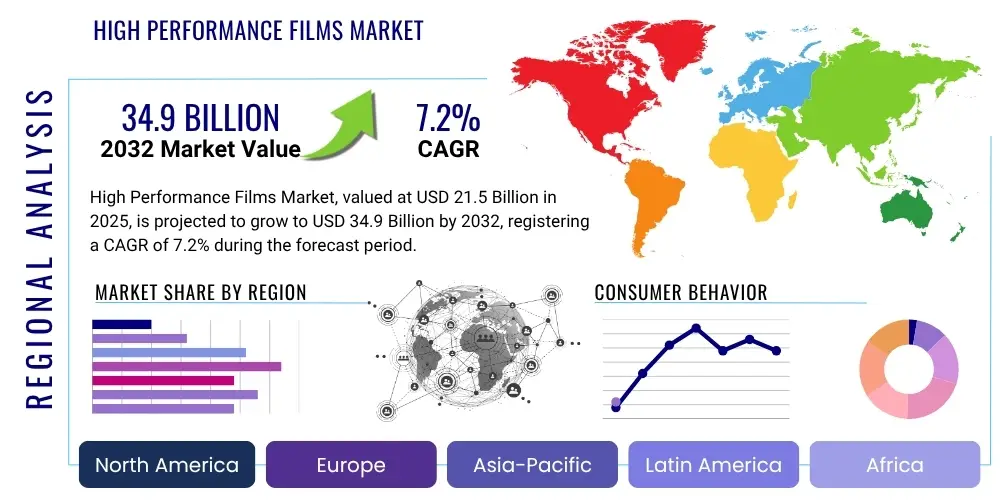

High Performance Films Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429173 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

High Performance Films Market Size

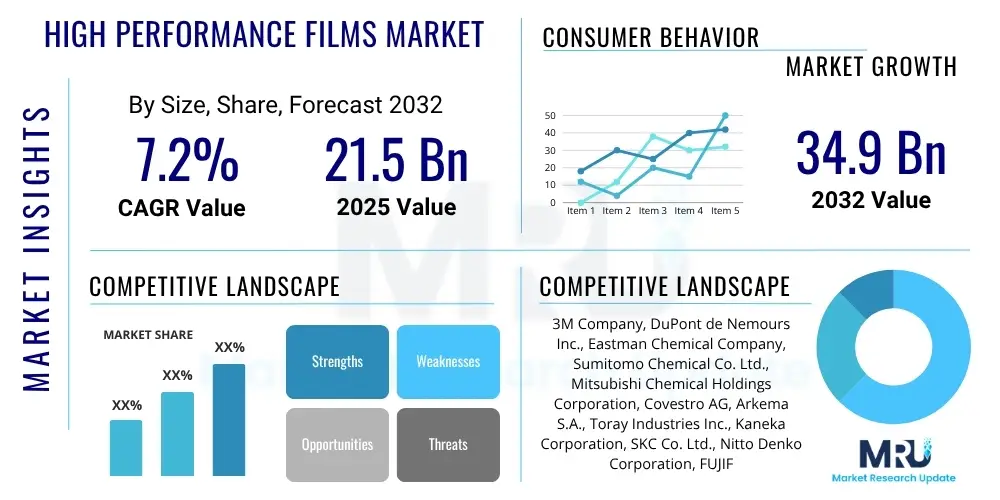

The High Performance Films Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2025 and 2032. The market is estimated at USD 21.5 Billion in 2025 and is projected to reach USD 34.9 Billion by the end of the forecast period in 2032.

High Performance Films Market introduction

High performance films are advanced polymeric materials engineered to exhibit superior mechanical, thermal, electrical, and optical properties, distinguishing them from conventional plastic films. These films are meticulously designed to withstand extreme environmental conditions, offer enhanced durability, and provide specific functionalities crucial for demanding applications. Their unique characteristics, such as excellent barrier properties, high tensile strength, thermal stability, chemical resistance, and optical clarity, enable their deployment in critical sectors where standard films would fail.

The product description encompasses a diverse range of materials including polyester (PET), polyimide (PI), fluoropolymers (e.g., PTFE, FEP), polycarbonate (PC), and polyether ether ketone (PEEK), among others. Each material offers a distinct set of advantages, allowing manufacturers to tailor films for specific performance requirements. For instance, polyimide films are renowned for their exceptional thermal stability and electrical insulation, making them ideal for flexible electronics, while fluoropolymers provide unparalleled chemical inertness and weather resistance for outdoor and harsh industrial applications.

Major applications of high performance films span across numerous industries including electronics (flexible displays, printed circuit boards), automotive (interior and exterior components, window films), packaging (barrier films for food and pharmaceuticals), aerospace (insulation, composites), medical (drug delivery, diagnostic devices), and renewable energy (solar panels). The benefits derived from these films are significant, encompassing improved product longevity, weight reduction, enhanced safety, superior aesthetic appeal, and critical functional performance like EMI shielding or UV protection. Driving factors for this market's growth include the escalating demand for lightweight and durable materials in various end-use industries, continuous technological advancements leading to novel film formulations, and a rising emphasis on energy efficiency and sustainable solutions across the globe.

High Performance Films Market Executive Summary

The High Performance Films Market is currently experiencing robust growth, driven by an increasing demand for advanced material solutions across diverse industries. Business trends indicate a strong focus on innovation, with manufacturers investing heavily in research and development to produce films with enhanced functionalities, such as improved barrier properties, higher thermal resistance, and advanced optical characteristics. Strategic partnerships, mergers, and acquisitions are prevalent as companies seek to consolidate market share, expand product portfolios, and gain access to new technologies and geographical markets. Furthermore, the market is witnessing a shift towards sustainable manufacturing practices and the development of eco-friendly films, responding to growing environmental concerns and regulatory pressures.

Regional trends highlight Asia Pacific as the leading and fastest-growing market, primarily fueled by rapid industrialization, burgeoning electronics manufacturing bases, and significant investments in infrastructure development in countries like China, India, Japan, and South Korea. North America and Europe represent mature markets, characterized by stable demand from established industries such as automotive and aerospace, alongside increasing adoption in specialized medical and defense applications. Emerging economies in Latin America, the Middle East, and Africa are showing promising growth potential, driven by urbanization, expanding manufacturing sectors, and rising disposable incomes leading to increased consumption of packaged goods and consumer electronics.

Segment trends reveal dynamic shifts within the market. By material type, polyester and polyimide films continue to dominate due to their versatile properties and cost-effectiveness, while fluoropolymers and polyether ether ketone (PEEK) are gaining traction in ultra-high performance applications. In terms of application, the electronics sector remains a significant consumer, with flexible displays, printed circuit boards, and advanced packaging driving demand. The automotive industry is also a key growth area, utilizing high performance films for lightweighting, aesthetic enhancements, and functional purposes such as protective and window films. The packaging segment, particularly for food and pharmaceuticals, is exhibiting substantial growth due to the demand for extended shelf life and enhanced product protection, propelled by advancements in barrier film technologies.

AI Impact Analysis on High Performance Films Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the High Performance Films Market, focusing on aspects like optimizing manufacturing processes, accelerating material discovery, enhancing quality control, and improving supply chain efficiencies. The key themes revolve around leveraging AI to achieve higher precision, reduce waste, predict material behaviors more accurately, and ultimately foster the creation of next-generation films with unprecedented properties. There is a strong expectation that AI will streamline complex R&D cycles, enable predictive maintenance for film production equipment, and personalize film solutions to specific customer needs, leading to significant cost savings and faster time-to-market for innovative products.

- AI-driven material discovery and design accelerates the development of novel film formulations with tailored properties.

- Predictive analytics optimize manufacturing parameters, reducing waste and improving production efficiency and consistency.

- Automated visual inspection systems enhance quality control, detecting defects with higher accuracy and speed than manual methods.

- Supply chain optimization through AI improves inventory management, logistics, and demand forecasting for raw materials and finished films.

- AI algorithms enable simulation and modeling of film performance, reducing the need for extensive physical prototyping.

- Personalized film solutions can be developed faster by analyzing vast datasets of application requirements and material properties.

- Predictive maintenance for production machinery minimizes downtime and extends equipment lifespan, boosting operational efficiency.

DRO & Impact Forces Of High Performance Films Market

The High Performance Films Market is significantly influenced by a confluence of drivers, restraints, and opportunities that shape its growth trajectory and competitive landscape. Key drivers include the ever-increasing demand for advanced materials in the electronics industry, particularly for flexible displays, printed circuit boards, and touch sensors, where lightweight, durable, and thermally stable films are crucial. The automotive sector's shift towards electric vehicles (EVs) and autonomous driving technologies also fuels demand for films used in battery insulation, interior surfaces, and sensor integration. Furthermore, the rising global population and urbanization trends contribute to a greater need for advanced packaging solutions that offer extended shelf life and enhanced product protection for food, pharmaceuticals, and consumer goods.

Despite robust growth, the market faces several restraints. The high manufacturing cost associated with producing high performance films, often involving complex polymerization processes and specialized equipment, poses a significant barrier, especially for new entrants. Volatility in raw material prices, such as petrochemical derivatives, can directly impact production costs and profit margins, creating uncertainty for manufacturers. Stringent environmental regulations concerning the use and disposal of certain polymers and chemicals employed in film production also add to operational complexities and necessitate investments in eco-friendly alternatives. Intense competition from established players, coupled with the threat of substitute materials like advanced coatings or composites, can exert downward pressure on pricing and market share.

Opportunities for growth are abundant within this dynamic market. The emergence of new applications in areas like flexible electronics, wearable technology, smart textiles, and sustainable energy solutions (e.g., advanced solar films) presents fertile ground for innovation and market expansion. The development of biodegradable and compostable high performance films offers a compelling opportunity to address environmental concerns and cater to a growing consumer preference for sustainable products. Moreover, customizing film solutions to meet precise specifications for niche applications, alongside continued advancements in nanotechnology and surface modification techniques, can unlock new revenue streams. The overall impact forces include the moderate bargaining power of buyers due to product differentiation and essential functionality, high bargaining power of suppliers for specialized raw materials, a moderate threat of new entrants due to high capital investment and technical expertise required, a moderate threat of substitutes as performance superiority is a key differentiator, and intense competitive rivalry driven by product innovation and market penetration strategies.

Segmentation Analysis

The High Performance Films Market is comprehensively segmented based on various factors, including material type, application, and end-use industry, providing a granular view of market dynamics and growth opportunities. Understanding these segments is crucial for stakeholders to identify key demand areas, assess competitive landscapes, and strategize for optimal market penetration. Each segment possesses distinct characteristics and growth drivers, reflecting the diverse utility and specialized requirements for high performance films across the global industrial ecosystem.

- By Material Type:

- Polyester (PET) Films

- Polyimide (PI) Films

- Fluoropolymer Films (PTFE, FEP, PFA, ETFE)

- Polycarbonate (PC) Films

- Polyether Ether Ketone (PEEK) Films

- PEN (Polyethylene Naphthalate) Films

- Other Specialty Films (e.g., PPS, PEI, PSU)

- By Application:

- Optical Films

- Barrier Films

- Protective Films

- Electrically Conductive Films

- Heat Control Films

- Insulation Films

- Packaging Films

- Decorative Films

- Graphic Films

- By End-Use Industry:

- Electronics (Displays, PCBs, Flexible Electronics, Touch Panels)

- Automotive (Interior, Exterior, Window Tint, Battery Components)

- Packaging (Food, Pharmaceutical, Consumer Goods)

- Aerospace and Defense (Aircraft Interiors, Composites, Insulation)

- Medical (Drug Delivery, Diagnostic Devices, Wearables)

- Building and Construction (Smart Windows, Roofing, Façade)

- Renewable Energy (Solar Panels, Wind Turbines)

- Industrial (Adhesives, Tapes, Labels)

Value Chain Analysis For High Performance Films Market

The value chain for the High Performance Films Market is intricate, spanning from the sourcing of raw materials to the final integration into end-user products, involving multiple stages of transformation and distribution. Upstream analysis focuses on the procurement of specialized polymers and chemical additives that form the fundamental building blocks of these films. Key raw material suppliers provide a diverse range of resins, including polyester, polyimide, fluoropolymers, and polycarbonates, along with performance-enhancing additives such as UV stabilizers, antioxidants, and adhesion promoters. The quality and consistent supply of these high-grade materials are paramount, as they directly influence the ultimate performance characteristics of the finished films, making supplier relationships a critical component of the value chain.

Midstream activities involve the actual manufacturing processes where raw materials are converted into high performance films. This typically includes extrusion, casting, coating, lamination, and various surface treatment techniques. Film manufacturers employ advanced technologies and stringent quality control measures to produce films with precise thickness, optical properties, barrier characteristics, and mechanical strength. These manufacturers often specialize in particular film types or application areas, leveraging proprietary formulations and processing expertise to create differentiated products. Investments in R&D are crucial at this stage to develop new film grades and improve existing ones, addressing evolving industry demands and regulatory requirements.

Downstream analysis encompasses the distribution and integration of high performance films into end products. Fabricators and converters play a vital role, often modifying the films through processes like slitting, cutting, printing, and applying adhesives to meet specific customer specifications. These processed films are then supplied to various end-use industries, including electronics, automotive, packaging, aerospace, and medical, where they become integral components of diverse products. Distribution channels are varied, including direct sales from manufacturers to large-volume customers, indirect sales through a network of distributors and agents who serve smaller clients and regional markets, and increasingly, specialized online platforms for niche products. Both direct and indirect channels are critical for market reach and customer engagement, ensuring that specialized films reach their intended applications efficiently.

High Performance Films Market Potential Customers

The High Performance Films Market caters to a broad spectrum of end-users and buyers across numerous industries, each seeking specific performance attributes for their applications. One of the most significant customer bases is the electronics industry, which utilizes these films extensively in the manufacturing of flexible displays, printed circuit boards (PCBs), touch panels, and various electronic components. Manufacturers of smartphones, tablets, laptops, and other consumer electronics rely on high performance films for insulation, thermal management, optical clarity, and electrical conductivity, driving consistent demand for advanced film solutions that enable miniaturization and enhanced device functionality.

Another crucial segment comprises the automotive industry, where high performance films are integral to both interior and exterior applications. Automotive OEMs and aftermarket suppliers use these films for window tinting, protective coatings on painted surfaces, interior decorative components, and crucial functional elements within electric vehicle batteries and sensor systems. The demand for lightweight materials, enhanced durability, and improved aesthetics in modern vehicles drives the adoption of these specialized films. Furthermore, the packaging industry represents a substantial customer base, with food, pharmaceutical, and specialty goods manufacturers employing barrier films for extended shelf life, product protection, and attractive branding. These films are critical for preventing moisture and oxygen ingress, thus preserving product integrity and safety.

Beyond these major sectors, significant potential customers exist in specialized industries such as aerospace and defense, where films are used for insulation, structural components, and advanced composites due to their extreme temperature resistance and strength-to-weight ratio. The medical sector utilizes high performance films in drug delivery systems, diagnostic devices, and wearable medical technology, requiring biocompatibility, chemical resistance, and precision. The building and construction industry also increasingly adopts these films for smart windows, energy-efficient roofing, and decorative facades. Each of these end-user segments is a key buyer of high performance films, driven by the need for superior material performance that conventional films cannot provide, contributing to the market's sustained growth and diversification.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 21.5 Billion |

| Market Forecast in 2032 | USD 34.9 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, DuPont de Nemours Inc., Eastman Chemical Company, Sumitomo Chemical Co. Ltd., Mitsubishi Chemical Holdings Corporation, Covestro AG, Arkema S.A., Toray Industries Inc., Kaneka Corporation, SKC Co. Ltd., Nitto Denko Corporation, FUJIFILM Holdings Corporation, Saint-Gobain S.A., DAIKIN INDUSTRIES Ltd., Wipak Group, Avery Dennison Corporation, Tesa SE, Tekra, LLC, LINTEC Corporation, UBE Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Performance Films Market Key Technology Landscape

The High Performance Films Market is characterized by a dynamic and continuously evolving technology landscape, with innovations driving both product development and manufacturing efficiencies. Advanced polymerization techniques are foundational, allowing for the synthesis of specialty polymers with precise molecular structures and tailored properties. This includes the development of novel monomer chemistries and sophisticated catalyst systems that yield polymers with enhanced thermal stability, mechanical strength, chemical resistance, and optical clarity, crucial for demanding applications in electronics and aerospace.

Film manufacturing processes also represent a critical technological domain. Extrusion technologies, including cast film and blown film extrusion, are continuously being refined to achieve tighter thickness tolerances, improved surface quality, and multi-layer film structures for enhanced barrier properties. Coating and lamination technologies are vital for applying functional layers, such as anti-reflective coatings, hard coats, conductive layers, or adhesive systems, directly onto the film substrate. Precision coating methods, like gravure, slot die, and reverse roll coating, ensure uniform application and optimal performance of these functional layers.

Furthermore, surface treatment technologies play a significant role in modifying film surfaces to impart specific functionalities, such as improved adhesion, printability, or hydrophobicity. Techniques like plasma treatment, corona discharge, and flame treatment alter the surface energy of films, enabling better bonding with inks, adhesives, or other layers. The integration of nanotechnology is an emerging frontier, where nanoparticles are incorporated into film matrices or applied as coatings to create films with superior UV protection, antimicrobial properties, enhanced barrier performance, or novel optical characteristics. These technological advancements collectively contribute to the development of next-generation high performance films that meet increasingly stringent industry requirements and open up new application possibilities across various sectors.

Regional Highlights

- North America: This region is a mature market for high performance films, characterized by significant demand from the automotive, aerospace, and electronics industries, particularly in the United States and Canada. Strong R&D infrastructure and a focus on advanced manufacturing drive innovation. The automotive sector's pivot towards electric vehicles heavily influences the demand for films in battery components and lightweight vehicle construction. Stringent regulations regarding environmental impact also push for sustainable film solutions.

- Europe: Europe represents another key market, with countries like Germany, France, and the UK leading in specialized applications. The region benefits from a robust automotive sector, advanced packaging industry, and a growing emphasis on renewable energy. European manufacturers are at the forefront of developing eco-friendly and high-barrier films, driven by stringent EU environmental policies and consumer preferences for sustainable products. Investments in smart technologies and flexible electronics further contribute to market growth.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for high performance films globally, primarily driven by rapid industrialization, burgeoning electronics manufacturing, and infrastructure development in countries such as China, India, Japan, and South Korea. The region's expanding middle class and increasing disposable incomes fuel the demand for consumer electronics and packaged goods, directly boosting the market. Major investments in renewable energy and the presence of leading film manufacturers also solidify APAC's dominant position.

- Latin America: This region is an emerging market for high performance films, exhibiting steady growth propelled by expanding manufacturing sectors and increasing investments in infrastructure. Brazil and Mexico are key contributors, with rising demand from the packaging, automotive, and construction industries. While the market is smaller compared to APAC or North America, urbanization and economic development are creating new opportunities for film manufacturers to establish a stronger presence.

- Middle East and Africa (MEA): The MEA region shows promising potential for high performance films, primarily driven by diversification efforts from oil-dependent economies, significant construction activities, and growth in the packaging sector. Investments in renewable energy projects, particularly solar, are creating a niche demand for specialized films. Challenges include limited local manufacturing capabilities and reliance on imports, but increasing industrialization efforts are expected to foster growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Performance Films Market.- 3M Company

- DuPont de Nemours Inc.

- Eastman Chemical Company

- Sumitomo Chemical Co. Ltd.

- Mitsubishi Chemical Holdings Corporation

- Covestro AG

- Arkema S.A.

- Toray Industries Inc.

- Kaneka Corporation

- SKC Co. Ltd.

- Nitto Denko Corporation

- FUJIFILM Holdings Corporation

- Saint-Gobain S.A.

- DAIKIN INDUSTRIES Ltd.

- Wipak Group

- Avery Dennison Corporation

- Tesa SE

- Tekra, LLC

- LINTEC Corporation

- UBE Corporation

Frequently Asked Questions

What defines a high performance film?

High performance films are advanced polymeric materials engineered to offer superior mechanical, thermal, electrical, and optical properties, exceeding those of conventional plastic films. They are designed to withstand extreme conditions and provide specialized functionalities.

What are the primary applications of high performance films?

Key applications include electronics (flexible displays, PCBs), automotive (lightweight components, window films), advanced packaging (barrier films), aerospace (insulation), medical devices, and renewable energy (solar panels).

Which materials are commonly used in high performance films?

Common materials include polyester (PET), polyimide (PI), fluoropolymers (e.g., PTFE, FEP), polycarbonate (PC), and polyether ether ketone (PEEK, PEN), selected for their specific property profiles.

What are the main drivers of growth in the High Performance Films Market?

Growth is primarily driven by increasing demand from the electronics, automotive, and packaging industries, coupled with continuous technological advancements, the trend towards lightweighting, and a focus on energy efficiency.

How does sustainability impact the High Performance Films Market?

Sustainability drives innovation in the market, leading to the development of biodegradable, recyclable, and bio-based films, as well as more energy-efficient production processes, in response to environmental regulations and consumer demand.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager