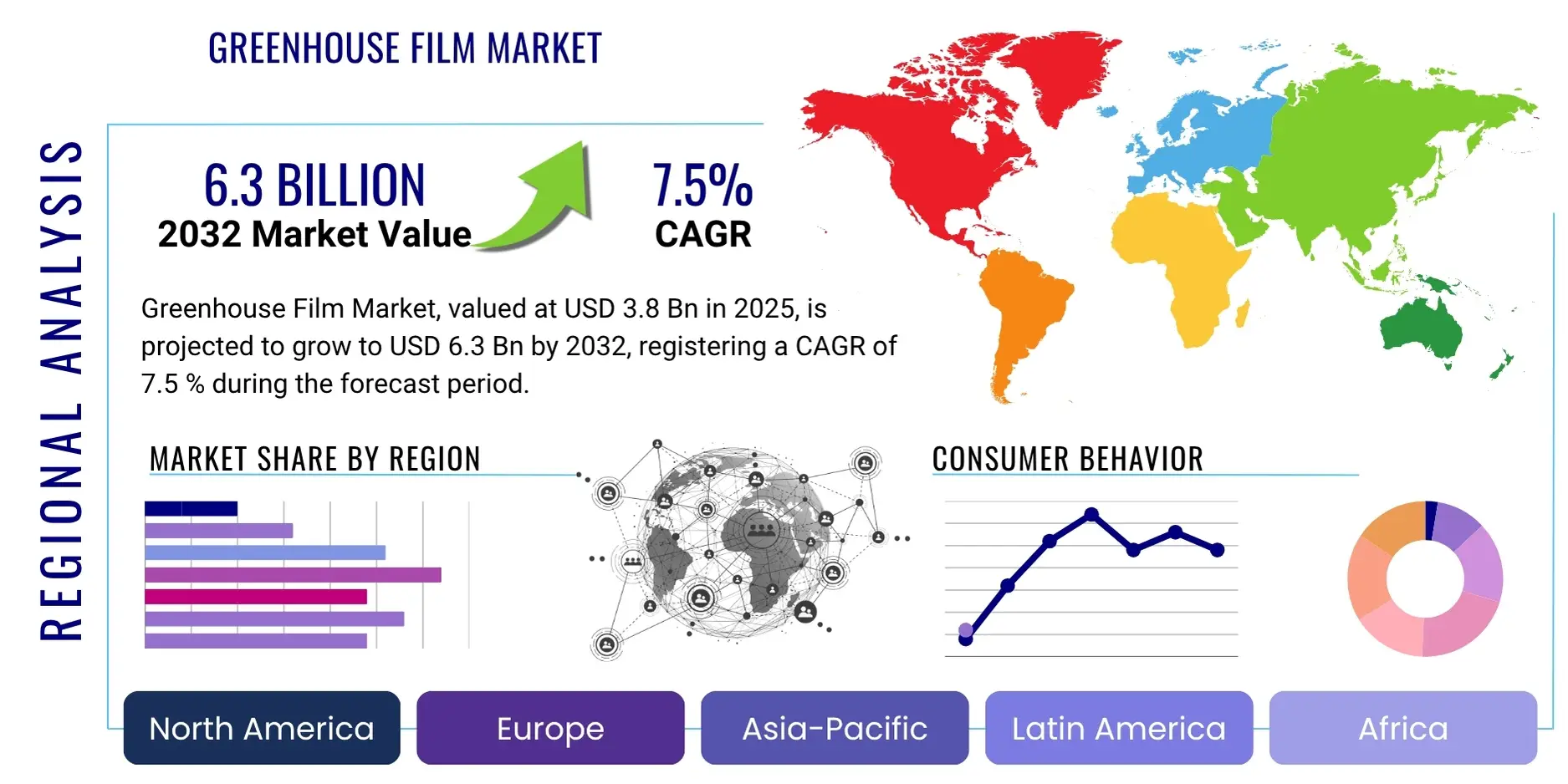

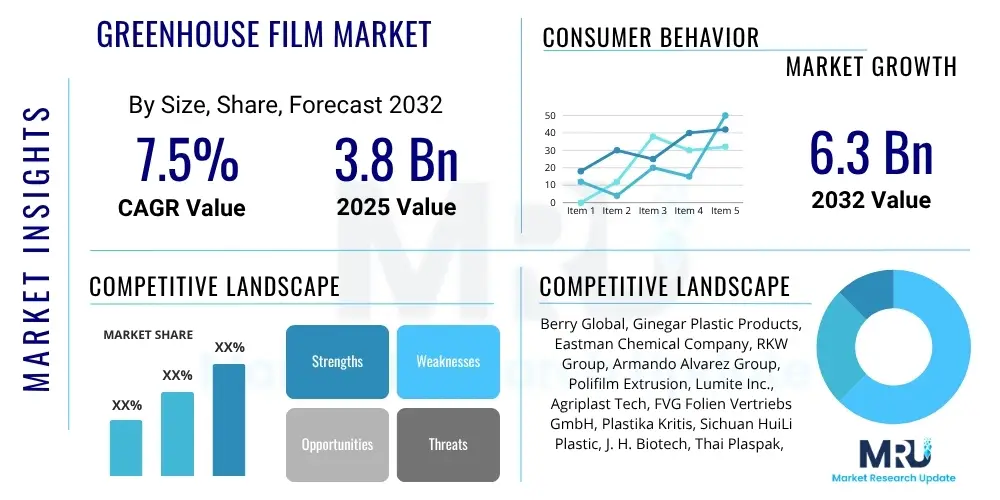

Greenhouse Film Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428323 | Date : Oct, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Greenhouse Film Market Size

The Greenhouse Film Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2025 and 2032. The market is estimated at USD 3.8 Billion in 2025 and is projected to reach USD 6.3 Billion by the end of the forecast period in 2032.

Greenhouse Film Market introduction

The Greenhouse Film Market encompasses the global trade and utilization of specialized plastic films engineered to cover greenhouses, facilitating optimal growing conditions for various agricultural and horticultural crops. These films serve as protective barriers, managing internal climate by controlling temperature, humidity, and light transmission, thereby extending growing seasons and enhancing crop yields. The products available range from basic polyethylene films to advanced multi-layered co-extruded films, each designed with specific properties like UV stabilization, anti-drip capabilities, thermal insulation, and light diffusion. Their primary application lies in controlled environment agriculture, including the cultivation of vegetables, fruits, flowers, and ornamental plants, as well as in nurseries for seedling propagation. The market's robust growth is underpinned by an escalating global population, which necessitates increased food production, coupled with the increasing adoption of protected cultivation techniques to mitigate the impacts of climate variability and improve resource efficiency. These films offer significant benefits by shielding crops from adverse weather, pests, and diseases, reducing water consumption through minimized evaporation, and creating an environment conducive to accelerated plant growth, ultimately leading to higher quality produce and improved profitability for growers.

Product descriptions within this market segment are diverse, reflecting the specialized needs of modern agriculture. Polyethylene (PE) remains the most common base material, often modified with various additives. Ethylene Vinyl Acetate (EVA) films offer superior thermal insulation and elasticity, while Polyvinyl Chloride (PVC) films provide excellent light transmission and durability. Multi-layer co-extrusion technology has revolutionized the market, allowing manufacturers to combine different polymers and additives into a single film structure, imparting multiple functionalities such as improved strength, enhanced UV blocking, infrared reflection, and anti-condensation properties. These advanced films are crucial for precision agriculture, enabling growers to fine-tune environmental parameters to suit specific crop requirements, from delicate ornamentals to robust staple crops, ensuring consistent quality and reduced reliance on outdoor climatic conditions. The continuous innovation in film technology, including the development of photoselective and biodegradable options, further expands their utility and appeal.

Major applications of greenhouse films are predominantly found in commercial horticulture and intensive agriculture operations worldwide. They are instrumental in growing high-value crops like tomatoes, cucumbers, peppers, strawberries, and various cut flowers, ensuring year-round supply irrespective of local climate patterns. Beyond food crops, these films are extensively used in nurseries for germinating seeds and nurturing young plants, providing a stable environment critical for their early development. The benefits derived from using greenhouse films are manifold and include extended growing seasons, allowing multiple harvests per year; protection against extreme weather events such as frost, hail, and excessive rain; significant reduction in pest and disease incidence due to controlled access; and more efficient use of resources like water and fertilizers. Driving factors for market expansion are intrinsically linked to global food security concerns, the growing consumer demand for fresh produce, limited arable land, and the increasing awareness among farmers about the economic advantages of controlled environment agriculture, particularly in regions facing harsh climates or water scarcity. Furthermore, supportive government policies promoting agricultural modernization and sustainable farming practices also contribute significantly to market acceleration.

Greenhouse Film Market Executive Summary

The Greenhouse Film Market is characterized by dynamic business trends, marked by a strong emphasis on sustainability, technological innovation, and strategic partnerships. Companies are increasingly investing in research and development to produce eco-friendly films, including biodegradable and recyclable options, in response to growing environmental concerns and stricter regulations regarding plastic waste. There is a discernible shift towards advanced multi-functional films that integrate features like enhanced thermal insulation, diffused light transmission for better plant growth, and anti-aging properties to extend film lifespan. The market is also witnessing consolidation, with larger players acquiring smaller, specialized manufacturers to expand their product portfolios and geographical reach. Furthermore, the integration of smart technologies, such as sensors and IoT devices, with greenhouse structures is driving demand for films that can complement these systems, enabling more precise climate control and resource management. Business models are evolving, moving towards value-added services, including technical support for film installation and maintenance, to foster stronger customer relationships and ensure optimal product performance, thereby creating a more comprehensive solution for growers.

Regional trends reveal diverse growth trajectories and market dynamics across different geographical areas. Asia Pacific, particularly countries like China, India, and Japan, stands out as a dominant and rapidly expanding market due to its vast agricultural base, increasing population, and governmental support for modern farming techniques. The region's demand is driven by the need for enhanced food production and the adoption of protected cultivation to improve yields and protect crops from monsoon variations and other climatic challenges. North America and Europe, characterized by technologically advanced agricultural sectors, show a steady demand for high-performance, specialized films that cater to precision agriculture and high-value crop cultivation. These regions are also at the forefront of adopting sustainable film solutions. Latin America and the Middle East & Africa are emerging as significant growth markets, fueled by agricultural modernization efforts, increasing investments in horticulture, and the necessity to combat water scarcity and harsh desert climates through controlled environment agriculture. Each region presents unique opportunities and challenges, influencing product development and distribution strategies for market players.

Segmentation trends highlight distinct growth patterns across various film types, thicknesses, applications, and functionalities. By material, polyethylene (PE) films continue to hold the largest market share due to their cost-effectiveness and versatility, though advanced alternatives like EVA and specialized PVC films are gaining traction for their superior performance characteristics. The market is increasingly segmenting by film thickness, with multi-layer films offering enhanced durability and specific functionalities becoming more prevalent, catering to both standard and extended-life applications. In terms of application, commercial horticulture, encompassing fruits, vegetables, and flowers, remains the largest segment, driven by the demand for year-round fresh produce. However, niche applications in medicinal plant cultivation and aquaponics are also expanding. Functional films, such as those providing UV protection, thermal insulation, or anti-drip properties, are experiencing robust demand as growers seek to optimize specific environmental parameters. The trend is towards integrated functionality, where a single film can offer multiple benefits, moving away from single-purpose solutions. This evolving demand for specialized and high-performance films signifies a maturing market focused on efficiency, productivity, and sustainability in agricultural practices.

AI Impact Analysis on Greenhouse Film Market

Common user questions regarding AI's impact on the Greenhouse Film Market often revolve around how artificial intelligence can enhance crop yield, optimize resource utilization, enable predictive maintenance for film integrity, and automate climate control within greenhouses. Growers are keen to understand how AI-driven insights can translate into tangible benefits, such as reduced energy consumption, improved disease detection, and more efficient water management, all while leveraging the protective environment provided by greenhouse films. Concerns are also raised about the initial investment required for AI integration, the complexity of data interpretation, and the need for specialized sensors and compatible film properties. Users anticipate that AI will facilitate a more precise and responsive agricultural system, where the greenhouse film acts as an optimized shell, allowing AI algorithms to fine-tune internal conditions based on real-time data, ultimately leading to higher productivity and sustainability.

The integration of AI in greenhouse agriculture is profoundly transforming how growers manage their operations, subsequently influencing the demand and characteristics of greenhouse films. AI-powered systems can analyze vast amounts of data from environmental sensors—monitoring temperature, humidity, CO2 levels, and light intensity—to provide real-time recommendations for adjusting ventilation, irrigation, and nutrient delivery. This level of precision agriculture, often referred to as smart farming, maximizes the effectiveness of the greenhouse film by ensuring that the controlled environment it creates is utilized to its fullest potential. For instance, AI algorithms can predict optimal times for venting or shading, directly impacting the thermal and light management capabilities of the film. This not only enhances crop growth but also reduces energy waste, making the entire operation more sustainable. The demand for films that can integrate seamlessly with sensor technology, such as those with specific light diffusion or transmission properties, is therefore on the rise, pushing manufacturers to innovate film formulations that complement AI-driven strategies.

Furthermore, AI is instrumental in predictive analytics and automation, significantly impacting the operational efficiency of greenhouses. AI models can forecast pest outbreaks or disease risks by analyzing historical data and current environmental conditions, prompting proactive measures that protect crops within the film-enclosed space. This reduces the reliance on manual inspection and chemical interventions, leading to healthier produce. AI also plays a role in optimizing the lifespan and performance of the greenhouse film itself through structural health monitoring and predictive maintenance. By analyzing stress points or degradation patterns, AI can alert growers to potential film failures before they occur, allowing for timely repairs or replacements and minimizing crop exposure to adverse conditions. This capability extends the effective life of the film and ensures consistent environmental control. Consequently, the evolving role of AI necessitates films that are durable, optically stable over time, and capable of maintaining their functional properties under varied stress, driving manufacturers to develop higher quality, longer-lasting products that support advanced digital agriculture ecosystems.

- AI-driven climate control optimization within greenhouses.

- Enhanced precision irrigation and nutrient delivery through AI analytics.

- Predictive analytics for pest and disease detection, reducing chemical use.

- Automated monitoring of crop health and growth rates.

- Optimization of energy consumption for heating, cooling, and lighting.

- Real-time data interpretation for informed decision-making by growers.

- Potential for smart films integrated with embedded sensors.

- Forecasting optimal harvest times and yield predictions.

- Improved resource efficiency, including water and fertilizer management.

DRO & Impact Forces Of Greenhouse Film Market

The Greenhouse Film Market is propelled by a confluence of powerful drivers that underscore its essential role in modern agriculture. Foremost among these is the rapidly increasing global population, which exerts immense pressure on food supply chains, necessitating higher agricultural output from limited arable land. Controlled environment agriculture, facilitated by greenhouse films, offers a viable solution by maximizing yields per square meter and allowing for year-round cultivation. This demand is further amplified by changing dietary preferences and the growing consumer desire for fresh, locally sourced produce, regardless of seasonal limitations. Technological advancements in film manufacturing, such as multi-layer co-extrusion and the development of specialized additives, continuously enhance film performance, offering improved durability, thermal efficiency, and light management, which attracts more growers to protected cultivation. Government initiatives and subsidies promoting sustainable farming practices, water conservation, and agricultural modernization also provide significant impetus, particularly in developing economies where food security is a critical concern. These drivers collectively create a robust and expanding market for greenhouse films.

Despite the strong growth drivers, the market faces several restraining factors that could impede its trajectory. The most prominent restraint is the volatility in raw material prices, primarily polymers like polyethylene, which are derivatives of crude oil. Fluctuations in petroleum prices directly impact manufacturing costs, leading to unpredictable pricing for end-users and potentially affecting market stability and profitability. Environmental concerns associated with plastic waste also pose a significant challenge. Traditional greenhouse films are made from non-biodegradable plastics, contributing to landfill waste and microplastic pollution after their useful life. This has led to increasing regulatory scrutiny and public pressure for more sustainable alternatives, pushing manufacturers to invest heavily in biodegradable or recyclable films, which often come with higher production costs. Furthermore, the initial capital investment required for setting up a greenhouse infrastructure, including the cost of high-quality films, can be substantial, posing a barrier to entry for small-scale farmers or those in emerging markets with limited access to financing. These factors necessitate continuous innovation and strategic responses from market participants.

Amidst these dynamics, significant opportunities emerge that promise to reshape and expand the Greenhouse Film Market. The burgeoning interest in sustainable and eco-friendly solutions presents a major avenue for growth, particularly in the development and commercialization of biodegradable, bio-based, and fully recyclable greenhouse films. These innovations not only address environmental concerns but also cater to a growing segment of environmentally conscious consumers and growers. The integration of smart technologies, such as IoT sensors, AI-powered climate control systems, and automated irrigation within greenhouses, creates demand for "smart films" that can seamlessly interact with these systems, potentially with embedded functionalities or optimized optical properties. Emerging economies in Asia Pacific, Latin America, and Africa, with their vast agricultural sectors and increasing adoption of modern farming techniques, offer untapped market potential. As climate change intensifies, the need for resilient and protected agriculture systems will only grow, positioning greenhouse films as a critical component in mitigating agricultural risks and ensuring food security. The impact forces influencing the market are profound, including the imperative of global food security, the increasing scarcity of water resources pushing efficient farming methods, and the unpredictable nature of climate change requiring controlled environments. Additionally, the need for enhanced pest and disease control without excessive chemical use reinforces the value proposition of enclosed growing spaces provided by films.

Segmentation Analysis

The Greenhouse Film Market is extensively segmented across several key dimensions including material type, film thickness, application, and specific functionality, each revealing distinct market dynamics and growth potential. This multi-faceted segmentation allows for a granular understanding of grower needs and technological advancements within the industry. Polyethylene continues to dominate the material segment due to its cost-effectiveness and versatility, but specialized polymers like Ethylene Vinyl Acetate (EVA) and multi-layer compositions are gaining significant traction for their enhanced performance attributes such as improved thermal insulation and durability. The diversity in film thickness caters to various climatic conditions and crop requirements, from lightweight films for temporary structures to robust, long-life films for permanent installations. Applications span the broad spectrum of commercial and private horticulture and agriculture, with a pronounced focus on high-value crops that benefit most from controlled environments. Furthermore, films are increasingly differentiated by their advanced functionalities, such as UV blocking, anti-drip properties, and light diffusion, which are critical for optimizing specific aspects of plant growth and greenhouse management. Understanding these segments is crucial for market players to tailor their product offerings and strategic approaches to meet the evolving demands of modern agriculture.

- By Material

- Polyethylene (PE)

- Ethylene Vinyl Acetate (EVA)

- Polyvinyl Chloride (PVC)

- Polycarbonate

- Others (e.g., Ethylene Tetrafluoroethylene (ETFE))

- By Thickness

- 80 Micron to 200 Micron

- Above 200 Micron

- Multi-layer Films

- By Application

- Horticulture (Flowers, Ornamentals)

- Agriculture (Vegetables, Fruits, Field Crops)

- Nurseries

- Others (e.g., Hydroponics, Aquaponics)

- By Functionality

- UV Protection

- Thermal Insulation

- Anti-drip/Anti-fog

- Light Diffusion

- Infrared Blocking

- Anti-aging

- Photoselective

Value Chain Analysis For Greenhouse Film Market

The value chain for the Greenhouse Film Market begins with the upstream analysis, primarily focusing on the sourcing and processing of raw materials. This stage is dominated by petrochemical companies that produce various polymers, most notably polyethylene (LDPE, LLDPE, HDPE), ethylene-vinyl acetate (EVA), and polyvinyl chloride (PVC), which form the fundamental building blocks of greenhouse films. Key additives such as UV stabilizers, antioxidants, anti-drip agents, thermal enhancers, and light diffusers are also sourced from specialty chemical manufacturers. The quality and availability of these raw materials directly impact the final product's performance and cost. Manufacturers of greenhouse films engage in complex extrusion processes, often involving multi-layer co-extrusion technology, to combine these materials and additives into films with desired properties like strength, transparency, durability, and specific optical characteristics. This upstream segment is characterized by significant capital investment in polymer production facilities and a global supply network that influences the pricing and supply chain stability for film producers.

Moving further along the value chain, the film manufacturing stage involves companies that transform raw polymers into finished greenhouse films. These manufacturers utilize advanced extrusion lines, sometimes involving 3-layer, 5-layer, or even 7-layer co-extrusion technologies, to produce films with tailored functionalities. The manufacturing process often includes quality control measures to ensure the films meet specific standards for thickness uniformity, tensile strength, tear resistance, and optical properties. Once manufactured, these films are then distributed through various channels to reach the end-users. The downstream analysis involves the distribution network, which can be direct or indirect. Direct channels include manufacturers selling directly to large commercial growers, agricultural cooperatives, or large-scale greenhouse projects. This approach allows for direct communication, custom orders, and specialized technical support.

Indirect distribution channels involve a network of wholesalers, distributors, and agricultural retailers who stock and supply greenhouse films to a broader range of customers, including small to medium-sized farmers, hobby growers, and local nurseries. These intermediaries play a crucial role in market penetration, especially in fragmented agricultural markets, by providing local access, warehousing, and often offering ancillary services like installation advice or financing options. The ultimate customers, or end-users, are diverse, ranging from large commercial vegetable and flower growers, research institutions, and plant nurseries to individual hobbyists. The choice of distribution channel often depends on the scale of the operation, geographical reach, and the specific needs of the customer segment. An efficient value chain ensures the timely and cost-effective delivery of high-quality greenhouse films, supporting the productivity and profitability of modern agriculture. The strong interplay between raw material suppliers, film manufacturers, and an effective distribution network is vital for sustained market growth and innovation, responding to evolving demands for advanced and sustainable film solutions.

Greenhouse Film Market Potential Customers

The primary potential customers for the Greenhouse Film Market are diverse, encompassing a wide array of end-users deeply embedded within the agricultural and horticultural sectors. Commercial growers represent the largest segment, including large-scale farms specializing in vegetables such as tomatoes, cucumbers, and peppers, as well as fruit cultivation like strawberries and berries. These growers rely heavily on greenhouse films to extend their growing seasons, protect crops from adverse weather conditions and pests, and ensure a consistent, high-quality yield for retail and wholesale markets. They seek durable, high-performance films that offer specific functionalities like thermal insulation, UV protection, and anti-drip properties, which directly impact their operational efficiency and profitability. Their purchasing decisions are often influenced by the film's lifespan, its contribution to energy savings, and its overall return on investment, making them discerning buyers who prioritize long-term value and performance.

Beyond large commercial operations, the market also serves numerous medium and small-scale farmers and independent growers who utilize greenhouses for specialized crops, organic produce, or local market supply. These customers may have smaller operational budgets but still require reliable films to safeguard their crops and enhance productivity. Nurseries, both commercial and institutional, form another significant customer base, using greenhouse films to create controlled environments for germinating seeds, propagating cuttings, and nurturing young plants before transplanting. The stable conditions provided by films are critical for early plant development, ensuring healthy growth and minimizing losses. These nurseries often require films that offer excellent light diffusion and precise temperature control to cater to the delicate needs of seedlings and young plants, emphasizing uniform growth and disease prevention.

Furthermore, educational institutions and agricultural research centers constitute a niche but important customer segment, utilizing greenhouse films for experimental purposes, crop development studies, and demonstrating advanced farming techniques. These organizations often require specialized films that can be adapted for various research parameters. Hobby farmers and home gardeners, while representing a smaller volume individually, collectively contribute to demand, especially for smaller rolls or custom-cut films for backyard greenhouses or polytunnels. As the agricultural landscape evolves with a greater emphasis on sustainability, precision agriculture, and local food systems, the spectrum of potential customers continues to broaden. Each segment, from large enterprises to individual enthusiasts, requires specific film types and services, driving manufacturers to offer a comprehensive range of products and flexible distribution solutions to cater to their varied needs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.8 Billion |

| Market Forecast in 2032 | USD 6.3 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Berry Global, Ginegar Plastic Products, Eastman Chemical Company, RKW Group, Armando Alvarez Group, Polifilm Extrusion, Lumite Inc., Agriplast Tech, FVG Folien Vertriebs GmbH, Plastika Kritis, Sichuan HuiLi Plastic, J. H. Biotech, Thai Plaspak, Eurofilm, Groupe Barbier, Toray Industries, Mitsubishi Chemical Corporation, SABIC, Kuraray Co. Ltd., Borealis AG. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Greenhouse Film Market Key Technology Landscape

The Greenhouse Film Market's technological landscape is characterized by continuous innovation aimed at enhancing film performance, durability, and functionality, ultimately improving agricultural productivity and sustainability. Multi-layer co-extrusion technology stands as a cornerstone, allowing manufacturers to combine different polymer resins and additives into distinct layers within a single film. This process enables the creation of films with highly specialized properties, such as a strong outer layer for tear resistance, an inner layer with anti-drip agents, and middle layers for thermal insulation or light diffusion. This advanced manufacturing technique significantly improves the film's mechanical strength, optical properties, and lifespan compared to traditional single-layer films. For instance, a 5-layer film can simultaneously offer superior UV stabilization, infrared blocking, and anti-condensation capabilities, catering to specific crop requirements and diverse climatic conditions. The precision offered by co-extrusion is critical for developing the next generation of high-performance greenhouse films.

Further technological advancements include the development of specialized additives that impart unique functionalities to the films. UV stabilizers, typically HALS (Hindered Amine Light Stabilizers), are crucial for extending the film's lifespan by protecting the polymer from degradation caused by solar radiation, which is essential for multi-year applications. Thermal films incorporate infrared (IR) blocking additives that trap heat inside the greenhouse during cooler periods, reducing heating costs and preventing nighttime temperature drops. Anti-drip or anti-fog additives are applied to the inner surface of the film to reduce surface tension, causing condensation to form as a thin, continuous sheet rather than large droplets, thus preventing water damage to plants and maintaining light transmission. Light diffusion agents scatter incoming sunlight, creating a more uniform light distribution inside the greenhouse, which minimizes shading and promotes even plant growth, particularly beneficial for crops sensitive to direct sunlight or in regions with intense solar radiation. These additive technologies are constantly being refined to offer greater efficiency and longer lasting effects.

Emerging technologies are also shaping the future of greenhouse films, with a strong focus on sustainability and smart integration. The development of biodegradable and bio-based films, derived from renewable resources, is a significant area of research and development, aiming to address environmental concerns associated with plastic waste. While still facing challenges in terms of cost and performance parity with conventional films, these innovations represent a crucial step towards a more circular economy in agriculture. Moreover, there is growing interest in "smart films" that could potentially integrate embedded sensors, or change their optical properties in response to environmental stimuli, such as temperature or light intensity. Though still largely in the conceptual or early development stages, these technologies envision a future where greenhouse films are active components of a highly intelligent and automated controlled environment agriculture system, capable of dynamic light management or real-time structural monitoring. This continuous technological evolution ensures that greenhouse films remain at the forefront of agricultural innovation, adapting to new challenges and opportunities in food production.

Regional Highlights

- North America: This region, encompassing the United States and Canada, represents a mature market with a high adoption rate of advanced greenhouse film technologies. The demand is driven by the need for year-round production of high-value crops, increasing consumer demand for fresh produce, and technological advancements in controlled environment agriculture. Growers are increasingly investing in multi-layer, high-performance films with thermal insulation and light diffusion properties to optimize energy efficiency and crop yields. Strict environmental regulations and a focus on sustainable agriculture also spur the adoption of more durable and recyclable film solutions. The presence of significant research and development initiatives further contributes to market growth and innovation.

- Europe: The European market is characterized by a strong emphasis on sustainable farming practices, food safety standards, and energy efficiency. Countries like the Netherlands, Spain, and Italy are major players in protected cultivation, driving demand for specialized films that meet stringent performance criteria. The market benefits from government support for agricultural modernization and the push towards reducing carbon footprints in farming. High-quality, long-life films with advanced features like anti-drip, UV stabilization, and infrared blocking are highly sought after to minimize environmental impact and maximize resource utilization. Innovation in biodegradable and bio-based films is also a significant trend here.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for greenhouse films, propelled by its vast agricultural land, enormous population, and escalating food security concerns. Countries such as China, India, Japan, and Australia are witnessing substantial investments in modern greenhouse technologies to boost agricultural output and protect crops from unpredictable weather patterns. The increasing disposable income and changing dietary habits are fueling the demand for fresh fruits, vegetables, and flowers, thereby driving the adoption of greenhouse films. Government initiatives supporting agricultural infrastructure development and technological transfer play a critical role in market expansion, with a growing interest in both cost-effective and functionally enhanced films.

- Latin America: This region presents significant growth opportunities, particularly in countries like Mexico, Brazil, and Chile, which are major exporters of horticultural products. The demand for greenhouse films is driven by the need to optimize crop production for both domestic consumption and international trade, especially against the backdrop of varying climatic conditions. Investment in modern agriculture and protected cultivation techniques is increasing, fostering the adoption of films that offer protection against pests, diseases, and extreme weather, while also extending growing seasons. The market is developing rapidly, moving towards more advanced film solutions to enhance competitiveness.

- Middle East and Africa (MEA): The MEA region is emerging as a crucial market for greenhouse films, largely due to severe water scarcity and challenging arid climates that make traditional open-field farming difficult. Countries like Saudi Arabia, UAE, and Israel are heavily investing in controlled environment agriculture and hydroponics to ensure food security and diversify their agricultural output. Greenhouse films are vital for creating viable growing conditions in harsh environments, enabling significant water savings and consistent yields. Government support and private investments in large-scale agricultural projects are key drivers, with a strong demand for films offering superior thermal insulation, UV protection, and durability to withstand extreme conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Greenhouse Film Market.- Berry Global Inc.

- Ginegar Plastic Products Ltd.

- Eastman Chemical Company

- RKW Group

- Armando Alvarez Group

- Polifilm Extrusion GmbH

- Lumite Inc.

- Agriplast Tech Pvt. Ltd.

- FVG Folien Vertriebs GmbH

- Plastika Kritis S.A.

- Sichuan HuiLi Plastic Co., Ltd.

- J. H. Biotech Co., Ltd.

- Thai Plaspak Co., Ltd.

- Eurofilm Ltd.

- Groupe Barbier

- Toray Industries Inc.

- Mitsubishi Chemical Corporation

- SABIC (Saudi Basic Industries Corporation)

- Kuraray Co. Ltd.

- Borealis AG

Frequently Asked Questions

Analyze common user questions about the Greenhouse Film market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a greenhouse film and why is it important in agriculture?

A greenhouse film is a specialized plastic sheeting used to cover greenhouse structures, creating a controlled environment for crop cultivation. It is crucial because it protects plants from adverse weather, pests, and diseases, extends growing seasons, optimizes light transmission, and helps regulate temperature and humidity, ultimately enhancing crop yield and quality.

What are the primary types of materials used for greenhouse films?

The primary materials include Polyethylene (PE) due to its cost-effectiveness, Ethylene Vinyl Acetate (EVA) for superior thermal insulation and elasticity, and Polyvinyl Chloride (PVC) known for excellent light transmission and durability. Advanced films often use multi-layer co-extrusion, combining these and other polymers with specific additives for enhanced functionality.

How do greenhouse films contribute to sustainable agriculture?

Greenhouse films contribute to sustainability by enabling efficient water use through reduced evaporation, minimizing the need for pesticides due to a controlled environment, extending local food production seasons, and potentially utilizing recycled or biodegradable materials. They optimize resource allocation, leading to higher yields on less land.

What are the key factors driving the growth of the Greenhouse Film Market?

Key growth drivers include the rising global population demanding increased food production, growing adoption of controlled environment agriculture, advancements in film technology offering improved performance, government support for modern farming, and the increasing need for climate change adaptation to ensure food security.

What role does technology play in modern greenhouse films?

Technology is pivotal, driving innovations like multi-layer co-extrusion for enhanced strength and functionality, specialized additives (UV stabilizers, anti-drip agents, thermal reflectors) for specific environmental controls, and the development of smart or biodegradable films. These advancements lead to films that offer improved durability, energy efficiency, and crop-specific growing conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager