High Temperature Insulation Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428497 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

High Temperature Insulation Market Size

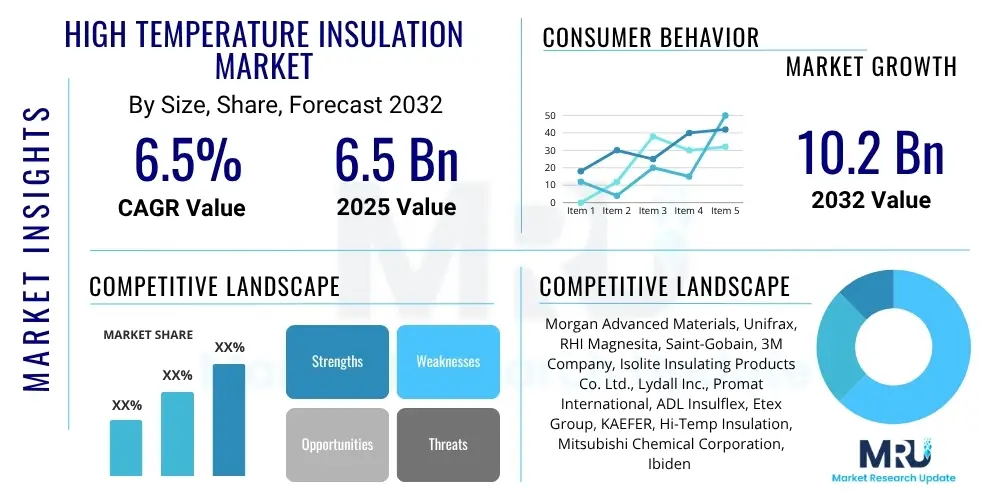

The High Temperature Insulation Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 6.5 Billion in 2025 and is projected to reach USD 10.2 Billion by the end of the forecast period in 2032.

High Temperature Insulation Market introduction

High temperature insulation (HTI) refers to a broad category of materials designed to provide thermal resistance and maintain structural integrity in extreme heat environments, typically exceeding 600°C (1112°F). These specialized materials are crucial for improving energy efficiency, ensuring operational safety, and optimizing process control across various industrial applications. Their primary function is to minimize heat transfer, thereby reducing energy consumption, protecting equipment and personnel, and enhancing the overall performance and longevity of high-temperature systems.

The product portfolio within the HTI market encompasses a diverse range of materials, including ceramic fibers, insulating firebricks, calcium silicate, microporous insulation, and refractory ceramics. Each material is engineered with unique properties to suit specific temperature ranges, mechanical stresses, and chemical environments. Major applications span critical sectors such as petrochemical refining, iron and steel manufacturing, cement and glass production, power generation, and advanced transportation systems like automotive and aerospace. The inherent benefits of HTI, such as significant energy savings, reduced carbon emissions, enhanced equipment lifespan, and improved workplace safety, are pivotal in driving its widespread adoption.

Key driving factors for market expansion include the global push for industrial energy efficiency, stringent environmental regulations aimed at reducing greenhouse gas emissions, and continuous growth in heavy industries. Additionally, the increasing demand for high-performance materials in emerging sectors like advanced manufacturing and sustainable energy solutions further propels market growth. The ongoing modernization of industrial infrastructure and the imperative to minimize operational costs are also significant contributors to the sustained demand for high temperature insulation products globally.

High Temperature Insulation Market Executive Summary

The High Temperature Insulation Market is experiencing robust growth, driven by escalating industrial demands for energy efficiency and emission reduction across various sectors. Business trends indicate a strong focus on advanced material development, emphasizing lighter weight, higher performance, and more environmentally sustainable insulation solutions. Strategic mergers and acquisitions are frequently observed as companies seek to consolidate market share, expand product portfolios, and enhance technological capabilities. Furthermore, digitalization is beginning to influence manufacturing processes and supply chain management, offering opportunities for improved efficiency and predictive maintenance in the HTI sector.

Regionally, the Asia Pacific (APAC) market continues to dominate, largely fueled by rapid industrialization, significant infrastructure development, and substantial investments in manufacturing hubs, particularly in countries like China and India. North America and Europe, while mature markets, demonstrate steady demand driven by strict energy efficiency mandates, refurbishment projects, and a focus on specialized, high-value applications. Emerging markets in Latin America and the Middle East and Africa are also showing promising growth, particularly in their burgeoning oil and gas, petrochemical, and power generation sectors, where HTI is critical for operational integrity and safety.

Segment trends highlight continued strong demand for ceramic fiber insulation due to its versatility, low thermal conductivity, and high-temperature resistance, making it suitable for a wide array of applications. Insulating firebricks and calcium silicate are also key segments, finding extensive use in high-heat industrial furnaces and boilers. The market is witnessing a shift towards innovative and environmentally friendly materials, with increasing R&D in microporous and nano-insulation technologies that offer superior thermal performance at reduced thicknesses. This evolution is crucial for addressing both performance requirements and sustainability goals across the diverse end-use industries.

AI Impact Analysis on High Temperature Insulation Market

Common user inquiries regarding AI's impact on the High Temperature Insulation (HTI) market often revolve around how artificial intelligence can optimize manufacturing processes, enhance product development, and improve the efficiency of HTI applications. Users are keen to understand if AI can lead to more precise material formulation, reduce waste, and provide predictive insights for equipment maintenance where HTI is critical. Concerns occasionally surface about the initial investment required for AI integration and the potential for job displacement, alongside expectations for revolutionary breakthroughs in material science and supply chain resilience. The overarching theme is a desire for greater operational efficiency, superior product performance, and a more data-driven approach to HTI solutions through AI adoption.

- AI driven predictive maintenance of high temperature systems reduces insulation failures.

- Optimized material design and formulation using AI algorithms for enhanced thermal performance.

- Improved manufacturing process control and energy efficiency in HTI production facilities.

- Enhanced quality control and defect detection through AI powered vision systems.

- Streamlined supply chain management and inventory optimization for HTI raw materials.

- Development of smart insulation solutions with integrated AI for real time monitoring.

- Accelerated R&D for novel HTI materials by simulating properties and performance.

- Reduced operational costs through AI facilitated energy management in industrial plants.

- Enhanced safety protocols by predicting potential thermal runaway scenarios.

DRO & Impact Forces Of High Temperature Insulation Market

The High Temperature Insulation Market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers include stringent regulations promoting energy efficiency and carbon emission reduction across industries, which mandate the adoption of superior insulation solutions. The robust growth of heavy industries such as iron and steel, cement, glass, and petrochemicals globally further fuels demand. Additionally, the increasing focus on operational safety and the need to extend the lifespan of industrial assets, coupled with the demand for lightweight and high-performance materials in aerospace and automotive applications, consistently propels market expansion.

However, the market also faces notable restraints. The relatively high initial capital expenditure associated with advanced HTI materials and their installation can be a barrier for some end-users. Fluctuations in the prices of critical raw materials, such as alumina, silica, and zirconia, introduce cost volatility for manufacturers. Furthermore, health and safety concerns related to certain fibrous insulation materials, requiring specialized handling and disposal, pose regulatory and operational challenges. Stringent environmental regulations concerning the production and disposal of some traditional HTI products also necessitate continuous innovation towards greener alternatives, adding to developmental costs.

Despite these challenges, significant opportunities abound. Technological advancements in nano-insulation and aerogel-based materials promise superior thermal performance at reduced thicknesses, opening new application avenues. The growing renewable energy sector, including concentrated solar power and advanced battery manufacturing, presents a novel demand front for specialized HTI. Moreover, the vast untapped potential in emerging economies, coupled with initiatives for industrial upgrading and modernization, offers substantial growth prospects. The increasing emphasis on circular economy principles also creates opportunities for developing recyclable and reusable HTI products, aligning with global sustainability goals and attracting environmentally conscious consumers and industries.

Segmentation Analysis

The High Temperature Insulation market is comprehensively segmented to provide a detailed understanding of its diverse landscape and growth dynamics. These segments are primarily categorized by material type, end-use industry, and operating temperature range, reflecting the varied requirements and applications across industrial sectors. This segmentation allows for precise market analysis, enabling stakeholders to identify specific growth drivers, understand competitive landscapes within niches, and formulate targeted strategies. The intricate nature of high temperature environments necessitates a broad spectrum of insulation solutions, each tailored to deliver optimal performance under specific conditions.

- By Material Type:

- Ceramic Fiber (RCF, AES Wool)

- Insulating Firebrick

- Calcium Silicate

- Microporous Insulation

- Aerogels

- Others (Mineral Wool, Glass Wool, Perlite)

- By End-Use Industry:

- Petrochemical

- Ceramics

- Glass

- Cement

- Iron & Steel

- Power Generation (Thermal, Nuclear, Renewable)

- Aluminum

- Automotive

- Aerospace & Defense

- Others (Food & Beverage, Construction, Electronics)

- By Temperature Range:

- Low Temperature (up to 600°C)

- Medium Temperature (600°C - 1200°C)

- High Temperature (Above 1200°C)

- By Form:

- Blankets

- Boards

- Modules

- Papers

- Felts

- Textiles

- Coatings

- Other (loose wool, custom shapes)

Value Chain Analysis For High Temperature Insulation Market

The value chain for the High Temperature Insulation market commences with the upstream segment, which involves the extraction and processing of critical raw materials. These raw materials typically include high-purity alumina, silica, zirconia, kaolin, and various mineral compounds such as gypsum and perlite. Suppliers in this phase are crucial for providing consistent quality and quantity of these basic components, which directly influence the performance characteristics and cost structure of the final insulation products. The relationships with these upstream suppliers are often long-term, driven by specialized material requirements and quality control standards.

Moving downstream, the value chain encompasses the manufacturing and conversion processes where raw materials are transformed into various HTI products such as ceramic fiber blankets, insulating firebricks, calcium silicate boards, and microporous panels. This stage involves complex engineering, advanced thermal processing, and rigorous quality assurance. Following manufacturing, products move through various distribution channels to reach end-user industries. Direct sales are common for large industrial customers and specialized projects, where manufacturers maintain direct relationships to provide technical support, custom solutions, and bulk deliveries. This approach allows for direct feedback and stronger customer engagement for complex applications.

Indirect distribution channels involve a network of distributors, wholesalers, and retailers who cater to a broader range of smaller clients, localized markets, or specific product lines. These intermediaries play a vital role in market penetration, inventory management, and providing localized technical support. The effectiveness of the distribution network, whether direct or indirect, is paramount in ensuring timely delivery, competitive pricing, and efficient market access. The entire value chain is characterized by a strong emphasis on material science expertise, manufacturing precision, and robust logistics to meet the demanding requirements of high-temperature industrial applications.

High Temperature Insulation Market Potential Customers

Potential customers for High Temperature Insulation products span a broad spectrum of heavy industries and specialized manufacturing sectors that operate processes at extreme temperatures. These end-users are primarily motivated by the need to enhance energy efficiency, reduce operational costs, ensure process stability, and maintain stringent safety standards. The core demand originates from industries where heat management is critical for both production output and environmental compliance, making HTI an indispensable component of their infrastructure.

Key segments of end-user/buyers include manufacturers in the iron and steel industry, which relies heavily on HTI for lining blast furnaces, tundishes, and other high-temperature processing units. Similarly, the cement and glass industries are significant consumers, requiring insulation for kilns, ovens, and melting furnaces to optimize thermal efficiency and product quality. The petrochemical and chemical processing sectors utilize HTI in reactors, reformers, and cracking units to prevent heat loss and ensure safe operation. Power generation facilities, particularly coal-fired, gas-fired, and nuclear power plants, also represent a substantial customer base, needing insulation for boilers, turbines, and exhaust systems.

Beyond these heavy industries, specialized sectors such as automotive and aerospace demand advanced, lightweight HTI solutions for engine components, exhaust systems, and spacecraft thermal protection. Other emerging buyers include manufacturers of advanced batteries, fuel cells, and concentrated solar power systems, where precise temperature control and energy conservation are paramount. Furthermore, construction companies increasingly seek fire protection insulation for industrial buildings and commercial structures, underscoring the diverse and expanding customer landscape for high temperature insulation materials.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.5 Billion |

| Market Forecast in 2032 | USD 10.2 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Morgan Advanced Materials, Unifrax, RHI Magnesita, Saint-Gobain, 3M Company, Isolite Insulating Products Co. Ltd., Lydall Inc., Promat International, ADL Insulflex, Etex Group, KAEFER, Hi-Temp Insulation, Mitsubishi Chemical Corporation, Ibiden Co. Ltd., Shandong Luyang Energy Saving Materials Co. Ltd., Beijing Hocreboard Building Materials Co. Ltd., Rockwool International A/S, Owens Corning, Johns Manville, Recticel NV |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Temperature Insulation Market Key Technology Landscape

The High Temperature Insulation market is characterized by a dynamic technology landscape, continually evolving to meet increasing demands for enhanced thermal performance, reduced weight, and improved environmental sustainability. One of the most significant technological advancements is the development of advanced material formulations, including nanoporous materials and aerogels. These innovations offer exceptionally low thermal conductivities even at extreme temperatures, allowing for thinner insulation layers and greater energy efficiency in compact spaces. Their lightweight properties are particularly beneficial for aerospace and automotive applications, where mass reduction is critical.

Another crucial area of innovation lies in the manufacturing processes for fiber-based insulation. Continuous advancements in the production of refractory ceramic fibers (RCF) and alkaline earth silicate (AES) wool focus on improving fiber morphology, reducing shot content, and enhancing thermal stability. Techniques such as sol-gel processing and electrospinning are gaining traction for creating highly uniform and high-performance ceramic fibers with tailored properties. Furthermore, the development of vacuum insulation panels (VIPs) represents a cutting-edge technology, combining a porous core material with a vacuum envelope to achieve unparalleled insulation values, albeit at higher costs, suitable for niche ultra-high-performance applications.

Beyond material science, the integration of smart technologies is beginning to influence the HTI sector. This includes the development of smart insulation systems with embedded sensors for real-time temperature monitoring, predictive maintenance, and fault detection in industrial environments. Additive manufacturing (3D printing) is also emerging as a promising technology, enabling the creation of complex, custom-shaped insulation components with intricate internal structures that are otherwise difficult or impossible to produce via conventional methods. These technological shifts are not only improving the efficacy of HTI but also contributing to greater industrial safety and efficiency, positioning the market for continued innovation and growth.

Regional Highlights

- North America: This region represents a mature yet stable market for High Temperature Insulation. Demand is primarily driven by stringent energy efficiency regulations, the modernization of existing industrial infrastructure, and a strong focus on advanced materials for aerospace and defense applications. The presence of key players and robust R&D activities further supports market expansion, especially in specialized and high-performance segments.

- Europe: Europe is characterized by strict environmental policies and a strong emphasis on sustainability, which fuels demand for greener and more energy-efficient HTI solutions. The region's industrial base, particularly in Germany, France, and the UK, continues to invest in optimizing thermal processes in sectors like glass, ceramics, and steel, ensuring steady market growth and innovation in materials.

- Asia Pacific (APAC): The APAC region stands as the largest and fastest-growing market for High Temperature Insulation. Rapid industrialization, significant investments in manufacturing sectors (steel, cement, glass, power generation) across countries like China, India, and Southeast Asia, and escalating energy demands are the primary growth drivers. Increasing infrastructure development and urbanization also contribute substantially to market expansion.

- Latin America: This region is an emerging market for HTI, with growth primarily stemming from expanding industrial sectors such as oil and gas, mining, and metals. Investments in industrial expansion and the modernization of existing facilities are gradually increasing the adoption of high temperature insulation solutions, albeit at a slower pace compared to APAC.

- Middle East and Africa (MEA): The MEA region exhibits promising growth, largely driven by its robust petrochemical, oil and gas, and power generation industries. Large-scale infrastructure projects, coupled with increasing industrialization efforts in countries like Saudi Arabia, UAE, and South Africa, are generating substantial demand for efficient thermal management solutions and high temperature insulation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Temperature Insulation Market.- Morgan Advanced Materials

- Unifrax

- RHI Magnesita

- Saint-Gobain

- 3M Company

- Isolite Insulating Products Co. Ltd.

- Lydall Inc.

- Promat International

- ADL Insulflex

- Etex Group

- KAEFER

- Hi-Temp Insulation

- Mitsubishi Chemical Corporation

- Ibiden Co. Ltd.

- Shandong Luyang Energy Saving Materials Co. Ltd.

- Beijing Hocreboard Building Materials Co. Ltd.

- Rockwool International A/S

- Owens Corning

- Johns Manville

- Recticel NV

Frequently Asked Questions

What is High Temperature Insulation?

High Temperature Insulation (HTI) refers to specialized materials designed to withstand and operate effectively in extreme heat environments, typically above 600°C (1112°F), to minimize heat transfer, conserve energy, and protect equipment and personnel.

What are the primary applications of HTI materials?

HTI materials are predominantly used in heavy industries such as iron and steel, petrochemicals, cement, glass, and power generation, as well as in automotive, aerospace, and advanced manufacturing for furnaces, kilns, boilers, and exhaust systems.

What are the key drivers of the High Temperature Insulation Market?

The market is driven by increasing industrial energy efficiency regulations, robust growth in heavy manufacturing sectors, rising demand for lightweight and high-performance materials, and a growing emphasis on operational safety and emission reduction globally.

What types of materials are commonly used for high temperature insulation?

Common HTI materials include ceramic fibers (RCF, AES wool), insulating firebricks, calcium silicate, microporous insulation, aerogels, and various refractory ceramics, each chosen based on specific temperature, mechanical, and chemical requirements.

How is AI impacting the High Temperature Insulation Market?

AI is increasingly being utilized to optimize material design and formulation, enhance manufacturing process control, enable predictive maintenance for insulated systems, and accelerate R&D for novel HTI solutions, leading to greater efficiency and performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- High Temperature Insulation Wool Market Size Report By Type (Fibreglass , Mineral Wool , Alkaline Earth Silicate (AES), Aluminium Silicate Wool (ASW) or Refractory Ceramic Fibre (RCF), Polycrystalline Wool/Fibre (PCW), Long Fibre, Vacuum-Formed Insulating Products , Polyurethane Foam , Polystyrene , Insulating Firebricks (IFB), Others), By Application (Insulation, Industrial Equipment, Others", , Construction, Transportation, Electrical and Electronics, Power Generation, Petrochemicals, Industrial, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- High Temperature Insulation Market Size Report By Type (Ceramic Fiber, Insulating Firebrick, Calcium Silicate, Other), By Application (Petrochemicals, Ceramics, Glass, Cement, Iron & Steel, Refractory, Powder Metallurgy, Aluminum, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- High Temperature Insulation (HTI) Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Ceramic Fiber, Insulating Firebrick, Calcium Silicate, Others), By Application (Petrochemicals, Cement, Refractory, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager