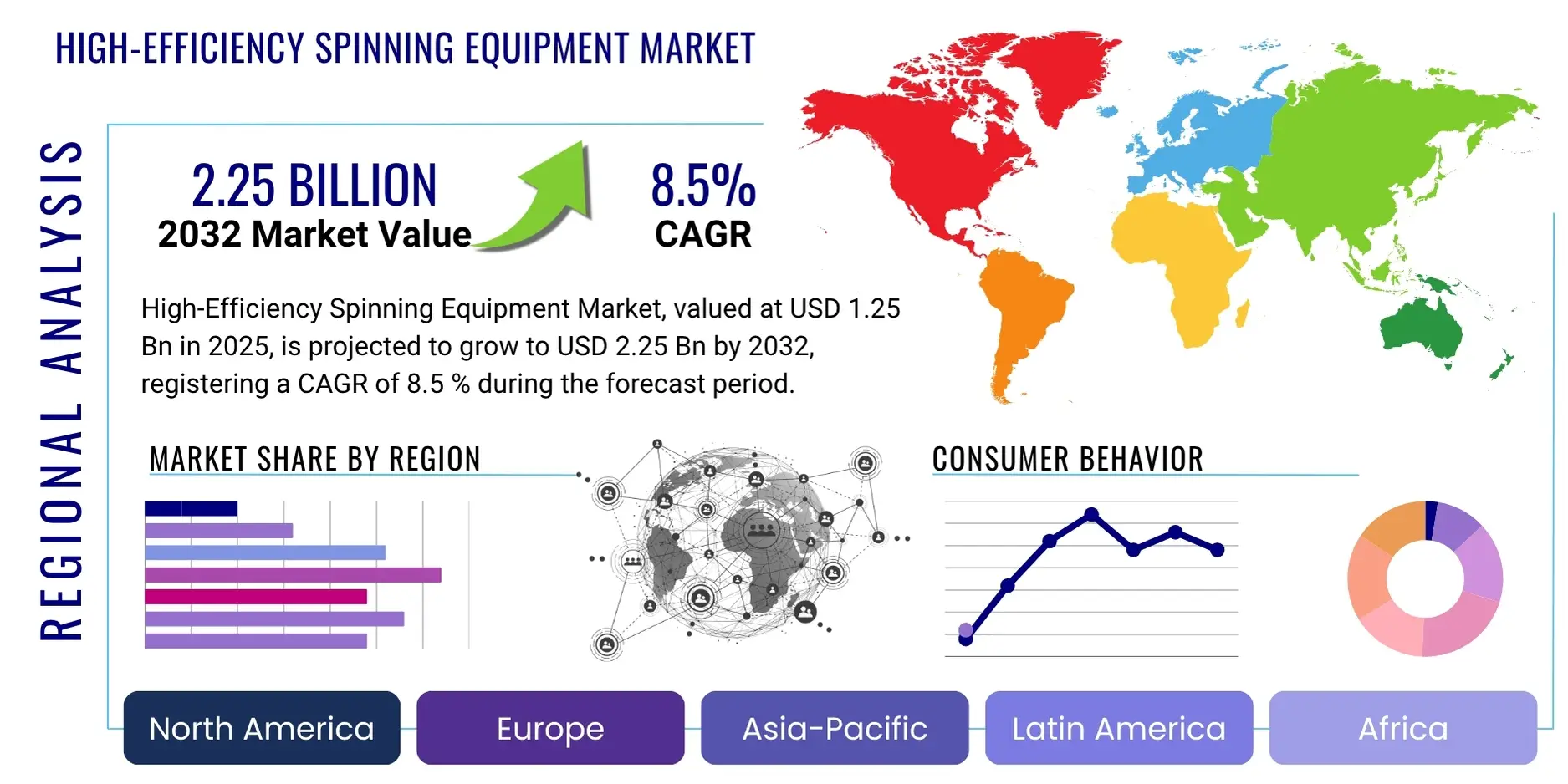

High-Efficiency Spinning Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428123 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

High-Efficiency Spinning Equipment Market Size

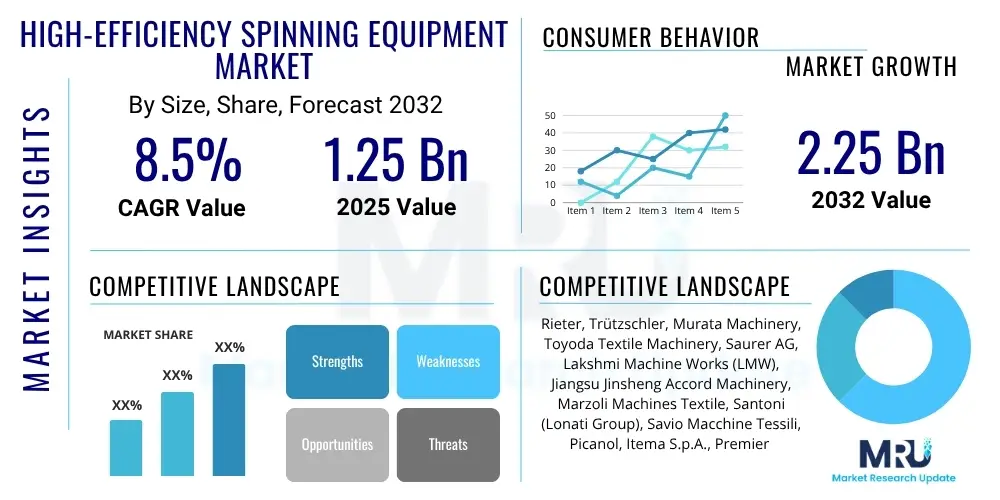

The High-Efficiency Spinning Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 1.25 billion in 2025 and is projected to reach USD 2.25 billion by the end of the forecast period in 2032.

High-Efficiency Spinning Equipment Market introduction

The High-Efficiency Spinning Equipment Market encompasses advanced machinery designed to convert staple fibers into yarn with enhanced productivity, reduced waste, and superior quality. This market is driven by the global demand for textile products and the industry's continuous pursuit of operational excellence and cost-effectiveness. Products in this segment include state-of-the-art ring spinning, rotor spinning, air-jet spinning, and compact spinning machines, each offering distinct advantages in terms of yarn characteristics and processing capabilities. Major applications span across various textile sectors, including apparel, home furnishings, automotive textiles, and technical textiles, where precise yarn specifications and consistent quality are paramount. The inherent benefits of these machines, such as higher output rates, lower energy consumption, reduced labor requirements, and improved yarn strength and uniformity, make them indispensable for modern textile manufacturers. Key driving factors for market growth include technological advancements in automation and digitalization, increasing focus on sustainable production methods, and the expanding global population's demand for textile goods.

High-Efficiency Spinning Equipment Market Executive Summary

The High-Efficiency Spinning Equipment Market is characterized by a strong emphasis on automation, digitalization, and integration of smart technologies to optimize production processes. Business trends indicate a shift towards modular and flexible machinery that can adapt to diverse fiber types and yarn specifications, coupled with growing investments in research and development for sustainable spinning solutions. Regional trends show Asia Pacific as the dominant market due to its robust textile manufacturing base and increasing investments in advanced machinery, followed by Europe and North America, which prioritize technological innovation and high-value product segments. Within market segments, fully automatic systems are gaining traction due to their ability to minimize human intervention and maximize efficiency, while compact spinning technology is witnessing significant adoption for its capacity to produce higher quality yarns with reduced fiber consumption. The market's competitive landscape is dynamic, with leading manufacturers continuously innovating to offer superior equipment that addresses evolving industry demands for productivity, quality, and environmental compliance, influencing investment decisions across the global textile value chain.

AI Impact Analysis on High-Efficiency Spinning Equipment Market

The integration of Artificial Intelligence (AI) into high-efficiency spinning equipment is poised to revolutionize textile manufacturing by addressing several critical user questions and operational challenges. Users are keen to understand how AI can enhance predictive maintenance, optimize process parameters in real-time, and contribute to the development of autonomous spinning operations. There is significant interest in AI's potential to improve yarn quality consistency by identifying and rectifying anomalies before they escalate, thereby reducing defects and waste. Manufacturers also inquire about AI's role in energy efficiency, seeking solutions that can intelligently manage power consumption based on production loads and environmental conditions. Furthermore, concerns about workforce upskilling and data security with AI-driven systems are frequently raised, highlighting the need for user-friendly interfaces and robust data protection protocols. The collective expectation is that AI will unlock new levels of efficiency, quality, and sustainability within the spinning industry.

AI's influence extends beyond mere automation, delving into sophisticated data analytics and learning capabilities that empower spinning mills to operate smarter. It enables machines to learn from vast datasets, recognize patterns, and make informed decisions that were previously reliant on human expertise, often leading to subjective outcomes. This shift towards data-driven decision-making means that machine settings can be dynamically adjusted for optimal performance across varying raw material characteristics and desired yarn properties, offering a level of precision unattainable through traditional methods. Such capabilities are crucial for modern textile production environments where agility and adaptability to market changes are paramount. The ability of AI to foresee potential equipment failures and recommend preventative actions minimizes costly downtime, transforming maintenance from a reactive to a proactive strategy.

Moreover, AI is instrumental in fostering a more sustainable manufacturing ecosystem by precisely managing resource utilization. By optimizing fiber consumption and reducing waste through intelligent process control, AI contributes significantly to environmental stewardship and cost savings. The technology also facilitates the creation of digital twins for spinning machines, allowing for virtual testing and optimization of new processes or materials without interrupting live production. This not only accelerates innovation but also reduces the financial and environmental risks associated with physical prototypes. As the textile industry continues to embrace Industry 4.0 principles, AI will serve as a foundational technology, driving the evolution towards fully integrated, intelligent, and autonomous spinning factories that can respond dynamically to market demands while upholding high standards of quality and sustainability.

- Enhanced predictive maintenance and fault detection, reducing downtime.

- Real-time process optimization for improved yarn quality and consistency.

- Automated anomaly detection in fiber feeding and yarn formation.

- Intelligent energy management based on production loads.

- Optimized resource utilization and waste reduction through AI algorithms.

- Data-driven decision-making for adaptable production strategies.

- Facilitation of autonomous operation and reduced human intervention.

DRO & Impact Forces Of High-Efficiency Spinning Equipment Market

The High-Efficiency Spinning Equipment Market is significantly shaped by a complex interplay of Drivers, Restraints, and Opportunities, collectively forming the impact forces that dictate its trajectory. A primary driver is the incessant global demand for textile products, fueled by population growth, fashion trends, and industrial applications, which compels manufacturers to adopt more productive and quality-focused machinery. Alongside this, the rising labor costs in traditional textile hubs and the increasing focus on automation across industries are pushing companies to invest in equipment that reduces reliance on manual labor while boosting output. Technological advancements, particularly in areas like digitalization, sensor integration, and artificial intelligence, are also critical drivers, enabling machines to offer superior performance, energy efficiency, and predictive maintenance capabilities. The competitive landscape further acts as a driver, as companies strive to maintain an edge by producing higher quality yarns at lower operational costs, necessitating continuous investment in modern spinning technology.

However, the market also faces considerable restraints that temper its growth. The high initial capital investment required for purchasing and installing state-of-the-art spinning equipment can be a significant barrier for smaller and medium-sized enterprises, especially in developing economies. Economic uncertainties and fluctuating raw material prices, such as cotton and synthetic fibers, can impact manufacturers' investment decisions and profitability, leading to delayed or scaled-back expansion plans. Additionally, the availability of skilled labor capable of operating and maintaining these sophisticated machines is a growing concern, as the technology becomes more complex. Environmental regulations and the pressure for sustainable manufacturing practices, while creating opportunities, can also act as a restraint if companies struggle to adapt their production processes and equipment to meet stringent new standards, incurring additional compliance costs.

Despite these challenges, numerous opportunities exist to propel the market forward. The growing demand for specialized and technical textiles in sectors like automotive, medical, and protective apparel presents a lucrative avenue for high-efficiency spinning equipment capable of processing advanced fibers. The increasing emphasis on sustainability and circular economy principles drives innovation in machinery that supports recycling and uses environmentally friendly processes, offering manufacturers a unique selling proposition. Furthermore, the adoption of Industry 4.0 technologies, including the Internet of Things (IoT), big data analytics, and cloud computing, creates opportunities for seamless integration, remote monitoring, and optimized supply chain management in spinning mills. Emerging markets, with their burgeoning populations and developing industrial bases, represent untapped potential for market expansion, provided that cost-effective and adaptable solutions can be offered to meet their specific needs. These forces necessitate strategic planning and continuous innovation from market players.

- Drivers:

- Increasing global demand for textile products.

- Rising labor costs and demand for automation in manufacturing.

- Technological advancements in spinning processes and controls.

- Focus on energy efficiency and sustainable production.

- Need for superior yarn quality and consistency.

- Competitive pressure to reduce operational costs.

- Restraints:

- High initial capital investment for advanced machinery.

- Economic uncertainties and fluctuating raw material prices.

- Shortage of skilled labor for operating and maintaining complex equipment.

- Stringent environmental regulations impacting production processes.

- Market saturation in some developed regions.

- Long payback periods for investment.

- Opportunities:

- Growing demand for technical and specialized textiles.

- Development of sustainable and eco-friendly spinning technologies.

- Integration of Industry 4.0 technologies (IoT, AI, Big Data).

- Expansion into emerging markets with developing textile industries.

- Customization and flexibility in machinery to meet diverse demands.

- Focus on circular economy principles in textile production.

Segmentation Analysis

The High-Efficiency Spinning Equipment Market is comprehensively segmented to provide a detailed understanding of its diverse facets, allowing for targeted strategic planning and market analysis. These segmentations typically involve categorizing the market based on the type of spinning technology employed, the specific applications of the produced yarn, the level of automation integrated into the machinery, and the end-use industries served. This granular approach helps identify niche market opportunities, understand competitive landscapes within specific sub-segments, and tailor product development to meet specialized customer needs. Each segment exhibits distinct growth drivers and challenges, reflecting varying technological maturity, adoption rates, and investment patterns across different regions and industrial verticals.

- By Type: Ring Spinning, Rotor Spinning (Open-End), Air-Jet Spinning, Friction Spinning, Compact Spinning

- By Application: Cotton Spinning, Wool Spinning, Synthetic Fiber Spinning, Blended Yarn Spinning, Technical Textiles

- By Automation Level: Semi-Automatic, Fully Automatic, Integrated Robotic Systems

- By End-Use Industry: Apparel, Home Furnishings, Automotive, Medical, Industrial

- By Component: Spinning Frames, Drafting Systems, Spindles, Motors, Control Systems

Value Chain Analysis For High-Efficiency Spinning Equipment Market

A comprehensive value chain analysis for the High-Efficiency Spinning Equipment Market illustrates the sequence of activities that transform raw materials into finished machinery delivered to end-users, highlighting key players and value-adding processes at each stage. The upstream segment involves the sourcing and processing of raw materials such as steel, aluminum, electronic components, and specialized engineering plastics from various suppliers. This stage is critical for ensuring the quality, durability, and technological sophistication of the final spinning equipment. Key activities include material procurement, component manufacturing, and the integration of advanced sensors and control systems, often supplied by specialized technology firms. Efficiency and reliability in the upstream segment directly impact the performance and cost-effectiveness of the spinning machines.

Midstream activities primarily focus on the design, engineering, assembly, and testing of the high-efficiency spinning equipment. This stage involves significant research and development investments to innovate new spinning technologies, enhance automation, and improve energy efficiency. Manufacturers differentiate themselves through proprietary designs, advanced software, and robust manufacturing processes that ensure precision and durability. Quality control is paramount during assembly and testing to guarantee the machinery meets stringent performance specifications and industry standards. This stage also includes the development of integrated solutions, such as intelligent monitoring systems and data analytics platforms, which add substantial value to the end-product.

Downstream activities involve the distribution, sales, installation, and after-sales services of the spinning equipment to textile manufacturers globally. Distribution channels typically include direct sales forces, regional distributors, and strategic partnerships, each offering varying levels of market penetration and customer support. Direct sales are often preferred for large-scale, complex installations, while distributors facilitate access to smaller markets. After-sales services, including technical support, spare parts availability, training, and maintenance contracts, are crucial for customer satisfaction and long-term relationships, significantly contributing to the overall value proposition. Effective logistics and supply chain management ensure timely delivery and efficient service provision, enhancing customer loyalty and market competitiveness.

High-Efficiency Spinning Equipment Market Potential Customers

The High-Efficiency Spinning Equipment Market primarily serves a diverse range of end-users and buyers within the global textile industry, all seeking to enhance their yarn production capabilities. The most prominent customer segment includes large-scale textile mills and integrated textile manufacturers that operate extensive production facilities and require high-volume, consistent yarn output. These entities often invest in state-of-the-art, fully automated spinning equipment to achieve economies of scale, reduce labor costs, and maintain competitive pricing in the global market. Their purchasing decisions are driven by factors such as machine productivity, yarn quality metrics, energy efficiency, and the availability of comprehensive after-sales support and spare parts, crucial for continuous operation.

Another significant customer base comprises medium-sized spinning units and specialized yarn producers who focus on niche markets or technical textiles. These customers often prioritize flexibility, precision, and the ability to process a wide variety of fibers, including specialty and synthetic materials, to meet specific performance requirements for their end products. They seek equipment that offers advanced control systems, adaptability for diverse yarn counts and blends, and features that can cater to smaller batch productions with high-quality standards. For these buyers, the total cost of ownership, including operational efficiency and the capacity for producing high-value-added yarns, often outweighs the initial capital expenditure.

Furthermore, emerging textile manufacturing hubs in developing countries represent a growing segment of potential customers. These buyers are often characterized by a strong focus on cost-effectiveness and durability, while simultaneously seeking to upgrade their production capabilities to meet international quality standards. They might opt for robust semi-automatic or fully automatic machines that offer a balance between investment cost and operational efficiency. Educational institutions and research laboratories involved in textile science and engineering also constitute a smaller but important customer segment, acquiring equipment for training, experimentation, and advanced material development, underscoring the market's reach across the entire textile ecosystem. The evolving demands of the global apparel, home furnishings, and industrial sectors directly influence the investment patterns of these diverse customer groups.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.25 billion |

| Market Forecast in 2032 | USD 2.25 billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces | >|

| Segments Covered | >|

| Key Companies Covered | Rieter, Trützschler, Murata Machinery, Toyoda Textile Machinery, Saurer AG, Lakshmi Machine Works (LMW), Jiangsu Jinsheng Accord Machinery, Marzoli Machines Textile, Santoni (Lonati Group), Savio Macchine Tessili, Picanol, Itema S.p.A., Premier Evolvics, Electro-Jet S.A., A.T.E. Enterprises Private Limited, Kirloskar Toyoda Textile Machinery Pvt. Ltd., Fongs Industries Co., Ltd., SSM Schärer Schweiter Mettler AG, Shima Seiki Mfg., Ltd., Comez (Comez International S.p.A.) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High-Efficiency Spinning Equipment Market Key Technology Landscape

The High-Efficiency Spinning Equipment Market is characterized by a dynamic and continuously evolving technology landscape, driven by the relentless pursuit of higher productivity, superior yarn quality, and increased operational efficiency. A central technological advancement is the widespread adoption of automation and robotics, moving from semi-automatic systems to fully integrated, intelligent manufacturing cells. This includes automated doffing, piecing, and material handling systems that significantly reduce labor requirements and minimize human error, leading to more consistent production. The integration of advanced sensor technologies, such as fiber analysis sensors and yarn monitoring devices, allows for real-time data collection and immediate adjustments to process parameters, ensuring optimal performance and defect prevention.

Another pivotal area of innovation lies in the development of sophisticated control systems and software, often incorporating artificial intelligence (AI) and machine learning (ML) algorithms. These intelligent systems enable predictive maintenance by analyzing machine performance data to anticipate potential failures, thereby minimizing unplanned downtime and extending equipment lifespan. Furthermore, AI and ML optimize spinning parameters based on raw material characteristics and desired yarn properties, leading to improved yarn strength, uniformity, and reduced waste. The advent of digital twins, which are virtual replicas of physical machines, allows manufacturers to simulate, test, and optimize processes in a virtual environment before implementing them in actual production, accelerating innovation and reducing development costs.

Moreover, the focus on energy efficiency and sustainable manufacturing practices is driving the development of new motor technologies, such as direct drive motors and optimized aerodynamic designs for improved energy consumption. Innovations in drafting systems, spindle technology, and rotor designs are continuously improving spinning speeds while maintaining or enhancing yarn quality. The shift towards Industry 4.0 principles facilitates the interconnectivity of machines (IoT), enabling seamless data exchange across the entire production floor and beyond, allowing for comprehensive factory management, remote monitoring, and integration with enterprise resource planning (ERP) systems. These technological advancements collectively contribute to a smarter, more efficient, and more responsive spinning industry, capable of meeting the complex demands of the modern textile market.

Regional Highlights

- North America: The North American market for high-efficiency spinning equipment is characterized by a strong emphasis on technological innovation, automation, and the production of high-value-added textiles. While the region's overall textile manufacturing capacity might not match Asia's, it leads in adopting advanced machinery for specialized applications, technical textiles, and sustainable production practices. Investment in R&D and smart factory solutions is a key trend, driven by the need to offset higher labor costs and meet stringent quality standards. The market here focuses on niche products like medical textiles, automotive components, and protective wear, requiring precision and reliability from spinning equipment.

- Europe: Europe represents a mature market for high-efficiency spinning equipment, with a focus on innovation, quality, and sustainability. Countries like Germany, Italy, and Switzerland are home to leading textile machinery manufacturers and also significant adopters of advanced spinning technologies. The European market prioritizes machines that offer superior yarn quality, energy efficiency, and a reduced environmental footprint, aligning with strict environmental regulations and consumer demand for eco-friendly products. There's a strong trend towards Industry 4.0 integration, including AI, IoT, and automation, to optimize production and maintain a competitive edge in high-end textile segments.

- Asia Pacific (APAC): The Asia Pacific region dominates the global High-Efficiency Spinning Equipment Market, primarily due to the presence of major textile manufacturing hubs in countries like China, India, Vietnam, and Bangladesh. This region is driven by immense domestic and export demand for textiles, leading to continuous investments in expanding and modernizing spinning capacities. The adoption of high-efficiency equipment is fueled by rising labor costs, the need to improve product quality, and the increasing focus on energy conservation. While cost-effectiveness remains a key consideration, there is a growing trend towards integrating advanced automation and digital solutions to enhance competitiveness and meet global standards.

- Latin America: The Latin American market for high-efficiency spinning equipment is in a growth phase, driven by increasing textile production in countries such as Brazil, Mexico, and Argentina. Manufacturers in this region are focused on upgrading their existing infrastructure to improve efficiency, reduce operational costs, and produce higher quality yarns to cater to both domestic and export markets. Investments are gradually shifting towards more automated and energy-efficient machines, as textile industries in these countries seek to compete with established global players. Government initiatives supporting local manufacturing and trade agreements also play a role in stimulating demand for modern spinning technology.

- Middle East and Africa (MEA): The Middle East and Africa region presents nascent but growing opportunities for the high-efficiency spinning equipment market. Countries like Turkey (considered part of MEA in some classifications), Egypt, and South Africa are investing in modernizing their textile sectors to diversify their economies and reduce reliance on imports. The demand is primarily driven by the need for localized textile production to serve growing domestic populations and cater to regional markets. While cost remains a significant factor, there is increasing interest in durable, efficient, and technologically advanced machinery that can withstand challenging operating conditions and provide a strong return on investment. Infrastructure development and government support for industrial growth are key enablers in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High-Efficiency Spinning Equipment Market.- Rieter

- Trützschler

- Murata Machinery

- Toyoda Textile Machinery

- Saurer AG

- Lakshmi Machine Works (LMW)

- Jiangsu Jinsheng Accord Machinery

- Marzoli Machines Textile

- Santoni (Lonati Group)

- Savio Macchine Tessili

- Picanol

- Itema S.p.A.

- Premier Evolvics

- Electro-Jet S.A.

- A.T.E. Enterprises Private Limited

- Kirloskar Toyoda Textile Machinery Pvt. Ltd.

- Fongs Industries Co., Ltd.

- SSM Schärer Schweiter Mettler AG

- Shima Seiki Mfg., Ltd.

- Comez (Comez International S.p.A.)

Frequently Asked Questions

Analyze common user questions about the High-Efficiency Spinning Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate for the High-Efficiency Spinning Equipment Market?

The market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032, driven by automation, quality demands, and sustainability goals.

How is AI impacting the High-Efficiency Spinning Equipment Market?

AI enhances predictive maintenance, optimizes real-time process parameters, improves yarn quality consistency, and aids in intelligent energy management, leading to smarter, more efficient textile production.

What are the primary drivers for this market's expansion?

Key drivers include increasing global demand for textiles, rising labor costs necessitating automation, continuous technological advancements, and the growing emphasis on energy efficiency and sustainable manufacturing practices.

Which regions are leading in the adoption of high-efficiency spinning equipment?

The Asia Pacific region, particularly China and India, dominates due to its large textile manufacturing base, while Europe and North America lead in technological innovation and high-value product segments.

What are the main types of high-efficiency spinning equipment available?

The market primarily features Ring Spinning, Rotor Spinning (Open-End), Air-Jet Spinning, Friction Spinning, and Compact Spinning technologies, each suited for different yarn characteristics and production needs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager