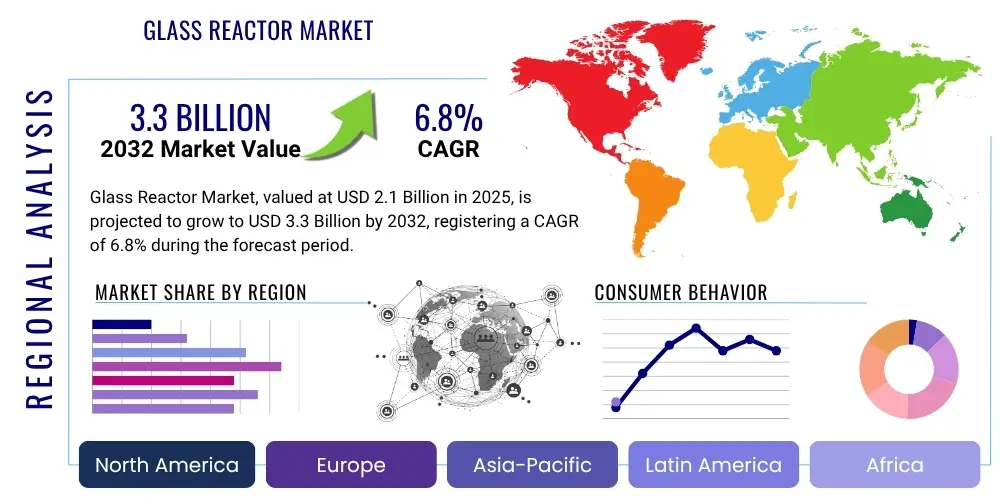

Glass Reactor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429304 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Glass Reactor Market Size

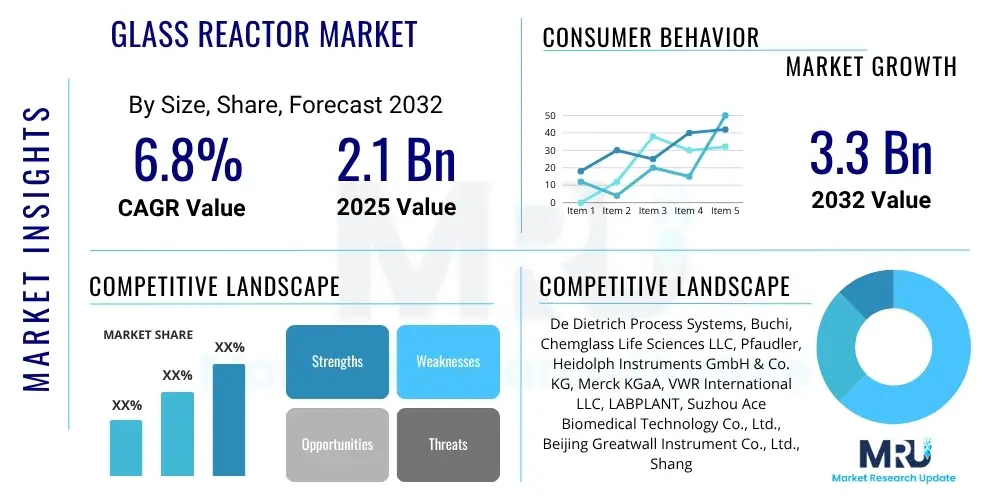

The Glass Reactor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 2.1 Billion in 2025 and is projected to reach USD 3.3 Billion by the end of the forecast period in 2032.

Glass Reactor Market introduction

The Glass Reactor Market encompasses a diverse range of vessels designed for chemical synthesis, material processing, and research and development activities, predominantly used in pharmaceutical, chemical, and biotechnology industries. These reactors are distinguished by their borosilicate glass construction, which offers exceptional resistance to corrosion from a wide array of acids, bases, and organic solvents, while also providing visual monitoring of reaction progress. The product portfolio includes jacketed glass reactors for precise temperature control, double-walled reactors, and multi-purpose systems that can be configured for various unit operations such as mixing, distillation, reflux, and extraction. Key benefits include inertness, transparency, and ease of cleaning, crucial for maintaining product purity and process integrity.

Major applications of glass reactors span across pharmaceutical manufacturing for active pharmaceutical ingredient (API) synthesis, fine chemical production, and the development of new chemical entities in academic and industrial research laboratories. They are indispensable in processes requiring high purity and inert conditions, where metal contamination must be avoided. The market's growth is primarily driven by increasing investments in pharmaceutical and biotechnology R&D, the expanding fine chemicals sector, and stringent regulatory requirements that necessitate controlled and observable reaction environments. Furthermore, the rising demand for specialized chemicals and advanced materials contributes significantly to the market expansion, as glass reactors facilitate the complex and sensitive reactions required for their synthesis.

Glass Reactor Market Executive Summary

The Glass Reactor Market is experiencing robust growth, propelled by sustained business trends such as increasing automation in chemical processing, the adoption of modular reactor designs for enhanced flexibility, and the development of larger volume glass reactors to meet industrial scale production demands. These trends aim to optimize operational efficiency, reduce downtime, and improve safety standards across various industries. The shift towards continuous flow chemistry and process intensification also favors the demand for sophisticated glass reactor systems that can integrate seamlessly into advanced manufacturing workflows. Strategic partnerships between manufacturers and end-users are fostering innovations in reactor design and material science, leading to more durable and efficient products.

Regionally, the Asia Pacific (APAC) region is emerging as a significant growth hub due to rapid industrialization, burgeoning pharmaceutical and chemical manufacturing sectors, and increasing R&D investments, particularly in China and India. North America and Europe continue to hold substantial market shares, driven by established biotechnology and pharmaceutical industries, stringent regulatory frameworks, and a strong emphasis on research and innovation. Segment-wise, the pharmaceutical industry remains the dominant application area for glass reactors, attributed to the critical need for purity, sterility, and visibility in drug synthesis. The biotechnology segment is also witnessing accelerated growth, fueled by advancements in biologics and personalized medicine, further diversifying the market landscape and presenting new opportunities for specialized glass reactor solutions.

AI Impact Analysis on Glass Reactor Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the operational efficiency, safety, and research capabilities within the Glass Reactor Market. Common questions revolve around AI's ability to optimize reaction parameters, predict equipment failures, automate complex processes, and enhance data analysis for process development. There is significant interest in how AI can move beyond simple data logging to provide predictive insights, reducing human error and improving experimental reproducibility. Concerns also include the integration challenges with existing legacy systems, the need for specialized data scientists, and the potential costs associated with implementing AI-driven solutions in a laboratory or industrial setting.

The core themes indicate a strong expectation that AI will lead to more intelligent, autonomous, and efficient glass reactor systems. Users anticipate AI will provide real-time decision support, allowing for dynamic adjustments to temperature, stirring speed, and reagent addition based on reaction kinetics and historical data. This proactive approach is expected to minimize waste, optimize yield, and accelerate the discovery and development cycles for new compounds. Furthermore, the potential for AI to enhance safety protocols through anomaly detection and predictive maintenance of reactor components is a major area of interest, contributing to safer working environments.

- AI-driven optimization of reaction parameters for improved yield and selectivity.

- Predictive maintenance schedules for glass reactors, reducing unexpected downtime.

- Automated data acquisition and real-time analysis for enhanced process control.

- Development of smart glass reactors with integrated AI for autonomous operation.

- Enhanced safety monitoring through AI-powered anomaly detection in reaction processes.

- Accelerated R&D cycles through AI-guided experimentation and synthetic route planning.

- Improved resource efficiency by optimizing energy consumption and solvent usage.

DRO & Impact Forces Of Glass Reactor Market

The Glass Reactor Market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, which collectively shape its trajectory and competitive landscape. Key drivers include the consistent growth in pharmaceutical and biotechnology research and development expenditures, pushing the demand for specialized and high-purity reaction vessels. The increasing global demand for fine chemicals, advanced materials, and specialty polymers also necessitates the use of versatile and corrosion-resistant reactors. Furthermore, stringent regulatory guidelines for product quality and process safety in various industries promote the adoption of highly controlled and observable reaction systems, where glass reactors excel due to their transparency and inertness. The trend towards process intensification and green chemistry initiatives further bolsters the market, as glass reactors facilitate cleaner and more efficient synthesis pathways.

However, several restraints challenge market expansion. The relatively high initial capital investment required for purchasing and installing advanced glass reactor systems can be a barrier for small and medium-sized enterprises. The inherent fragility of glass, despite advancements in borosilicate technology, poses risks of breakage and requires careful handling and maintenance, leading to potential downtime and replacement costs. Technical complexities associated with scaling up reactions from laboratory to pilot or production scale using glass reactors can also limit their application in certain large-volume industrial processes. The competitive pressure from alternative reactor materials like stainless steel or Hastelloy, which offer superior robustness for high-pressure and high-temperature applications, also presents a significant restraint to glass reactor adoption in specific industrial contexts.

Opportunities within the Glass Reactor Market arise from the burgeoning biotechnology sector, particularly in emerging economies, which offers new avenues for specialized bioreactors and cell culture applications. The increasing focus on personalized medicine and advanced therapies demands smaller batch sizes and highly controlled processes, which glass reactors are well-suited for. Innovations in modular and customizable reactor designs provide flexibility and appeal to a wider range of research and production needs. The development of advanced sensing technologies and automation integration offers enhanced process control and safety, further expanding the capabilities and attractiveness of glass reactors. The impact forces within the market, such as the bargaining power of buyers driven by product differentiation and customization needs, and the threat of new entrants due to specialized manufacturing requirements, play crucial roles in shaping competitive strategies and market dynamics.

Segmentation Analysis

The Glass Reactor Market is comprehensively segmented across various parameters, including reactor type, volume, application, and end-user industry, providing a detailed view of its diverse landscape and consumer needs. This segmentation allows for a precise understanding of market dynamics, identifying specific growth areas and competitive advantages within different niches. Analyzing these segments helps manufacturers tailor their products and marketing strategies to meet the distinct requirements of diverse industrial applications, from small-scale laboratory research to large-scale pilot production. The granularity of segmentation reflects the specialized nature of chemical and biological processes, where specific reactor characteristics are paramount for successful outcomes.

- By Type:

- Jacketed Glass Reactors

- Double-Walled Glass Reactors

- Single-Walled Glass Reactors

- Photochemical Glass Reactors

- High Pressure Glass Reactors

- By Volume:

- Up to 10 Liters

- 10 to 50 Liters

- 50 to 100 Liters

- Above 100 Liters

- By Application:

- Chemical Synthesis

- Distillation

- Crystallization

- Extraction

- Reflux

- Mixing

- By End-User Industry:

- Pharmaceutical & Biotechnology

- Fine Chemicals

- Research & Academia

- Food & Beverage

- Cosmetics

- Specialty Chemicals

Value Chain Analysis For Glass Reactor Market

The value chain for the Glass Reactor Market begins with the upstream analysis, focusing on the procurement of specialized raw materials. The primary raw material is high-quality borosilicate glass, known for its thermal shock resistance and chemical inertness. Key suppliers in this segment provide glass tubing, sheets, and other components. Beyond glass, the upstream also includes suppliers of specialized components such as robust mechanical seals, stirrers made from inert materials like PTFE, temperature sensors, heating/cooling circulators, and various fittings and valves. The quality and availability of these raw materials and components directly influence the manufacturing process, product quality, and ultimately, the cost efficiency of the final glass reactor system. Supplier relationships are critical for ensuring consistent material quality and timely delivery, underpinning the entire production cycle.

Moving downstream, the value chain encompasses the manufacturing, assembly, distribution, and end-use of glass reactor systems. Manufacturers design and assemble the various components into integrated reactor units, often incorporating advanced features like automation, vacuum systems, and customized configurations. The distribution channel plays a vital role in connecting these manufacturers with their potential customers. Distribution can be direct, where manufacturers sell directly to large industrial clients or research institutions, often involving customized solutions and extensive technical support. Alternatively, indirect channels involve working with a network of specialized distributors and resellers who have established market presence and provide local support, sales, and service to a broader range of smaller clients and laboratories.

The interplay between direct and indirect distribution channels is crucial for market penetration and customer reach. Direct sales allow for deeper customer engagement and tailored solutions, particularly for complex and high-value projects. Indirect channels, on the other hand, provide broader market access, especially in diverse geographical regions and for standardized products. Both channels require effective logistics, technical expertise, and post-sales support to ensure customer satisfaction. Ultimately, the end-users, primarily pharmaceutical companies, fine chemical manufacturers, biotech firms, and academic research institutions, drive the demand and derive value from these sophisticated reactor systems for their critical chemical and biological processes, closing the loop of the value chain by informing future product development and innovation.

Glass Reactor Market Potential Customers

The Glass Reactor Market serves a diverse yet highly specialized range of potential customers, primarily operating within sectors that demand stringent control, inert conditions, and visibility during chemical or biological synthesis and processing. The largest segment of end-users are pharmaceutical and biotechnology companies, which utilize glass reactors extensively for the synthesis of active pharmaceutical ingredients (APIs), intermediates, and the development of new drug candidates. Their need for high purity, sterile conditions, and the ability to visually monitor reactions makes glass reactors indispensable in drug discovery, process development, and small-to-medium scale production. These customers often require reactors capable of handling sensitive biological materials and complex multi-step organic reactions, emphasizing inertness and precise temperature control.

Another significant group of potential customers includes fine chemical manufacturers and specialty chemical producers. These industries rely on glass reactors for synthesizing high-value chemicals, polymers, and materials where product integrity and controlled reaction environments are crucial. The ability of glass reactors to resist corrosion from aggressive reagents and prevent metal contamination is highly valued in these applications. Academic and industrial research institutions, including universities and contract research organizations (CROs), also represent a substantial customer base. Researchers leverage glass reactors for fundamental research, process optimization, and the exploration of novel synthetic pathways, benefiting from the versatility and transparency that glass offers for experimental observation and data collection. The flexibility of glass reactors in accommodating various experimental setups is a key factor for these research-oriented customers.

Beyond these primary segments, the cosmetics industry utilizes glass reactors for formulating ingredients and producing personal care products, where purity and precise mixing are essential. The food and beverage sector also finds applications for glass reactors in processes like flavor extraction or specialized ingredient synthesis, though to a lesser extent than pharmaceuticals or chemicals. Essentially, any industry requiring bench-scale to pilot-scale chemical reactions under controlled, visible, and inert conditions, particularly where contamination or corrosion is a concern, represents a potential customer for glass reactor systems. The demand profile of these customers is characterized by a strong emphasis on product quality, operational safety, and the ability to customize reactor configurations to meet specific process requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.1 Billion |

| Market Forecast in 2032 | USD 3.3 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | De Dietrich Process Systems, Buchi, Chemglass Life Sciences LLC, Pfaudler, Heidolph Instruments GmbH & Co. KG, Merck KGaA, VWR International LLC, LABPLANT, Suzhou Ace Biomedical Technology Co., Ltd., Beijing Greatwall Instrument Co., Ltd., Shanghai Chemdo Trading Co., Ltd., Shandong Senz Chemical Co., Ltd., OLABO, Wuxi Huajin Chemical Equipment Co., Ltd., Jiangsu Nanda Glass Instrument Co., Ltd., Jinan Labtech Equipment Co., Ltd., Mumbai Instrument Company. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Glass Reactor Market Key Technology Landscape

The Glass Reactor Market is continually evolving with technological advancements aimed at enhancing safety, efficiency, and versatility in chemical and biological processes. A key aspect of the technology landscape is the integration of advanced automation and control systems. Modern glass reactors are equipped with sophisticated sensors for real-time monitoring of temperature, pressure, pH, and stirring speed, often linked to programmable logic controllers (PLCs) or distributed control systems (DCS). This allows for precise parameter control, remote operation, and automated sequence execution, minimizing human intervention and improving reproducibility. The adoption of modular reactor designs is also a significant trend, enabling users to easily reconfigure reactor setups for different applications, thereby maximizing asset utilization and adapting to changing research or production needs without extensive retooling.

Innovations in stirring technology are crucial for optimizing mixing efficiency and heat transfer, especially for viscous solutions or processes involving solid suspension. This includes magnetic stirrers, overhead stirrers with various impeller designs (e.g., anchor, propeller, turbine), and specialized impellers for demanding applications, all designed to minimize shear forces and ensure homogeneity. Furthermore, advancements in material science are leading to more durable borosilicate glass compositions and improved sealing technologies, reducing the risk of leaks and enhancing operational safety, particularly under vacuum or moderate pressure conditions. The development of specialized coatings for glass surfaces to improve chemical resistance or reduce fouling is also gaining traction, extending reactor lifespan and cleaning intervals.

The integration of process analytical technology (PAT) tools into glass reactor systems is a significant technological driver. This involves embedding inline or online analytical sensors, such as FTIR, Raman spectroscopy, or particle size analyzers, directly into the reactor to provide real-time data on reaction progress, component concentrations, and physical properties. This enables proactive process adjustments, leading to improved yield, quality, and accelerated process development. Beyond hardware, the advent of software solutions for data visualization, process simulation, and predictive modeling is transforming how researchers and engineers interact with glass reactors, making them more intelligent and capable of handling complex synthetic challenges. The ongoing convergence of these technologies ensures that glass reactors remain at the forefront of innovation in laboratory and industrial chemical processing.

Regional Highlights

The global Glass Reactor Market exhibits significant regional variations in growth and demand, driven by differing industrial landscapes, research investments, and regulatory environments. North America and Europe continue to be mature markets, characterized by well-established pharmaceutical and biotechnology industries, strong emphasis on research and development, and a high adoption rate of advanced laboratory equipment. These regions benefit from substantial government and private funding in life sciences, driving demand for high-quality, precision glass reactors for drug discovery, clinical trials, and specialized chemical synthesis. The presence of leading research universities and a robust regulatory framework also contributes to consistent market growth and innovation within these regions.

Asia Pacific (APAC) is emerging as the fastest-growing region in the Glass Reactor Market, propelled by rapid industrialization, expanding pharmaceutical manufacturing bases, and increasing investments in scientific research, particularly in countries like China, India, and South Korea. The cost-effectiveness of manufacturing and the burgeoning demand for generic drugs and fine chemicals in these economies contribute significantly to market expansion. Latin America and the Middle East and Africa (MEA) regions, while smaller in market share, are experiencing steady growth. This growth is primarily fueled by increasing healthcare expenditures, expanding chemical industries, and growing interest in biotechnological research, indicating promising future opportunities for glass reactor manufacturers.

- North America: Leading market due to extensive pharmaceutical and biotechnology R&D, advanced research infrastructure, and high adoption of sophisticated laboratory equipment.

- Europe: Strong market driven by robust fine chemical and pharmaceutical industries, stringent quality standards, and continuous innovation in process technology.

- Asia Pacific (APAC): Fastest-growing market, characterized by rapid industrialization, expanding manufacturing capabilities in pharmaceuticals and chemicals, and increasing research investments in countries like China and India.

- Latin America: Emerging market with growing investments in healthcare infrastructure and chemical production, leading to increased demand for glass reactors.

- Middle East & Africa (MEA): Developing market, driven by expanding pharmaceutical sectors and increasing focus on industrial diversification and research initiatives.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Glass Reactor Market.- De Dietrich Process Systems

- Buchi

- Chemglass Life Sciences LLC

- Pfaudler

- Heidolph Instruments GmbH & Co. KG

- Merck KGaA

- VWR International LLC

- LABPLANT

- Suzhou Ace Biomedical Technology Co., Ltd.

- Beijing Greatwall Instrument Co., Ltd.

- Shanghai Chemdo Trading Co., Ltd.

- Shandong Senz Chemical Co., Ltd.

- OLABO

- Wuxi Huajin Chemical Equipment Co., Ltd.

- Jiangsu Nanda Glass Instrument Co., Ltd.

- Jinan Labtech Equipment Co., Ltd.

- Mumbai Instrument Company

- KGW-Isotherm

- Thermo Fisher Scientific Inc.

- IKA Works, Inc.

Frequently Asked Questions

Analyze common user questions about the Glass Reactor market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of glass reactors?

Glass reactors are predominantly used in pharmaceutical, fine chemical, and biotechnology industries for chemical synthesis, distillation, crystallization, extraction, and mixing processes due to their inertness and visibility.

Why choose a glass reactor over other materials like stainless steel?

Glass reactors are preferred for their excellent corrosion resistance to acids and bases, transparency allowing visual monitoring of reactions, and absence of metal ion contamination, crucial for high-purity applications.

What factors drive the growth of the Glass Reactor Market?

Market growth is driven by increasing R&D investments in pharmaceuticals and biotech, rising demand for specialized chemicals, and stringent regulatory requirements for process control and product quality.

What are the main types of glass reactors available?

The main types include jacketed glass reactors for precise temperature control, double-walled for enhanced insulation, single-walled for simpler applications, and specialized photochemical or high-pressure glass reactors.

How does AI impact the future of glass reactors?

AI is expected to enhance glass reactors through optimized reaction parameters, predictive maintenance, automated process control, and advanced data analysis, leading to improved efficiency, safety, and accelerated R&D cycles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager