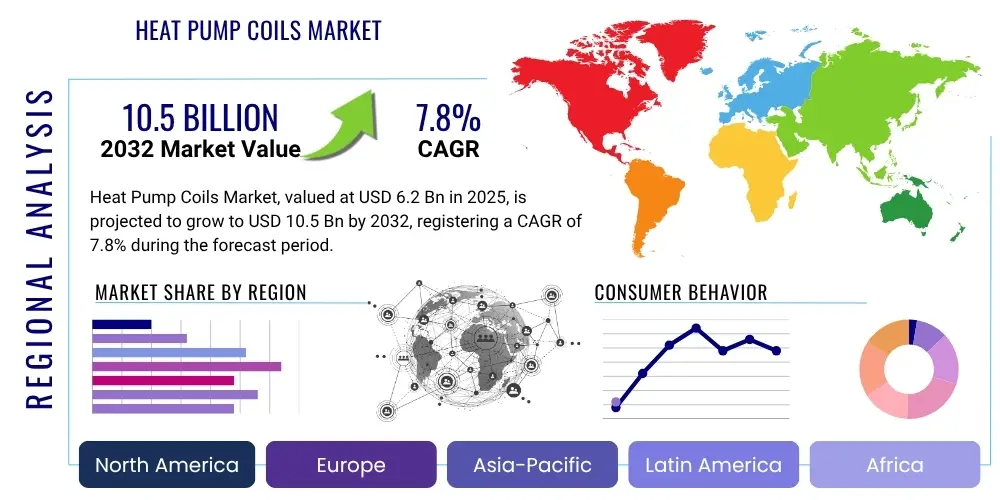

Heat Pump Coils Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429643 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Heat Pump Coils Market Size

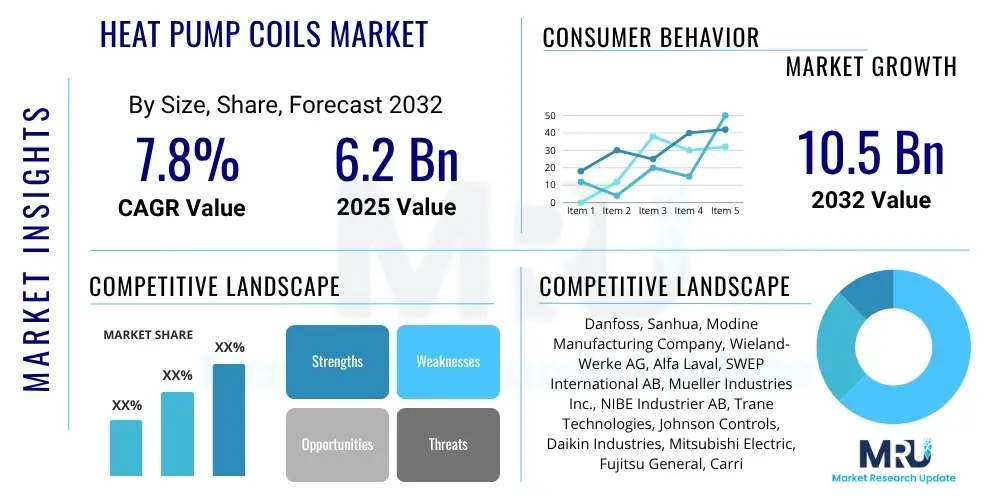

The Heat Pump Coils Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 6.2 billion in 2025 and is projected to reach USD 10.5 billion by the end of the forecast period in 2032.

Heat Pump Coils Market introduction

The Heat Pump Coils Market is experiencing robust growth driven by the escalating demand for energy-efficient heating and cooling solutions worldwide. Heat pump coils are critical components in heat pump systems, facilitating the essential heat exchange processes that enable these systems to transfer thermal energy. These coils, typically made from materials like copper or aluminum, function as evaporators and condensers, absorbing heat from a source (such as air, water, or ground) and releasing it to a sink, or vice versa. This fundamental operation underpins the performance and efficiency of modern heat pump technology, making the coils indispensable for their widespread adoption in diverse applications.

The product description for heat pump coils encompasses a variety of designs and materials optimized for different refrigerant types and operational environments. They can be categorized by their function within the heat pump cycle, primarily as evaporator coils which absorb heat and condenser coils which release it. Furthermore, advances in coil technology include microchannel coils, fin-and-tube coils, and specialized coatings designed to enhance heat transfer efficiency and corrosion resistance. The material choice significantly impacts durability, cost, and performance, with copper coils offering excellent thermal conductivity and aluminum coils providing lighter weight and often more cost-effective solutions.

Major applications of heat pump coils span across residential, commercial, and industrial sectors. In residential buildings, they are integral to air-source, ground-source, and water-source heat pumps used for space heating, cooling, and domestic hot water. Commercial applications include large HVAC systems for offices, retail spaces, and public buildings, where energy efficiency is paramount for operational costs. Industrial processes are increasingly adopting heat pumps for waste heat recovery and process heating/cooling, leveraging the coils for high-temperature heat transfer. The primary benefits include significant energy savings, reduced greenhouse gas emissions, enhanced indoor comfort, and operational flexibility. Key driving factors for market expansion include stringent energy efficiency regulations, growing environmental concerns, rising electricity prices, and governmental incentives promoting sustainable building technologies.

Heat Pump Coils Market Executive Summary

The Heat Pump Coils Market is undergoing a transformative period marked by innovation and expanding adoption across various sectors. Business trends indicate a strong focus on research and development to improve coil designs, enhance material efficiency, and integrate smart technologies for optimized performance. There is also a notable trend towards strategic partnerships and collaborations among manufacturers, technology providers, and HVAC system integrators to develop more comprehensive and sustainable heating and cooling solutions. Companies are investing in automated manufacturing processes to meet the increasing demand and ensure high quality standards, while also exploring advanced materials that offer better heat transfer capabilities and corrosion resistance, aligning with the industry's push for extended product lifecycles and reduced environmental impact. The market is witnessing a shift towards coils optimized for low Global Warming Potential (GWP) refrigerants, driven by evolving environmental regulations.

Regional trends reveal distinct growth patterns and drivers. Europe is at the forefront of heat pump adoption, spurred by ambitious decarbonization targets and significant government subsidies for heat pump installations, particularly in countries like Germany, France, and the UK. North America is experiencing steady growth, supported by federal and state incentives aimed at promoting energy efficiency and electrification of heating, alongside increasing consumer awareness regarding the long-term cost savings of heat pumps. The Asia Pacific region presents a substantial growth opportunity, driven by rapid urbanization, industrialization, and a rising middle class seeking modern, energy-efficient HVAC solutions, particularly in China, Japan, and South Korea. Emerging markets in Latin America, the Middle East, and Africa are also showing nascent growth, as infrastructure development and increasing environmental consciousness begin to drive demand for efficient heating and cooling technologies.

Segment trends highlight particular areas of accelerated growth within the heat pump coils market. The residential sector continues to be a dominant application segment, with a surge in demand for compact, high-efficiency coils suitable for various home sizes and types. The commercial segment is witnessing increased adoption due to the need for large-scale, reliable, and energy-efficient HVAC systems in new constructions and retrofit projects. From a coil type perspective, evaporator and condenser coils remain central, but there is growing interest in specialized coils, such as those for desuperheaters, which improve overall system efficiency by recovering waste heat. Material-wise, while copper and aluminum remain primary, the development of hybrid materials and advanced coatings for improved durability and performance in challenging environments is a significant trend. The shift towards natural refrigerants and lower GWP synthetic refrigerants is also influencing coil design and material selection, necessitating robust solutions that can handle different operational pressures and temperatures.

AI Impact Analysis on Heat Pump Coils Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Heat Pump Coils Market frequently center on how AI can enhance efficiency, reduce costs, and improve the sustainability of heat pump systems. Users are keen to understand AI's role in optimizing coil design for superior heat transfer, streamlining manufacturing processes to minimize waste and defects, and enabling predictive maintenance for extended component lifespan. There is significant interest in how AI algorithms can analyze real-time operational data to adjust heat pump settings, thereby maximizing energy savings and overall system performance, including the optimal functioning of coils. Concerns also include the integration of AI with smart home and building management systems to create a more responsive and efficient thermal environment, directly impacting the demand for and specifications of heat pump coils.

- AI optimizes coil design through simulation and generative design, leading to higher heat transfer efficiency and reduced material usage.

- AI enhances manufacturing processes by detecting defects in real-time, improving quality control, and reducing production costs.

- Predictive maintenance powered by AI monitors coil performance, forecasting potential failures and enabling proactive servicing, extending coil lifespan.

- AI-driven smart control systems optimize heat pump operation, ensuring coils function at peak efficiency based on environmental conditions and user demand.

- Supply chain optimization using AI improves inventory management and logistics for coil components, reducing lead times and costs.

- AI aids in material selection and development for coils by predicting performance characteristics of new alloys and coatings.

- Integration of AI in building management systems allows for dynamic adjustment of heating and cooling, directly influencing the load and efficiency requirements of heat pump coils.

DRO & Impact Forces Of Heat Pump Coils Market

The Heat Pump Coils Market is significantly shaped by a combination of drivers, restraints, and opportunities, alongside various impact forces. The primary drivers include global efforts to combat climate change, leading to stringent energy efficiency mandates and carbon emission reduction targets, which inherently favor heat pump technologies. Rising electricity and gas prices incentivize consumers and businesses to seek more cost-effective heating and cooling solutions, positioning heat pumps as an attractive alternative. Governments worldwide are providing substantial subsidies, tax credits, and financial incentives for heat pump installations, further accelerating market growth. The increasing awareness among consumers about the environmental benefits and long-term economic advantages of heat pumps also acts as a strong market driver.

Despite the strong growth drivers, several restraints pose challenges to the market. The high initial investment cost of heat pump systems, including specialized coils, can be a barrier for some potential buyers compared to traditional HVAC systems. A lack of skilled installers and service technicians for heat pump systems, particularly in emerging markets, limits adoption rates. Furthermore, evolving regulations regarding refrigerants, particularly the phasing out of high Global Warming Potential (GWP) refrigerants like R-410A, necessitate continuous research and development into new, compliant coil designs and materials, adding to production complexities and costs. Fluctuations in raw material prices, such as copper and aluminum, also impact manufacturing costs and market stability.

Opportunities for market expansion are abundant, with the vast retrofit market offering significant potential as older HVAC systems are replaced with more efficient heat pumps. The development of smart heat pumps integrated with IoT and AI technologies presents an opportunity for enhanced performance, remote monitoring, and predictive maintenance, requiring advanced coil designs. Emerging economies, driven by rapid urbanization and infrastructure development, represent new untapped markets for heat pump adoption. Furthermore, ongoing research into advanced materials, such as microchannel technology and enhanced surface coatings, promises to improve coil efficiency and durability, opening avenues for product differentiation and innovation. The increasing demand for heat pumps in industrial process heating and cooling also offers a niche but growing market segment.

The impact forces influencing the market are multifaceted. Regulatory forces, including energy efficiency standards and environmental protection laws, directly shape product development and market accessibility. Technological forces, such as advancements in refrigerant technology and coil manufacturing processes, continually push the boundaries of performance and efficiency. Economic forces, including global economic growth, energy price volatility, and consumer purchasing power, dictate market demand and investment levels. Environmental forces, primarily climate change concerns and the push for decarbonization, are fundamental in driving the shift towards sustainable heating and cooling solutions like heat pumps, thereby boosting demand for their core components, including coils. The collective action of these forces creates a dynamic and evolving landscape for the heat pump coils market.

Segmentation Analysis

The Heat Pump Coils Market is comprehensively segmented based on various critical parameters, providing a granular view of market dynamics and opportunities. These segmentations are crucial for understanding market preferences, technological advancements, and the diverse applications of heat pump coils across different end-use sectors. The market is primarily analyzed by coil type, material, application, and refrigerant type, each offering distinct insights into market demand and supply patterns. This detailed breakdown helps stakeholders identify growth areas, tailor product offerings, and devise effective market entry strategies, ensuring that products meet specific industry requirements and regulatory standards globally.

- By Coil Type

- Evaporator Coils

- Condenser Coils

- Desuperheater Coils

- Reversing Valve Coils

- Other Coil Types

- By Material

- Copper

- Aluminum

- Steel

- Copper-Aluminum Hybrid

- Other Materials

- By Application

- Residential

- Commercial

- Office Buildings

- Retail Stores

- Healthcare Facilities

- Educational Institutions

- Hospitality

- Other Commercial

- Industrial

- Process Heating

- Waste Heat Recovery

- Agriculture

- Data Centers

- Other Industrial

- By Refrigerant Type

- R-410A

- R-32

- R-290 (Propane)

- R-134a

- CO2 (R-744)

- Other Refrigerants

Value Chain Analysis For Heat Pump Coils Market

The value chain for the Heat Pump Coils Market encompasses a series of interconnected stages, from raw material sourcing to the final end-use and after-sales services, highlighting the flow of goods and value creation. The upstream analysis begins with the extraction and processing of raw materials such as copper, aluminum, and steel, which are fundamental for coil manufacturing. Key suppliers in this stage include metal refineries, tube manufacturers, and fin producers, providing the basic components that are then shaped and assembled into coils. The efficiency and cost-effectiveness at this initial stage significantly influence the overall production cost and quality of the final heat pump coils. Relationships with reliable and cost-competitive raw material suppliers are critical for maintaining production consistency and managing supply chain risks within the market.

Further down the value chain, the manufacturing of heat pump coils involves specialized processes such as tube bending, fin stamping, coil assembly, brazing, and leak testing. These operations are typically carried out by dedicated coil manufacturers or in-house divisions of larger HVAC system producers. Once manufactured, the coils move into the downstream analysis, where they are integrated into complete heat pump units by HVAC system assemblers. These finished heat pump systems are then distributed through various channels to reach the end-users. The performance and integration capabilities of the coils directly impact the efficiency and reliability of the final heat pump system, making quality control and precise specifications paramount throughout the manufacturing and assembly stages. Innovation in manufacturing techniques, such as automation and advanced joining methods, is crucial for efficiency.

The distribution channel for heat pump coils can be categorized as direct or indirect. Direct channels involve coil manufacturers supplying directly to large Original Equipment Manufacturers (OEMs) who integrate the coils into their heat pump products. This approach often involves long-term contracts and customized specifications, fostering strong B2B relationships. Indirect channels typically involve wholesalers, distributors, and retailers who purchase coils or complete heat pump units and then supply them to HVAC contractors, installers, and smaller end-users. This broad network ensures wider market reach and accessibility. The increasing complexity of heat pump systems necessitates robust support for installers, including training and technical assistance, to ensure proper installation and maintenance. After-sales service, including spare parts supply and technical support for coil-related issues, also forms a crucial part of the value chain, ensuring customer satisfaction and product longevity.

Heat Pump Coils Market Potential Customers

The potential customers for the Heat Pump Coils Market are diverse, spanning across multiple sectors that rely on efficient heating, ventilation, and air conditioning (HVAC) systems. A primary customer segment consists of HVAC system manufacturers, who are the direct buyers of heat pump coils for integration into their complete heat pump units. These manufacturers require coils that meet specific performance standards, design specifications, and compatibility requirements for various refrigerants and system capacities. Their purchasing decisions are driven by factors such as coil efficiency, durability, cost-effectiveness, and the supplier's ability to provide custom solutions and reliable delivery schedules, making them a cornerstone of demand for coil producers. Building strong, long-term relationships with these OEMs is crucial for coil manufacturers.

Beyond the direct manufacturers, end-users and intermediaries form another significant customer base. This includes building owners in residential, commercial, and industrial sectors who invest in heat pump systems for their properties. Residential homeowners and developers are increasingly opting for heat pumps due to energy efficiency benefits and environmental concerns, indirectly driving demand for coils through system manufacturers and installers. Commercial building managers, institutional facility operators (e.g., hospitals, schools), and industrial plant operators seek robust, high-performance heat pumps to manage their heating and cooling loads efficiently, prioritizing reliability, operational cost savings, and adherence to environmental regulations. Their needs vary based on building size, climate, and specific operational requirements, influencing the type and capacity of coils procured by their system providers.

Furthermore, HVAC contractors, installers, and energy service companies (ESCOs) represent key intermediaries who purchase heat pump systems (which contain the coils) and are responsible for installation, maintenance, and sometimes system design. These professionals play a vital role in recommending specific heat pump solutions to end-users and are influenced by factors such as ease of installation, product reliability, manufacturer support, and availability of spare parts. Their preference for certain brands or coil types can significantly impact market uptake. Additionally, governmental and non-governmental organizations involved in energy efficiency programs or sustainable development initiatives can indirectly act as customers by promoting and subsidizing heat pump technologies, thereby stimulating overall market demand for their components, including the essential coils.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.2 billion |

| Market Forecast in 2032 | USD 10.5 billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Danfoss, Sanhua, Modine Manufacturing Company, Wieland-Werke AG, Alfa Laval, SWEP International AB, Mueller Industries Inc., NIBE Industrier AB, Trane Technologies, Johnson Controls, Daikin Industries, Mitsubishi Electric, Fujitsu General, Carrier Global Corporation, Rheem Manufacturing Company, Emerson Electric Co., Goodman Manufacturing, LG Electronics, Samsung HVAC, Lennox International Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Heat Pump Coils Market Key Technology Landscape

The technology landscape for the Heat Pump Coils Market is characterized by continuous innovation aimed at improving heat transfer efficiency, reducing size and weight, enhancing durability, and adapting to new refrigerant standards. One prominent technological advancement is the widespread adoption of microchannel coils, which offer significantly higher heat transfer coefficients compared to traditional fin-and-tube designs. These coils feature multiple small channels through which the refrigerant flows, maximizing the surface area for heat exchange within a compact footprint. This design leads to greater energy efficiency, reduced refrigerant charge, and often lower material costs, making them increasingly popular in modern heat pump systems, especially in applications where space is at a premium and efficiency is critical. The precise manufacturing required for microchannel coils demands advanced fabrication techniques and quality control.

Another crucial area of technological development involves enhanced surface coils and advanced fin geometries. Manufacturers are continually researching and developing innovative fin designs, such as louvered, corrugated, or wavy fins, to disrupt the boundary layer airflow and maximize turbulent flow, thereby increasing the heat transfer rate. Similarly, inner-grooved tubes are used to enhance the internal surface area and promote more efficient heat exchange between the refrigerant and the tube wall. These enhancements contribute to overall system efficiency, allowing heat pumps to perform better across a wider range of operating conditions. Materials science also plays a significant role, with ongoing research into corrosion-resistant coatings and advanced alloys for tubes and fins to extend coil lifespan and maintain performance in harsh or humid environments, ensuring long-term reliability and reducing maintenance requirements for end-users.

The integration of smart controls and sensors is also revolutionizing the heat pump coil market. Digital sensors can monitor real-time temperature, pressure, and refrigerant flow within the coils, providing data that can be used by smart control systems to optimize heat pump operation. This includes adjusting compressor speed, fan speed, and defrost cycles to ensure the coils are operating at their peak efficiency, minimizing energy consumption. Furthermore, advanced manufacturing techniques, including robotic assembly and automated brazing, are improving the precision and consistency of coil production, leading to higher quality and lower defect rates. Research into new, environmentally friendly refrigerants, such as R-32, R-290 (propane), and CO2 (R-744), is also driving coil technology to adapt to different pressures and thermodynamic properties, requiring new material specifications and design considerations to ensure safety and optimal performance with these next-generation refrigerants.

Regional Highlights

- North America: This region exhibits robust growth in the Heat Pump Coils Market, driven by government incentives like tax credits and rebates for energy-efficient HVAC systems. The increasing focus on decarbonization and electrification in residential and commercial sectors, particularly in the US and Canada, fuels demand. The market benefits from established HVAC infrastructure and a strong consumer awareness regarding energy savings, with an emphasis on reliable and high-performance coils for diverse climatic conditions.

- Europe: Europe stands as a leading market for heat pump coils, propelled by ambitious climate targets, stringent energy efficiency regulations, and substantial government subsidies for heat pump installations across member states. Countries like Germany, France, the UK, and Nordic nations are seeing rapid adoption of heat pumps to reduce reliance on fossil fuels, directly boosting the demand for advanced and efficient coils. The region also emphasizes coils optimized for natural refrigerants and lower GWP synthetic alternatives.

- Asia Pacific (APAC): The APAC market is characterized by rapid urbanization, industrialization, and infrastructure development, particularly in countries such as China, Japan, South Korea, and India. This growth translates into increasing demand for both residential and commercial heat pump systems. While cost remains a significant factor, growing environmental awareness and rising energy costs are driving the adoption of energy-efficient solutions, making it a high-growth region for heat pump coils.

- Latin America: The Heat Pump Coils Market in Latin America is in an emerging phase, with gradual growth influenced by urbanization, increasing disposable incomes, and a growing recognition of energy efficiency benefits. Brazil and Mexico are key markets, showing nascent demand in both residential and commercial construction sectors. Economic stability and policy support for sustainable building practices will be crucial for accelerating market expansion in this region.

- Middle East and Africa (MEA): This region presents unique opportunities and challenges. High cooling demand in the Middle East and growing electrification efforts in Africa are slowly driving the adoption of heat pumps, though traditional cooling systems still dominate. Investment in infrastructure projects and growing environmental consciousness, particularly concerning energy consumption in extreme climates, are expected to foster future growth in the demand for specialized, durable heat pump coils.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Heat Pump Coils Market.- Danfoss

- Sanhua

- Modine Manufacturing Company

- Wieland-Werke AG

- Alfa Laval

- SWEP International AB

- Mueller Industries Inc.

- NIBE Industrier AB

- Trane Technologies

- Johnson Controls

- Daikin Industries

- Mitsubishi Electric

- Fujitsu General

- Carrier Global Corporation

- Rheem Manufacturing Company

- Emerson Electric Co.

- Goodman Manufacturing

- LG Electronics

- Samsung HVAC

- Lennox International Inc.

Frequently Asked Questions

What is the primary function of heat pump coils?

Heat pump coils are essential components in heat pump systems, primarily responsible for the efficient transfer of thermal energy between the refrigerant and the surrounding environment (air, water, or ground). They function as evaporators to absorb heat and condensers to release it, facilitating both heating and cooling cycles.

What materials are commonly used for manufacturing heat pump coils?

The most common materials used for manufacturing heat pump coils are copper and aluminum. Copper offers excellent thermal conductivity and corrosion resistance, while aluminum provides a lighter and often more cost-effective solution. Hybrid combinations and specialized coatings are also employed for enhanced performance and durability.

How do microchannel coils improve heat pump efficiency?

Microchannel coils significantly improve heat pump efficiency by featuring multiple small channels that increase the surface area for heat exchange in a compact design. This design enhances the heat transfer coefficient, reduces refrigerant charge requirements, and often leads to lower material consumption compared to traditional fin-and-tube coils.

What are the main applications for heat pump coils?

Heat pump coils are extensively used across residential, commercial, and industrial sectors. In residential buildings, they enable space heating, cooling, and hot water production. Commercial applications include HVAC systems for offices and retail, while industrial uses range from process heating and cooling to waste heat recovery.

How do government regulations impact the Heat Pump Coils Market?

Government regulations profoundly impact the Heat Pump Coils Market by setting stringent energy efficiency standards and mandating the phase-out of high Global Warming Potential (GWP) refrigerants. These regulations drive innovation in coil design, material selection, and manufacturing processes to ensure compliance and promote the adoption of more sustainable and efficient heat pump technologies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager