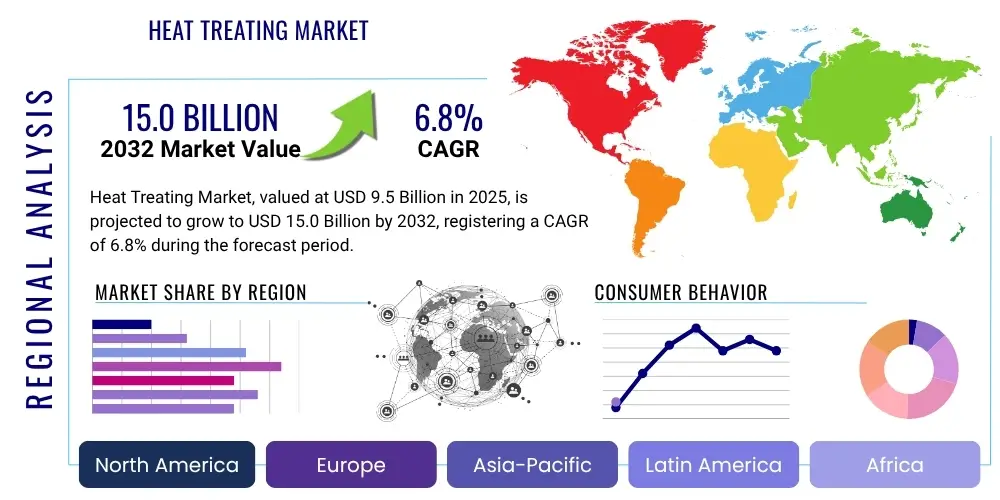

Heat Treating Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428587 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Heat Treating Market Size

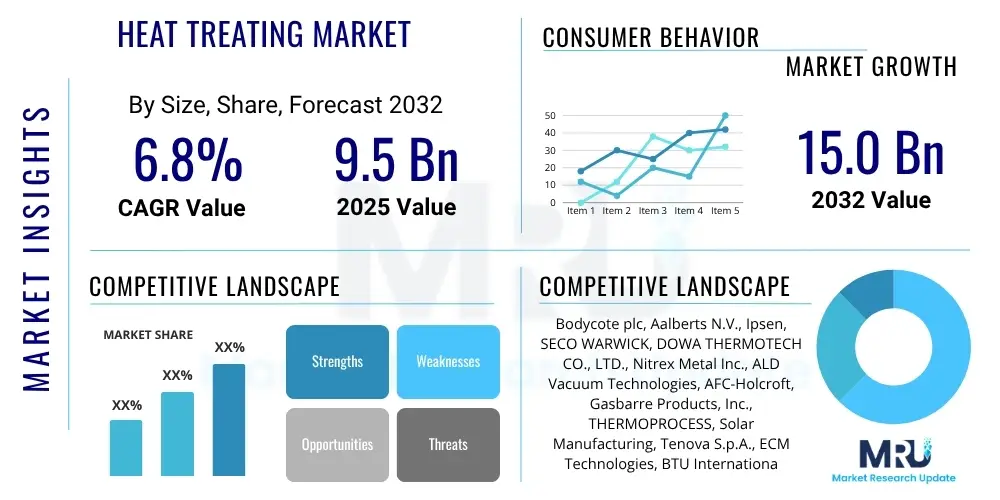

The Heat Treating Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $9.5 Billion in 2025 and is projected to reach $15.0 Billion by the end of the forecast period in 2032.

Heat Treating Market introduction

The Heat Treating Market encompasses a range of metallurgical processes applied to metals and alloys to alter their physical, and sometimes chemical, properties. These processes involve heating materials to specific temperatures, holding them at that temperature for a predetermined time, and then cooling them at controlled rates. The primary goal is to enhance properties such as hardness, strength, ductility, wear resistance, and fatigue life, which are crucial for the performance and longevity of manufactured components in various industrial applications. Common heat treatment processes include hardening, annealing, tempering, carburizing, nitriding, and induction hardening, each designed to achieve specific material characteristics.

The products and services within this market primarily revolve around specialized furnaces, quenching media, atmosphere control systems, and associated automation and quality control equipment. These technologies enable precise manipulation of material microstructure to meet stringent performance requirements. Major applications span across critical sectors such as automotive, aerospace and defense, industrial machinery, construction, and energy, where component reliability and durability are paramount. The benefits derived from heat treatment are significant, contributing to improved product quality, reduced failure rates, and extended operational lifespespans for components under demanding conditions.

The market's growth is predominantly driven by the continuous expansion of manufacturing industries globally, particularly the increasing demand for high-performance and lightweight materials in automotive and aerospace sectors, as well as the need for robust machinery in industrial and construction applications. Advancements in material science, coupled with the ongoing push for greater energy efficiency and environmental compliance in manufacturing processes, further propel innovation and adoption within the heat treating domain, solidifying its essential role in modern industrial production.

Heat Treating Market Executive Summary

The global Heat Treating Market is characterized by robust business trends emphasizing automation, digitalization, and sustainability. Manufacturers are increasingly investing in advanced furnace technologies and integrated process controls to enhance efficiency, reduce energy consumption, and ensure consistent product quality. There is a growing inclination towards vacuum heat treatment, induction hardening, and other specialized processes that offer superior results for complex geometries and advanced alloys, driven by the demand for higher precision and environmental benefits. The focus remains on optimizing operational costs while adhering to strict material performance standards, fostering innovation in equipment design and process methodologies across the industry.

Regional trends indicate significant growth in the Asia Pacific region, primarily fueled by rapid industrialization, expanding automotive production, and a booming electronics manufacturing sector in countries like China, India, and Southeast Asian nations. North America and Europe, while more mature markets, are witnessing substantial investments in advanced heat treatment technologies, particularly for aerospace, defense, and high-tech industrial applications, driven by stringent quality requirements and a push for Industry 4.0 integration. Emerging markets in Latin America and the Middle East and Africa are also showing promising potential, spurred by infrastructure development and increasing manufacturing capabilities, leading to a rising demand for heat treated components.

Segmentation trends reveal a strong demand for outsourced heat treating services, as smaller manufacturers leverage the expertise and specialized equipment of commercial heat treaters to meet their material processing needs without significant capital investment. By process, vacuum heat treatment and nitriding are gaining traction due to their ability to provide superior surface properties and minimize distortion for critical components. The automotive and aerospace sectors continue to be dominant end-use industries, necessitating innovative solutions for lightweight and high-strength materials. Furthermore, there is an increasing shift towards multi-process furnaces and flexible systems that can accommodate a wider range of materials and treatment specifications, reflecting the evolving and diverse requirements of modern manufacturing.

AI Impact Analysis on Heat Treating Market

User inquiries concerning AI's influence on the Heat Treating Market frequently center on its potential to revolutionize process control, enhance predictive maintenance, and significantly improve overall quality assurance. There is a strong interest in how AI can optimize energy consumption, predict material behavior, and manage complex heat treatment recipes, moving beyond traditional statistical process control. Users are keen to understand the practical implementation challenges, the return on investment, and whether AI integration might lead to job displacement or require substantial upskilling of the workforce. The overarching theme is an expectation for AI to bring greater precision, efficiency, and reliability to a historically experience-driven and energy-intensive industrial process.

- AI-driven optimization of furnace parameters for energy efficiency and reduced cycle times.

- Predictive maintenance analytics for heat treatment equipment, minimizing downtime and operational costs.

- Enhanced quality control through real-time data analysis, detecting defects and ensuring consistent material properties.

- Development of autonomous systems for process adjustment, leading to higher precision and repeatability.

- Simulation and modeling of heat treatment processes, allowing for virtual testing and material property prediction.

- Improved recipe management and customization for various alloys and geometries using machine learning algorithms.

- Optimization of quenching processes through AI analysis of cooling curves and fluid dynamics.

- Reduced human error through intelligent decision-making support and automated task execution.

DRO & Impact Forces Of Heat Treating Market

The Heat Treating Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, shaping its current trajectory and future outlook. Key drivers include the ever-increasing global demand for high-performance and lightweight materials across diverse industries, particularly automotive, aerospace, and energy, which necessitates advanced heat treatment processes to achieve desired mechanical properties. The growing adoption of automation and digitalization in manufacturing also pushes for more sophisticated and integrated heat treating solutions, aiming for higher efficiency, precision, and repeatability. Additionally, the continuous emphasis on extending the lifespan and improving the reliability of industrial components contributes to sustained demand for specialized heat treatment services.

However, the market faces considerable restraints. The heat treating process is inherently energy-intensive, leading to high operational costs, especially with fluctuating global energy prices, which can impact profitability and competitiveness. Stringent environmental regulations related to emissions, waste disposal, and energy consumption compel companies to invest in more sustainable, albeit often costlier, technologies and practices. Furthermore, a persistent shortage of skilled labor capable of operating and maintaining advanced heat treatment equipment, coupled with a deep understanding of metallurgy, poses a significant challenge for market players. The substantial capital investment required for state-of-the-art furnaces and peripheral equipment also acts as a barrier to entry and expansion for some businesses.

Despite these challenges, numerous opportunities exist to propel market growth. The integration of Industry 4.0 technologies, including IoT, big data analytics, and Artificial Intelligence, offers pathways for process optimization, predictive maintenance, and enhanced quality control, creating new avenues for efficiency and innovation. The rise of additive manufacturing (3D printing) presents a unique opportunity, as many 3D-printed metal parts require post-processing heat treatments to achieve desired properties. Moreover, the ongoing development of new alloys with unique characteristics necessitates bespoke heat treatment solutions, opening new research and development fronts. Expanding into emerging markets, particularly in Asia Pacific and Latin America, where industrialization is accelerating, offers significant growth potential, while the focus on developing and adopting more energy-efficient and environmentally friendly heat treating technologies provides a competitive edge.

Segmentation Analysis

The Heat Treating Market is comprehensively segmented across various dimensions, including the specific treatment process, the end-use industry, the type of furnace utilized, the material being treated, and the nature of the service provided. This segmentation helps to understand the diverse demands and technological preferences within the industry. Each segment represents distinct market dynamics, driven by specific industrial needs, material science advancements, and operational considerations. The granular analysis of these segments is crucial for identifying key growth areas, competitive landscapes, and emerging trends that influence market development and strategic investment decisions.

- By Process:

- Hardening

- Annealing

- Tempering

- Carburizing

- Nitriding

- Carbonitriding

- Induction Hardening

- Vacuum Heat Treatment

- Cryogenic Treatment

- Solution Treatment

- Precipitation Hardening

- By End-Use Industry:

- Automotive

- Aerospace and Defense

- Industrial Machinery

- Construction

- Energy (Oil & Gas, Power Generation)

- Tool & Die

- Medical Devices

- Electronics

- Agriculture

- Mining

- Railway

- By Furnace Type:

- Batch Furnaces

- Continuous Furnaces

- Vacuum Furnaces

- Atmosphere Furnaces

- Induction Furnaces

- Salt Bath Furnaces

- Fluidized Bed Furnaces

- Brazing Furnaces

- By Material:

- Steel (Carbon Steel, Alloy Steel, Stainless Steel, Tool Steel)

- Aluminum Alloys

- Titanium Alloys

- Nickel Alloys

- Copper Alloys

- Cast Iron

- Superalloys

- Ceramics

- By Service Type:

- In-House Services

- Outsourced Services (Commercial Heat Treaters)

- Consulting & Technical Support

- Equipment Maintenance & Upgrade

Value Chain Analysis For Heat Treating Market

The value chain for the Heat Treating Market begins with upstream activities involving raw material suppliers and equipment manufacturers. Raw material suppliers provide the basic metals, alloys, and processing gases (such as nitrogen, argon, hydrogen, and endothermic gas) that are treated. Equipment manufacturers design, produce, and supply the specialized furnaces, quenching systems, atmosphere control units, and other necessary machinery crucial for heat treatment operations. This upstream segment is characterized by specialized engineering and significant capital investment in research and development to create advanced, energy-efficient, and precise heat treating technologies that cater to evolving industrial demands and material science breakthroughs.

Further along the value chain, the heat treatment processes are executed either by in-house departments of large manufacturing companies or, more commonly, by specialized commercial heat treating service providers. These service providers act as critical intermediaries, offering their expertise and high-capital equipment to a wide array of downstream customers. The downstream analysis primarily focuses on the diverse end-use industries that require heat treated components. These include the automotive sector for engine components, gears, and chassis parts; aerospace and defense for critical structural and engine components; industrial machinery for tools, dies, and heavy equipment parts; medical devices for implants and surgical instruments; and the energy sector for oil and gas drilling components and power generation equipment. The performance and reliability of these final products heavily depend on the quality and precision of the heat treatment received.

The distribution channels in the heat treating market are varied. Equipment manufacturers typically engage in direct sales to large industrial clients and commercial heat treaters, often involving extensive consultation, customization, installation, and after-sales support. For smaller components or more standardized treatments, indirect channels through distributors or specialized agents may be utilized. Commercial heat treating services are often supplied directly to manufacturers, with a strong emphasis on building long-term contractual relationships based on quality, turnaround time, and technical capability. The decision between in-house and outsourced heat treatment often hinges on factors such as production volume, required specialization, capital expenditure constraints, and the strategic importance of process control, making both direct service provision and indirect equipment sales vital components of the market's commercial landscape.

Heat Treating Market Potential Customers

Potential customers for the Heat Treating Market primarily encompass a broad spectrum of manufacturing industries that require enhanced material properties for their products and components. These end-users are driven by the need for increased durability, strength, wear resistance, and performance in often demanding operating environments. Key buyers include large-scale original equipment manufacturers (OEMs) and their extensive supply chains, who integrate heat treated parts into their final assemblies. The consistent demand for high-quality, reliable components across these sectors underpins the market's stability and growth.

The primary segments of end-users for heat treating services and equipment are the automotive, aerospace and defense, and industrial machinery sectors. Automotive manufacturers rely on heat treatment for critical engine components, transmission gears, crankshafts, and chassis parts to ensure vehicle safety and longevity. The aerospace and defense industry requires extremely precise heat treatments for aircraft structural components, landing gear, and engine parts, where material integrity is paramount for operational safety. Industrial machinery, including agricultural equipment, construction machinery, and heavy equipment, also constitutes a significant customer base, needing hardened and tempered parts to withstand arduous operational conditions and minimize downtime.

Beyond these major segments, the tool and die industry is a significant consumer, requiring heat treatment for molds, cutting tools, and forming tools to extend their operational life. The medical device sector utilizes heat treatment for surgical instruments, implants, and other critical components to achieve biocompatibility, corrosion resistance, and high strength. Furthermore, energy industries such as oil and gas, and power generation, depend on heat treated parts for drilling equipment, turbines, and structural components that must endure high temperatures, pressures, and corrosive environments. Smaller manufacturers and job shops also frequently outsource their heat treating needs to commercial service providers, becoming vital indirect customers for equipment suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $9.5 Billion |

| Market Forecast in 2032 | $15.0 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bodycote plc, Aalberts N.V., Ipsen, SECO WARWICK, DOWA THERMOTECH CO., LTD., Nitrex Metal Inc., ALD Vacuum Technologies, AFC-Holcroft, Gasbarre Products, Inc., THERMOPROCESS, Solar Manufacturing, Tenova S.p.A., ECM Technologies, BTU International, Tokyo Heat Treating Co., Ltd., FPM Heat Treating, Stack Metallurgical Group, Zion Industries, Inc., Bluewater Thermal Solutions, Paulo Products Company |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Heat Treating Market Key Technology Landscape

The Heat Treating Market is characterized by a dynamic and evolving technological landscape, driven by the need for greater precision, energy efficiency, and environmental compliance. A significant shift is observed towards advanced furnace technologies, including state-of-the-art vacuum furnaces that offer superior control over atmospheric conditions, minimizing oxidation and distortion for high-value components. These furnaces often integrate sophisticated monitoring systems, enabling real-time process adjustments and enhancing repeatability. Induction heating also remains a pivotal technology, particularly for localized hardening and annealing, prized for its speed, energy efficiency, and ability to treat specific areas of a component without affecting others, making it ideal for mass production lines requiring rapid throughput and selective property modification.

Beyond traditional methods, the industry is increasingly adopting specialized processes such as laser heat treatment and cryogenic treatment. Laser heat treatment provides highly localized surface hardening with minimal distortion, suitable for precise applications where conventional methods might be too aggressive. Cryogenic treatment, involving cooling components to extremely low temperatures, enhances wear resistance and dimensional stability, particularly in tool steels and advanced alloys, addressing niche requirements for extreme durability. The integration of Industry 4.0 principles is profoundly impacting the sector, with the deployment of Internet of Things (IoT) sensors, real-time data analytics, and artificial intelligence (AI) and machine learning (ML) algorithms. These technologies facilitate predictive maintenance, optimize process parameters, and enable remote monitoring, significantly improving operational efficiency and reducing downtime across the heat treating value chain.

Furthermore, advancements in controlled atmosphere furnaces continue to refine processes like carburizing and nitriding, offering precise control over carbon and nitrogen potential to achieve desired case depths and hardness profiles. Quenching technology is also seeing innovations, with the development of polymer quenchants and agitated bath systems designed to optimize cooling rates and minimize residual stress and distortion in treated parts. The ongoing development of new materials, including superalloys and components produced via additive manufacturing, necessitates continuous research into novel heat treatment techniques to unlock their full potential. This technological evolution underscores a market moving towards more automated, intelligent, and environmentally sustainable solutions to meet the escalating demands of modern manufacturing and material science.

Regional Highlights

- North America: This region is a mature market driven by the robust aerospace, automotive, and defense industries, which demand high-precision and high-performance heat treated components. Innovation in advanced materials and the adoption of Industry 4.0 technologies are key trends.

- Europe: Characterized by strong automotive and industrial machinery sectors, Europe emphasizes energy-efficient and environmentally compliant heat treatment solutions. Germany, Italy, and France are leading contributors, with a focus on specialized processes and advanced metallurgy.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, expanding manufacturing bases (especially automotive and electronics) in China, India, Japan, and South Korea. Increased infrastructure development and a growing middle class are boosting demand for heat treated products.

- Latin America: An emerging market with increasing industrialization, particularly in Brazil and Mexico, driven by automotive manufacturing and mining sectors. Investment in modernizing industrial infrastructure is spurring demand for heat treating services and equipment.

- Middle East and Africa (MEA): This region is experiencing growth due to investments in infrastructure development, oil and gas exploration, and a nascent manufacturing sector. Demand is primarily for durable components that can withstand harsh operating conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Heat Treating Market.- Bodycote plc

- Aalberts N.V.

- Ipsen

- SECO WARWICK

- DOWA THERMOTECH CO., LTD.

- Nitrex Metal Inc.

- ALD Vacuum Technologies

- AFC-Holcroft

- Gasbarre Products, Inc.

- THERMOPROCESS (A division of SMS group)

- Solar Manufacturing

- Tenova S.p.A.

- ECM Technologies

- BTU International

- Tokyo Heat Treating Co., Ltd.

- FPM Heat Treating

- Stack Metallurgical Group

- Zion Industries, Inc.

- Bluewater Thermal Solutions

- Paulo Products Company

Frequently Asked Questions

What is the projected growth rate of the Heat Treating Market?

The Heat Treating Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032, reaching an estimated value of $15.0 Billion by the end of the forecast period.

Which industries are the primary end-users for heat treating services?

The primary end-users include the automotive, aerospace and defense, industrial machinery, construction, and energy sectors, all requiring enhanced material properties for their components.

How is AI impacting the Heat Treating Market?

AI is significantly impacting the market by enabling advanced process optimization, predictive maintenance for equipment, enhanced quality control through real-time data analysis, and intelligent automation of treatment parameters, leading to greater efficiency and precision.

What are the main challenges faced by the Heat Treating Market?

Key challenges include high energy consumption and operational costs, stringent environmental regulations, a shortage of skilled labor, and the substantial capital investment required for advanced equipment.

What are the key technological trends in heat treating?

Key technological trends involve the adoption of vacuum heat treatment, induction heating, laser heat treatment, cryogenic processes, and the integration of Industry 4.0 technologies such as IoT, AI, and real-time data analytics for process control and efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Heat Treating Market Size Report By Type (Steel, Cast Iron, Others, Atmosphere Furnaces, Applied Energy, Vacuum Furnaces, Others), By Application (Automotive, Aerospace, Metalworking, Machine, Construction, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Gcc Heat Treating Market Size Report By Type (Steel, Cast Iron, Others), By Application (Automotive, Aerospace, Metalworking, Machine, Construction, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Dry Vibratables Market Statistics 2025 Analysis By Application (Foundry, Steel, Heat Treating & Forging), By Type (Spinel (Alumina + Magnesite), Silica, High Alumina), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Refractory Castables Market Statistics 2025 Analysis By Application (Foundry, Steel, Heat Treating & Forging), By Type (Traditional Castables, Low Cement Castables, Light Weight Castables), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Extruded Graphite Market Statistics 2025 Analysis By Application (Heat Treating Field, Foundry & HY Metallurgy Field, Chemical Processing Field), By Type (Pitch Impregnated Type, Un-impregnated Type, Round Type, Square Type), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager