Gas Valve Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430585 | Date : Nov, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Gas Valve Market Size

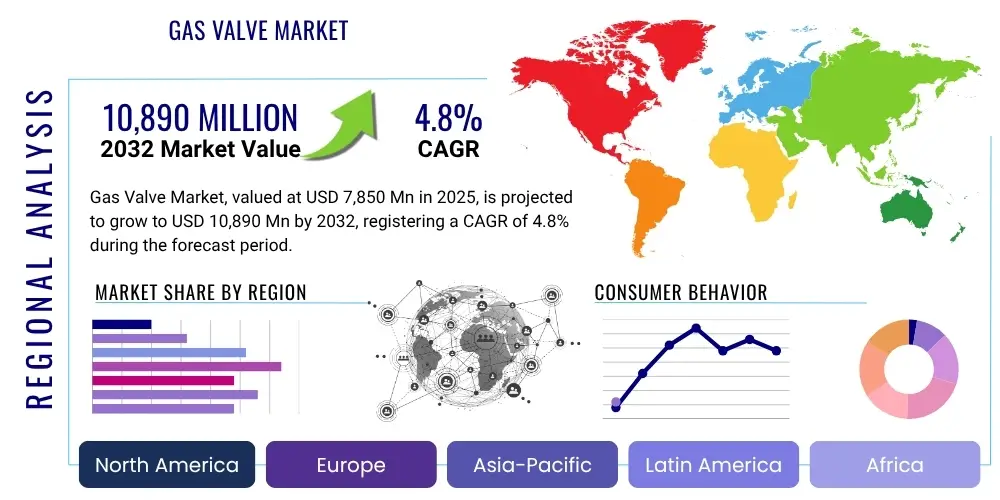

The Gas Valve Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at $7,850 million in 2025 and is projected to reach $10,890 million by the end of the forecast period in 2032.

Gas Valve Market introduction

The Gas Valve Market encompasses the manufacturing, distribution, and sale of devices designed to control the flow, pressure, or direction of gases within a system. These critical components are essential across various sectors, ensuring safe and efficient operation of gas-related equipment and infrastructure. Products range from simple manual shut-off valves to complex automated control valves, each engineered for specific applications and gas types.

Major applications of gas valves span industrial processes such as oil and gas extraction, power generation, and chemical processing, where precise control over flammable and hazardous gases is paramount. In commercial settings, they are vital for HVAC systems, fire suppression, and gas distribution networks within buildings. Residential applications include gas stoves, water heaters, and home heating systems, prioritizing safety and ease of use. The primary benefits derived from gas valves include enhanced safety by preventing leaks and controlling pressure, improved operational efficiency through optimized gas flow, and reliable system performance under diverse conditions. Key driving factors for market growth include the ongoing expansion of industrial infrastructure, stringent safety regulations, and the increasing global demand for energy, particularly natural gas.

Gas Valve Market Executive Summary

The Gas Valve Market is experiencing robust growth, propelled by sustained industrialization, particularly in emerging economies, and the escalating demand for advanced safety and control mechanisms in gas handling systems. Business trends indicate a strong shift towards automation and smart valve technologies, integrating IoT and AI for predictive maintenance and remote operation. This digital transformation is enhancing operational efficiency and reducing downtime, making processes safer and more cost-effective for end-users across various industries.

Regionally, Asia Pacific stands out as the fastest-growing market due to rapid industrial expansion, increasing energy consumption, and significant infrastructure development projects. North America and Europe maintain stable demand, driven by stringent regulatory frameworks, replacement of aging infrastructure, and adoption of advanced valve solutions for efficiency upgrades. Segment trends reveal the industrial sector as the dominant consumer, with a rising emphasis on high-performance and specialty valves. The residential and commercial segments are also seeing steady growth, fueled by new construction activities and the need for compliant, energy-efficient gas systems.

AI Impact Analysis on Gas Valve Market

Common user questions regarding AI's impact on the Gas Valve Market frequently revolve around how artificial intelligence can enhance safety, optimize performance, and enable predictive maintenance for critical gas infrastructure. Users are keen to understand the practical applications of AI in monitoring valve health, detecting anomalies, and automating control processes, thereby reducing operational risks and improving efficiency. There are also queries about the integration challenges, data security implications, and the return on investment for adopting AI-powered valve solutions, reflecting a balance between enthusiasm for innovation and practical concerns about implementation.

- AI enables predictive maintenance by analyzing sensor data for early fault detection, preventing unscheduled downtime.

- Optimized valve operation through AI algorithms adjusts flow and pressure for peak efficiency, reducing energy consumption.

- Enhanced safety protocols via real-time anomaly detection and automated emergency shutdowns.

- Facilitates remote monitoring and control, especially in hazardous or difficult-to-access environments.

- Supports advanced diagnostics by processing complex operational data, identifying root causes of issues.

- Enables smart valve systems capable of self-learning and adapting to changing operational conditions.

- Improves asset management by forecasting lifespan and recommending maintenance schedules.

DRO & Impact Forces Of Gas Valve Market

The Gas Valve Market is significantly influenced by a dynamic interplay of driving forces, inherent restraints, and emerging opportunities, all shaped by various impact forces. Key drivers include the escalating global demand for energy, particularly natural gas, which necessitates extensive pipeline networks and processing facilities requiring robust valve solutions. The rapid industrialization and urbanization in developing countries further fuel demand for gas infrastructure. Moreover, increasingly stringent safety and environmental regulations worldwide mandate the use of high-quality, reliable, and leak-proof valves, compelling industries to upgrade existing systems and invest in advanced technologies. The growth of smart cities and smart infrastructure initiatives also contributes to the adoption of advanced, IoT-enabled gas valves.

However, the market faces several restraints. High initial investment costs for advanced and specialized gas valves can deter small and medium-sized enterprises. The volatility in raw material prices, such as metals like steel and brass, directly impacts manufacturing costs and profit margins. Additionally, the complex regulatory landscape, varying across regions and applications, poses challenges for manufacturers in product development and market entry. Opportunities in the market arise from the increasing focus on sustainable energy sources, including hydrogen infrastructure, which requires specialized valves. The ongoing trend of industrial automation and the integration of IoT and AI into valve technology present significant avenues for innovation and market expansion. Furthermore, the substantial need for replacing aging gas infrastructure in developed economies offers a steady demand for new valve installations and upgrades.

Impact forces on the market include technological advancements, which drive the development of more efficient, durable, and intelligent valves. Environmental concerns and policies are pushing for valves with minimal emissions and higher energy efficiency. Geopolitical factors, such as energy policies and trade agreements, can influence market dynamics, particularly in oil and gas-producing regions. Economic cycles affect investment in new projects, thereby impacting valve demand. The rise of cybersecurity threats also influences the design and implementation of smart valves, emphasizing secure communication protocols and data protection.

Segmentation Analysis

The Gas Valve Market is extensively segmented based on various attributes to cater to diverse industrial, commercial, and residential requirements. These segmentations provide a granular view of market dynamics, enabling stakeholders to understand specific demand patterns, technological preferences, and growth opportunities. The primary segmentation categories include valve type, material of construction, application, and end-user, each offering unique insights into the market structure and competitive landscape. Understanding these segments is crucial for strategic planning, product development, and market penetration strategies.

Each segment reflects distinct operational environments and performance criteria, from the high-pressure, corrosive settings in oil and gas to the precise control required in residential heating systems. The choice of valve type and material is often dictated by the gas medium, temperature, pressure, and regulatory compliance. The evolution of these segments is also influenced by advancements in manufacturing processes, material science, and the increasing demand for smart, automated solutions that offer enhanced safety and efficiency. This detailed segmentation analysis helps in identifying niche markets and tailoring products to meet specific customer needs.

- By Type:

- Ball Valve

- Gate Valve

- Globe Valve

- Plug Valve

- Butterfly Valve

- Solenoid Valve

- Check Valve

- Pressure Relief Valve

- Other Types

- By Material:

- Cast Iron

- Steel (Carbon Steel, Stainless Steel, Alloy Steel)

- Brass

- Bronze

- Plastic (PVC, CPVC, PEX)

- Aluminum

- Other Materials

- By Application:

- Oil & Gas

- Power Generation

- Chemical & Petrochemical

- Water & Wastewater Treatment

- HVAC (Heating, Ventilation, and Air Conditioning)

- Food & Beverage

- Pharmaceutical

- Pulp & Paper

- Mining

- Other Industrial Applications

- By End-User:

- Industrial

- Commercial

- Residential

- Utilities

Value Chain Analysis For Gas Valve Market

The value chain for the Gas Valve Market begins with upstream activities, primarily involving the sourcing and processing of raw materials such as various grades of steel, cast iron, brass, bronze, and plastics. This stage also includes the manufacturing of specialized components like actuators, seals, and springs, which are crucial for valve functionality. Key players in this segment are material suppliers and component manufacturers who adhere to strict quality standards to ensure the integrity and performance of the final valve products. Efficiency and cost-effectiveness in raw material acquisition and component production are vital for maintaining competitive pricing and product quality in the downstream stages.

Midstream activities involve the core manufacturing processes, including casting, machining, assembly, and rigorous testing of the gas valves. Leading valve manufacturers focus on advanced engineering, quality control, and compliance with industry standards and certifications. Post-manufacturing, the downstream segment encompasses distribution, sales, installation, and after-sales services. Distribution channels are varied, including direct sales to large industrial clients and OEMs, and indirect sales through a network of distributors, wholesalers, and retailers for broader market reach, particularly for commercial and residential applications. The effectiveness of these distribution channels greatly influences market penetration and customer satisfaction. After-sales support, including maintenance, repairs, and spare parts supply, plays a critical role in customer retention and brand reputation.

The distinction between direct and indirect distribution is significant. Direct channels often involve specialized sales teams working closely with large industrial customers, offering tailored solutions, technical support, and project management. Indirect channels leverage a network of intermediaries who provide local presence, inventory management, and installation services, reaching a wider range of smaller businesses and individual consumers. E-commerce platforms are also emerging as a significant indirect channel, especially for standard and replacement parts, offering convenience and broader accessibility to customers.

Gas Valve Market Potential Customers

The Gas Valve Market serves a diverse range of potential customers across industrial, commercial, and residential sectors, each with unique demands and purchasing criteria. In the industrial segment, primary end-users include oil and gas companies involved in exploration, production, refining, and transportation, where valves are critical for process control and safety in high-pressure and corrosive environments. Power generation plants, particularly those relying on natural gas or other gaseous fuels, are significant buyers, as are chemical and petrochemical processing facilities that require precise control over highly reactive or hazardous gases. Other industrial consumers include companies in water and wastewater treatment, mining, and food and beverage processing, which utilize gas valves for various utility and process applications.

Commercial customers encompass building contractors, HVAC system installers, and facility managers for large commercial buildings, hospitals, hotels, and educational institutions. These buyers require gas valves for heating, ventilation, air conditioning systems, and fire suppression systems, prioritizing reliability, energy efficiency, and compliance with building codes. The residential sector includes individual homeowners, home builders, and appliance manufacturers. Here, gas valves are integral components in domestic appliances such as gas stoves, ovens, water heaters, and home heating systems, with a strong emphasis on safety, ease of use, and durability to ensure reliable operation within a household setting. Furthermore, municipal gas utilities represent a significant customer base, procuring valves for their extensive gas distribution networks, requiring durable and long-lasting solutions for infrastructure management and public safety.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $7,850 million |

| Market Forecast in 2032 | $10,890 million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Emerson Electric Co., Flowserve Corporation, A. O. Smith Corporation, Honeywell International Inc., IMI PLC, Kitz Corporation, Metso Outotec, Parker Hannifin Corporation, Rotork PLC, Spirax Sarco Engineering PLC, Valmet Corporation, Schlumberger Limited, Baker Hughes Company, Crane Co., Danfoss A/S, Weir Group PLC, Alfa Laval AB, Bray International, Inc., Watts Water Technologies, Inc., NIBCO Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gas Valve Market Key Technology Landscape

The Gas Valve Market is undergoing a significant technological transformation, driven by the demand for enhanced safety, efficiency, and intelligence in gas handling systems. A paramount technological trend is the integration of smart actuators and IoT capabilities into valve designs. These advancements enable remote monitoring, predictive maintenance, and real-time data analytics, allowing operators to oversee valve performance, detect anomalies, and schedule maintenance proactively, thereby minimizing downtime and operational risks. Smart valves often incorporate sensors that measure parameters such as pressure, temperature, flow rate, and vibration, transmitting this data wirelessly to control systems or cloud platforms for analysis.

Another crucial aspect of the technology landscape involves advancements in material science. The development of new alloys, composites, and specialized coatings is enhancing the durability, corrosion resistance, and operational lifespan of gas valves, particularly in harsh or highly corrosive environments common in the oil and gas and chemical industries. These advanced materials contribute to the creation of valves capable of withstanding extreme temperatures and pressures, while also reducing the total cost of ownership over their lifecycle. Furthermore, additive manufacturing, also known as 3D printing, is emerging as a technology to produce complex valve geometries and components with greater precision and customization, which can lead to more efficient designs and faster prototyping.

The increasing emphasis on cybersecurity is also shaping the technological evolution of smart gas valves. As more valves become connected to networks, ensuring the security of these devices and the data they transmit is paramount to prevent unauthorized access, manipulation, or cyberattacks that could compromise critical infrastructure. Manufacturers are investing in robust encryption protocols, secure communication channels, and authentication mechanisms to protect smart valve systems. Additionally, the adoption of advanced control algorithms and artificial intelligence is allowing valves to perform self-diagnostics, optimize their own performance based on environmental conditions, and even initiate autonomous adjustments or emergency shutdowns in response to critical events, marking a significant leap towards fully autonomous gas management systems.

Regional Highlights

- North America: A mature market characterized by stringent safety regulations, significant investment in infrastructure upgrades, and a growing adoption of smart valve technologies for efficiency and compliance. The U.S. and Canada are key contributors.

- Europe: Driven by environmental policies, a focus on energy efficiency, and the replacement of aging gas distribution networks. Germany, the UK, and France are leading countries, with an increasing emphasis on sustainable gas solutions.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, urbanization, increasing energy demand, and large-scale infrastructure projects in countries like China, India, and Southeast Asian nations.

- Latin America: Exhibiting steady growth due to investments in oil and gas exploration and production, particularly in Brazil and Mexico, alongside expanding residential and commercial construction.

- Middle East and Africa (MEA): Dominated by the vast oil and gas industry, with substantial investments in upstream, midstream, and downstream projects. Saudi Arabia, UAE, and Qatar are significant markets for industrial gas valves.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gas Valve Market.- Emerson Electric Co.

- Flowserve Corporation

- A. O. Smith Corporation

- Honeywell International Inc.

- IMI PLC

- Kitz Corporation

- Metso Outotec

- Parker Hannifin Corporation

- Rotork PLC

- Spirax Sarco Engineering PLC

- Valmet Corporation

- Schlumberger Limited

- Baker Hughes Company

- Crane Co.

- Danfoss A/S

- Weir Group PLC

- Alfa Laval AB

- Bray International, Inc.

- Watts Water Technologies, Inc.

- NIBCO Inc.

Frequently Asked Questions

What is the projected growth rate for the Gas Valve Market?

The Gas Valve Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032.

What are the primary applications of gas valves?

Gas valves are primarily used in industrial applications such as oil and gas, power generation, and chemical processing, as well as in commercial HVAC systems and residential gas appliances.

How does AI impact the Gas Valve Market?

AI enhances gas valve market operations through predictive maintenance, optimized performance, real-time anomaly detection, and remote control capabilities, significantly improving safety and efficiency.

Which region is expected to lead market growth?

Asia Pacific is anticipated to be the fastest-growing region in the Gas Valve Market due to rapid industrialization, urbanization, and increasing energy demand.

What are the main types of gas valves?

Common types of gas valves include ball valves, gate valves, globe valves, plug valves, butterfly valves, solenoid valves, and check valves, each suited for specific control functions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager