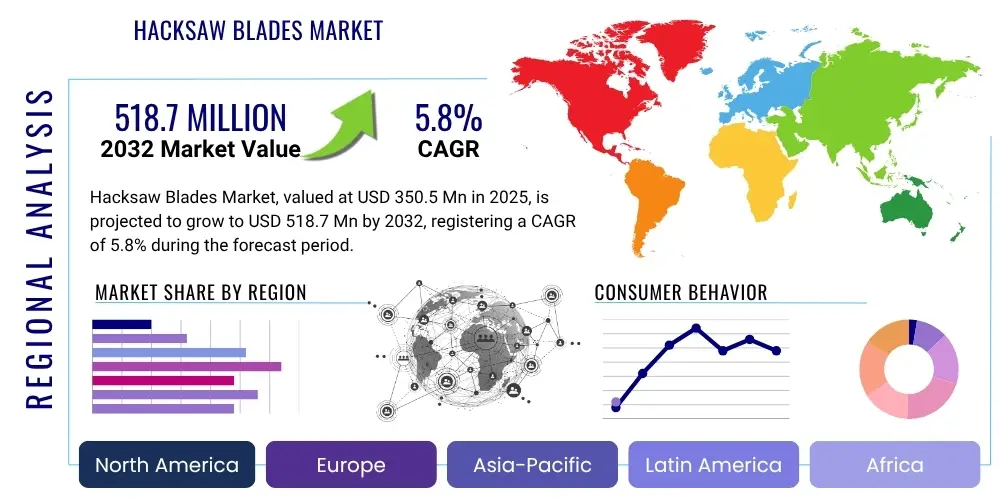

Hacksaw Blades Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430139 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Hacksaw Blades Market Size

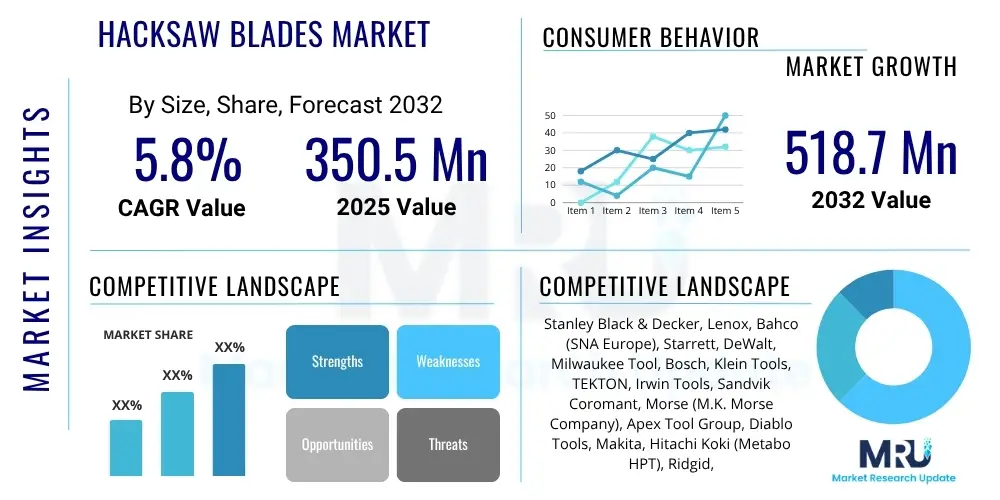

The Hacksaw Blades Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 350.5 million in 2025 and is projected to reach USD 518.7 million by the end of the forecast period in 2032.

Hacksaw Blades Market introduction

The Hacksaw Blades Market encompasses the global production, distribution, and consumption of a fundamental tool used across various industries and for numerous DIY applications. Hacksaw blades are essential cutting instruments, characterized by their slender, toothed metal strips designed to be fitted into a hacksaw frame. These blades are primarily engineered for cutting through a wide array of materials, including metals, plastics, wood, and composite materials, making them indispensable in construction, manufacturing, automotive repair, plumbing, and general maintenance.

The core product description revolves around the diverse materials and designs of these blades, which include carbon steel, bi-metal, and high-speed steel (HSS) constructions, each optimized for specific cutting tasks and material hardness. Major applications span from heavy industrial fabrication to delicate crafting, providing precision and efficiency. Benefits of hacksaw blades include their versatility, portability, cost-effectiveness, and the ability to achieve clean, accurate cuts in situations where power tools might be impractical or excessive. Their universal utility ensures sustained demand across a broad spectrum of end-users.

Driving factors for the Hacksaw Blades Market include continuous expansion in global construction and infrastructure projects, robust growth in the manufacturing sector, and the enduring popularity of DIY activities among consumers. Technological advancements in blade materials and manufacturing processes, leading to enhanced durability, cutting performance, and specialized applications, further propel market growth. The increasing adoption of precision tools in various professional trades also contributes significantly to market expansion.

Hacksaw Blades Market Executive Summary

The Hacksaw Blades Market is experiencing steady growth, driven by sustained industrialization, construction boom across developing economies, and consistent demand from repair and maintenance sectors globally. Business trends indicate a strong focus on innovation in blade materials, emphasizing bi-metal and specialized alloys for enhanced durability and cutting efficiency, alongside a growing shift towards e-commerce platforms for broader market reach. Manufacturers are investing in advanced coating technologies and precise tooth geometries to cater to increasingly demanding material applications, while also exploring sustainable manufacturing practices.

Regionally, the Asia Pacific (APAC) market is poised for significant expansion, fueled by rapid urbanization, substantial infrastructure development projects, and a burgeoning manufacturing base, particularly in countries like China and India. North America and Europe, while mature markets, demonstrate stable demand primarily driven by replacement needs, specialized industrial applications, and a strong DIY culture, with a premium placed on high-performance and ergonomic tool solutions. Emerging economies in Latin America and the Middle East and Africa are also showing promising growth due to expanding construction activities and industrial diversification efforts.

Segment trends highlight the dominance of bi-metal blades due to their superior lifespan and cutting versatility across different materials. High-speed steel blades maintain a strong presence for general-purpose metal cutting, while carbon steel blades remain popular for softer materials and cost-sensitive applications. The increasing demand for precision and efficiency is leading to greater adoption of power hacksaw blades in industrial settings, complementing the enduring requirement for hand hacksaw blades in manual and lighter-duty tasks. The market is witnessing a convergence of demand for both specialized, high-performance blades and economical, general-use variants.

AI Impact Analysis on Hacksaw Blades Market

Common user questions regarding AI's impact on the Hacksaw Blades Market often revolve around how such traditional tools could be influenced by advanced digital technologies. Users are curious about potential applications in manufacturing optimization, material science advancements, supply chain efficiencies, and even demand forecasting. Key themes include the possibility of AI-driven automation in blade production, predictive maintenance for manufacturing equipment, smarter inventory management, and the use of AI to analyze material compositions for developing next-generation blades. Concerns also touch upon the potential for job displacement in manufacturing and the ethical considerations of integrating AI into industrial processes. There is a clear expectation that AI will primarily enhance the backend operations rather than directly impact the user experience of the blade itself, focusing on efficiency, cost reduction, and quality improvement throughout the product lifecycle.

- AI can optimize manufacturing processes, leading to higher precision and reduced waste in blade production.

- Predictive maintenance for production machinery can prevent downtime, ensuring consistent quality and supply of hacksaw blades.

- AI-driven supply chain management improves inventory forecasting and logistics, minimizing stockouts and improving delivery times.

- Material science research aided by AI can accelerate the development of new, more durable, and efficient blade alloys and coatings.

- Automated quality control systems using AI can detect microscopic defects, enhancing the overall reliability and performance of hacksaw blades.

DRO & Impact Forces Of Hacksaw Blades Market

The Hacksaw Blades Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, all shaped by various impact forces. Key drivers include the robust global growth in construction and infrastructure development, particularly in emerging economies, which fuels continuous demand for cutting tools. The expansion of manufacturing industries, encompassing automotive, aerospace, and general fabrication, further propels the market as hacksaw blades remain indispensable for metalworking and assembly tasks. Additionally, the enduring popularity of DIY projects and home improvement activities, supported by readily available tools and instructional content, contributes to consistent consumer demand. Advancements in material science leading to more durable and efficient blade designs also act as a strong driver.

Conversely, several restraints impede the market's growth trajectory. Intense competition from alternative cutting technologies, such as angle grinders, reciprocating saws, and plasma cutters, particularly in heavy-duty industrial applications, poses a significant challenge. The volatility of raw material prices, primarily steel and other alloys, can impact manufacturing costs and ultimately retail prices, affecting profit margins and consumer affordability. Environmental regulations pertaining to manufacturing processes and the disposal of metal waste also present compliance challenges and potentially increase operational costs for manufacturers. Moreover, the inherent nature of hacksaw blades as a mature product means that breakthrough innovations that could drastically expand the market are less frequent.

Opportunities for growth lie in the increasing demand for specialized blades tailored for cutting new and advanced materials, such as composites used in aerospace and automotive sectors. Expansion into untapped emerging markets, where industrialization and construction are nascent but growing rapidly, offers considerable potential. The rise of e-commerce platforms provides manufacturers with direct access to a wider customer base, enabling more efficient distribution and personalized marketing strategies. Furthermore, the development of sustainable manufacturing practices and recyclable blade options could appeal to environmentally conscious consumers and industries, creating a niche market. Impact forces such as global economic cycles directly affect construction and manufacturing spending, influencing demand. Regulatory shifts in labor safety and environmental standards also necessitate adaptation from manufacturers, while rapid technological advancements in competitive tools could disrupt traditional hacksaw blade usage patterns.

Segmentation Analysis

The Hacksaw Blades Market is extensively segmented to reflect the diverse applications, materials, and user requirements inherent in this mature yet evolving industry. Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for end-users to select the most appropriate tools for their specific tasks. Segmentation helps in identifying niche markets, competitive landscapes, and growth opportunities across various dimensions, from the composition of the blade itself to its intended use and how it reaches the consumer. This multi-faceted approach ensures comprehensive market coverage and strategic planning.

- By Material:

- Carbon Steel Hacksaw Blades

- Bi-Metal Hacksaw Blades

- High-Speed Steel (HSS) Hacksaw Blades

- Tungsten Carbide Hacksaw Blades

- Diamond Grit Hacksaw Blades

- By Type:

- Hand Hacksaw Blades

- Power Hacksaw Blades

- Reciprocating Hacksaw Blades

- Band Saw Blades (for power hacksaws)

- By Application:

- Metalworking (Fabrication, Welding, Machining)

- Woodworking

- Plumbing

- Automotive Industry (Repair, Manufacturing)

- Construction and Infrastructure

- Electrical and HVAC

- DIY and Home Improvement

- General Maintenance and Repair

- By Distribution Channel:

- Offline (Hardware Stores, Industrial Suppliers, Specialty Tool Shops)

- Online (E-commerce Platforms, Manufacturer Websites)

Value Chain Analysis For Hacksaw Blades Market

The value chain for the Hacksaw Blades Market begins with the upstream procurement of raw materials, primarily high-quality steel alloys, including carbon steel, high-speed steel, and various bi-metal compositions. Key suppliers in this stage are metallurgical companies that process and provide these specialized metals, often with specific mechanical properties like hardness and flexibility suitable for blade manufacturing. Other upstream components include abrasive materials for grinding, various coatings (e.g., TiN, TiCN) for enhanced durability and friction reduction, and packaging materials. The efficiency and cost-effectiveness at this stage directly influence the final product quality and price competitiveness, making strong supplier relationships crucial for manufacturers.

Following the raw material procurement, manufacturing involves several complex processes such as strip preparation, tooth cutting (stamping, milling, or laser cutting), heat treatment for hardening, grinding, welding (for bi-metal blades), and application of coatings. Quality control is paramount at every stage to ensure blade consistency, sharpness, and durability. Once manufactured, the blades are then packaged and enter the distribution phase. This phase can involve both direct and indirect channels. Direct distribution typically involves manufacturers selling large quantities directly to major industrial clients, original equipment manufacturers (OEMs), or large construction firms, often through dedicated sales teams or specialized industrial suppliers.

Indirect distribution forms the broader part of the downstream activities, reaching a wider array of end-users. This involves a network of wholesalers, distributors, hardware stores, home improvement centers, and a rapidly expanding e-commerce presence. Wholesalers and distributors serve as intermediaries, stocking products from multiple manufacturers and supplying to smaller retailers and contractors. Hardware stores and DIY centers cater to individual consumers and small businesses, providing accessibility and immediate availability. Online channels, including major e-commerce platforms and manufacturer-owned websites, offer convenience, broader product selection, and competitive pricing, reaching customers globally and allowing for efficient comparison and purchase. Effective management of this multi-tiered distribution network is vital for market penetration and customer reach.

Hacksaw Blades Market Potential Customers

The Hacksaw Blades Market caters to a diverse range of potential customers, spanning both professional and consumer segments. On the professional front, major end-users include entities within the metalworking and fabrication industries, such as welding shops, machine shops, and metal foundries, where precise and efficient cutting of various metal profiles is a daily requirement. The automotive sector, encompassing both manufacturing plants and repair garages, relies heavily on hacksaw blades for tasks like exhaust system repairs, panel cutting, and component fabrication. Construction and infrastructure companies utilize these blades for cutting pipes, conduits, structural elements, and rebar, making them indispensable on job sites.

Furthermore, skilled trades like plumbing, electrical work, and carpentry represent significant customer segments. Plumbers use hacksaw blades for cutting pipes made of copper, PVC, and steel, while electricians employ them for cutting conduits and wiring channels. Carpenters, though often using specialized woodworking saws, may still use hacksaws for cutting nails, bolts, or small metal fittings embedded in wood. HVAC technicians also depend on hacksaw blades for cutting ductwork and various fittings. Industrial maintenance departments across various sectors, from manufacturing plants to utility providers, consistently purchase hacksaw blades for routine repairs and modifications.

On the consumer side, the market for hacksaw blades is robust among DIY enthusiasts and hobbyists. Individuals undertaking home renovation projects, small repairs, or creative crafting often find hacksaw blades to be versatile and cost-effective tools for cutting a variety of materials encountered around the house or workshop. This segment values ease of use, affordability, and the ability to perform tasks that do not warrant specialized power tools. Educational institutions and vocational training centers also represent a steady customer base, equipping students with fundamental tool skills. The broad applicability of hacksaw blades ensures a consistently wide and varied customer base across industrial, commercial, and residential applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 350.5 million |

| Market Forecast in 2032 | USD 518.7 million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stanley Black & Decker, Lenox, Bahco (SNA Europe), Starrett, DeWalt, Milwaukee Tool, Bosch, Klein Tools, TEKTON, Irwin Tools, Sandvik Coromant, Morse (M.K. Morse Company), Apex Tool Group, Diablo Tools, Makita, Hitachi Koki (Metabo HPT), Ridgid, Dremel, Disston, Olson Saw |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hacksaw Blades Market Key Technology Landscape

The Hacksaw Blades Market is characterized by continuous advancements in metallurgical science and manufacturing processes, aimed at enhancing blade performance, durability, and versatility. A pivotal technology is the development and refinement of bi-metal construction, where a high-speed steel cutting edge is electron beam welded to a flexible alloy steel back. This combination offers the superior cutting ability of HSS with the shatter resistance and flexibility of alloy steel, significantly improving safety and lifespan. Further material innovations include the use of cobalt alloys in HSS for increased heat resistance and hardness, as well as the integration of tungsten carbide grit or diamond particles for specialized blades designed to cut extremely hard or abrasive materials like ceramics, cast iron, and composites.

Beyond material composition, advancements in tooth geometry and grinding techniques play a crucial role. Manufacturers are employing precision laser cutting and advanced grinding processes to achieve optimal tooth profiles, varying tooth pitches (variable pitch) for smoother cutting and reduced vibration, and specific rake angles tailored for different materials. This allows for more efficient chip evacuation and reduced friction, leading to faster cuts and longer blade life. Heat treatment technologies, such as cryogenic treatment or advanced tempering processes, are also continuously refined to optimize the crystal structure of the steel, imparting superior hardness and wear resistance without compromising toughness. These processes are critical for ensuring the blade retains its sharpness under demanding conditions.

Surface coating technologies represent another significant area of innovation. Coatings such as Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Aluminum Titanium Nitride (AlTiN) are applied to blades to reduce friction, increase surface hardness, and enhance resistance to wear and heat. These advanced coatings prolong blade life, improve cutting speed, and allow blades to perform effectively in aggressive cutting environments. Furthermore, manufacturers are increasingly adopting automated and robotic manufacturing systems for greater precision, consistency, and efficiency in production. Digital quality control systems, leveraging optical inspection and sensor technology, ensure that each blade meets stringent performance standards. These technological advancements collectively contribute to higher performance, longer-lasting, and more specialized hacksaw blades, meeting the evolving demands of both industrial and consumer markets.

Regional Highlights

- North America: A mature market characterized by a strong demand for high-quality, durable hacksaw blades driven by well-established manufacturing, construction, and automotive industries. Replacement demand and specialized applications, particularly in industrial maintenance and DIY sectors, contribute significantly. Emphasis on premium brands and ergonomic design is prevalent.

- Europe: Similar to North America, Europe is a mature market focusing on precision, sustainability, and innovative blade technologies. Strict quality standards and environmental regulations influence product development. Germany, the UK, and France are key contributors, driven by advanced manufacturing and a robust professional trades sector.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, extensive infrastructure development, and burgeoning manufacturing activities, especially in China, India, and Southeast Asian countries. High demand for both cost-effective general-purpose blades and increasingly for higher-performance bi-metal options due to economic growth and urbanization.

- Latin America: Experiencing consistent growth driven by ongoing construction projects, expanding automotive production, and increasing industrial investment. Brazil and Mexico are leading markets, with a growing appetite for both domestic and imported hacksaw blades to support their developing economies.

- Middle East and Africa (MEA): An emerging market propelled by significant investments in construction, oil and gas, and infrastructure development, particularly in the GCC countries and parts of Africa. Demand for hacksaw blades is steadily rising to support these large-scale projects and a growing industrial base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hacksaw Blades Market.- Stanley Black & Decker

- Lenox (a Stanley Black & Decker brand)

- Bahco (SNA Europe)

- The L.S. Starrett Company

- DeWalt (a Stanley Black & Decker brand)

- Milwaukee Tool (a Techtronic Industries brand)

- Bosch

- Klein Tools

- TEKTON

- Irwin Tools (a Stanley Black & Decker brand)

- Sandvik Coromant (a Sandvik Group company)

- M.K. Morse Company

- Apex Tool Group

- Diablo Tools (a Freud America Inc. brand)

- Makita Corporation

- Hitachi Koki (Metabo HPT)

- RIDGID (a Emerson brand)

- Dremel (a Bosch brand)

- Disston Company

- Olson Saw Company

Frequently Asked Questions

What are hacksaw blades primarily used for?

Hacksaw blades are versatile cutting tools primarily used for cutting metals, but they are also effective on plastics, wood, and various composite materials across construction, manufacturing, plumbing, and DIY applications.

What are the main types of hacksaw blades available?

The main types include hand hacksaw blades for manual use and power hacksaw blades (such as reciprocating and band saw blades) for mechanized cutting. They are also categorized by material, including carbon steel, bi-metal, and high-speed steel.

How is the Hacksaw Blades Market projected to grow?

The Hacksaw Blades Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% from 2025 to 2032, driven by industrialization, construction activities, and advancements in blade technology.

What materials are hacksaw blades commonly made from?

Hacksaw blades are commonly made from carbon steel for general use, high-speed steel (HSS) for durability, and bi-metal (HSS cutting edge welded to a flexible steel back) for superior performance and longevity.

What factors are driving the demand for hacksaw blades?

Key drivers include global growth in construction and infrastructure, expansion of manufacturing industries, the increasing popularity of DIY activities, and continuous technological advancements in blade materials and designs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Hacksaw Blades Market Statistics 2025 Analysis By Application (Metal, Plastic), By Type (Bi-Metal, High Speed Steel, Carbon Steel), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- High Speed Hacksaw Blades Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Band Saw Blades, Circular Saw Blades, Other), By Application (Pipe Cutting, Solid Cutting, Wood Cutting, Plastic Cutting, Machinable Metal Cutting, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager