manufacturers. For instance, EPC firms frequently integrate boiler systems into larger food processing plant projects, managing the entire installation and commissioning process. After-sales support, including maintenance, spare parts supply, and technical assistance, forms a critical part of the value chain, ensuring the long-term operational efficiency and safety of the installed boiler systems and fostering long-term customer relationships. The effectiveness of the entire value chain is paramount for delivering high-quality products and services to the demanding food processing industry.

Gas Fired Water-Tube Food Processing Boiler Market Potential Customers

Potential customers for Gas Fired Water-Tube Food Processing Boilers are predominantly found across various sub-sectors of the global food and beverage industry, where the generation of steam or hot water is a critical and continuous requirement for their production processes. These end-users typically include large-scale food processing plants that require high volumes of consistent, clean steam for operations such as pasteurization in dairy and beverage facilities, sterilization in canning and preservation units, cooking and baking in confectionery and bread production, and general heating for processing meat, poultry, and seafood. Dairy processing plants, for example, rely on these boilers for milk pasteurization, cheese production, and sterilization of equipment to prevent contamination, while beverage manufacturers utilize them for processes like brewing, bottling, and sanitization of pipelines. Additionally, industries producing processed fruits, vegetables, oils, and fats, which demand precise temperature control and hygienic conditions, are also significant buyers. The increasing scale of food production globally and the stringent regulatory environment surrounding food safety drive these companies to invest in efficient, reliable, and compliant boiler systems, making them key target demographics. Small and medium-sized food processors also constitute a segment of potential customers, particularly those looking to upgrade older, less efficient systems or expand their production capabilities to meet growing demand and regulatory standards.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.2 Billion |

| Market Forecast in 2032 | USD 1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Cleaver-Brooks, Miura Co Ltd, Fulton Boiler Works, Viessmann, Bosch Industriekessel GmbH, Cochran Ltd, Kawasaki Heavy Industries, Thermax Ltd, Babcock Wanson, Siemens AG (for controls), John Thompson Boilers, Hurst Boiler & Welding Co, IHI Corporation, Byworth Boilers, York-Shipley Global, Spirax Sarco (for controls and accessories), Clayton Industries, Cannon Boiler Works, Alfa Laval (for heat exchangers), Parker Boiler |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gas Fired Water-Tube Food Processing Boiler Market Key Technology Landscape

The technological landscape of the Gas Fired Water-Tube Food Processing Boiler Market is characterized by continuous innovation aimed at enhancing efficiency, safety, and environmental performance, alongside meeting the rigorous demands of the food industry. Modern gas-fired water-tube boilers incorporate advanced combustion technologies, such as low NOx (nitrogen oxide) burners and intelligent flame management systems, to reduce harmful emissions and ensure cleaner operation. Material science plays a crucial role, with manufacturers utilizing high-grade stainless steel and specialized alloys to withstand corrosive environments, high temperatures, and frequent cleaning cycles inherent in food processing, ensuring boiler longevity and preventing contamination. The integration of sophisticated automation and control systems, including Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems, is paramount. These systems enable precise monitoring of operational parameters like pressure, temperature, and fuel-to-air ratios, allowing for automatic adjustments to maintain optimal performance and ensure consistent steam quality, which is critical for food safety and product consistency. The digital transformation extends to connectivity, with many boilers now featuring remote monitoring capabilities through IoT sensors and cloud-based platforms, enabling operators to track performance, diagnose issues, and initiate maintenance from anywhere. This level of control and data accessibility not only improves operational efficiency but also facilitates compliance with regulatory requirements and enhances overall plant safety.

Further technological advancements include the development of highly efficient economizers and air preheaters that recover waste heat from flue gases to preheat feedwater or combustion air, significantly improving overall thermal efficiency and reducing fuel consumption. Blowdown heat recovery systems are also becoming standard, recapturing energy from boiler blowdown water. Modulating burners are a key technology, allowing boilers to adjust heat output precisely to match fluctuating steam demands, preventing wasteful cycling and maximizing energy savings. For the food processing sector specifically, advancements in steam purity systems, such as advanced deaeration and water treatment technologies, are essential to ensure that the steam coming into direct or indirect contact with food products meets the highest hygienic standards, free from impurities that could affect product taste, safety, or shelf-life. The trend towards modular boiler designs also represents a technological shift, offering flexibility in installation, scalability for future expansion, and ease of maintenance. These combined technological innovations are driving the evolution of gas-fired water-tube boilers into more intelligent, sustainable, and reliable assets for the modern food processing industry, addressing both operational efficiency and environmental responsibility.

Regional Highlights

- North America: This region demonstrates a mature market with stable demand, primarily driven by the replacement and upgrade of aging infrastructure, coupled with stringent environmental regulations and a strong focus on energy efficiency. The U.S. and Canada are leading adopters of advanced boiler technologies, with significant investments in automation and smart boiler systems for optimized performance in large-scale food processing operations. The demand for processed food remains consistently high, supporting continuous investments.

- Europe: The European market is characterized by a strong emphasis on sustainability, low emissions, and high energy efficiency standards. Countries like Germany, the UK, and France are at the forefront of adopting innovative boiler solutions, including those capable of utilizing renewable natural gas. The presence of well-established food and beverage industries and strict EU directives on environmental protection and food safety contribute to sustained market growth, with a focus on technological refinement and operational cost reduction.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market, propelled by rapid industrialization, increasing population, rising disposable incomes, and the consequent surge in demand for processed foods. Countries such as China, India, and ASEAN nations are witnessing substantial investments in new food processing plants and expanding existing facilities. This growth is also fueled by government initiatives promoting industrial development and a growing awareness of food safety and quality, creating a significant market for new boiler installations.

- Latin America: This region presents a developing market with significant growth potential, particularly in countries like Brazil, Mexico, and Argentina. Expanding food processing capabilities, driven by both domestic consumption and export markets, lead to increasing demand for industrial boilers. Investments in modernizing food production facilities and improving operational efficiencies are key drivers, alongside the need to meet evolving international food safety standards.

- Middle East and Africa (MEA): The MEA market is an emerging region with growing opportunities, primarily due to diversification efforts in economies seeking to reduce reliance on oil and gas, leading to investments in sectors like food processing. Countries in the GCC region and South Africa are seeing increased construction of food production facilities. The demand is driven by local food security initiatives, population growth, and the development of new industrial zones, necessitating robust and efficient boiler solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gas Fired Water-Tube Food Processing Boiler Market.- Cleaver-Brooks

- Miura Co Ltd

- Fulton Boiler Works

- Viessmann

- Bosch Industriekessel GmbH

- Cochran Ltd

- Kawasaki Heavy Industries

- Thermax Ltd

- Babcock Wanson

- Siemens AG (for controls)

- John Thompson Boilers

- Hurst Boiler & Welding Co

- IHI Corporation

- Byworth Boilers

- York-Shipley Global

- Spirax Sarco (for controls and accessories)

- Clayton Industries

- Cannon Boiler Works

- Alfa Laval (for heat exchangers)

- Parker Boiler

Frequently Asked Questions

What factors are driving the growth of the Gas Fired Water-Tube Food Processing Boiler Market?

The market growth is primarily driven by the increasing global demand for processed foods, stringent food safety and environmental regulations, the ongoing focus on energy efficiency in industrial operations, and continuous technological advancements in boiler design and control systems. The reliability and clean combustion of natural gas also contribute significantly.

How does AI impact the operational efficiency and maintenance of these boilers?

AI significantly enhances operational efficiency through real-time monitoring and predictive maintenance, reducing unscheduled downtime and optimizing fuel consumption. It also improves process control for consistent steam quality, provides automated fault detection, and delivers data-driven insights for better energy management and reduced costs.

What are the primary applications of Gas Fired Water-Tube Boilers in the food processing industry?

These boilers are widely used for essential processes such as sterilization, pasteurization, cooking, baking, distillation, and general heating in various food sectors including dairy, beverages, meat and poultry, confectionery, canned foods, and baked goods, ensuring hygienic and efficient production.

What are the key challenges or restraints in the Gas Fired Water-Tube Food Processing Boiler Market?

Key challenges include the high initial capital investment required for installation, potential volatility in natural gas prices, the complexity of complying with evolving environmental regulations, and the need for skilled labor for specialized maintenance and operation. These factors can impact adoption rates and operational budgets.

Which regions are expected to show the most significant growth in this market?

The Asia Pacific region is anticipated to exhibit the most significant growth due to rapid industrialization, increasing demand for processed foods, and substantial investments in food processing infrastructure in countries like China and India. Emerging markets in Latin America and MEA also present strong growth opportunities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager