Healthcare 3D Printing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428994 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Healthcare 3D Printing Market Size

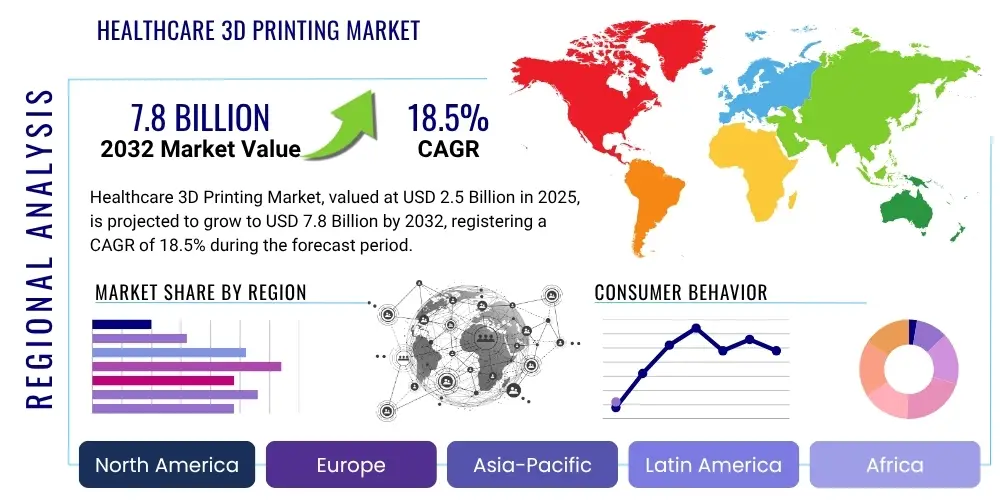

The Healthcare 3D Printing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2025 and 2032. The market is estimated at USD 2.5 Billion in 2025 and is projected to reach USD 7.8 Billion by the end of the forecast period in 2032.

Healthcare 3D Printing Market introduction

Healthcare 3D printing, also known as additive manufacturing, represents a transformative technology within the medical sector, enabling the creation of intricate, patient-specific anatomical models, surgical guides, prosthetics, implants, and even biological tissues. This innovative approach involves building three-dimensional objects layer by layer from a digital design, utilizing a range of biocompatible materials such as polymers, metals, ceramics, and advanced biomaterials. The core product offering includes 3D printers specifically designed for medical applications, a diverse array of specialized printing materials, and comprehensive services spanning design, prototyping, and post-processing.

Major applications of healthcare 3D printing extend across numerous medical disciplines, including dentistry for crowns and aligners, orthopedics for customized implants and prosthetics, surgical planning for complex procedures, and increasingly, regenerative medicine for tissue engineering and bioprinting. The primary benefits derived from this technology are unparalleled customization, enabling tailored medical solutions that precisely fit individual patient anatomies, leading to improved surgical outcomes and patient comfort. Furthermore, it enhances precision in medical procedures, reduces surgical times, and offers the potential for cost-effectiveness through optimized design and material usage. Key driving factors propelling market growth include the escalating demand for personalized medicine, a global rise in the geriatric population, the increasing prevalence of chronic diseases requiring advanced treatment solutions, significant advancements in bioprinting research, and growing investments in healthcare infrastructure and R&D.

Healthcare 3D Printing Market Executive Summary

The Healthcare 3D Printing Market is experiencing robust expansion, driven by continuous technological innovation and the increasing adoption of personalized medical solutions. Key business trends include a surge in strategic collaborations between technology providers and healthcare institutions, a focused emphasis on the development of novel biocompatible materials, and the expansion of service offerings to encompass the entire product lifecycle from design to clinical application. Companies are investing heavily in research and development to overcome regulatory hurdles and enhance the capabilities of bioprinting, paving the way for more complex tissue and organ fabrication, thereby solidifying the market's trajectory towards advanced regenerative medicine applications.

Regionally, North America maintains its dominance due to high healthcare expenditure, significant R&D investments, and a well-established regulatory framework supporting technological integration. Europe is also a major contributor, characterized by advanced healthcare systems and strong academic research, while the Asia Pacific region is emerging as the fastest-growing market. This growth in APAC is fueled by improving healthcare infrastructure, a large patient pool, and increasing awareness regarding the benefits of 3D printing in medicine. Developing economies are presenting significant opportunities as they invest in modernizing their healthcare capabilities, driven by a desire to provide advanced treatment options and enhance patient care accessibility.

In terms of segment trends, the materials segment, particularly advanced polymers and biomaterials, is witnessing substantial growth due to the demand for diverse and specialized applications. The services segment is also rapidly expanding, providing crucial support for design, prototyping, and post-processing, which are essential for clinical implementation. Furthermore, the application-specific segments such as surgical guides and dental applications continue to demonstrate strong uptake due to their proven efficacy and tangible patient benefits. Bioprinting, though still nascent, represents a high-potential segment, with ongoing research promising to unlock groundbreaking therapeutic possibilities in tissue engineering and drug discovery, indicating a shift towards more complex and life-altering applications in the long term.

AI Impact Analysis on Healthcare 3D Printing Market

Common user inquiries regarding the influence of Artificial Intelligence (AI) on the Healthcare 3D Printing Market frequently revolve around its potential to enhance design processes, optimize material usage, improve manufacturing precision, accelerate research and development, and facilitate personalized treatment strategies. Users are keen to understand how AI can automate complex design tasks, predict optimal printing parameters, and integrate with patient data to create highly customized medical devices and tissues. There is significant interest in AI's role in advancing bioprinting capabilities, particularly in ensuring the viability and functionality of printed biological structures, while also acknowledging concerns about data privacy, ethical considerations, and the regulatory landscape governing AI-driven medical innovations. The key themes highlight expectations for AI to deliver unprecedented levels of precision, efficiency, and personalization, fundamentally transforming the capabilities and accessibility of 3D printed healthcare solutions.

- AI optimizes design of patient-specific implants and prosthetics through generative design algorithms.

- Predictive analytics powered by AI enhances material selection and print parameter optimization, reducing waste and improving product quality.

- AI-driven image processing improves the accuracy of converting medical scans into 3D printable models for surgical planning.

- Automated quality control systems utilizing AI identify defects in printed medical devices, ensuring higher safety standards.

- AI accelerates drug discovery by facilitating the bioprinting of complex organ-on-a-chip models for high-throughput screening.

- Machine learning algorithms enable personalized treatment planning by analyzing vast patient data to customize surgical guides and devices.

- AI aids in real-time monitoring and adjustment of bioprinting processes, improving cell viability and tissue structure fidelity.

DRO & Impact Forces Of Healthcare 3D Printing Market

The Healthcare 3D Printing Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, shaped by powerful impact forces. Key drivers include the ever-increasing demand for personalized medical devices and patient-specific solutions, which 3D printing inherently supports by allowing for intricate customization. Furthermore, advancements in bioprinting research and regenerative medicine are opening new frontiers for tissue and organ fabrication, attracting substantial investment and fostering innovation. The global aging population and the rising incidence of chronic diseases also contribute to market growth, as 3D printing offers advanced solutions for surgical procedures, implants, and prosthetics that address complex medical needs more effectively than traditional methods. Government support through funding and favorable regulatory policies, alongside increased healthcare expenditure worldwide, further propels market expansion.

Despite these strong drivers, the market faces several notable restraints. The high initial capital investment required for 3D printing equipment and specialized materials can be a significant barrier for smaller healthcare facilities or emerging markets. The complex and evolving regulatory landscape for medical devices and bioprinted tissues poses challenges, demanding extensive testing and approval processes that can delay market entry. Moreover, a shortage of skilled professionals with expertise in both additive manufacturing and medical applications limits widespread adoption. Technical limitations, such as the restricted range of biocompatible materials suitable for all applications and the current scalability issues in bioprinting, also hinder market growth. Addressing these challenges requires concerted efforts in training, standardization, and continued R&D to broaden material compatibility and streamline regulatory pathways.

Opportunities for growth are abundant, particularly in emerging economies where healthcare infrastructure is rapidly developing and there is a strong demand for advanced medical technologies. The expanding scope of applications beyond traditional implants to include drug discovery, patient education models, and point-of-care manufacturing presents lucrative avenues. The convergence of 3D printing with artificial intelligence and machine learning is also creating new possibilities for design optimization, process automation, and personalized medicine, unlocking higher levels of precision and efficiency. Impact forces such as the strong bargaining power of buyers, driven by increasing competition and the availability of diverse solutions, compel manufacturers to continuously innovate and offer competitive pricing. The threat of new entrants, although moderated by high capital costs and regulatory complexities, encourages existing players to maintain technological leadership. The threat of substitutes, while limited for highly customized solutions, exists from conventional manufacturing methods for more standardized products, necessitating continuous demonstration of the unique value proposition of 3D printing. Intense competitive rivalry among key players drives innovation, product differentiation, and strategic alliances to capture market share.

Segmentation Analysis

The Healthcare 3D Printing Market is comprehensively segmented across various dimensions to provide a detailed understanding of its dynamics and growth prospects. These segmentations are critical for identifying specific market trends, target audiences, and areas of high growth potential. The market is typically analyzed by component, technology, application, and end-user, each offering unique insights into the structure and operational aspects of this innovative sector. Understanding these segments helps stakeholders, from manufacturers to healthcare providers and investors, to strategically position themselves and tailor their offerings to specific market needs and opportunities.

- By Component:

- Printers

- Materials

- Polymers

- Metals

- Ceramics

- Biomaterials

- Services

- Designing and Consulting

- Prototyping

- Post-processing

- By Technology:

- Stereolithography (SLA)

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- Digital Light Processing (DLP)

- Binder Jetting

- PolyJet

- Bioprinting

- Other Technologies

- By Application:

- Surgical Guides

- Implants

- Prosthetics and Orthotics

- Dental Applications

- Crowns and Bridges

- Dental Models

- Clear Aligners

- Surgical Guides

- Tissue Engineering and Regenerative Medicine

- Drug Discovery and Development

- Medical Tools and Devices

- Anatomical Models for Education and Training

- By End-User:

- Hospitals and Surgical Centers

- Academic and Research Institutions

- Pharmaceutical and Biotechnology Companies

- Medical Device Companies

- Contract Research Organizations (CROs)

- Dental Clinics and Labs

Value Chain Analysis For Healthcare 3D Printing Market

The value chain for the Healthcare 3D Printing Market encompasses a series of interconnected activities, beginning with upstream raw material suppliers and extending through manufacturing, distribution, and ultimately to the end-users. The upstream segment involves the provision of specialized materials, including biocompatible polymers, metals like titanium, ceramics, and advanced biomaterials such as hydrogels and bio-inks. These suppliers are crucial as the quality and characteristics of their materials directly impact the final product's performance and regulatory approval. Research and development also play a significant upstream role, constantly innovating new materials and processes that push the boundaries of medical applications.

Midstream activities primarily involve the design and manufacturing phases, where specialized software is used to create digital models from patient scans, followed by the actual 3D printing process. This segment includes printer manufacturers, software developers, and specialized service bureaus that offer design, printing, and post-processing services. Downstream activities focus on the distribution and end-use of the 3D printed products. Distribution channels can be direct, with manufacturers selling directly to hospitals, clinics, or research institutions, particularly for high-value or highly customized items. Indirect distribution involves third-party distributors or medical device companies that integrate 3D printed components into their broader product portfolios, reaching a wider array of healthcare providers. The end-users, such as hospitals, surgical centers, dental clinics, and research institutions, form the final link, benefiting from patient-specific implants, surgical guides, and anatomical models that enhance patient care and outcomes.

Healthcare 3D Printing Market Potential Customers

The primary beneficiaries and key potential customers for healthcare 3D printing products and services are diverse, spanning various segments of the medical and research communities. Hospitals and surgical centers represent a significant customer base, adopting 3D printing for patient-specific surgical planning, customized implants, and anatomical models that improve surgical precision and reduce operating times. Dental clinics and laboratories are also major end-users, leveraging the technology for producing crowns, bridges, dental models, and clear aligners with high accuracy and efficiency, revolutionizing orthodontic and restorative dentistry practices.

Academic and research institutions constitute another vital segment, utilizing 3D printing for advanced research in tissue engineering, drug discovery, and medical education, creating complex biological structures and realistic training models. Pharmaceutical and biotechnology companies are increasingly exploring 3D printing for creating organ-on-a-chip models, drug delivery systems, and personalized dosage forms, accelerating drug development and testing processes. Furthermore, medical device manufacturers frequently integrate 3D printing into their production lines for prototyping, manufacturing custom components, and producing specialized tools. Contract Research Organizations (CROs) also serve as potential customers, employing 3D printing capabilities to support various clinical trials and research projects for their clients, underlining the broad applicability and growing integration of this technology across the healthcare ecosystem.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.5 Billion |

| Market Forecast in 2032 | USD 7.8 Billion |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3D Systems Corporation, Stratasys Ltd., Materialise NV, EOS GmbH, Voxeljet AG, EnvisionTEC GmbH (ETEC), GE Additive, HP Inc., Formlabs Inc., Organovo Holdings Inc., Cellink AB (BICO Group), Renishaw plc, Aspect Biosystems Ltd., Carbon Inc., Sintx Technologies Inc., Desktop Metal Inc., Nexa3D, Prodways Group, UnionTech Inc., XJet Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Healthcare 3D Printing Market Key Technology Landscape

The Healthcare 3D Printing Market is characterized by a diverse and rapidly evolving technology landscape, with various additive manufacturing techniques tailored to specific medical applications. Stereolithography (SLA) is widely used for creating highly detailed, smooth surface models and guides, leveraging UV light to cure liquid photopolymer resins layer by layer. Fused Deposition Modeling (FDM) offers cost-effectiveness and versatility, primarily using thermoplastic filaments to build robust parts, often for anatomical models and some prosthetic components. Selective Laser Sintering (SLS) is prominent for its ability to produce functional parts from powdered polymers, metals, or ceramics, suitable for durable implants and complex prototypes due to its material diversity and absence of support structures.

Digital Light Processing (DLP) is gaining traction for its speed and resolution, using a digital light projector to cure an entire layer of resin at once, which is beneficial for high-throughput production of dental aligners and surgical guides. Bioprinting represents a cutting-edge segment, utilizing bio-inks laden with living cells to construct functional tissues and organs, a technology critical for regenerative medicine and drug testing. Other technologies, such as PolyJet and Binder Jetting, also contribute significantly; PolyJet offers multi-material and multi-color printing capabilities for realistic anatomical models, while Binder Jetting is used for high-volume metal and ceramic part production. The continuous innovation in these technologies, coupled with advancements in material science, is expanding the possibilities for customization, precision, and application in the healthcare sector, driving the market forward.

Regional Highlights

- North America: This region holds the largest share of the healthcare 3D printing market, driven by high healthcare expenditure, significant research and development activities, and a robust presence of key market players and technological innovators. The United States, in particular, leads in adopting advanced medical technologies, supported by favorable government initiatives and extensive investment in personalized medicine.

- Europe: Europe is another prominent region, characterized by advanced healthcare infrastructure, strong academic research in medical technology, and supportive regulatory frameworks. Countries like Germany, the UK, and France are at the forefront, with increasing collaborations between research institutions and industry players to develop and commercialize 3D printed medical devices and solutions.

- Asia Pacific (APAC): The APAC region is projected to exhibit the highest growth rate during the forecast period. This growth is attributed to improving healthcare facilities, a large and aging population, rising awareness of advanced treatment options, and increasing governmental support for healthcare innovation in countries such as China, India, and Japan. Rapid economic development and increasing foreign investments further bolster market expansion.

- Latin America: This region shows significant potential for growth, driven by increasing healthcare investments and a growing demand for advanced medical solutions. Countries like Brazil and Mexico are emerging as key markets, with a focus on improving healthcare access and modernizing medical infrastructure, creating opportunities for 3D printing technologies.

- Middle East and Africa (MEA): The MEA region is witnessing gradual adoption of healthcare 3D printing, primarily in technologically advanced countries such as UAE, Saudi Arabia, and South Africa. Investments in healthcare tourism and infrastructure development, coupled with a rising prevalence of chronic diseases, are expected to fuel market growth, although regulatory and economic challenges persist.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Healthcare 3D Printing Market.- 3D Systems Corporation

- Stratasys Ltd.

- Materialise NV

- EOS GmbH

- Voxeljet AG

- EnvisionTEC GmbH (ETEC)

- GE Additive

- HP Inc.

- Formlabs Inc.

- Organovo Holdings Inc.

- Cellink AB (BICO Group)

- Renishaw plc

- Aspect Biosystems Ltd.

- Carbon Inc.

- Sintx Technologies Inc.

- Desktop Metal Inc.

- Nexa3D

- Prodways Group

- UnionTech Inc.

- XJet Ltd.

Frequently Asked Questions

What are the primary applications of 3D printing in healthcare?

The primary applications include patient-specific surgical guides, custom implants and prosthetics, dental devices (crowns, bridges, aligners), anatomical models for surgical planning and education, and advanced bioprinting for tissue engineering and drug discovery platforms.

What materials are commonly used in healthcare 3D printing?

Common materials include biocompatible polymers (e.g., PEEK, PLA, ABS), metals (e.g., titanium, stainless steel), ceramics (e.g., zirconia, alumina), and advanced biomaterials (e.g., hydrogels, collagen, alginate) used in bioprinting.

What are the key benefits of using 3D printing in healthcare?

Key benefits include enhanced personalization of medical devices, improved surgical precision, reduced surgical times, better patient outcomes and comfort, and the potential for cost-effectiveness through optimized designs and on-demand manufacturing.

What challenges does the healthcare 3D printing market face?

Challenges include high initial capital investment costs, complex and evolving regulatory pathways for approval, limitations in material availability for all applications, and a shortage of skilled professionals with expertise in both 3D printing and medical fields.

How is AI impacting the future of healthcare 3D printing?

AI is set to revolutionize healthcare 3D printing by optimizing design processes, enabling predictive analytics for material and print parameters, automating quality control, accelerating drug discovery through bioprinted models, and facilitating highly personalized treatment plans.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager