General Purpose DC Contactor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427917 | Date : Oct, 2025 | Pages : 251 | Region : Global | Publisher : MRU

General Purpose DC Contactor Market Size

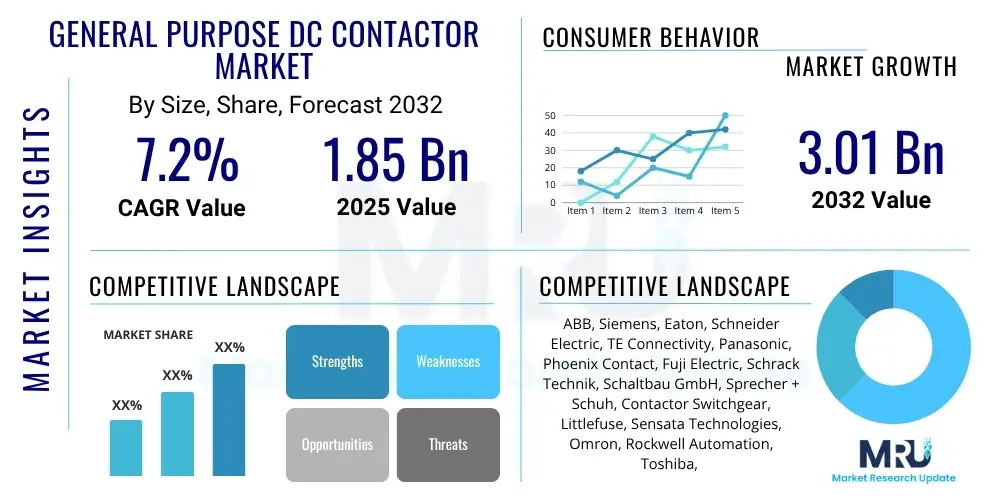

The General Purpose DC Contactor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2025 and 2032. The market is estimated at USD 1.85 billion in 2025 and is projected to reach USD 3.01 billion by the end of the forecast period in 2032.

General Purpose DC Contactor Market introduction

The General Purpose DC Contactor Market encompasses a diverse range of electromagnetic switches designed to control direct current (DC) circuits. These devices are critical components in numerous electrical systems, facilitating the switching, connecting, and disconnecting of power circuits. Unlike AC contactors, DC contactors are specifically engineered to handle the unique challenges of interrupting DC loads, such as the absence of a natural zero crossing point in the current waveform, which can lead to severe arcing and contact erosion. Their robust design typically includes features like magnetic blowouts or arc chutes to effectively extinguish arcs, ensuring reliable and safe operation across various applications. The market is defined by its foundational role in electrification, supporting infrastructure where direct current is a primary power source or storage medium, driving continuous innovation in design and material science to meet evolving industry demands.

Key product characteristics of general purpose DC contactors include their voltage and current ratings, contact configuration (e.g., normally open, normally closed), coil voltage, and enclosure type. They are available in a broad spectrum of specifications to suit different operational environments, from compact units for small appliances to heavy-duty contactors for industrial machinery and high-power applications. Major applications span industrial automation, where they control motors, heaters, and lighting; electric vehicles (EVs) and their charging infrastructure, managing battery power and charging currents; renewable energy systems such as solar inverters and wind turbines, handling the DC power generated; telecommunications equipment for power distribution; and material handling systems like forklifts and electric vehicles within warehouses. The widespread adoption of DC power in modern systems underscores the indispensable nature of these components, making them foundational to the advancement of various technological sectors.

The benefits derived from employing general purpose DC contactors are substantial, including enhanced operational safety, improved system reliability, and efficient power management. Their ability to precisely control high DC currents minimizes wear on sensitive components and extends equipment lifespan, reducing maintenance costs and downtime. Driving factors for market growth include the global push towards electrification across transportation and industrial sectors, the burgeoning demand for renewable energy solutions, and the increasing sophistication of battery storage systems. Furthermore, the rising adoption of automation and robotics in manufacturing, which often rely on DC motors and power supplies, further fuels the demand for high-performance DC contactors. Innovations in material science and manufacturing processes are also contributing to the development of more compact, efficient, and cost-effective contactors, broadening their applicability and accelerating market expansion.

General Purpose DC Contactor Market Executive Summary

The General Purpose DC Contactor Market is experiencing robust growth, propelled by several overarching business trends that prioritize efficiency, reliability, and integration. A significant trend is the relentless drive towards higher power density and miniaturization, allowing for more compact system designs without compromising performance. This is particularly crucial in space-constrained applications such as electric vehicles and advanced robotics. Concurrently, there is a growing demand for contactors with enhanced smart features, including integrated diagnostics, communication capabilities (e.g., CAN bus, Ethernet), and predictive maintenance functionalities, facilitating seamless integration into Industry 4.0 environments and smart grids. Manufacturers are increasingly focusing on developing environmentally friendly products, utilizing sustainable materials and processes, and designing contactors with extended lifespans and recyclability. The market also sees a strong emphasis on cost optimization through advanced manufacturing techniques and economies of scale, making sophisticated DC power control solutions more accessible to a broader range of industries.

Regional dynamics play a pivotal role in shaping the market landscape. Asia Pacific (APAC) stands out as the fastest-growing region, primarily driven by rapid industrialization, extensive investments in renewable energy infrastructure, and the booming electric vehicle market in countries like China, India, and Japan. Governments in these regions are actively promoting clean energy and electric mobility through supportive policies and incentives, further accelerating demand for DC contactors. North America and Europe, while more mature, are demonstrating steady growth, fueled by stringent energy efficiency regulations, modernization of industrial infrastructure, and substantial investments in smart grid technologies and EV charging networks. Latin America, the Middle East, and Africa are emerging as promising markets, with increasing industrial development, rising energy demands, and a gradual shift towards sustainable energy solutions creating new avenues for market penetration. Each region's unique regulatory environment and technological adoption rates contribute to differentiated market growth trajectories.

Segmentation trends within the General Purpose DC Contactor Market reveal distinct areas of accelerated growth. By application, the electric vehicle (EV) and EV charging infrastructure segment is witnessing explosive growth, driven by global efforts to decarbonize transportation and the increasing consumer adoption of EVs. Renewable energy applications, including solar photovoltaic (PV) systems, wind turbines, and battery energy storage systems (BESS), also represent a high-growth segment, as countries worldwide expand their green energy capacities. Industrial automation and robotics continue to be foundational segments, with demand consistently rising due to ongoing digitalization and automation efforts across manufacturing sectors. In terms of product type, high-voltage and high-current contactors are gaining prominence to support larger-scale industrial machinery and advanced power systems, while hermetically sealed contactors are increasingly preferred for harsh environments, offering superior protection against dust, moisture, and corrosive elements. These segment-specific trends highlight the market's adaptability and responsiveness to the evolving technological and environmental priorities of various end-user industries.

AI Impact Analysis on General Purpose DC Contactor Market

Common user questions regarding AI's impact on the General Purpose DC Contactor Market often center on how artificial intelligence will revolutionize product design, manufacturing efficiency, and operational capabilities. Users are keen to understand if AI can lead to smarter, more predictive contactor functionalities, enhance reliability through advanced diagnostics, and optimize energy management in complex DC systems. There is also significant interest in AI's role in streamlining production processes, minimizing defects, and enabling more responsive supply chain management within the contactor manufacturing industry. Users frequently inquire about the potential for AI-driven predictive maintenance to extend the lifespan of contactors and reduce unexpected failures, particularly in mission-critical applications where downtime is costly. Furthermore, questions arise concerning AI's contribution to the integration of contactors into smart grid and IoT ecosystems, facilitating intelligent decision-making and automated control, ultimately improving overall system performance and energy efficiency.

- AI-driven optimization of contactor design for enhanced performance and reduced material usage.

- Predictive maintenance algorithms leveraging AI to forecast contactor failure, extending operational lifespan.

- AI-powered quality control in manufacturing, identifying defects with higher precision and speed.

- Smart contactors with embedded AI for adaptive switching, optimizing energy flow based on real-time data.

- Improved supply chain resilience through AI-driven demand forecasting and inventory management for components.

- AI integration enabling sophisticated diagnostic capabilities for remote monitoring and troubleshooting.

- Enhanced energy management in DC microgrids through AI-controlled contactor operation, balancing loads and sources.

- Development of self-learning contactor systems that adapt to varying load conditions and environmental factors.

- Automated testing and validation of contactors during manufacturing using AI-powered vision systems.

- AI-assisted material selection to improve contactor durability, thermal management, and arc suppression.

DRO & Impact Forces Of General Purpose DC Contactor Market

The General Purpose DC Contactor Market is shaped by a complex interplay of drivers, restraints, and opportunities, all of which exert significant impact forces on its trajectory. Key drivers include the pervasive global trend towards electrification, particularly evident in the rapidly expanding electric vehicle (EV) sector, where DC contactors are indispensable for battery management and charging infrastructure. The burgeoning renewable energy sector, encompassing solar photovoltaics, wind power, and advanced battery energy storage systems (BESS), further amplifies demand as these systems rely heavily on DC power control. Additionally, the increasing adoption of industrial automation, robotics, and smart manufacturing initiatives, which often utilize DC motors and power supplies, consistently fuels market growth. Advances in power electronics and material science enable the development of more efficient and reliable contactors, overcoming previous technical limitations and broadening their application scope. These synergistic factors create a strong positive momentum, pushing the market forward and necessitating continuous innovation from manufacturers.

Despite these robust drivers, the market faces several notable restraints. The high initial cost associated with advanced DC contactors, especially those designed for high-voltage and high-current applications or featuring intelligent functionalities, can act as a barrier to adoption for some budget-sensitive end-users or in emerging markets. Technical complexities related to arc suppression in DC circuits, which are inherently more challenging than in AC circuits, necessitate sophisticated and often expensive design solutions. Intense competition from alternative switching technologies, such as solid-state relays (SSRs) in certain lower-power or high-frequency applications, poses a competitive threat. Moreover, the lack of standardized regulations and varying safety compliance requirements across different regions can complicate market entry and product development for global manufacturers, requiring significant investment in localized product adaptations. These restraints compel manufacturers to focus on cost-effective innovation, performance differentiation, and strategic market positioning to maintain competitiveness.

Opportunities for growth are abundant and diverse, driven by emerging technological landscapes and evolving market needs. The accelerating development of fast and ultra-fast EV charging stations, demanding increasingly higher voltage and current ratings for DC contactors, presents a significant growth avenue. The expansion of DC microgrids and smart grids, alongside grid modernization efforts, creates new applications for intelligent DC contactors capable of seamless integration and communication. Furthermore, the growing market for specialized DC contactors in niche applications, such as data centers, marine vessels, and aerospace, offers untapped potential for specialized product development. Strategic collaborations between contactor manufacturers and system integrators, EV manufacturers, or renewable energy project developers can unlock new market segments and accelerate technological adoption. The ongoing research and development into novel arc extinguishing techniques, advanced contact materials, and compact designs also promise to create next-generation contactors with superior performance and a broader appeal, enabling market players to capture new value and sustain long-term growth.

Segmentation Analysis

The General Purpose DC Contactor Market is comprehensively segmented across various parameters, allowing for a granular understanding of its diverse landscape and enabling targeted strategic planning for market participants. These segmentations are crucial for identifying key growth areas, understanding customer needs, and tailoring product offerings to specific application requirements. Analyzing the market through these lenses provides insights into the evolving preferences of end-users, technological advancements driving demand in particular niches, and the competitive dynamics within each segment. The overarching goal of this detailed segmentation is to illuminate the intricate structure of the market, distinguishing between different product types, operational characteristics, and ultimate end-use applications, thereby offering a multifaceted view of market opportunities and challenges.

- By Type

- Single-pole DC Contactors: Used for simple ON/OFF switching of a single circuit.

- Multi-pole DC Contactors: Designed to switch multiple circuits simultaneously, common in complex systems.

- Open Type DC Contactors: Contacts are visible and accessible, typically for controlled indoor environments.

- Enclosed Type DC Contactors: Contacts are protected by an enclosure, suitable for harsh or outdoor conditions.

- Hermetically Sealed DC Contactors: Vacuum or gas-filled enclosure for superior arc suppression and environmental protection.

- By Voltage Rating

- Low Voltage DC Contactors (up to 150V): Applications in small battery systems, light industrial.

- Medium Voltage DC Contactors (151V - 750V): Common in EV batteries, solar arrays, forklifts.

- High Voltage DC Contactors (above 750V): Essential for fast EV charging, grid-scale energy storage, heavy industrial.

- By Current Rating

- Low Current DC Contactors (up to 100A): Used in control circuits, small power applications.

- Medium Current DC Contactors (101A - 500A): Standard for EVs, industrial machinery.

- High Current DC Contactors (above 500A): Critical for rapid chargers, large battery banks, heavy-duty applications.

- By Application

- Industrial Automation & Control: Motor control, power switching in factories, robotics.

- Electric Vehicles (EVs) & Charging Infrastructure: Battery disconnect, charging station power management.

- Renewable Energy Systems (Solar, Wind, BESS): Inverter control, grid connection, energy storage management.

- Material Handling Equipment: Forklifts, automated guided vehicles (AGVs), electric lifting devices.

- Telecommunications: Power distribution in base stations, data centers.

- Marine & Aerospace: Power systems in electric boats, aircraft auxiliary power units.

- Data Centers: UPS systems, DC power distribution.

- By End-User Industry

- Automotive: EV manufacturers, charging network operators.

- Energy & Utilities: Solar farms, wind farms, grid operators, battery storage providers.

- Manufacturing & Automation: Factories, process industries, robotics manufacturers.

- Telecommunications: Network providers, data center operators.

- Transportation (other than automotive): Rail, marine, aerospace.

- Commercial & Residential: Building automation, smart homes (though less prevalent for general purpose).

Value Chain Analysis For General Purpose DC Contactor Market

The value chain for the General Purpose DC Contactor Market is a multi-tiered structure, commencing with the upstream suppliers of raw materials and specialized components. This initial stage involves the procurement of essential metals such as copper for contacts and coils, silver alloys for superior conductivity and arc resistance, and various plastics and ceramics for insulation and housing. Semiconductor manufacturers provide critical electronic components for smart contactors, while specialized suppliers furnish magnetic materials for arc chutes and blowout coils. The quality and cost-effectiveness of these upstream inputs directly influence the final product's performance, durability, and market competitiveness. Strong relationships with reliable and technologically advanced raw material and component suppliers are paramount for contactor manufacturers to ensure consistent quality, manage supply chain risks, and optimize production costs, laying the foundation for the entire value proposition of the end product.

Moving downstream, the value chain progresses through the manufacturing and assembly of the contactors, followed by their distribution to various end-users. Manufacturers invest heavily in precision engineering, automated assembly lines, and rigorous quality control to produce robust and reliable contactors that meet stringent industry standards. After production, contactors typically reach end-users through a combination of direct and indirect distribution channels. Direct sales are often employed for large industrial clients, original equipment manufacturers (OEMs) who integrate contactors into their larger systems (e.g., EV battery packs, industrial machinery, solar inverters), or specialized project developers. This allows for direct technical support, customization, and relationship building. The effectiveness of this stage is crucial, as it determines the availability, reach, and after-sales support for the product, directly impacting customer satisfaction and market penetration. Timely delivery and comprehensive technical assistance are often deciding factors for large-scale buyers.

Indirect distribution channels, on the other hand, involve a network of distributors, wholesalers, and retailers who provide broader market access, especially for smaller businesses, MRO (Maintenance, Repair, and Operations) buyers, and local integrators. These intermediaries play a vital role in warehousing, localizing inventory, and offering localized support, making products accessible across diverse geographical areas. Furthermore, the rise of e-commerce platforms has created new avenues for indirect sales, allowing for efficient reach to a global customer base. The ultimate downstream segment comprises the diverse range of end-users who integrate these DC contactors into their applications, including automotive manufacturers (for EVs), renewable energy project developers, industrial automation integrators, telecommunications companies, and material handling equipment manufacturers. Effective collaboration and feedback loops between manufacturers and these end-users are critical for continuous product improvement, innovation, and adapting to evolving market demands, ensuring the contactors meet the specific performance and reliability requirements of their final operational environments.

General Purpose DC Contactor Market Potential Customers

The General Purpose DC Contactor Market serves a wide array of potential customers across numerous industries, each with distinct needs and application requirements for controlling direct current. One of the most significant and rapidly growing customer segments is the automotive industry, particularly electric vehicle (EV) manufacturers and their extensive supply chain. These customers require high-voltage, high-current DC contactors for battery disconnection, pre-charging circuits, and managing power flow within the EV powertrain. Additionally, the developers and operators of EV charging infrastructure, from residential chargers to commercial fast-charging stations, are crucial buyers, as DC contactors are essential for safely and efficiently delivering power to vehicles. The continuous innovation in EV technology and the global push towards electrification ensure this segment remains a primary growth driver, demanding contactors that offer superior reliability, thermal management, and compact designs suitable for demanding automotive environments.

Another major customer base resides within the renewable energy sector, encompassing solar photovoltaic (PV) system integrators, wind turbine manufacturers, and developers of battery energy storage systems (BESS). In solar installations, DC contactors are vital for connecting and disconnecting PV arrays, and for integration with inverters and grid connection points. Wind turbines utilize them for pitch control systems and generator circuits. BESS applications, ranging from residential to grid-scale, rely heavily on DC contactors for battery isolation, overcurrent protection, and managing energy flow between storage units and the grid. These customers prioritize contactors that can withstand extreme environmental conditions, offer long operational lifespans, and provide robust performance under continuous cycling. The global transition to sustainable energy sources ensures sustained demand from this segment, driving innovation towards higher voltage ratings, enhanced safety features, and smart integration capabilities for grid modernization.

Beyond the automotive and renewable energy sectors, a substantial number of potential customers come from traditional industrial automation, material handling, and telecommunications industries. Industrial original equipment manufacturers (OEMs) and system integrators utilize DC contactors in motor control centers, robotics, conveyor systems, and various process control applications where DC motors and power supplies are prevalent. Material handling equipment manufacturers, such as those producing electric forklifts, automated guided vehicles (AGVs), and electric lifting platforms, represent a steady customer base due to their reliance on DC battery power. The telecommunications industry requires DC contactors for power distribution in cellular base stations, data centers, and network infrastructure, where reliable power management is critical for continuous operation. Furthermore, niche markets such as marine vessels (electric ferries, ships), aerospace (aircraft auxiliary power units), and mining equipment also contribute to the demand, seeking specialized contactors designed for harsh environments and mission-critical reliability. These diverse applications collectively underscore the foundational role of general purpose DC contactors in modern electrical and electronic systems across the industrial landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.85 Billion |

| Market Forecast in 2032 | USD 3.01 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB, Siemens, Eaton, Schneider Electric, TE Connectivity, Panasonic, Phoenix Contact, Fuji Electric, Schrack Technik, Schaltbau GmbH, Sprecher + Schuh, Contactor Switchgear, Littlefuse, Sensata Technologies, Omron, Rockwell Automation, Toshiba, GIGAVAC, Zettler Relays, Chint Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

General Purpose DC Contactor Market Key Technology Landscape

The General Purpose DC Contactor Market is continuously evolving, driven by advancements in several key technological areas aimed at improving performance, reliability, and efficiency. One critical aspect is arc suppression technology, which is paramount in DC contactors due to the absence of a natural zero crossing in direct current, making arc extinguishing more challenging. Innovations include enhanced magnetic blowout systems, which use magnetic fields to stretch and cool the arc, and advanced arc chute designs that segment and dissipate the arc energy more effectively. Hermetic sealing technologies, often employing ceramic-to-metal seals and inert gas filling, are also crucial for isolating the contacts from the environment, preventing arc re-ignition, and ensuring stable performance in harsh conditions or vacuum environments. These sophisticated arc management techniques are fundamental to increasing the breaking capacity and extending the lifespan of DC contactors, especially in high-voltage and high-current applications.

Another significant area of technological development lies in contact materials and coil technology. Manufacturers are continuously researching and adopting new contact materials, such as silver-nickel (AgNi), silver-tin oxide (AgSnO2), and other composite alloys, to provide superior conductivity, resistance to welding, and reduced contact erosion under repetitive switching cycles. These materials are selected to optimize performance characteristics under specific load conditions and environmental factors, ensuring long-term reliability. Concurrently, advancements in coil technology focus on designing more efficient and robust coils that require less power to operate, generate less heat, and are more resilient to voltage fluctuations. The integration of permanent magnets into coil designs further enhances magnetic blowout capabilities, allowing for more compact and powerful contactors. These material and design innovations directly contribute to the miniaturization of contactors while improving their current-carrying capacity and overall operational efficiency, aligning with the growing demand for space-saving and energy-efficient solutions.

Furthermore, the market is witnessing a strong push towards incorporating smart features and advanced monitoring capabilities, driven by the rise of Industry 4.0 and the Internet of Things (IoT). This includes embedding sensors for temperature, current, and voltage monitoring, enabling real-time diagnostics and predictive maintenance functionalities. Communication interfaces, such as CAN bus, Ethernet, or wireless protocols, are increasingly integrated to allow contactors to communicate with supervisory control systems, providing valuable operational data and enabling remote control. The use of advanced computational fluid dynamics (CFD) and finite element analysis (FEA) in the design phase is also becoming standard practice, allowing engineers to simulate and optimize thermal management, magnetic fields, and mechanical stress, leading to more robust and reliable designs. These technological innovations not only enhance the core functionality of DC contactors but also transform them into intelligent components within complex electrical systems, facilitating greater control, efficiency, and overall system resilience across a broad spectrum of modern applications.

Regional Highlights

- North America: This region demonstrates steady growth driven by significant investments in renewable energy projects, particularly solar and energy storage, and the rapid expansion of electric vehicle infrastructure. Stringent energy efficiency regulations and the modernization of aging industrial infrastructure also fuel demand. The U.S. and Canada are leading in smart grid development, integrating advanced DC power solutions.

- Europe: Europe is a mature but high-growth market, characterized by strong governmental support for electric mobility and renewable energy targets. Countries like Germany, Norway, and the UK are at the forefront of EV adoption and charging network build-out, requiring robust DC contactors. Emphasis on industrial automation and energy transition further propels demand for reliable DC switching solutions.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market, largely due to rapid industrialization, massive investments in renewable energy (especially in China and India), and the booming electric vehicle manufacturing sector. China, in particular, dominates in EV production and charging infrastructure, creating immense demand for high-voltage DC contactors. Expanding manufacturing bases and smart city initiatives also contribute significantly.

- Latin America: This region is an emerging market with growing industrialization and increasing focus on renewable energy adoption, especially in countries like Brazil and Mexico. While starting from a smaller base, investments in mining, telecommunications, and a nascent EV market are expected to drive gradual but consistent growth for DC contactors.

- Middle East and Africa (MEA): MEA presents significant opportunities, particularly with Saudi Arabia and UAE investing heavily in diversification away from oil, including large-scale renewable energy projects and smart city developments. Africa's growing industrial base and efforts to expand access to electricity also create demand, especially for off-grid and microgrid DC applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the General Purpose DC Contactor Market.- ABB

- Siemens

- Eaton

- Schneider Electric

- TE Connectivity

- Panasonic

- Fuji Electric

- Schrack Technik

- Schaltbau GmbH

- Sprecher + Schuh

- Contactor Switchgear

- Littlefuse

- Sensata Technologies

- Omron

- Rockwell Automation

- Toshiba

- GIGAVAC

- Zettler Relays

- Chint Group

- Mitsubishi Electric

Frequently Asked Questions

What is a General Purpose DC Contactor and its primary function?

A General Purpose DC Contactor is an electrically controlled switch used for making or breaking a DC (Direct Current) electrical power circuit. Its primary function is to safely and reliably control high current DC loads, such as those found in electric vehicles, solar power systems, and industrial machinery, by isolating or connecting power sources with precision and preventing destructive arcing.

How does a DC Contactor differ from an AC Contactor?

DC Contactors differ from AC Contactors primarily in their arc suppression mechanisms. DC circuits lack a natural zero crossing point for current, making arc extinguishing more challenging. DC contactors are specifically designed with magnetic blowouts, arc chutes, or hermetic sealing to rapidly extinguish sustained arcs, ensuring safe operation and preventing contact welding, unlike AC contactors which rely on the alternating current's natural zero crossing.

What are the key applications driving the growth of the DC Contactor Market?

The key applications driving market growth include the rapidly expanding electric vehicle (EV) and EV charging infrastructure sector, where DC contactors are crucial for battery management and power control. Additionally, the flourishing renewable energy sector, encompassing solar PV systems, wind turbines, and battery energy storage systems (BESS), heavily relies on DC contactors for efficient power switching and grid integration, alongside increasing demand from industrial automation and robotics.

What technological advancements are enhancing DC Contactor performance?

Technological advancements enhancing DC contactor performance include sophisticated arc suppression techniques like improved magnetic blowouts and advanced arc chute designs, new contact materials (e.g., silver alloys) for enhanced durability and conductivity, and hermetic sealing for operation in harsh environments. Furthermore, the integration of smart features, such as sensors for real-time diagnostics and communication protocols, is transforming contactors into intelligent components for smart grid and IoT applications.

What are the main challenges faced by manufacturers in the General Purpose DC Contactor Market?

Manufacturers face challenges such as the high cost of specialized materials and complex arc suppression technologies, intense competition from alternative switching solutions like solid-state relays, and the need to develop compact, high-performance contactors for increasingly space-constrained applications. Additionally, navigating diverse regional regulations and achieving global standardization for product safety and performance remains a significant hurdle in product development and market expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager