Global Printing Plates Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430171 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Global Printing Plates Market Size

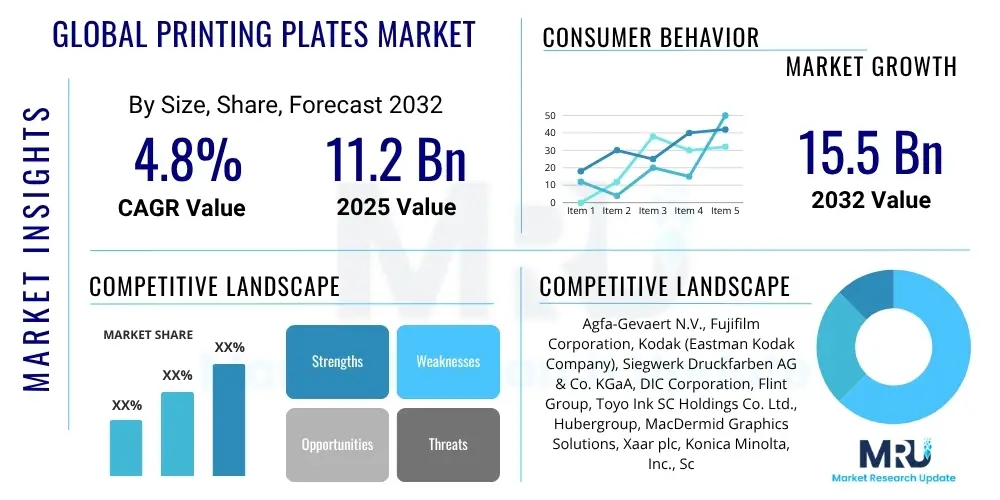

The Global Printing Plates Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 11.2 Billion in 2025 and is projected to reach USD 15.5 Billion by the end of the forecast period in 2032.

Global Printing Plates Market introduction

The Global Printing Plates Market encompasses the manufacturing, distribution, and consumption of plates used in various printing processes, primarily offset, flexography, and gravure. Printing plates are essential intermediaries that transfer an image from a digital file or film onto a substrate such as paper, plastic, or metal, forming the core of conventional printing technologies. These plates are typically made from materials like aluminum, polyester, or polymers and are processed to create the desired image, which then picks up ink and transfers it to the printing surface.

Major applications for printing plates span across a multitude of industries including commercial printing for brochures, books, and magazines, extensive packaging operations for food and consumer goods, newspaper production, and specialized applications like security printing and label manufacturing. The inherent benefits of printing plates include their capacity for high-volume production, precise image reproduction, cost-effectiveness for long runs, and versatility across different material types. This makes them indispensable for mass communication and product branding, offering a durable and reliable method for consistent print quality.

Key driving factors for the printing plates market include the sustained growth of the global packaging industry, fueled by e-commerce expansion and changing consumer lifestyles, and the increasing demand for high-quality commercial printing in emerging economies. Additionally, continuous technological advancements in plate manufacturing, such as the development of processless and more environmentally friendly plates, are contributing to market expansion by enhancing efficiency and sustainability. The perpetual need for marketing materials, publications, and product information across diverse sectors ensures a foundational demand for printing plates, despite the rise of digital printing alternatives.

Global Printing Plates Market Executive Summary

The Global Printing Plates Market is characterized by a blend of technological innovation and persistent demand from traditional print sectors, alongside dynamic shifts in business, regional, and segment trends. Business trends highlight a growing emphasis on sustainable manufacturing practices, with a noticeable rise in the development and adoption of eco-friendly and processless plates that reduce chemical waste and energy consumption. Consolidation among major players is also a prominent feature, driven by the need for economies of scale and comprehensive product portfolios to address diverse market needs. Furthermore, there is an increasing investment in automation and integration within printing facilities, which consequently influences the demand for compatible plate technologies that can streamline workflows and enhance operational efficiency.

Regionally, the market exhibits varied growth dynamics. Asia Pacific continues to dominate the global market, primarily due to robust manufacturing activities, particularly in packaging and commercial printing, and the rapid industrialization of economies like China and India. North America and Europe represent mature markets where growth is primarily driven by technological upgrades, replacement demand, and a strong focus on high-quality and specialized printing applications, including sophisticated packaging and security documents. Latin America and the Middle East and Africa are emerging as significant growth pockets, propelled by rising disposable incomes, urbanization, and increasing investment in local printing infrastructure, leading to greater adoption of advanced printing plate solutions.

Segment-wise, the market is witnessing divergent growth trajectories. Flexographic plates are experiencing substantial growth, largely attributed to the booming packaging sector, which demands flexible and durable printing solutions for various substrates. Offset printing plates, while mature, maintain a strong market share due to their cost-effectiveness and high-quality output for commercial and newspaper printing, though digital CTP plates are increasingly preferred for their faster turnaround times and superior registration. There is a general trend towards Computer-to-Plate (CTP) technologies across all segments, indicating a shift away from traditional analog methods due to CTP's enhanced precision, efficiency, and reduced manual intervention. The demand for specialized plates tailored for specific applications, such as UV ink compatibility or enhanced durability, also contributes significantly to segment-specific advancements.

AI Impact Analysis on Global Printing Plates Market

Common user questions regarding AI's impact on the Global Printing Plates Market frequently revolve around how artificial intelligence can enhance production efficiency, improve quality control, and contribute to sustainable practices. Users are keen to understand whether AI can automate complex plate-making processes, optimize material usage, or predict maintenance needs for equipment, thereby reducing operational costs and waste. There is also interest in how AI might influence personalized printing demands and overall supply chain management within the printing plate ecosystem. The overarching themes reflect expectations for increased automation, data-driven decision-making, and improved sustainability through AI integration, with some underlying concerns about job displacement and the initial investment required for AI implementation.

- Automated pre-press workflows for plate imaging and processing, reducing human error and increasing speed.

- Predictive maintenance for printing plate equipment, minimizing downtime and extending machinery lifespan.

- Enhanced quality control systems using AI-powered vision for defect detection and consistency assurance in plate production.

- Optimized material usage and waste reduction through AI algorithms that analyze production data and suggest efficient layouts.

- Personalized plate design and production capabilities, allowing for quicker adaptation to customized print jobs and shorter runs.

- Supply chain optimization for raw materials and finished plates, improving inventory management and logistics efficiency.

- Data-driven insights into plate performance and print quality, facilitating continuous improvement and innovation in plate technology.

DRO & Impact Forces Of Global Printing Plates Market

The Global Printing Plates Market is influenced by a complex interplay of drivers, restraints, and opportunities, all shaped by various impact forces. Key drivers include the ever-expanding global packaging industry, propelled by e-commerce growth and a rising consumer base that demands aesthetically pleasing and informative product packaging. The increasing demand for high-quality commercial printing in advertising, publishing, and marketing sectors further fuels the market, especially in developing economies. Additionally, continuous technological advancements in plate manufacturing, leading to faster, more durable, and environmentally friendly plates, contribute significantly to market growth. Urbanization, rising disposable incomes, and the expansion of organized retail also play crucial roles in driving the demand for printed materials and consequently, printing plates.

However, the market faces significant restraints. The escalating competition from digital printing technologies, particularly for short-run jobs and personalized prints, poses a threat to traditional plate-based printing. Strict environmental regulations concerning chemical usage and waste disposal in plate processing compel manufacturers to invest heavily in sustainable solutions, which can increase production costs. Volatility in raw material prices, especially for aluminum and polymers, directly impacts manufacturing costs and profit margins. Furthermore, the declining circulation of newspapers and magazines in some developed regions due to the shift towards digital media channels presents a challenge for segments heavily reliant on these applications.

Opportunities for growth lie primarily in emerging markets, where industrialization and consumer spending are rapidly increasing, leading to greater demand for printing services. The development and adoption of sustainable and processless printing plates, which reduce environmental impact and operational complexity, offer a significant growth avenue. Specialization in niche applications such as security printing, anti-counterfeiting, and high-end decorative packaging provides avenues for premium product offerings. Moreover, the integration of printing plate manufacturing with smart factory concepts and industry 4.0 initiatives can lead to enhanced efficiency, cost reduction, and improved product quality, opening new avenues for innovation and competitive advantage.

Impact forces within the market structure are also critical. The bargaining power of buyers is moderate to high, as large printing houses often have significant purchasing volumes and can negotiate prices, especially given the presence of multiple plate suppliers. The bargaining power of suppliers of raw materials (aluminum, polymers, chemicals) is also moderate, influenced by global commodity prices and supply chain dynamics. The threat of substitutes, primarily digital printing, is considerable and continuously evolving, pushing plate manufacturers to innovate. The threat of new entrants is relatively low due to high capital investment requirements, technological expertise, and established distribution networks. Competitive rivalry among existing players is intense, driven by product differentiation, pricing strategies, and geographical expansion efforts, all aiming to capture a larger market share in this essential yet evolving industry.

Segmentation Analysis

The Global Printing Plates Market is comprehensively segmented by various parameters including type, material, and application, reflecting the diverse needs and technological landscapes across the printing industry. This segmentation provides a granular view of the market, allowing for a detailed analysis of growth drivers and challenges within specific niches. The evolution of printing technologies and environmental considerations continuously shapes these segments, leading to innovations and shifts in market share. Understanding these distinct segments is crucial for stakeholders to identify key opportunities, tailor product offerings, and develop effective market strategies, addressing the specific demands of different end-user industries and geographic regions.

- By Type

- Thermal CTP Plates

- UV CTP Plates

- Analog Plates

- Digital Plates (DIP)

- Flexographic Plates

- Gravure Plates

- Lithographic Plates

- By Material

- Aluminum Plates

- Polyester Plates

- Polymer Plates

- Rubber Plates

- By Application

- Commercial Printing

- Packaging Printing

- Newspaper Printing

- Magazine Printing

- Label Printing

- Security Printing

- By Technology

- Offset Printing Plates

- Flexography Printing Plates

- Gravure Printing Plates

- Digital Printing Plates

Value Chain Analysis For Global Printing Plates Market

The value chain for the Global Printing Plates Market begins with a robust upstream segment focused on the sourcing and processing of raw materials. This includes suppliers of high-grade aluminum sheets, various polymers, and specialized chemicals like photopolymers, sensitizers, and developers. These raw materials undergo intricate manufacturing processes to produce the base plates, which are then coated with light-sensitive emulsions. The quality and cost-effectiveness of these upstream inputs significantly impact the final product's performance and market price. Strategic partnerships with raw material suppliers are crucial for manufacturers to ensure consistent quality and manage supply chain volatility.

The core of the value chain involves the printing plate manufacturers themselves, who transform raw materials into finished plates through processes such as coating, drying, and cutting. This stage also includes research and development efforts to innovate new plate technologies, such as processless or water-washable plates, which enhance efficiency and reduce environmental impact. Following manufacturing, the plates move through a critical distribution channel to reach end-users. This channel can be direct, where large printing plate manufacturers sell directly to major printing houses, often involving technical support and bulk delivery. Alternatively, an indirect distribution model is common, particularly for smaller and medium-sized printers, where a network of distributors, wholesalers, and agents plays a vital role in storage, localized sales, and logistics, providing access to a broader customer base.

The downstream segment of the value chain comprises the end-users, primarily printing companies that purchase and utilize these plates for various applications. These include commercial printers, packaging manufacturers, newspaper and magazine publishers, and specialized label and security printing firms. These end-users conduct plate imaging (e.g., CTP processing) and then run the plates on their printing presses to produce final printed materials. The efficiency of this downstream usage, coupled with the plate's performance characteristics like durability, image fidelity, and run length, directly influences the overall value proposition. Feedback from these end-users often drives innovation and product improvements back up the value chain, ensuring that printing plates continue to meet evolving industry demands and contribute effectively to the final printed product.

Global Printing Plates Market Potential Customers

The primary potential customers and end-users of printing plates in the global market encompass a wide array of businesses within the printing and publishing sectors, each with distinct needs and application requirements. Commercial printing houses represent a significant customer segment, relying on printing plates for producing diverse materials such as brochures, catalogs, annual reports, direct mail, books, and promotional items. These entities demand plates that offer high resolution, color accuracy, and efficiency for both short and long print runs, often utilizing a mix of offset and digital plate technologies to cater to their varied client demands and project specifications.

Another crucial customer segment is packaging manufacturers, which utilize printing plates extensively for producing flexible packaging, corrugated boxes, labels, cartons, and other packaging solutions for industries ranging from food and beverages to pharmaceuticals and consumer goods. The growth of e-commerce and the increasing need for brand differentiation drive sustained demand in this sector, favoring flexographic and lithographic plates that provide excellent print quality on a variety of substrates. These customers prioritize plates that offer durability, consistency, and the ability to reproduce intricate designs and vibrant colors to enhance product appeal and meet stringent regulatory standards.

Furthermore, newspaper and magazine publishers, despite facing challenges from digital media, remain significant buyers, particularly in regions where print media retains a strong readership. They require cost-effective, high-speed plates capable of long runs and quick turnaround times. Label printers constitute a rapidly growing segment, driven by product serialization, branding, and regulatory compliance needs across industries. Finally, security printing firms, involved in producing banknotes, passports, government documents, and other items requiring anti-counterfeiting measures, represent a highly specialized customer base. These firms demand plates with exceptional precision, intricate detail reproduction, and sometimes proprietary features to facilitate complex security elements, thereby solidifying their position as critical buyers in the global printing plates market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 11.2 Billion |

| Market Forecast in 2032 | USD 15.5 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Agfa-Gevaert N.V., Fujifilm Corporation, Kodak (Eastman Kodak Company), Siegwerk Druckfarben AG & Co. KGaA, DIC Corporation, Flint Group, Toyo Ink SC Holdings Co. Ltd., Hubergroup, MacDermid Graphics Solutions, Xaar plc, Konica Minolta, Inc., Screen Holdings Co. Ltd., Mitsubishi Imaging (MPM), Toray Industries, Inc., Chemence, Technova Imaging Systems, Huaguang Graphics, Lucky Huaguang Graphics Co. Ltd., Guangdong Huayuan Printing Plate Co. Ltd., IBF GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Global Printing Plates Market Key Technology Landscape

The Global Printing Plates Market is characterized by a dynamic and evolving technology landscape, with continuous innovation aimed at enhancing efficiency, quality, and environmental sustainability. Computer-to-Plate (CTP) technology stands as a cornerstone, replacing traditional film-based plate making. CTP systems utilize lasers to directly image digital data onto printing plates, significantly improving image quality, registration accuracy, and workflow speed while reducing material waste associated with film. This technology comes in various forms, including thermal CTP, which uses heat-sensitive plates, and UV-sensitive CTP, which uses ultraviolet light to expose plates, each offering distinct advantages depending on the printing application and press requirements.

Further technological advancements include the development of processless plates, which eliminate the need for chemical processing steps after imaging. These plates are designed to be exposed and then directly mounted onto the press, where the non-image areas are washed away by fountain solution or ink. This innovation drastically reduces chemical consumption, water usage, and energy, thereby offering substantial environmental and economic benefits. Similarly, water-washable plates, particularly prevalent in flexography, provide an eco-friendlier alternative to solvent-based plate processing, catering to increasing regulatory pressures and industry demand for greener solutions.

In addition to CTP and greener plate technologies, advancements in direct laser engraving (DLE) for flexographic and gravure printing plates are transforming the market by offering unparalleled precision and customization. DLE allows for the direct creation of high-definition images on polymer or rubber plates, eliminating intermediate steps and enabling complex designs and improved ink transfer. Materials science also plays a crucial role, with ongoing research into new polymer compositions and aluminum alloys that enhance plate durability, print run length, and compatibility with a wider range of inks and press conditions. These technological shifts collectively drive the market forward, pushing towards greater automation, reduced environmental footprint, and superior print output across all segments of the printing industry.

Regional Highlights

- North America: A mature market characterized by high adoption of advanced CTP technologies and processless plates, driven by demands for efficiency and environmental compliance. Significant market share in commercial and packaging printing, with consistent investment in technological upgrades.

- Europe: Focus on sustainable printing solutions and high-quality output, especially in countries like Germany and the UK. Stringent environmental regulations accelerate the adoption of eco-friendly plates, while demand for specialized applications such as security printing remains strong.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by rapid industrialization, expanding manufacturing sectors, and increasing consumer demand in countries like China, India, and Japan. Strong growth in packaging and commercial printing, making it a key production hub.

- Latin America: An emerging market showing steady growth, fueled by increasing investment in printing infrastructure and rising demand for packaged goods and commercial print services. Brazil and Mexico are leading contributors to market expansion in the region.

- Middle East and Africa (MEA): Gradually developing market with growing infrastructure projects and diversification of economies leading to increased printing activities. Opportunities exist in commercial printing and packaging, driven by urbanization and rising consumer spending.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Global Printing Plates Market.- Agfa-Gevaert N.V.

- Fujifilm Corporation

- Kodak (Eastman Kodak Company)

- Siegwerk Druckfarben AG & Co. KGaA

- DIC Corporation

- Flint Group

- Toyo Ink SC Holdings Co. Ltd.

- Hubergroup

- MacDermid Graphics Solutions

- Xaar plc

- Konica Minolta, Inc.

- Screen Holdings Co. Ltd.

- Mitsubishi Imaging (MPM)

- Toray Industries, Inc.

- Chemence

- Technova Imaging Systems

- Huaguang Graphics

- Lucky Huaguang Graphics Co. Ltd.

- Guangdong Huayuan Printing Plate Co. Ltd.

- IBF GmbH

Frequently Asked Questions

What is the projected growth rate for the Global Printing Plates Market?

The Global Printing Plates Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032, driven by packaging industry growth and technological advancements.

What are the primary types of printing plates available in the market?

The primary types include Thermal CTP Plates, UV CTP Plates, Analog Plates, Digital Plates (DIP), Flexographic Plates, Gravure Plates, and Lithographic Plates, each suited for different printing processes and applications.

How is AI impacting the printing plates industry?

AI is impacting the industry by enabling automated pre-press workflows, predictive maintenance for equipment, enhanced quality control, optimized material usage, and personalized plate design, leading to increased efficiency and sustainability.

Which region dominates the Global Printing Plates Market?

The Asia Pacific (APAC) region currently dominates the Global Printing Plates Market, driven by robust manufacturing activities, particularly in packaging and commercial printing, and rapid industrialization in countries like China and India.

What are "processless" printing plates and their benefits?

Processless printing plates are advanced plates that eliminate the need for chemical processing after imaging, allowing them to be directly mounted onto the press. Their benefits include reduced chemical waste, lower water and energy consumption, and streamlined workflow, contributing to environmental sustainability and operational efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager