Glulam Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428207 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Glulam Market Size

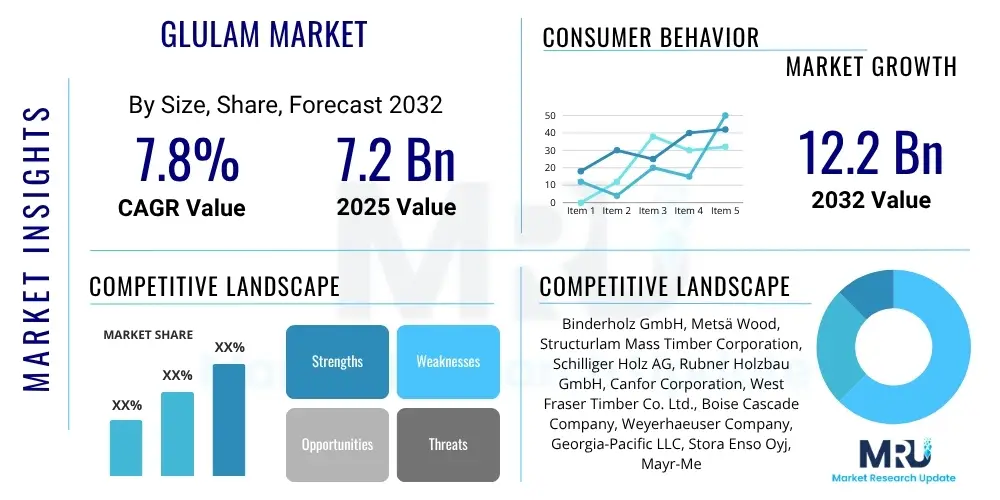

The Glulam Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 7.2 Billion in 2025 and is projected to reach USD 12.2 Billion by the end of the forecast period in 2032.

Glulam Market introduction

The Glulam market encompasses the production, distribution, and application of glued laminated timber, an engineered wood product made by bonding together multiple layers of solid timber with durable, moisture-resistant structural adhesives. This innovative construction material offers superior strength, durability, and dimensional stability compared to traditional solid timber, making it increasingly popular in various building and infrastructure projects. Glulam's unique characteristics allow for the creation of large, aesthetically pleasing structural elements that can span significant distances and bear substantial loads, contributing to more open and adaptable architectural designs.

Major applications for Glulam span a wide array of construction sectors, including residential buildings, commercial complexes, educational institutions, sports arenas, and intricate bridge structures. Its inherent benefits, such as a high strength-to-weight ratio, excellent fire resistance when sized appropriately, and outstanding aesthetic appeal, position it as a preferred material for architects and engineers seeking sustainable and high-performance solutions. The material's capacity for prefabrication significantly reduces on-site construction time and labor costs, further enhancing its attractiveness in a rapidly evolving construction landscape.

Driving factors for the Glulam market's growth are primarily centered around the global push for sustainable construction practices, increasing demand for environmentally friendly building materials, and the rising adoption of mass timber construction techniques. Additionally, urbanization trends, a growing focus on resilient infrastructure, and advancements in timber engineering are propelling the market forward. The aesthetic versatility and structural integrity of Glulam also appeal to modern design sensibilities, fostering its integration into an increasing number of diverse and complex architectural visions worldwide.

Glulam Market Executive Summary

The Glulam market is experiencing robust growth driven by converging trends in sustainable construction, technological advancements, and evolving consumer preferences for natural aesthetics and environmental responsibility. Business trends highlight a significant shift towards mass timber construction, where Glulam plays a pivotal role alongside cross-laminated timber (CLT) and other engineered wood products. This shift is supported by increasing investments in manufacturing capabilities, research and development aimed at improving product performance, and the expansion of supply chains to meet escalating global demand. Companies are increasingly focusing on vertical integration and strategic partnerships to enhance their market presence and optimize production efficiency, ensuring a consistent supply of high-quality Glulam products for diverse applications.

Regional trends indicate North America and Europe as established markets with high adoption rates, primarily due to stringent environmental regulations, a mature timber industry, and a strong emphasis on green building certifications. The Asia Pacific region is emerging as a significant growth engine, fueled by rapid urbanization, infrastructure development, and growing awareness of sustainable construction practices in countries like China, India, and Japan. Latin America and the Middle East & Africa are also witnessing gradual but steady growth, driven by investments in residential and commercial construction and a nascent but growing interest in engineered wood solutions. Each region presents unique opportunities and challenges, requiring tailored market entry strategies and product offerings to cater to local construction norms and material preferences.

Segmentation trends reveal that the commercial and residential sectors continue to dominate the Glulam market, with increasing adoption in multi-story buildings, public facilities, and custom homes. The infrastructure segment, particularly for bridges and large-span structures, is also gaining traction due showcasing Glulam's structural capabilities and durability. In terms of wood type, spruce and pine remain the most commonly used species, favored for their availability and structural properties, while advancements in adhesive technology are broadening the scope for other timber species. The market is also seeing a rise in specialized Glulam products tailored for specific performance requirements, such as enhanced fire resistance or aesthetic finishes, indicating a trend towards greater customization and product diversification to meet evolving architectural and engineering demands.

AI Impact Analysis on Glulam Market

Users frequently inquire about artificial intelligence's potential to revolutionize Glulam manufacturing, design, and supply chain management. Key themes revolve around improving production efficiency, optimizing material utilization to reduce waste, enhancing structural analysis for safer and more complex designs, and streamlining logistics. Concerns also exist regarding the initial investment required for AI integration, the need for a skilled workforce to manage these new systems, and the implications for traditional manufacturing jobs. There is a strong expectation that AI will lead to more sustainable and cost-effective Glulam products, ultimately driving greater adoption in the construction industry.

- Design Optimization: AI algorithms can analyze complex structural data, enabling architects and engineers to design Glulam structures with optimal material usage, improved load-bearing capacity, and enhanced aesthetic outcomes, reducing design iterations and potential errors.

- Manufacturing Efficiency: AI-powered systems can monitor production lines, predict machinery maintenance needs, optimize timber cutting patterns to minimize waste, and control adhesive application for consistent quality, leading to higher output and lower operational costs.

- Quality Control: Machine vision and AI can perform real-time defect detection in timber laminations and finished Glulam beams, ensuring product consistency and adherence to stringent quality standards, far surpassing manual inspection capabilities.

- Supply Chain Management: AI can predict demand fluctuations, optimize inventory levels, route logistics more efficiently, and manage raw material sourcing, leading to reduced lead times, lower transportation costs, and a more resilient supply chain for Glulam manufacturers.

- Sustainability and Resource Management: AI helps in tracking the provenance of timber, optimizing forest management practices, and reducing carbon footprint across the entire Glulam lifecycle by providing data-driven insights into resource consumption and waste generation.

- Automated Fabrication: Integration of AI with CNC machinery can lead to highly automated Glulam fabrication processes, enabling rapid production of complex, custom-shaped elements with extreme precision, catering to the growing demand for prefabrication.

DRO & Impact Forces Of Glulam Market

The Glulam market is influenced by a dynamic interplay of drivers, restraints, and opportunities that collectively shape its growth trajectory and competitive landscape. A primary driver is the accelerating global shift towards sustainable construction practices, where Glulam, as a renewable and carbon-sequestering material, offers a compelling alternative to more energy-intensive building materials like steel and concrete. Its aesthetic appeal, coupled with superior structural performance and design flexibility, makes it a favored choice for modern architectural projects emphasizing both form and function. Furthermore, the growing adoption of modular and prefabricated construction techniques significantly boosts Glulam's demand, as it facilitates rapid on-site assembly, reduces labor costs, and improves construction efficiency across various project scales. Technological advancements in timber engineering and adhesive technology also continue to enhance Glulam's performance characteristics, expanding its application possibilities and reinforcing its market position.

Despite the strong tailwinds, the Glulam market faces several significant restraints. The initial cost of Glulam products can sometimes be higher than conventional materials, particularly in regions where the timber supply chain is less developed or where steel and concrete are more entrenched and subsidized. Regulatory complexities and varying building codes across different regions can also impede widespread adoption, requiring extensive certification and approval processes for new Glulam products and applications. A lack of skilled labor trained in Glulam installation and construction techniques, especially in emerging markets, presents another barrier. Additionally, persistent misconceptions regarding wood's fire resistance and susceptibility to moisture damage, though largely addressed by modern Glulam treatments and design principles, continue to pose challenges to market acceptance and necessitate ongoing education for specifiers and end-users.

Opportunities for growth in the Glulam market are abundant and diverse. The increasing acceptance of mass timber construction, including hybrid structures combining Glulam with other materials, presents significant avenues for expansion, particularly in high-rise and long-span applications. The development of innovative Glulam products with enhanced fire protection, improved acoustic properties, and integrated insulation offers new market niches and performance advantages. Emerging markets, with their burgeoning construction sectors and increasing environmental awareness, represent untapped potential for market penetration. Moreover, strategic collaborations between Glulam manufacturers, architects, engineers, and construction firms can foster innovation, streamline project delivery, and further integrate Glulam into mainstream construction practices. The ongoing development of digital design tools and prefabrication technologies will continue to unlock Glulam's full potential, driving both demand and efficiency.

Segmentation Analysis

The Glulam market is comprehensively segmented across various dimensions, including application, end-use, wood type, and bonding type, reflecting the diverse requirements and preferences of the construction industry. This granular segmentation provides critical insights into market dynamics, enabling stakeholders to identify specific growth areas and tailor product offerings to targeted consumer groups. Understanding these segments is vital for strategic planning, product development, and effective market penetration, as each segment responds to distinct market drivers and possesses unique demand characteristics.

- By Application:

- Residential: Single-family homes, multi-family dwellings, apartment complexes.

- Commercial: Office buildings, retail spaces, hotels, restaurants, public buildings.

- Industrial: Factories, warehouses, agricultural structures, manufacturing facilities.

- Bridges & Infrastructure: Pedestrian bridges, road bridges, railway bridges, retaining walls, other civil engineering structures.

- Educational Institutions: Schools, universities, libraries.

- Sports & Leisure Facilities: Gymnasiums, stadiums, community centers, swimming pools.

- By End-Use:

- Beams: Primary load-bearing elements in roofs, floors, and walls.

- Columns: Vertical structural supports.

- Panels: Large-format structural panels, often used in walls, floors, and roofs.

- Trusses: Structural framework for roofs and bridges.

- Lintels: Horizontal beams over openings like doors and windows.

- Arches: Curved structural elements.

- Purlins: Horizontal beams supporting roof rafters.

- By Wood Type:

- Spruce: Widely available, good strength-to-weight ratio, commonly used in Europe.

- Pine: Strong, durable, cost-effective, prevalent in North America and Europe.

- Fir: Excellent strength, often used for demanding applications.

- Larch: High natural durability and weather resistance, suitable for exterior applications.

- Douglas Fir: High strength and stiffness, popular in North America for large structures.

- Other Softwoods: Hemlock, Cedar, etc., used based on regional availability and specific project requirements.

- By Bonding Type:

- Melamine-Urea-Formaldehyde (MUF): Cost-effective, good moisture resistance, commonly used for interior and protected exterior applications.

- Phenol-Resorcinol-Formaldehyde (PRF): Superior moisture and weather resistance, suitable for exposed exterior and marine environments.

- Polyurethane (PU): Formaldehyde-free, high strength, excellent bond durability, growing in popularity for eco-friendly construction.

- Epoxy: High strength, excellent chemical resistance, specialized applications.

- Emulsion Polymer Isocyanate (EPI): Good performance, lower formaldehyde emissions, increasingly used for structural applications.

Value Chain Analysis For Glulam Market

The Glulam market's value chain is a complex network spanning raw material sourcing to end-user application, involving multiple stages and diverse stakeholders, each adding significant value to the final product. The upstream segment of the value chain begins with sustainable forest management and logging, where timber is harvested from responsibly managed forests. This is followed by sawmill operations, which process logs into lumber, drying and sorting it based on grade and species. Key players in this stage include logging companies, sawmills, and suppliers of specialized adhesives (e.g., MUF, PRF, PU) which are crucial for the lamination process. Efficient raw material procurement and quality control at this stage are paramount to ensure the structural integrity and longevity of the Glulam product.

Midstream activities involve the actual manufacturing of Glulam beams and components. This stage typically includes sophisticated processes such as timber grading, finger-jointing individual laminations to achieve desired lengths, applying adhesives, and pressing the laminated layers under heat and pressure to form the final Glulam product. Advanced machinery, including CNC routers and specialized presses, plays a vital role in achieving precision and consistency. Glulam manufacturers transform raw lumber into high-value engineered wood products, often also performing initial fabrication like cutting, shaping, and pre-drilling according to project specifications. This manufacturing expertise and technological investment are critical for meeting diverse architectural and engineering demands.

The downstream segment focuses on distribution, marketing, and the ultimate installation of Glulam products. Distribution channels can be direct, where manufacturers supply directly to large construction companies or project developers, or indirect, through a network of specialized timber distributors, building material suppliers, and retail lumber yards. Indirect channels often provide logistical support, smaller order fulfillment, and regional market access. End-users, including architects, structural engineers, general contractors, and developers, engage with these channels to procure Glulam for their projects. Effective collaboration and communication across the entire value chain, from forest to final structure, are essential for ensuring timely delivery, cost-efficiency, and successful project outcomes. The rise of prefabrication further emphasizes the integration and coordination required throughout the value chain to deliver complete Glulam structural systems.

Glulam Market Potential Customers

The Glulam market serves a broad and diverse range of potential customers, each with specific needs and project requirements that align with the material's unique properties and benefits. Foremost among these are architects and structural engineers, who are the primary specifiers of building materials. They choose Glulam for its structural performance, aesthetic versatility, sustainability credentials, and ability to create large, open-span designs that are challenging with other materials. Their decisions are heavily influenced by design intent, building codes, performance specifications, and the desire to incorporate environmentally responsible materials into their projects.

General contractors and construction companies represent another significant customer segment. They are interested in Glulam's ease of installation, potential for prefabrication, which reduces on-site labor and construction time, and overall project cost-effectiveness. The ability to receive pre-cut and pre-finished Glulam components directly to the construction site significantly streamlines their operations. Developers, ranging from residential home builders to large-scale commercial property developers, are also key buyers, driven by market demand for sustainable buildings, faster construction cycles, and the enhanced marketability of structures featuring natural wood elements and robust structural systems.

Beyond traditional construction, government agencies and municipalities are increasingly becoming important customers, particularly for public infrastructure projects such as bridges, community centers, schools, and sports facilities. Their focus often includes long-term durability, low maintenance, public safety, and adherence to green building initiatives and procurement policies. Homeowners, though typically indirectly purchasing Glulam through builders or architects for custom homes or renovations, constitute an underlying demand driver for residential applications, valuing the material's aesthetic appeal, warmth, and environmental benefits. Each customer group seeks specific value propositions from Glulam, underscoring the need for manufacturers and suppliers to offer tailored solutions and comprehensive technical support.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 7.2 Billion |

| Market Forecast in 2032 | USD 12.2 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Binderholz GmbH, Metsä Wood, Structurlam Mass Timber Corporation, Schilliger Holz AG, Rubner Holzbau GmbH, Canfor Corporation, West Fraser Timber Co. Ltd., Boise Cascade Company, Weyerhaeuser Company, Georgia-Pacific LLC, Stora Enso Oyj, Mayr-Melnhof Holz Holding AG, Setra Group, Eugen Decker Holzindustrie KG, Pfeifer Group, CombiWood, Rosboro, antec Timber GmbH & Co KG, Unalam, Kalesnikoff Lumber Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Glulam Market Key Technology Landscape

The Glulam market is increasingly shaped by a dynamic technological landscape that continuously drives innovation in manufacturing processes, product performance, and application methods. Advanced manufacturing technologies are at the forefront, with highly automated production lines integrating sophisticated machinery for timber grading, finger-jointing, and pressing. Computer Numerical Control (CNC) machining centers are becoming standard, enabling precise cutting, drilling, and shaping of Glulam components to exact architectural specifications, significantly reducing on-site fabrication and waste. These technologies allow for the efficient production of complex, custom-designed elements, which is critical for meeting the intricate demands of modern mass timber construction projects.

Innovations in adhesive technology represent another critical aspect of the Glulam market's technological evolution. The development of new, more environmentally friendly, and high-performance structural adhesives, such as formaldehyde-free polyurethane (PU) glues and emulsion polymer isocyanate (EPI) adhesives, is addressing growing concerns about volatile organic compound (VOC) emissions and contributing to healthier indoor air quality. These advanced adhesives not only improve the bond strength and durability of Glulam but also enhance its resistance to moisture and harsh environmental conditions, expanding its suitability for a wider range of applications, including exposed exterior structures and regions with extreme climates. Ongoing research focuses on developing bio-based adhesives to further reduce the environmental footprint of Glulam products.

Furthermore, digital design and analysis tools are fundamentally transforming how Glulam structures are conceived and implemented. Building Information Modeling (BIM) software, coupled with advanced structural analysis programs, allows architects and engineers to model, simulate, and optimize Glulam designs with unprecedented accuracy. This integration facilitates clash detection, material optimization, and performance prediction, leading to more efficient designs and fewer construction errors. Sensor integration within Glulam manufacturing facilities for real-time quality control, along with advanced robotics for material handling and assembly, are also gaining traction. These technological advancements collectively enhance Glulam's competitiveness by improving its quality, reducing production costs, and broadening its structural and aesthetic possibilities, thereby making it an even more attractive solution for sustainable and high-performance construction.

Regional Highlights

- North America: This region stands as a mature yet continually expanding market for Glulam, driven by a strong focus on sustainable building practices, a robust residential and commercial construction sector, and significant advancements in mass timber technologies. The United States and Canada are leaders in adopting engineered wood products, fueled by increasing awareness of Glulam's environmental benefits, structural performance in seismic zones, and aesthetic appeal. Supportive building codes and a well-established timber industry infrastructure further bolster market growth. Prefabrication and modular construction trends are particularly strong, creating high demand for pre-engineered Glulam components.

- Europe: Europe is another key region with a long history of timber construction and a strong commitment to environmental sustainability. Countries like Germany, Austria, and Scandinavia are at the forefront of Glulam production and innovation, driven by stringent energy efficiency regulations and a cultural preference for wood in construction. The market benefits from advanced manufacturing capabilities, extensive research and development in timber engineering, and a robust supply chain for certified sustainable timber. Public and private investments in glulam for institutional buildings, sports facilities, and multi-story residential structures are significant.

- Asia Pacific (APAC): The APAC region is projected to be one of the fastest-growing markets for Glulam, propelled by rapid urbanization, significant infrastructure development, and a growing emphasis on green building initiatives in economies such as China, Japan, India, and Australia. While traditional construction materials still dominate, increasing environmental awareness and the need for disaster-resilient structures are driving the adoption of engineered wood. Investments in local manufacturing capabilities and the transfer of advanced timber technologies from North America and Europe are key factors contributing to growth.

- Latin America: This region is experiencing nascent but steady growth in the Glulam market. Countries like Brazil and Chile, with vast forest resources, are exploring the potential of engineered wood products for residential, commercial, and even industrial applications. The market is primarily driven by increasing construction activities, growing interest in sustainable building materials, and the need for cost-effective and efficient construction solutions. Challenges include limited awareness, less developed supply chains, and competition from traditional materials, but opportunities exist for early market entrants.

- Middle East and Africa (MEA): The MEA region is an emerging market for Glulam, with growth spurred by ambitious infrastructure projects, a drive towards sustainable development, and a desire for distinctive architectural aesthetics. Countries in the GCC region, in particular, are investing in large-scale commercial and leisure projects where Glulam's aesthetic and structural properties can offer unique design solutions. However, challenges such as climate control, material sourcing, and specialized construction expertise need to be addressed for widespread adoption, making this a market with significant long-term potential.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Glulam Market.- Binderholz GmbH

- Metsä Wood

- Structurlam Mass Timber Corporation

- Schilliger Holz AG

- Rubner Holzbau GmbH

- Canfor Corporation

- West Fraser Timber Co. Ltd.

- Boise Cascade Company

- Weyerhaeuser Company

- Georgia-Pacific LLC

- Stora Enso Oyj

- Mayr-Melnhof Holz Holding AG

- Setra Group

- Eugen Decker Holzindustrie KG

- Pfeifer Group

- CombiWood

- Rosboro

- antec Timber GmbH & Co KG

- Unalam

- Kalesnikoff Lumber Co. Ltd.

Frequently Asked Questions

What is Glulam and how is it different from traditional timber?

Glulam, or glued laminated timber, is an engineered wood product made by bonding multiple layers of solid timber laminations with durable, moisture-resistant adhesives. It differs from traditional timber by offering superior strength, greater dimensional stability, and the ability to be manufactured into much larger and custom shapes, making it ideal for long spans and complex architectural designs. Its consistent quality and engineered properties often surpass those of solid sawn timber.

What are the primary applications of Glulam in construction?

Glulam is widely used across various construction sectors. Its primary applications include structural elements for residential homes (beams, columns), large-span structures in commercial buildings (offices, retail, public spaces), educational institutions, sports arenas, and even complex infrastructure projects like bridges. Its versatility allows for both aesthetic and structural functionality in diverse architectural projects.

Is Glulam a sustainable building material?

Yes, Glulam is considered a highly sustainable building material. It is made from a renewable resource (wood) sourced from sustainably managed forests, sequesters carbon, and typically requires less energy to produce than steel or concrete. Its efficient use of timber also minimizes waste. This makes Glulam an excellent choice for green building and environmentally conscious construction projects seeking to reduce their carbon footprint.

What are the main advantages of using Glulam?

Key advantages of Glulam include its exceptional strength-to-weight ratio, which allows for slender yet robust structures; its inherent aesthetic appeal, bringing warmth and natural beauty to interiors; excellent fire resistance due to its charring properties; and significant design flexibility, enabling long spans, curves, and unique shapes. It also offers good seismic performance and supports faster, more efficient construction through prefabrication.

How does Glulam perform in terms of fire resistance?

Glulam exhibits excellent inherent fire resistance, often outperforming unprotected steel. When exposed to fire, the outer layer of Glulam chars, forming an insulating barrier that protects the inner core and maintains structural integrity for an extended period. This predictable charring rate allows engineers to design Glulam structures that meet or exceed stringent fire safety requirements, providing ample time for evacuation and mitigating structural collapse.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager