Gravure Printing Ink Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429566 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Gravure Printing Ink Market Size

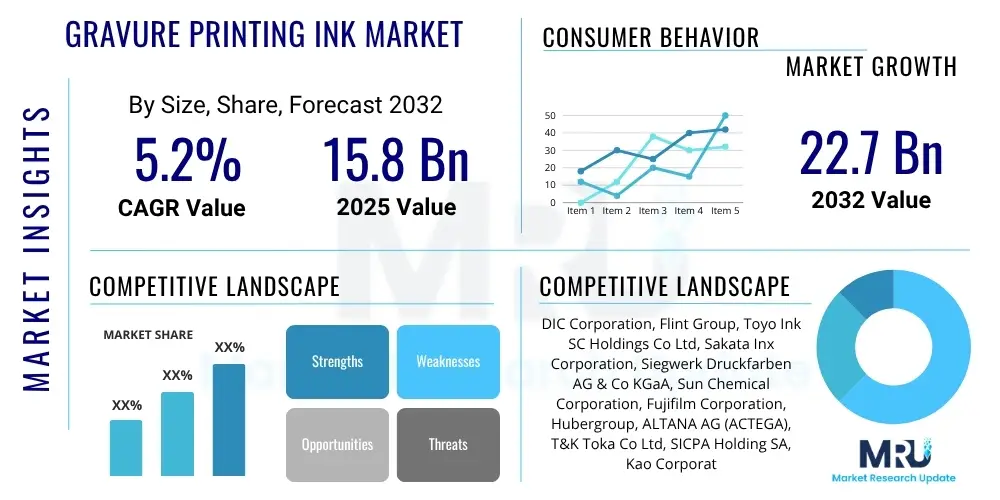

The Gravure Printing Ink Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.2% between 2025 and 2032. The market is estimated at USD 15.8 Billion in 2025 and is projected to reach USD 22.7 Billion by the end of the forecast period in 2032.

Gravure Printing Ink Market introduction

Gravure printing ink is a specialized ink formulation designed for the gravure printing process, known for its ability to produce high-quality, vibrant, and durable images on various substrates. This technique utilizes an engraved cylinder to transfer ink, making it ideal for long print runs where consistency and detail are paramount. The inks are typically characterized by low viscosity and quick drying times, crucial for the high-speed nature of gravure presses. They consist of pigments for color, resins for adhesion and film formation, solvents for viscosity control and drying, and various additives to enhance performance characteristics.

The primary applications of gravure printing inks span across several industries, with flexible packaging being a dominant sector due to the exceptional print quality achieved on films, foils, and laminates. These inks are also extensively used in publication printing for magazines, catalogs, and brochures, where visual appeal is critical. Furthermore, they find use in decorative applications for wallpapers, floor coverings, and textiles, offering superior color saturation and durability. The benefits of using gravure printing inks include excellent image reproduction, high gloss, superior adhesion, resistance to abrasion, and consistency across vast production volumes, all of which contribute to the premium aesthetic and functional qualities of the final printed product.

Driving factors for the gravure printing ink market include the expanding global packaging industry, particularly the demand for flexible packaging solutions that offer extended shelf life and attractive branding. The rising disposable incomes in emerging economies are leading to increased consumption of packaged goods, further fueling market growth. Moreover, advancements in ink technology, such as the development of environmentally friendly formulations (water-based and UV-curable inks) and performance-enhancing additives, are broadening their application scope and addressing sustainability concerns. The market also benefits from the continued preference for high-quality graphic reproduction in various consumer and industrial products, necessitating the superior capabilities of gravure printing.

Gravure Printing Ink Market Executive Summary

The Gravure Printing Ink Market is experiencing dynamic shifts driven by evolving business trends, pronounced regional variations, and distinct segment transformations. Business trends indicate a strong move towards sustainable ink formulations, including water-based and UV-curable options, in response to stringent environmental regulations and growing consumer preference for eco-friendly products. There is also an increasing integration of digital technologies for workflow optimization and supply chain management, even within traditional gravure printing. Regionally, Asia Pacific continues its dominance, fueled by rapid industrialization, urbanization, and a burgeoning consumer market, while mature markets in North America and Europe focus on innovation and value-added solutions to maintain competitiveness. Segment-wise, flexible packaging remains the largest application, driving demand for high-performance solvent-based inks, though water-based and UV-curable inks are gaining traction across various applications due to their compliance with environmental standards and improved performance characteristics.

AI Impact Analysis on Gravure Printing Ink Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize various aspects of the Gravure Printing Ink Market, from enhancing product development and manufacturing efficiency to improving quality control and optimizing supply chains. Key themes center on the potential for AI to accelerate the formulation of new inks with desired properties, predict and prevent production faults, personalize ink manufacturing for specific client needs, and facilitate more sustainable practices through optimized resource allocation. Concerns often arise regarding the initial investment cost, the need for specialized data infrastructure and skilled personnel, and the potential impact on traditional job roles within the printing and ink manufacturing sectors. Nevertheless, there is a strong expectation that AI will ultimately lead to more precise, cost-effective, and environmentally responsible ink production, thereby enhancing market competitiveness and driving innovation.

- AI-driven predictive analytics optimize ink formulation, reducing R&D cycles and material waste.

- Machine learning algorithms enhance quality control by detecting defects in real-time during ink production and printing.

- AI optimizes supply chain logistics, predicting demand, managing inventory, and improving raw material sourcing for inks.

- Automated process control systems powered by AI lead to increased operational efficiency and reduced downtime in ink manufacturing.

- AI facilitates personalized ink solutions, tailoring formulations to specific substrate and application requirements.

- Data analytics from AI systems can support the development of more sustainable, eco-friendly ink products.

- Predictive maintenance for printing equipment using AI extends machine lifespan and ensures consistent ink application.

DRO & Impact Forces Of Gravure Printing Ink Market

The Gravure Printing Ink Market is shaped by a confluence of driving forces, restraining factors, and emerging opportunities, all exerting significant impact on its growth trajectory. Key drivers include the exponential growth of the global packaging industry, particularly flexible packaging, which demands high-quality, durable, and visually appealing inks for effective branding and product protection. The increasing consumer preference for high-resolution graphics and sophisticated print finishes also fuels the adoption of gravure technology. Furthermore, rapid industrialization and urbanization in developing regions contribute to rising consumption of packaged goods and published materials, directly stimulating ink demand. Technological advancements in ink formulations, leading to improved performance, sustainability, and efficiency, are also critical growth enablers.

Conversely, the market faces several significant restraints. Stringent environmental regulations concerning Volatile Organic Compounds (VOCs) and hazardous air pollutants (HAPs) in traditional solvent-based inks necessitate costly reformulations and compliance efforts. The volatile pricing of key raw materials such as pigments, resins, and solvents can impact profit margins and production costs for ink manufacturers. Additionally, intense competition from alternative printing technologies like flexography and digital printing, which offer faster turnaround times and shorter run capabilities, poses a challenge, particularly for smaller print jobs. Health and safety concerns associated with certain ink chemicals also contribute to market pressures, driving the need for safer alternatives.

Amidst these challenges, significant opportunities abound for market players. The growing demand for sustainable and eco-friendly inks, including water-based, UV-curable, and bio-based formulations, presents a lucrative avenue for innovation and market differentiation. Expansion into untapped and emerging markets, particularly in Asia Pacific, Latin America, and Africa, offers substantial growth potential due to increasing industrial and consumer bases. Furthermore, the development of specialized inks for niche applications such as smart packaging, security printing, and advanced decorative materials can open new revenue streams. Strategic collaborations and mergers and acquisitions aimed at technological advancement and market consolidation also represent key impact forces shaping the industry's future landscape, pushing companies to invest in research and development to address evolving market needs and regulatory landscapes.

Segmentation Analysis

The Gravure Printing Ink Market is comprehensively segmented based on various attributes, including ink type, application, and end-use industry, providing a granular view of market dynamics and growth opportunities. This segmentation helps in understanding the specific demands and preferences across different sectors, allowing manufacturers and suppliers to tailor their product offerings and market strategies effectively. Each segment contributes uniquely to the overall market landscape, influenced by technological advancements, regulatory environments, and consumer trends. Analyzing these segments is crucial for identifying high-growth areas and potential challenges within the gravure printing ink industry.

- By Type

- Solvent-based Inks

- Water-based Inks

- UV-curable Inks

- Others (e.g., LED-UV, EB-curable)

- By Application

- Flexible Packaging

- Corrugated Packaging

- Publication Printing

- Decorative Printing

- Specialty Printing (e.g., security, labels)

- Others

- By End-Use Industry

- Food and Beverage

- Pharmaceuticals

- Cosmetics and Personal Care

- Industrial and Chemicals

- Textiles

- Automotive

- Others

- By Resin Type

- Polyurethane

- Nitrocellulose

- Polyamide

- Acrylic

- Others

Value Chain Analysis For Gravure Printing Ink Market

The value chain for the Gravure Printing Ink Market encompasses a series of interconnected stages, beginning with the sourcing of raw materials, progressing through manufacturing and distribution, and culminating with the end-users. Upstream activities involve a diverse range of suppliers providing essential components such as pigments, resins, solvents, and additives. These raw materials are critical for determining the final ink properties, including color, adhesion, drying speed, and durability. Downstream activities primarily involve printing companies, brand owners, and various end-use industries that apply the inks to their products, transforming them into finished goods. The efficiency and quality at each stage significantly impact the overall value and competitiveness of the final printed product in the market.

The upstream segment is characterized by specialized chemical manufacturers and commodity suppliers. Pigments, which impart color, are sourced from companies producing inorganic and organic dyes. Resins, crucial for adhesion and film formation, come from manufacturers specializing in polymers like nitrocellulose, polyamides, acrylics, and polyurethanes. Solvents, used to control viscosity and drying, are typically derived from petrochemical industries, although there's a growing shift towards bio-based alternatives. Additives, which provide specific performance characteristics like gloss, abrasion resistance, and anti-foaming, are sourced from specialty chemical suppliers. The quality and consistent supply of these raw materials are paramount for ink manufacturers to maintain their product standards and production schedules.

The downstream segment primarily consists of printing houses and converters who utilize gravure printing presses. These include large-scale flexible packaging converters, publication printers for magazines and catalogs, and manufacturers of decorative materials like wallpapers. The distribution channel for gravure printing inks can be both direct and indirect. Direct sales involve ink manufacturers selling directly to large-scale printing clients, allowing for customized formulations and close technical support. Indirect channels involve distributors and agents who cater to a wider range of smaller and medium-sized printers, providing logistical support, localized inventory, and sometimes technical services. The selection of distribution channels often depends on geographical reach, customer size, and the need for specialized support, ensuring that the inks reach the end-users efficiently and effectively, meeting their diverse application requirements and contributing to the aesthetic appeal and functionality of printed materials.

Gravure Printing Ink Market Potential Customers

The primary potential customers and end-users for gravure printing inks are diverse, spanning a multitude of industries that require high-quality, durable, and aesthetically appealing printed materials. These customers primarily consist of entities involved in converting raw materials into finished printed products, which are then used for branding, information dissemination, or decorative purposes. The demand for gravure printing inks is inherently tied to the production volumes and quality standards within these various end-use sectors, indicating a wide and robust customer base seeking superior print solutions for their products.

Flexible packaging converters represent a significant segment of potential customers. These companies specialize in printing on films, foils, and laminates for food and beverage packaging, pharmaceutical wraps, and personal care product pouches. Their need for gravure inks stems from the requirement for vibrant graphics, excellent adhesion to non-porous substrates, and resistance to wear and tear, ensuring product integrity and brand appeal on store shelves. Publication printers, including those producing magazines, catalogs, and brochures, also constitute a crucial customer group, relying on gravure inks for their ability to deliver sharp images, rich colors, and consistent quality across millions of copies, which is essential for capturing reader attention and delivering clear visual content.

Other key buyers include manufacturers of decorative products such as wallpapers, vinyl floorings, and textile prints, where gravure inks offer exceptional pattern reproduction and long-lasting colorfastness. Security printing companies, involved in producing banknotes, passports, and authentication labels, also utilize specialized gravure inks for their unique visual and tactile security features. Furthermore, label manufacturers for various industries, and companies involved in specialized industrial printing requiring high durability and chemical resistance, form part of the potential customer base. These diverse applications highlight the versatility and critical role of gravure printing inks in meeting the specific aesthetic and functional demands of a broad spectrum of end-use industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 15.8 Billion |

| Market Forecast in 2032 | USD 22.7 Billion |

| Growth Rate | 5.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DIC Corporation, Flint Group, Toyo Ink SC Holdings Co Ltd, Sakata Inx Corporation, Siegwerk Druckfarben AG & Co KGaA, Sun Chemical Corporation, Fujifilm Corporation, Hubergroup, ALTANA AG (ACTEGA), T&K Toka Co Ltd, SICPA Holding SA, Kao Corporation, Gans Ink & Supply Co, Wikoff Color Corporation, Dainichiseika Color & Chemicals Mfg Co Ltd, PPG Industries Inc, Lawter Inc (Harima Chemicals Group), INX International Ink Co, Zeller Gmelin GmbH & Co KG, Printcolor AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gravure Printing Ink Market Key Technology Landscape

The Gravure Printing Ink Market is consistently evolving, driven by advancements in material science, processing techniques, and application methods aimed at improving performance, sustainability, and efficiency. One significant area of technological development involves the formulation of inks with reduced environmental impact. This includes the widespread adoption of water-based inks, which replace traditional volatile organic compound (VOC) laden solvents with water, significantly lowering air pollution and improving workplace safety. Similarly, UV-curable and LED-UV inks are gaining prominence due to their instant drying properties, energy efficiency, and low-to-zero VOC emissions, offering a sustainable alternative that also enhances production speed.

Further technological innovations focus on enhancing the functional properties of gravure inks. This includes the development of high-performance pigments that offer improved lightfastness, chemical resistance, and color vibrancy, allowing for more durable and visually appealing prints. Advancements in resin technology are leading to inks with superior adhesion to challenging substrates like various plastic films and foils, which are prevalent in the flexible packaging sector. Additionally, specialty additives are being engineered to provide enhanced scratch resistance, heat resistance, and anti-scuff properties, crucial for demanding applications where printed materials are subjected to harsh conditions during handling, transportation, and end-use.

Moreover, the integration of smart technologies and nanotechnology is beginning to influence the gravure printing ink landscape. Nanoparticles are being incorporated into ink formulations to achieve unique optical, electrical, and barrier properties, opening doors for applications in smart packaging, conductive printing, and anti-counterfeiting measures. Automation and digital workflow integration in the ink manufacturing process, often supported by AI and machine learning, are improving consistency, reducing waste, and accelerating product development cycles. These technological strides not only address environmental and regulatory pressures but also enable gravure inks to meet the growing demand for specialized, high-performance, and sustainable printing solutions across diverse industrial and consumer applications.

Regional Highlights

- Asia Pacific: This region dominates the gravure printing ink market, primarily driven by rapid industrialization, burgeoning flexible packaging demand, and increasing consumer spending in countries like China, India, and Southeast Asian nations. The region benefits from a large manufacturing base and a growing need for high-quality packaging for food, pharmaceuticals, and personal care products.

- Europe: A mature market characterized by stringent environmental regulations, prompting a strong shift towards sustainable and eco-friendly ink solutions such as water-based and UV-curable inks. Countries like Germany, Italy, and the UK are at the forefront of innovation in specialty inks and high-performance applications, balancing environmental compliance with high-quality output.

- North America: This region exhibits a steady demand, with a focus on value-added packaging and advanced printing solutions. The market is influenced by technological advancements, demand for customized packaging, and a strong emphasis on brand differentiation. Manufacturers are investing in R&D to develop inks that meet both performance and sustainability criteria.

- Latin America: Expected to show significant growth, fueled by economic development, rising urbanization, and an expanding consumer base leading to increased demand for packaged goods. Brazil and Mexico are key markets, witnessing investments in printing infrastructure and a growing preference for advanced printing technologies.

- Middle East and Africa (MEA): An emerging market with considerable growth potential, primarily driven by infrastructure development, diversification of economies, and increasing disposable incomes. The demand for gravure printing inks is rising across sectors like food packaging and decorative applications, albeit from a lower base, presenting long-term opportunities for market players.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gravure Printing Ink Market.- DIC Corporation

- Flint Group

- Toyo Ink SC Holdings Co Ltd

- Sakata Inx Corporation

- Siegwerk Druckfarben AG & Co KGaA

- Sun Chemical Corporation

- Fujifilm Corporation

- Hubergroup

- ALTANA AG (ACTEGA)

- T&K Toka Co Ltd

- SICPA Holding SA

- Kao Corporation

- Gans Ink & Supply Co

- Wikoff Color Corporation

- Dainichiseika Color & Chemicals Mfg Co Ltd

- PPG Industries Inc

- Lawter Inc (Harima Chemicals Group)

- INX International Ink Co

- Zeller Gmelin GmbH & Co KG

- Printcolor AG

Frequently Asked Questions

What are the main types of gravure printing inks?

The main types of gravure printing inks include solvent-based inks, water-based inks, and UV-curable inks, each offering distinct advantages in terms of drying speed, substrate compatibility, and environmental impact.

How do environmental regulations impact the gravure printing ink market?

Environmental regulations, particularly those concerning VOC emissions, are significantly driving the market towards more sustainable formulations like water-based and UV-curable inks, pushing manufacturers to innovate and comply with stricter standards.

What are the primary applications of gravure printing inks?

Gravure printing inks are primarily used in flexible packaging for food and beverages, publication printing for magazines and catalogs, and decorative applications such as wallpapers, due to their superior print quality and durability.

Which region dominates the gravure printing ink market?

Asia Pacific currently dominates the gravure printing ink market, propelled by rapid industrial expansion, increasing demand for packaged goods, and a large manufacturing base in countries like China and India.

What innovations are shaping the future of gravure printing inks?

Future innovations in gravure printing inks are focused on developing bio-based and low-VOC formulations, incorporating nanotechnology for enhanced functional properties, and leveraging AI for optimized ink formulation and process control, driving sustainability and performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager